How to Use 12V PWM 80x80mm Fan: Examples, Pinouts, and Specs

Design with 12V PWM 80x80mm Fan in Cirkit Designer

Design with 12V PWM 80x80mm Fan in Cirkit DesignerIntroduction

The 12V PWM 80x80mm Fan is a compact and efficient cooling solution designed for a variety of applications. With its 80x80mm size, it is ideal for use in computer systems, power supplies, and other electronic devices requiring effective heat dissipation. The fan features pulse-width modulation (PWM) control, enabling variable speed operation to optimize airflow, reduce noise, and minimize power consumption. This makes it a versatile and energy-efficient choice for thermal management.

Explore Projects Built with 12V PWM 80x80mm Fan

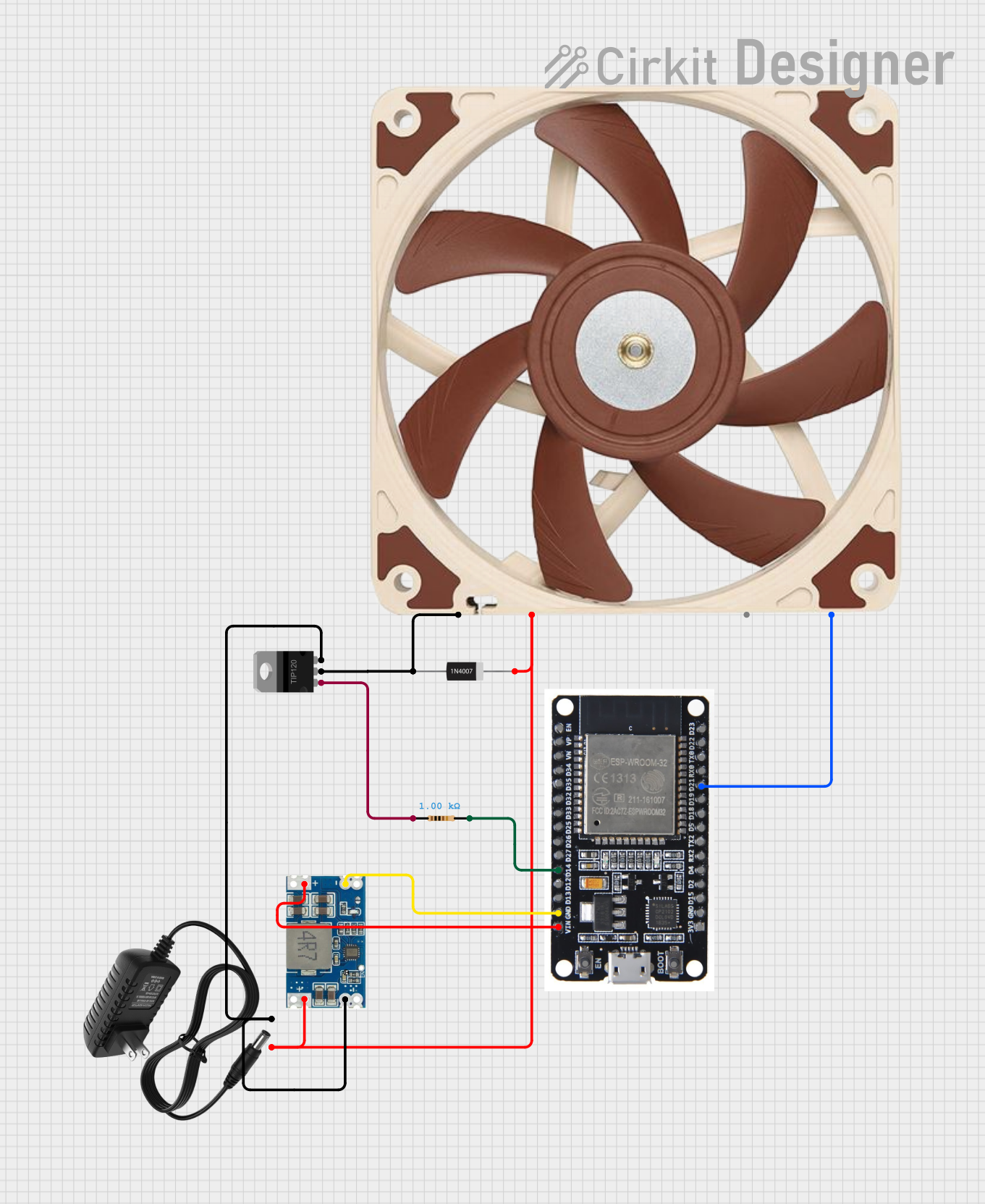

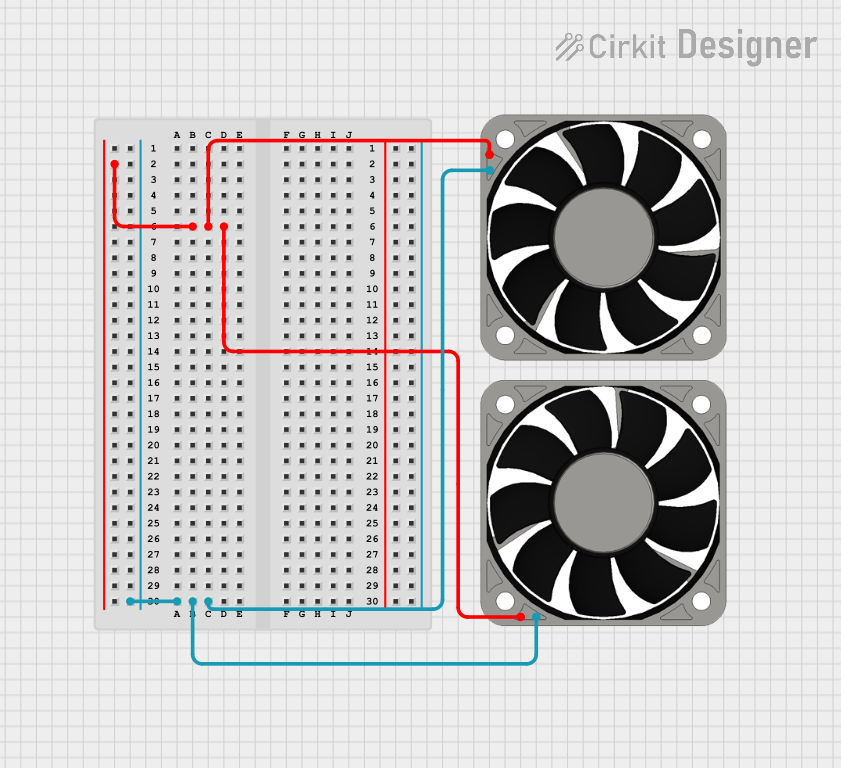

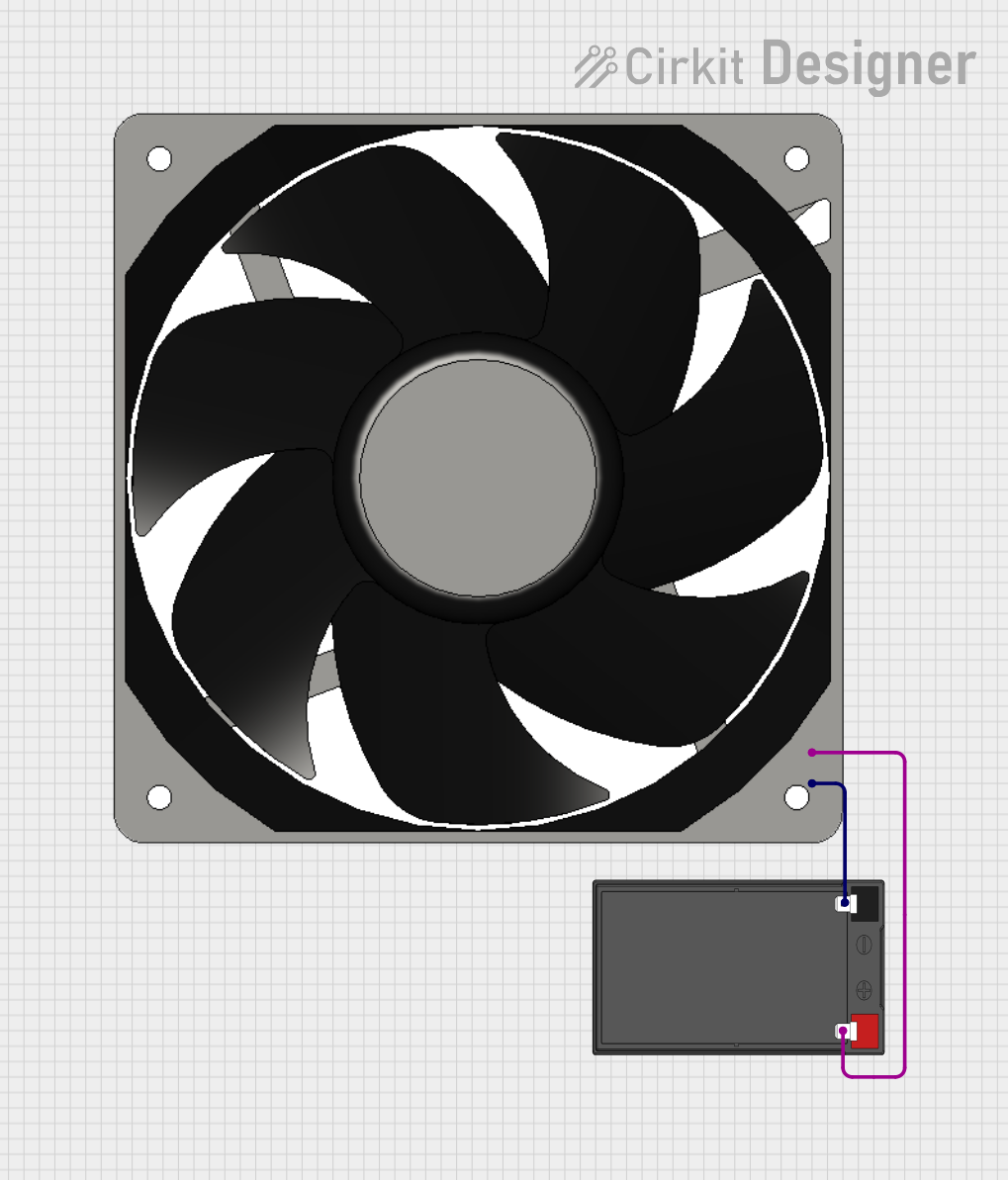

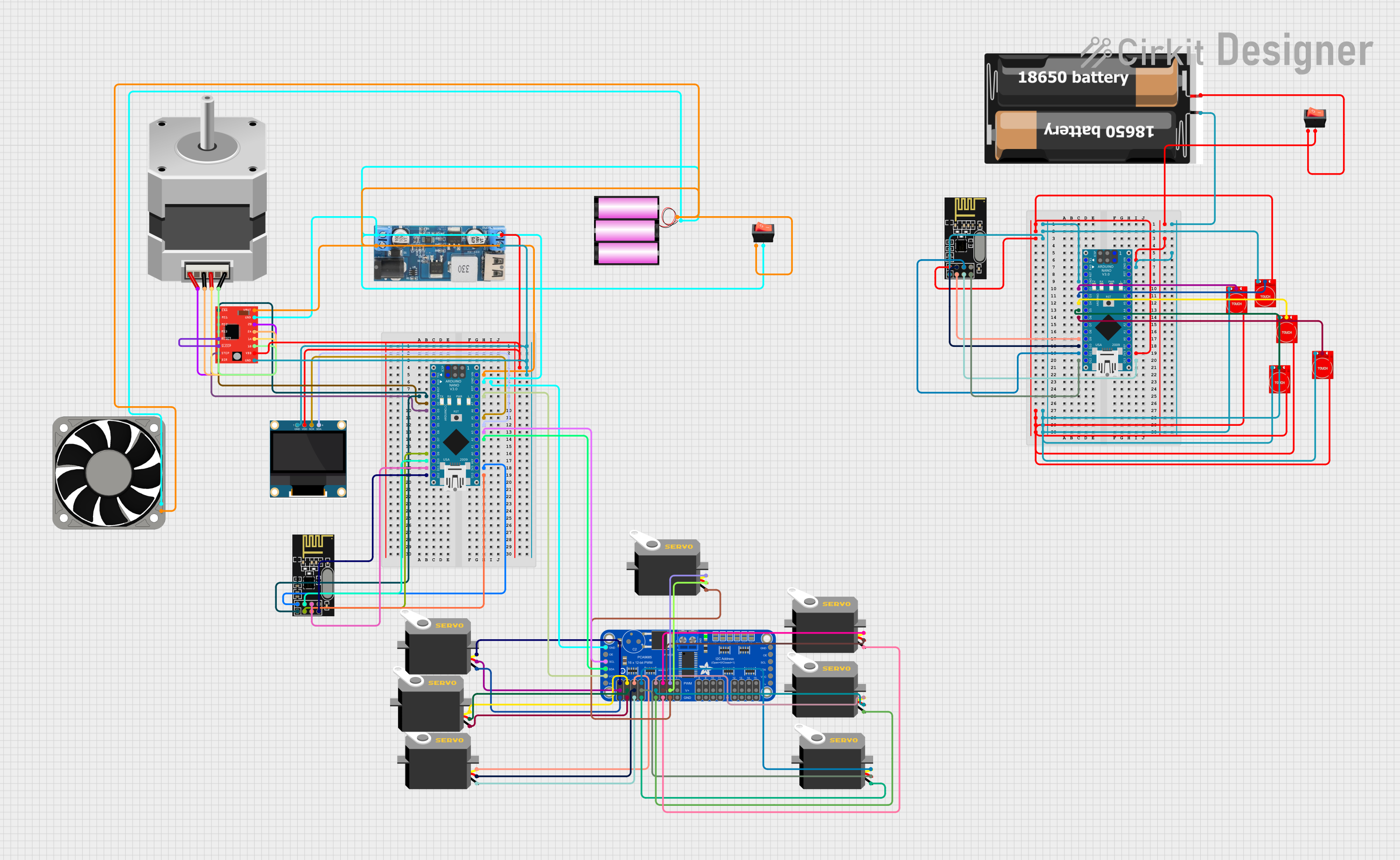

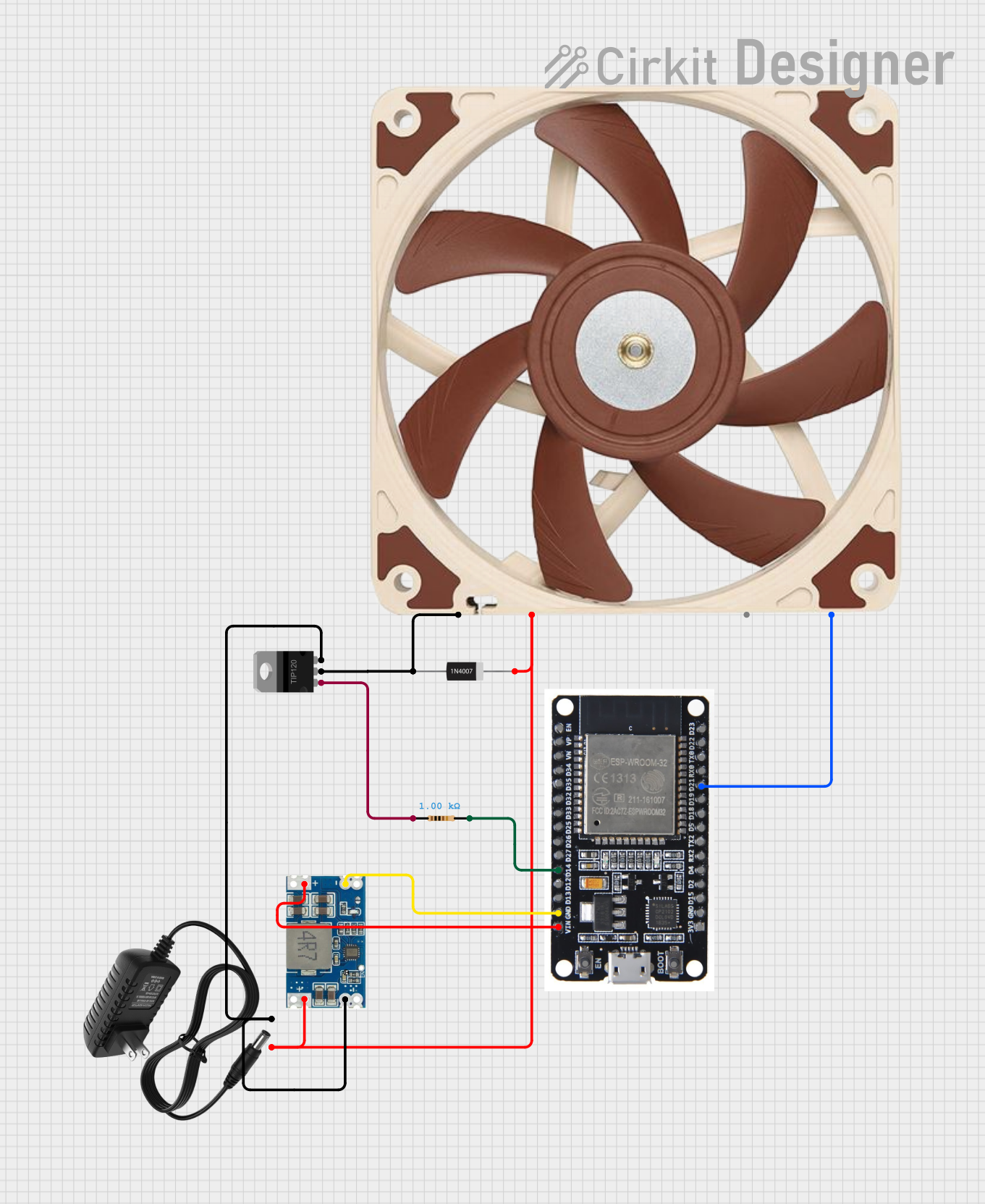

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

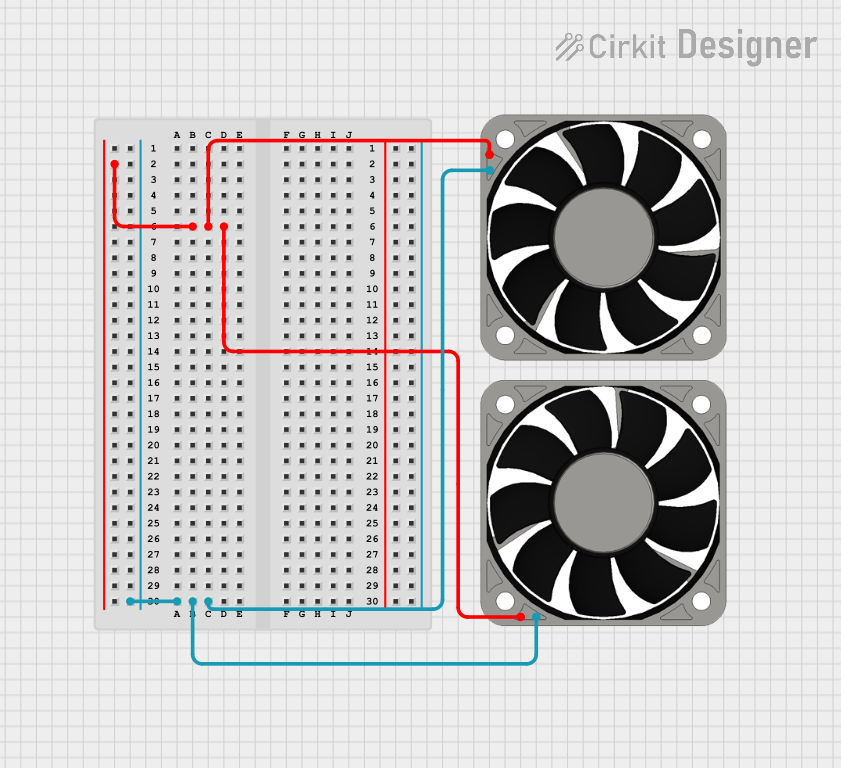

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 12V PWM 80x80mm Fan

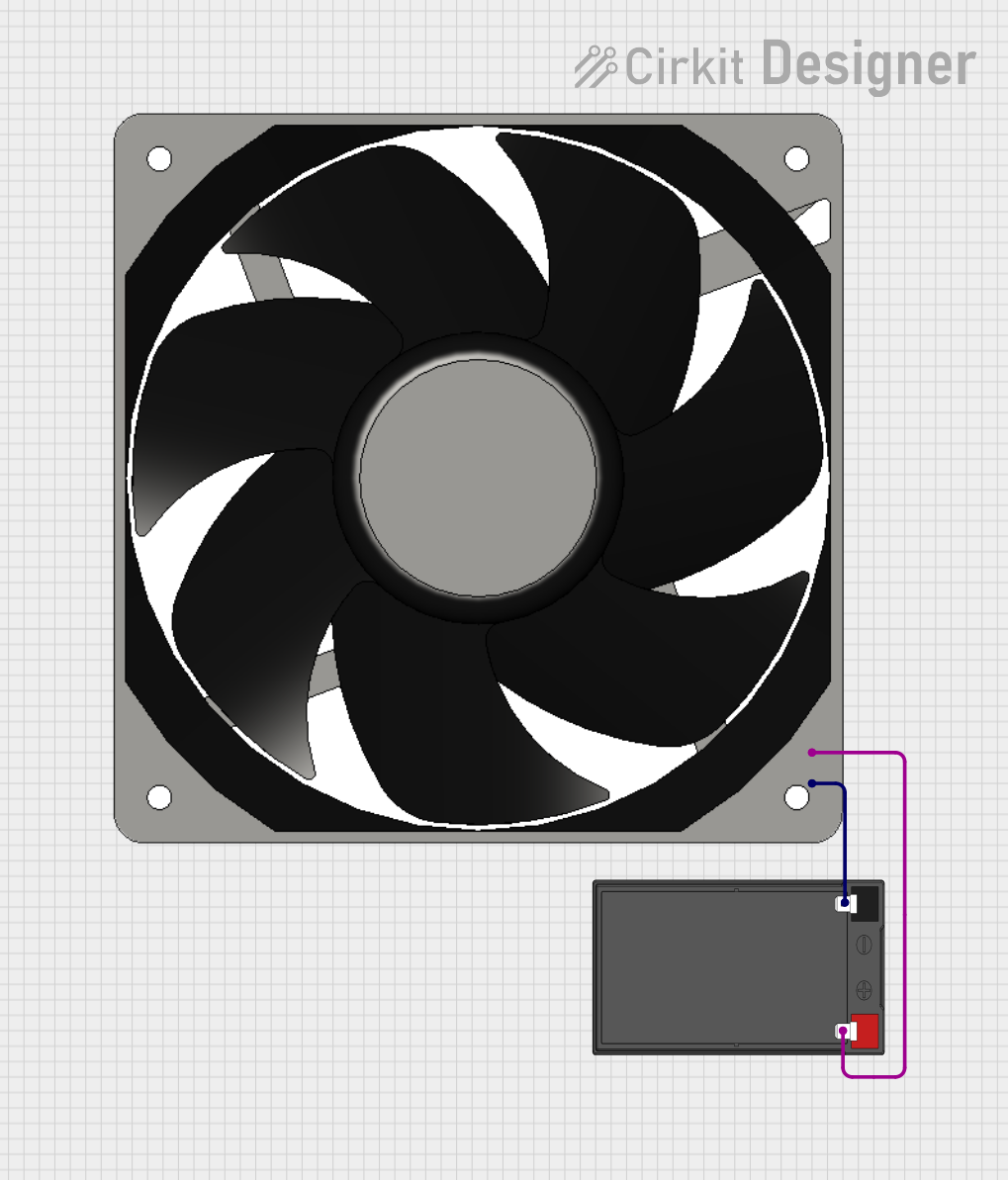

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

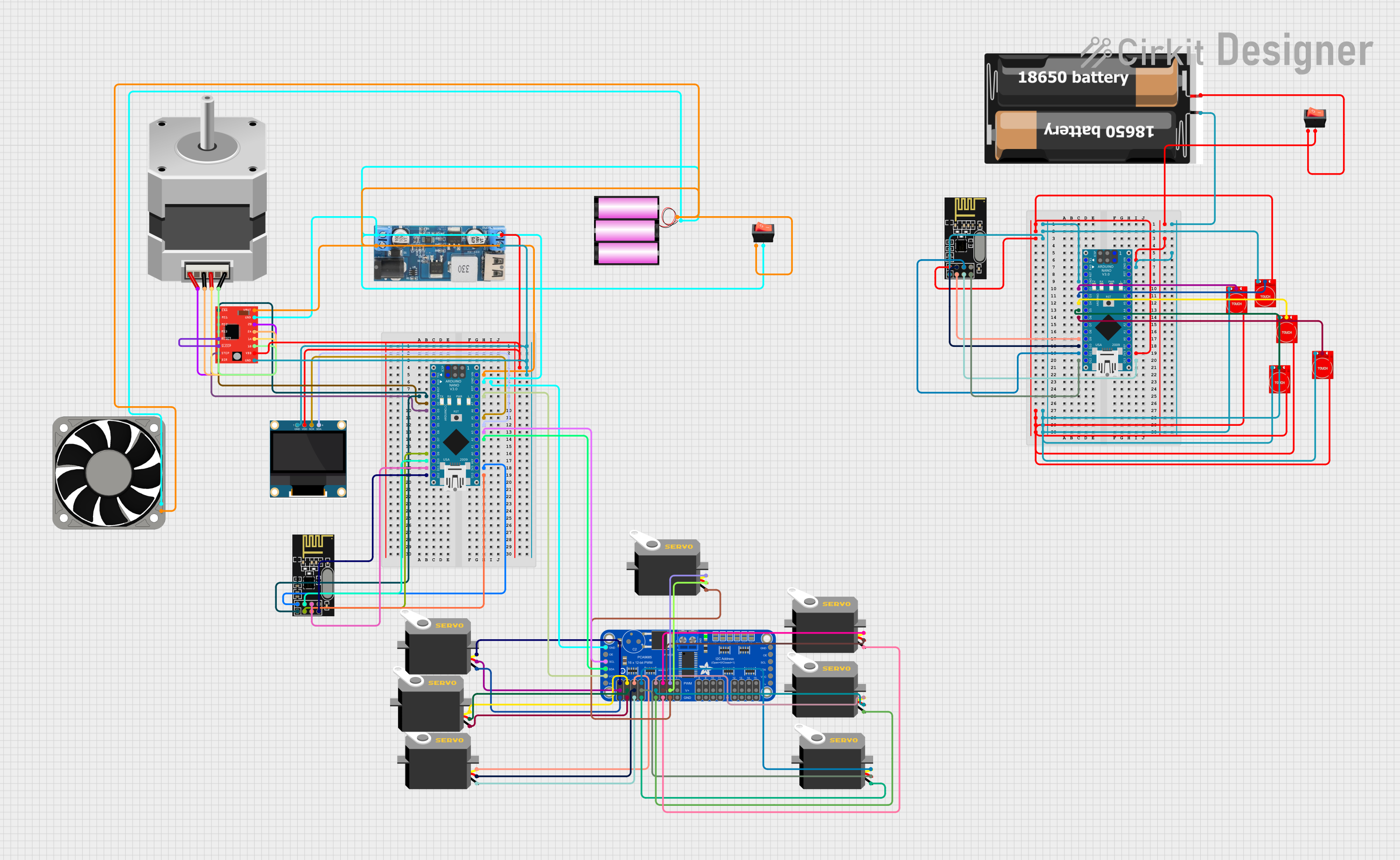

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Cooling for desktop computers, servers, and gaming systems

- Heat dissipation in power supplies and industrial equipment

- Ventilation in 3D printers and other compact electronic devices

- Custom cooling solutions for DIY electronics projects

Technical Specifications

Below are the key technical details and pin configuration for the 12V PWM 80x80mm Fan:

Key Technical Details

| Parameter | Specification |

|---|---|

| Operating Voltage | 12V DC |

| Current Rating | 0.15A to 0.30A (varies by model) |

| Power Consumption | 1.8W to 3.6W |

| Fan Dimensions | 80mm x 80mm x 25mm |

| Airflow | 30-50 CFM (Cubic Feet per Minute) |

| Speed Range | 800-3000 RPM (PWM controlled) |

| Noise Level | 20-35 dBA (depending on speed) |

| Connector Type | 4-pin PWM connector |

| Bearing Type | Sleeve or ball bearing |

| Operating Temperature | -10°C to 70°C |

| Lifespan | 30,000 to 50,000 hours |

Pin Configuration and Descriptions

The fan uses a standard 4-pin PWM connector. The pinout is as follows:

| Pin Number | Name | Description |

|---|---|---|

| 1 | GND | Ground connection for the fan |

| 2 | VCC | Power supply input (12V DC) |

| 3 | Tachometer | Outputs a signal for monitoring fan speed (RPM) |

| 4 | PWM Control | Accepts a PWM signal (typically 25kHz) to control fan speed (duty cycle) |

Usage Instructions

How to Use the Component in a Circuit

- Power Connection: Connect the VCC pin to a 12V DC power source and the GND pin to ground.

- PWM Control: Use a microcontroller (e.g., Arduino) or a dedicated PWM controller to send a PWM signal to the PWM Control pin. The duty cycle of the PWM signal determines the fan speed:

- 0% duty cycle: Fan is off

- 50% duty cycle: Fan runs at approximately half speed

- 100% duty cycle: Fan runs at full speed

- Tachometer Monitoring: If needed, connect the Tachometer pin to a microcontroller input pin to monitor the fan's RPM. The tachometer typically outputs two pulses per revolution.

Important Considerations and Best Practices

- PWM Signal Frequency: Ensure the PWM signal frequency is around 25kHz for optimal performance.

- Power Supply: Use a stable 12V DC power source to avoid damaging the fan.

- Mounting: Secure the fan using screws or clips to minimize vibration and noise.

- Airflow Direction: Check the fan's airflow direction (usually indicated by arrows on the fan housing) to ensure proper cooling.

- Avoid Blockages: Keep the fan's intake and exhaust areas clear of obstructions for maximum airflow.

Example: Connecting to an Arduino UNO

Below is an example of how to control the fan speed using an Arduino UNO:

// Define the PWM pin connected to the fan's PWM control pin

const int pwmPin = 9;

void setup() {

// Set the PWM pin as an output

pinMode(pwmPin, OUTPUT);

}

void loop() {

// Example: Gradually increase fan speed from 0% to 100%

for (int dutyCycle = 0; dutyCycle <= 255; dutyCycle += 5) {

analogWrite(pwmPin, dutyCycle); // Write PWM signal to the fan

delay(50); // Wait 50ms before increasing the duty cycle

}

// Example: Gradually decrease fan speed from 100% to 0%

for (int dutyCycle = 255; dutyCycle >= 0; dutyCycle -= 5) {

analogWrite(pwmPin, dutyCycle); // Write PWM signal to the fan

delay(50); // Wait 50ms before decreasing the duty cycle

}

}

Notes:

- The

analogWrite()function generates a PWM signal on the specified pin. - Ensure the Arduino's PWM pin is connected to the fan's PWM Control pin.

Troubleshooting and FAQs

Common Issues and Solutions

Fan Does Not Spin

- Cause: No power or incorrect wiring.

- Solution: Verify the VCC and GND connections. Ensure the power supply provides 12V DC.

Fan Runs at Full Speed Constantly

- Cause: PWM signal not connected or incorrect frequency.

- Solution: Check the PWM Control pin connection. Ensure the PWM signal frequency is around 25kHz.

Fan Speed Does Not Change

- Cause: Incorrect PWM duty cycle or faulty PWM signal.

- Solution: Verify the PWM signal using an oscilloscope. Ensure the duty cycle is within the 0-100% range.

Excessive Noise or Vibration

- Cause: Loose mounting or obstructed airflow.

- Solution: Secure the fan properly and clear any obstructions near the fan.

Tachometer Signal Not Detected

- Cause: Incorrect connection or incompatible microcontroller input.

- Solution: Verify the Tachometer pin connection. Ensure the microcontroller input pin is configured correctly.

FAQs

Q: Can I use a 5V PWM signal to control the fan?

A: Yes, most 12V PWM fans are compatible with 5V PWM signals. However, check the fan's datasheet to confirm compatibility.

Q: What happens if I don't connect the PWM Control pin?

A: The fan will typically run at full speed by default if the PWM Control pin is left unconnected.

Q: Can I use this fan with a 3-pin connector?

A: Yes, but you will lose PWM speed control. The fan will run at full speed when powered.

Q: How do I clean the fan?

A: Use compressed air to remove dust. Avoid using liquids or disassembling the fan.

This concludes the documentation for the 12V PWM 80x80mm Fan.