How to Use L12-30-50-6-R: Examples, Pinouts, and Specs

Design with L12-30-50-6-R in Cirkit Designer

Design with L12-30-50-6-R in Cirkit DesignerIntroduction

The L12-30-50-6-R is a compact linear actuator manufactured by Firgelli, designed for precision motion control in a variety of applications. This actuator is part of the "Actuator Linear" series and is characterized by its small size, high efficiency, and reliable performance. It is commonly used in robotics, home automation, medical devices, and industrial machinery where precise linear motion is required.

Explore Projects Built with L12-30-50-6-R

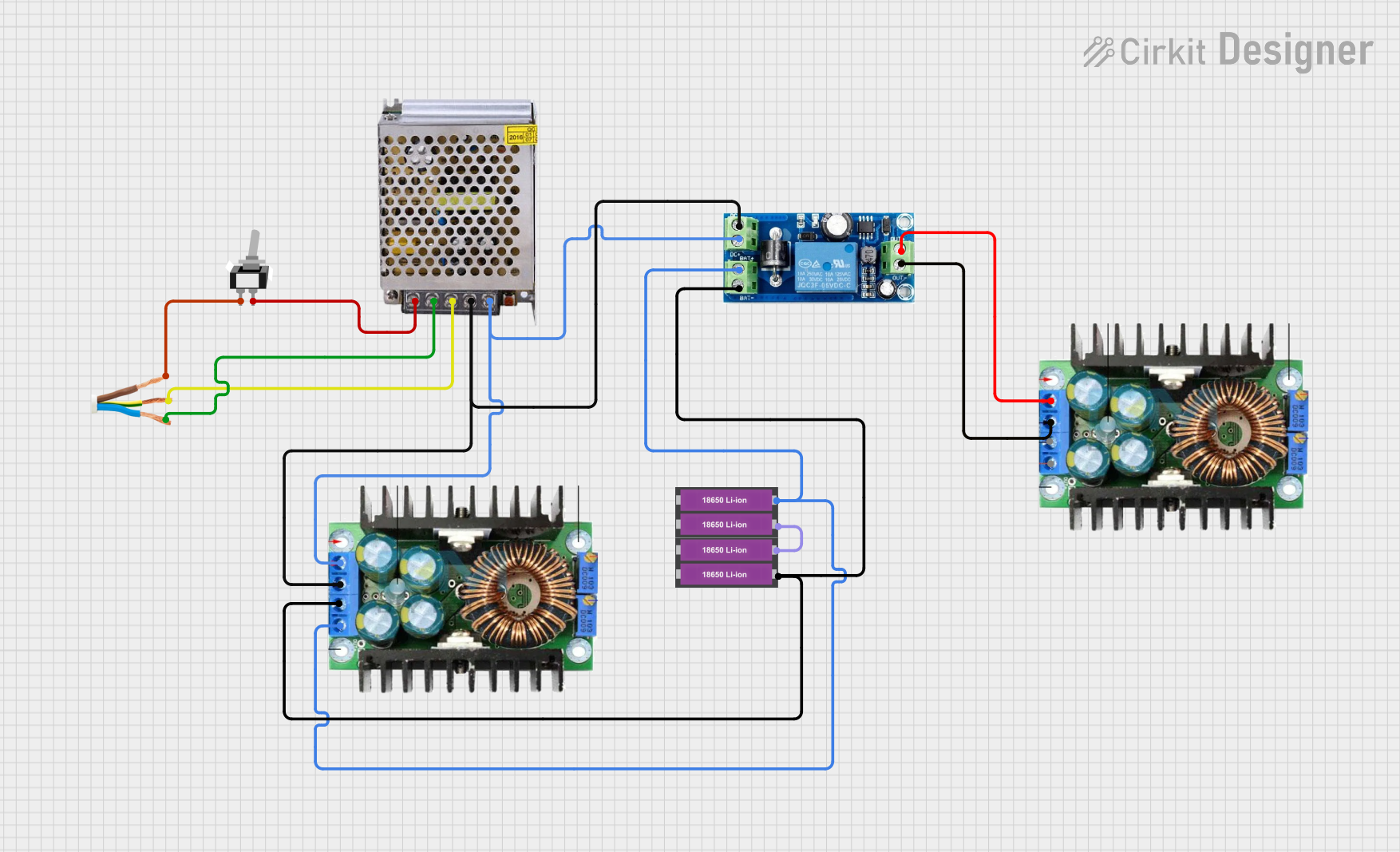

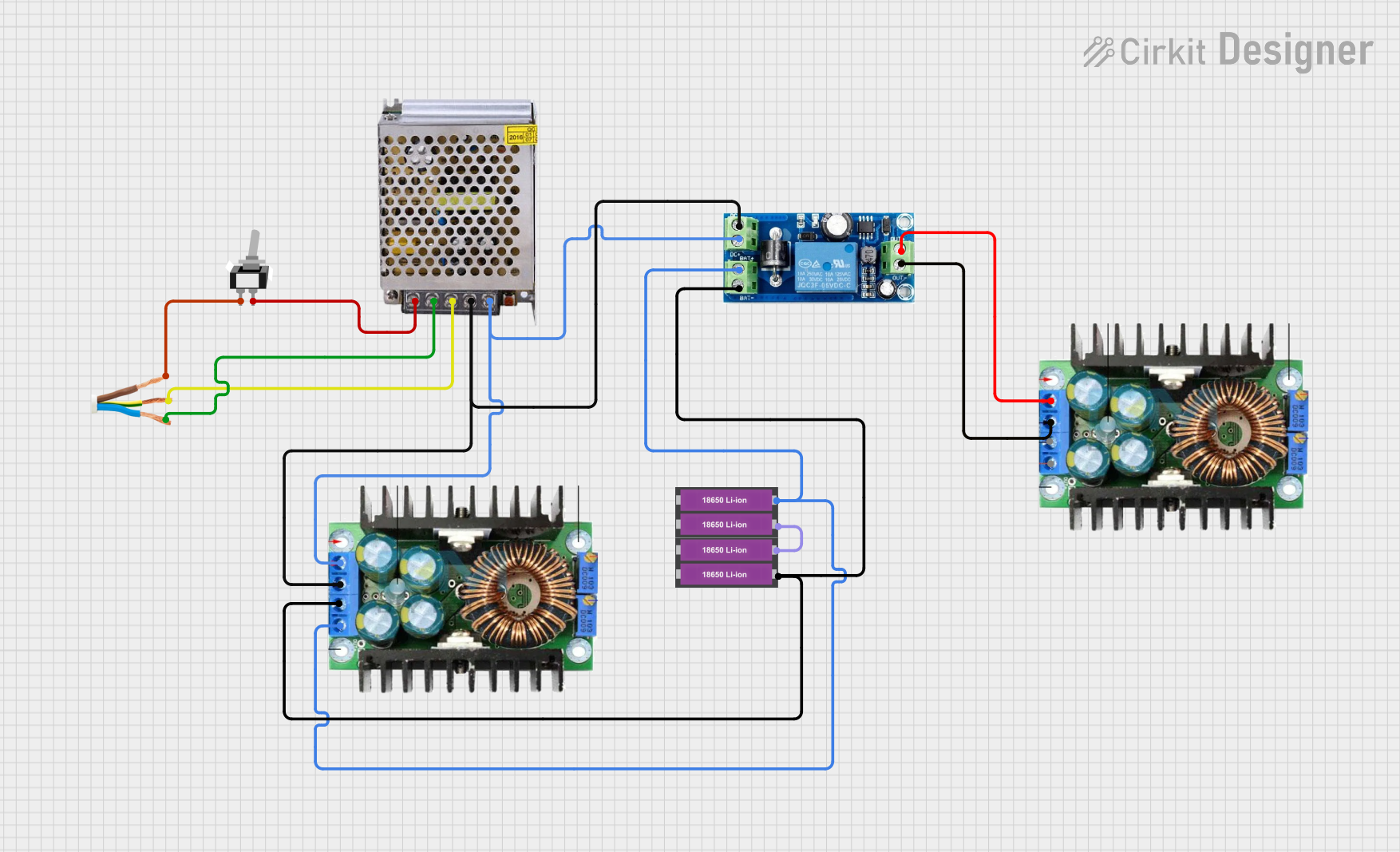

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L12-30-50-6-R

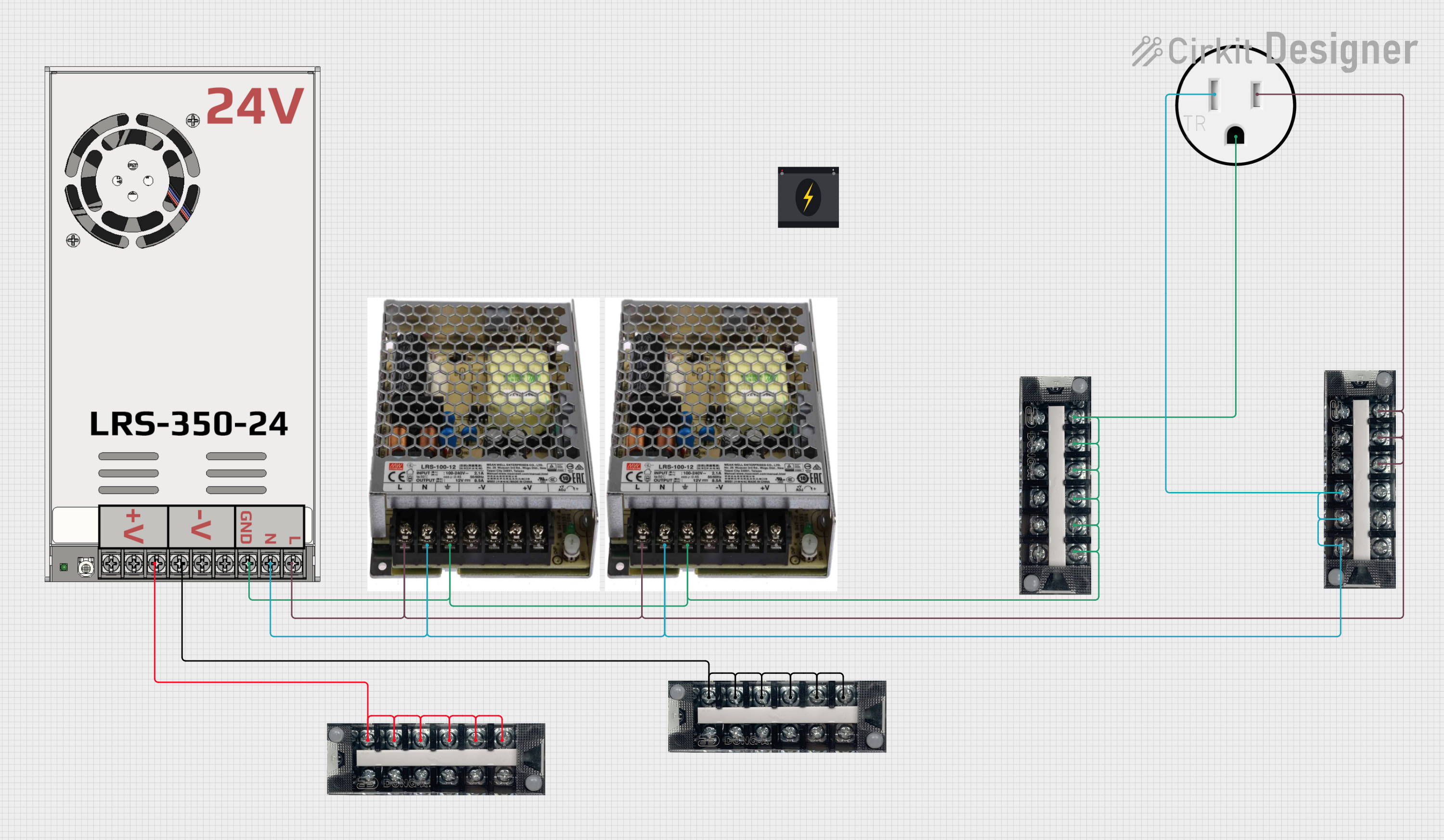

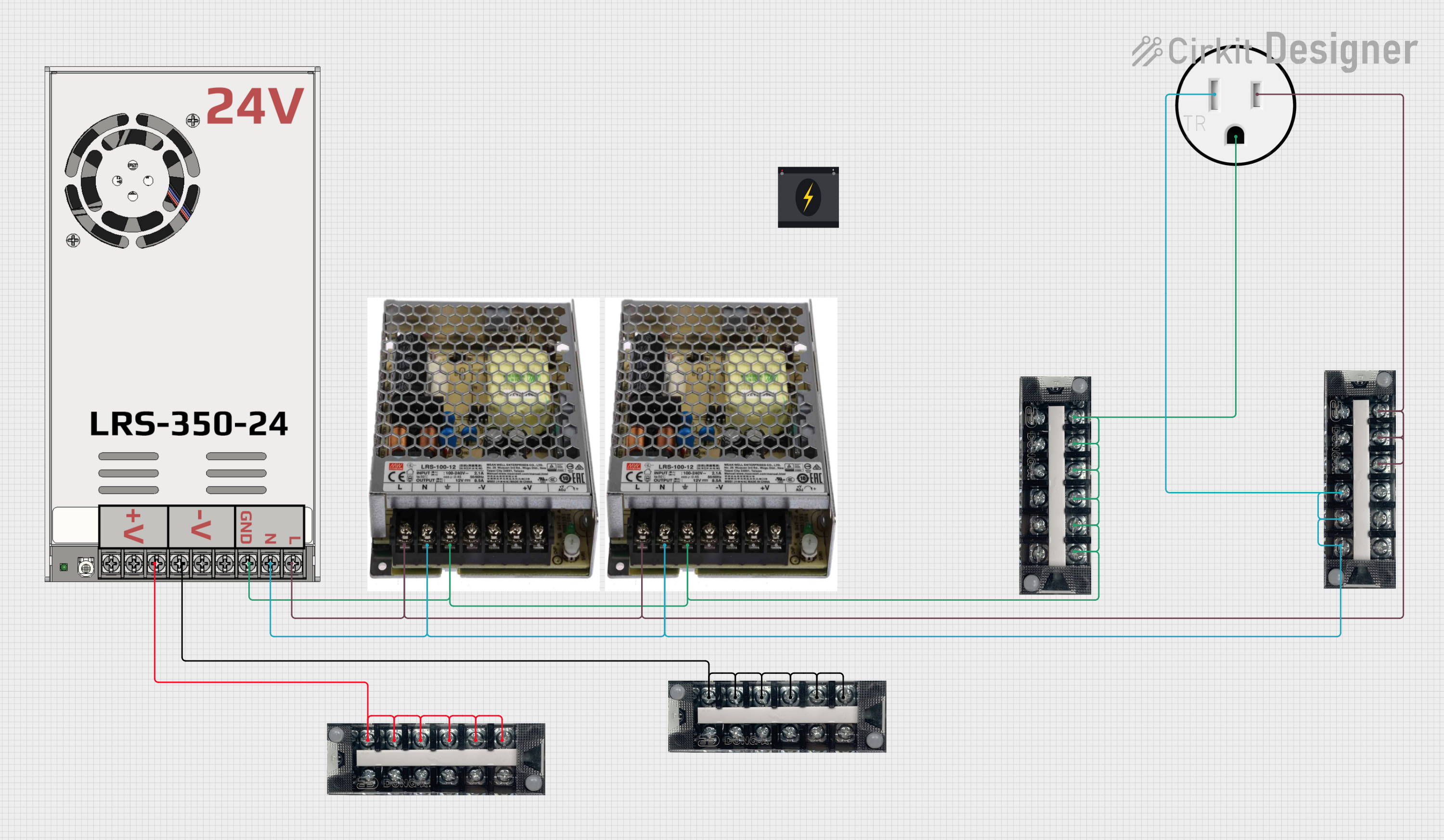

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: For precise movement of robotic arms or grippers.

- Home Automation: Used in motorized windows, doors, or adjustable furniture.

- Medical Devices: Incorporated into equipment requiring controlled linear motion.

- Industrial Machinery: For automated processes requiring accurate positioning.

Technical Specifications

The L12-30-50-6-R is designed to deliver consistent performance under various conditions. Below are its key technical details:

General Specifications

| Parameter | Value |

|---|---|

| Manufacturer | Firgelli |

| Part Number | L12-30-50-6-R |

| Stroke Length | 50 mm |

| Input Voltage | 6 V DC |

| Maximum Force | 30 N |

| Speed at No Load | 12 mm/s |

| Duty Cycle | 20% |

| Position Feedback | Optional (depending on model) |

| Operating Temperature | -10°C to +50°C |

Pin Configuration and Descriptions

The L12-30-50-6-R actuator typically comes with a 6-pin connector for control and feedback. Below is the pinout:

| Pin Number | Name | Description |

|---|---|---|

| 1 | V+ | Positive power supply (6 V DC) |

| 2 | GND | Ground connection |

| 3 | Control Signal | PWM or analog signal for position control |

| 4 | Feedback | Position feedback signal (optional, if supported) |

| 5 | NC | Not connected |

| 6 | NC | Not connected |

Usage Instructions

The L12-30-50-6-R is straightforward to use in a variety of circuits. Below are the steps and best practices for integrating it into your project:

How to Use the Component in a Circuit

- Power Supply: Connect the V+ pin to a 6 V DC power source and the GND pin to the ground.

- Control Signal: Use a PWM signal (typically from a microcontroller like an Arduino) to control the actuator's position. The duty cycle of the PWM signal determines the actuator's extension.

- Feedback (Optional): If your model supports position feedback, connect the feedback pin to an analog input on your microcontroller to monitor the actuator's position.

Important Considerations and Best Practices

- Duty Cycle: Operate the actuator within its 20% duty cycle to prevent overheating.

- Load Limits: Do not exceed the maximum force of 30 N to avoid damaging the actuator.

- Position Feedback: If using the feedback feature, ensure your microcontroller's ADC resolution is sufficient for accurate readings.

- Mounting: Securely mount the actuator to prevent misalignment or mechanical stress.

Example Code for Arduino UNO

Below is an example of how to control the L12-30-50-6-R actuator using an Arduino UNO:

// Define the PWM pin connected to the actuator's control signal

const int actuatorPin = 9;

void setup() {

// Set the actuator pin as an output

pinMode(actuatorPin, OUTPUT);

}

void loop() {

// Extend the actuator to 50% of its stroke

analogWrite(actuatorPin, 128); // 128 corresponds to 50% duty cycle (0-255 scale)

delay(2000); // Wait for 2 seconds

// Retract the actuator completely

analogWrite(actuatorPin, 0); // 0 corresponds to 0% duty cycle

delay(2000); // Wait for 2 seconds

}

Notes on the Code

- The

analogWritefunction generates a PWM signal to control the actuator's position. - Adjust the duty cycle (0-255) to achieve the desired extension.

Troubleshooting and FAQs

Common Issues Users Might Face

Actuator Not Moving:

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power supply voltage is 6 V DC and check all connections.

Overheating:

- Cause: Exceeding the 20% duty cycle or overloading the actuator.

- Solution: Reduce the duty cycle and ensure the load does not exceed 30 N.

Inaccurate Positioning:

- Cause: Noise in the feedback signal or incorrect PWM settings.

- Solution: Use proper filtering for the feedback signal and verify the PWM frequency.

No Feedback Signal:

- Cause: Feedback pin not connected or unsupported model.

- Solution: Check the datasheet to confirm feedback support and verify connections.

Solutions and Tips for Troubleshooting

- Use a multimeter to check the voltage at the actuator's pins.

- Test the actuator with a simple circuit before integrating it into a complex system.

- If using an Arduino, ensure the PWM frequency matches the actuator's requirements (typically 490 Hz for most Arduino boards).

By following this documentation, you can effectively integrate and operate the L12-30-50-6-R linear actuator in your projects.