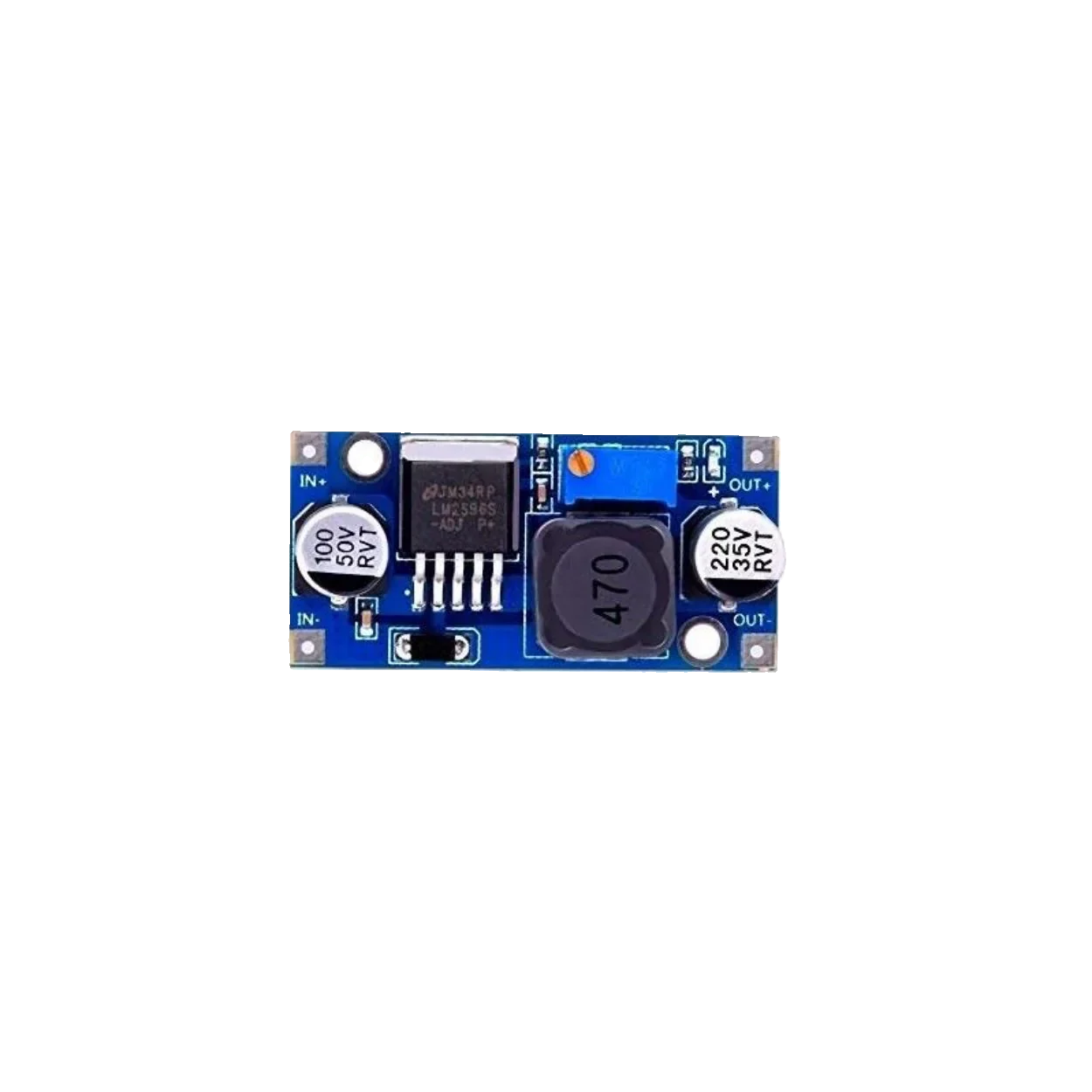

How to Use BUCK CONVERTER: Examples, Pinouts, and Specs

Design with BUCK CONVERTER in Cirkit Designer

Design with BUCK CONVERTER in Cirkit DesignerIntroduction

A buck converter is a type of DC-DC converter that steps down voltage while stepping up current. It achieves this by using a switching element (typically a transistor), an inductor, a diode, and a capacitor. Buck converters are highly efficient and are widely used in applications where a stable, lower voltage is required from a higher input voltage source.

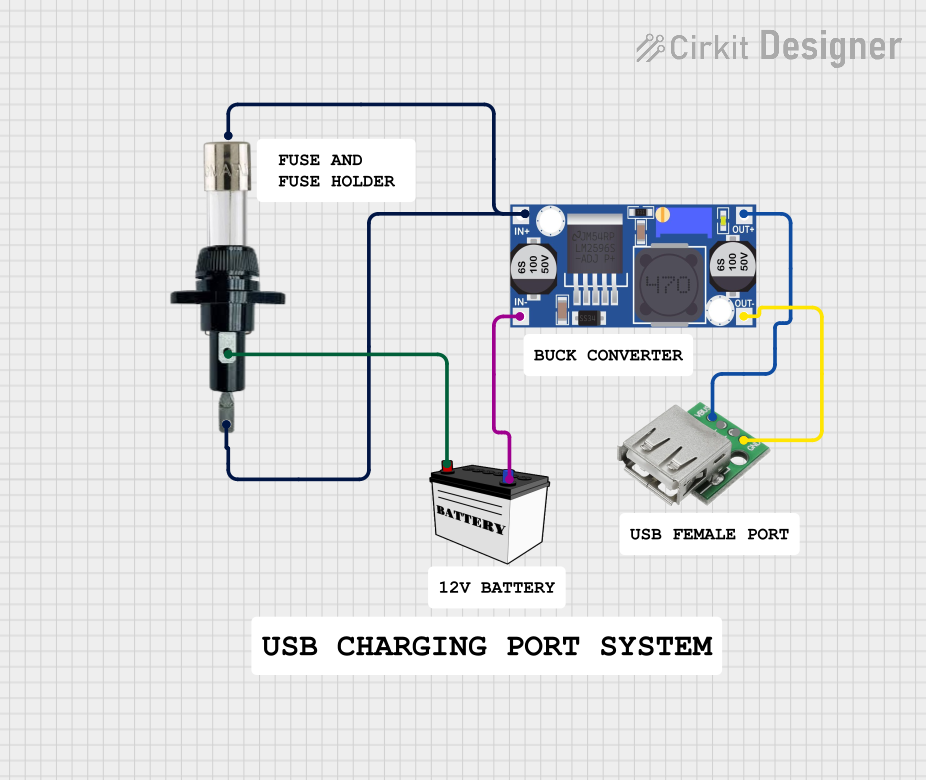

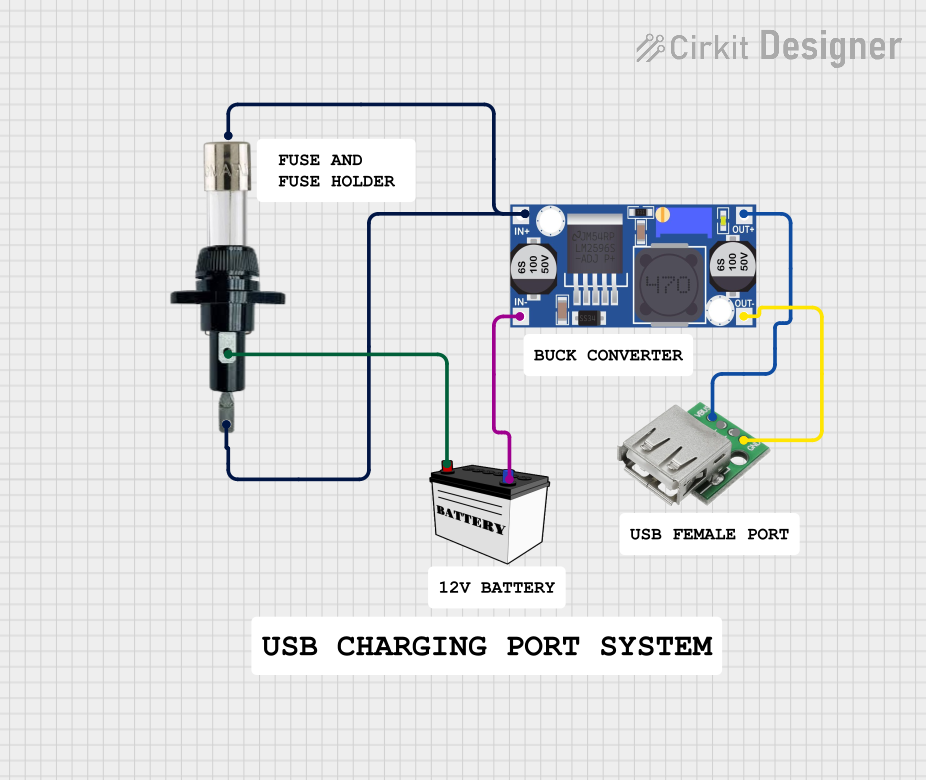

Explore Projects Built with BUCK CONVERTER

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with BUCK CONVERTER

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Powering microcontrollers and low-voltage devices from higher voltage sources

- Battery-powered systems to regulate voltage levels

- Voltage regulation in renewable energy systems (e.g., solar panels)

- Automotive electronics for stepping down 12V to lower voltages

- LED drivers and portable electronic devices

Technical Specifications

Below are the general technical specifications for a typical buck converter. Note that actual values may vary depending on the specific model.

Key Technical Details

- Input Voltage Range: 4.5V to 40V (varies by model)

- Output Voltage Range: Adjustable (e.g., 1.25V to 37V)

- Output Current: Up to 3A (or higher for advanced models)

- Efficiency: Up to 95% (depending on load and input/output conditions)

- Switching Frequency: 150 kHz to 1 MHz (varies by design)

- Thermal Protection: Built-in in many models

- Short-Circuit Protection: Available in most designs

Pin Configuration and Descriptions

The pinout of a buck converter module (e.g., LM2596-based module) is as follows:

| Pin Name | Description |

|---|---|

| VIN | Input voltage pin. Connect the higher voltage source here. |

| GND | Ground pin. Connect to the ground of the circuit. |

| VOUT | Output voltage pin. Provides the stepped-down voltage. |

| ADJ (optional) | Adjustment pin for setting the output voltage (used in adjustable models). |

Usage Instructions

How to Use the Component in a Circuit

- Connect the Input Voltage:

- Attach the positive terminal of the input voltage source to the

VINpin. - Connect the negative terminal of the input source to the

GNDpin.

- Attach the positive terminal of the input voltage source to the

- Connect the Load:

- Attach the positive terminal of the load to the

VOUTpin. - Connect the negative terminal of the load to the

GNDpin.

- Attach the positive terminal of the load to the

- Adjust the Output Voltage (if applicable):

- For adjustable buck converters, use the onboard potentiometer to set the desired output voltage.

- Measure the output voltage using a multimeter while adjusting the potentiometer.

- Power On:

- Turn on the input voltage source and verify the output voltage and current.

Important Considerations and Best Practices

- Input Voltage: Ensure the input voltage is within the specified range of the buck converter.

- Output Voltage: Do not exceed the rated output voltage or current of the module.

- Heat Dissipation: For high-power applications, ensure proper heat dissipation using heatsinks or fans.

- Capacitor Selection: Use low-ESR capacitors for better performance and stability.

- Inductor Selection: Ensure the inductor value matches the design requirements for your load.

- Filtering: Add input and output capacitors to reduce noise and improve stability.

Example: Using a Buck Converter with Arduino UNO

Below is an example of using a buck converter to power an Arduino UNO from a 12V source:

- Connect the 12V source to the

VINandGNDpins of the buck converter. - Adjust the output voltage to 5V using the potentiometer.

- Connect the

VOUTpin of the buck converter to the5Vpin of the Arduino UNO. - Connect the

GNDpin of the buck converter to theGNDpin of the Arduino UNO.

// Example Arduino code to blink an LED powered by a buck converter

// Ensure the buck converter is set to 5V output before connecting to Arduino

const int ledPin = 13; // Pin connected to the onboard LED

void setup() {

pinMode(ledPin, OUTPUT); // Set the LED pin as an output

}

void loop() {

digitalWrite(ledPin, HIGH); // Turn the LED on

delay(1000); // Wait for 1 second

digitalWrite(ledPin, LOW); // Turn the LED off

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Check the input voltage and ensure it is within the specified range.

- Verify all connections, especially

VINandGND. - Ensure the potentiometer is not set to the minimum output voltage.

Overheating:

- Ensure the load does not exceed the rated current of the buck converter.

- Add a heatsink or fan to improve heat dissipation.

Output Voltage Fluctuations:

- Check the input voltage stability.

- Add input and output capacitors to reduce noise.

- Verify the inductor and capacitor values are appropriate for the load.

Low Efficiency:

- Ensure the input voltage is not too close to the output voltage.

- Use low-ESR capacitors and high-quality components.

FAQs

Q: Can I use a buck converter to power sensitive electronics?

A: Yes, but ensure the output voltage is stable and noise-free. Adding filtering capacitors can help.

Q: What happens if I exceed the input voltage range?

A: Exceeding the input voltage range can damage the buck converter. Always stay within the specified range.

Q: Can I use a buck converter to step up voltage?

A: No, a buck converter is designed only to step down voltage. For stepping up voltage, use a boost converter.

Q: How do I calculate the required inductor value?

A: The inductor value depends on the input voltage, output voltage, switching frequency, and load current. Refer to the datasheet of the specific buck converter IC for detailed calculations.