How to Use AS5600 magnetic encoder: Examples, Pinouts, and Specs

Design with AS5600 magnetic encoder in Cirkit Designer

Design with AS5600 magnetic encoder in Cirkit DesignerIntroduction

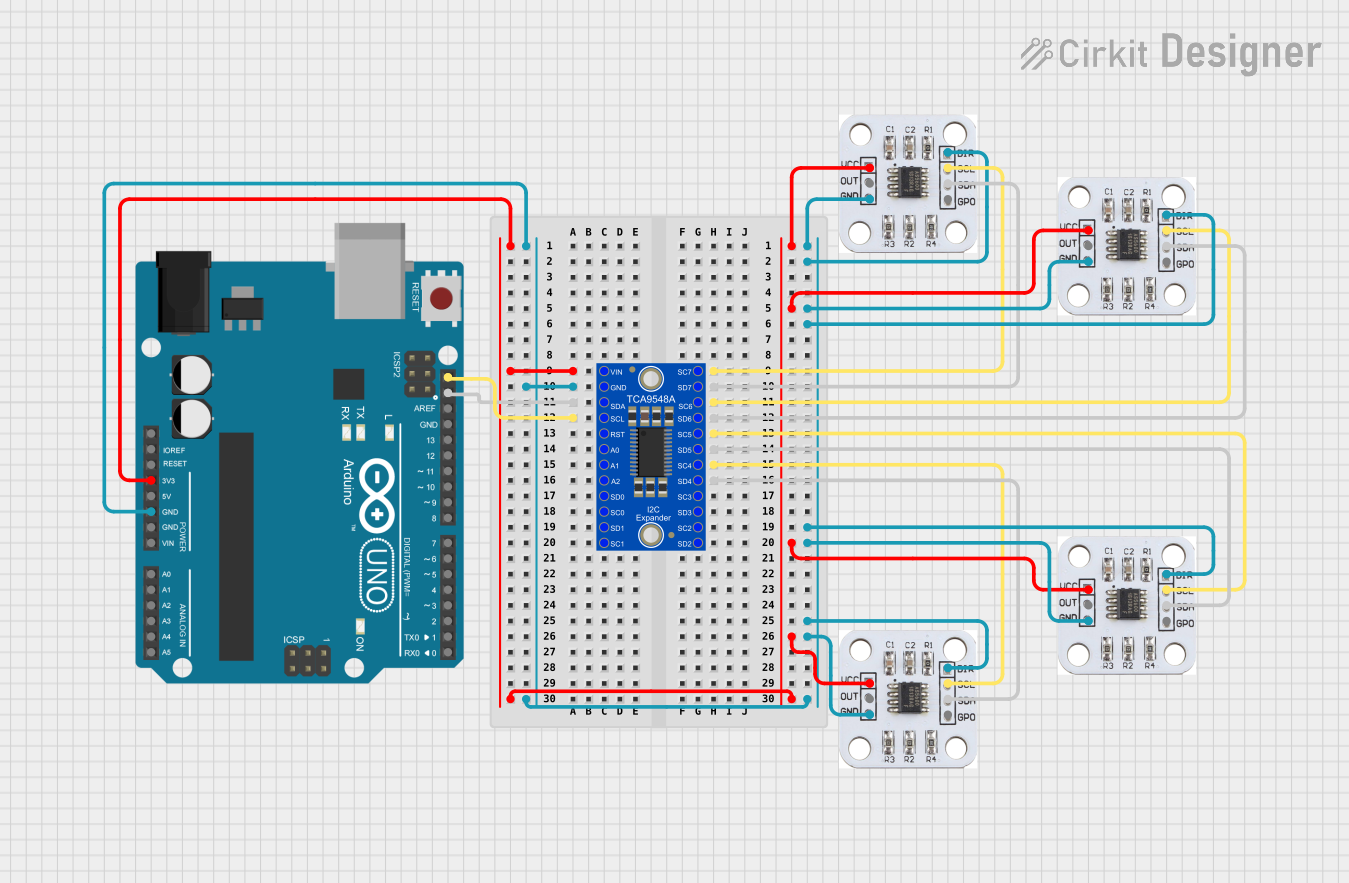

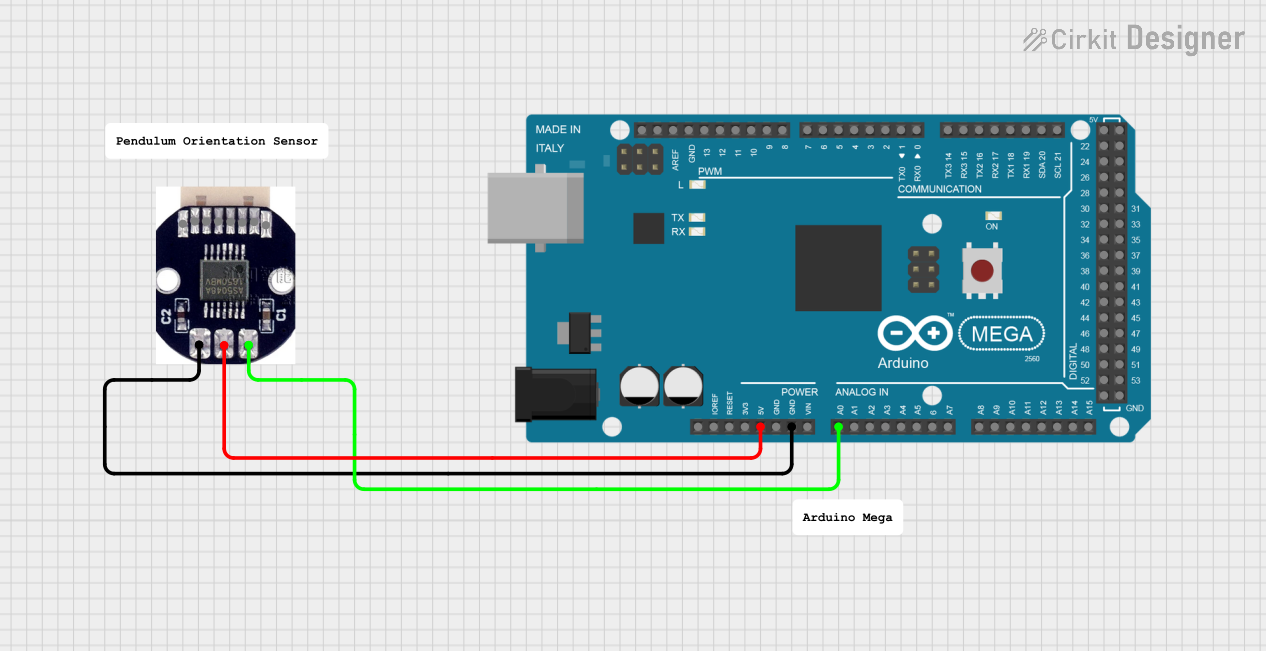

The AS5600 is a magnetic rotary position sensor that converts the angular position of a magnetic field to an analog or digital output signal. This contactless system is designed to measure the orientation of a magnetic field as perceived by the sensor. It is commonly used in applications requiring precise angle measurements, such as motor control, robotics, joysticks, and knob controls.

Explore Projects Built with AS5600 magnetic encoder

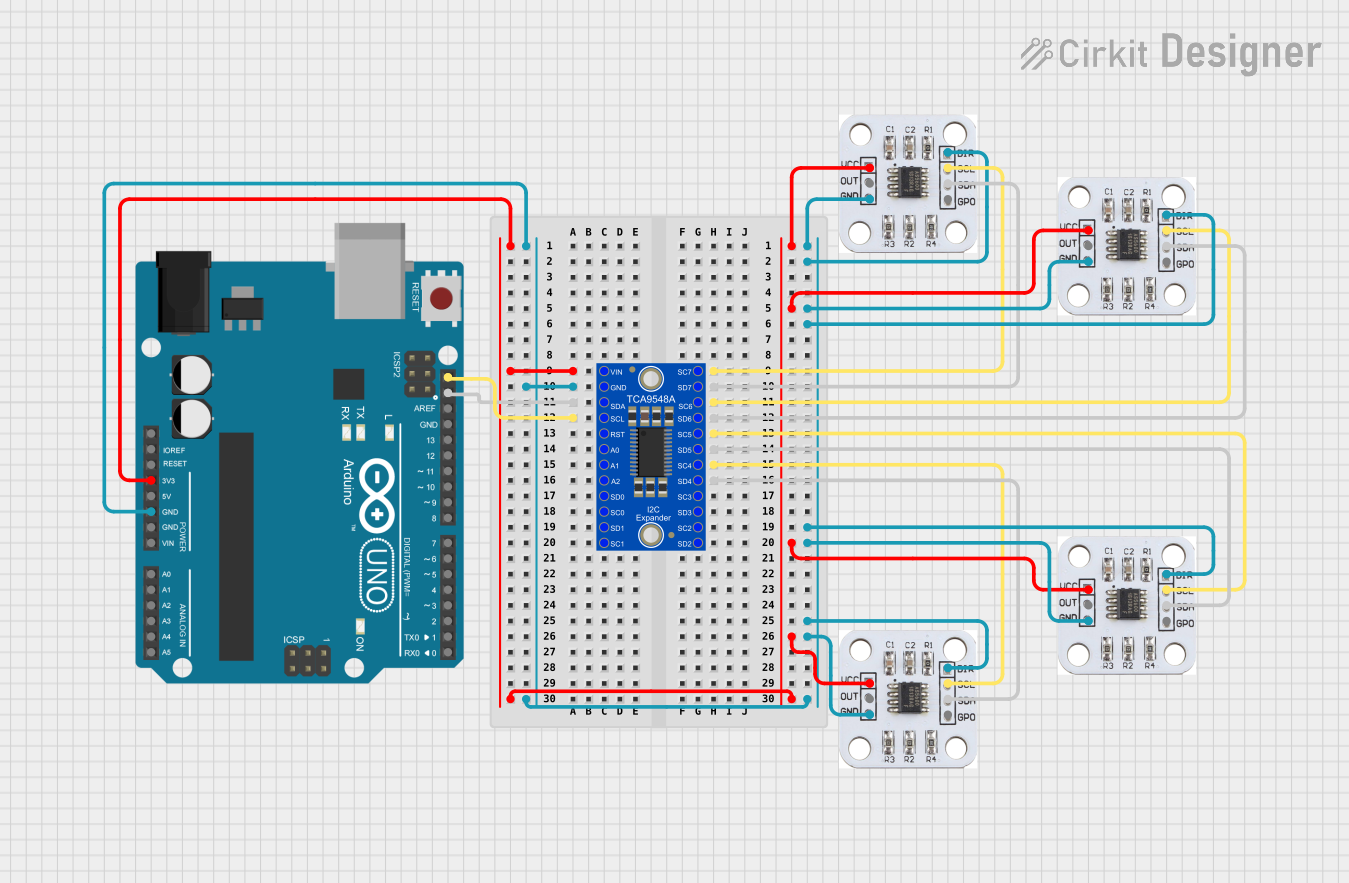

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with AS5600 magnetic encoder

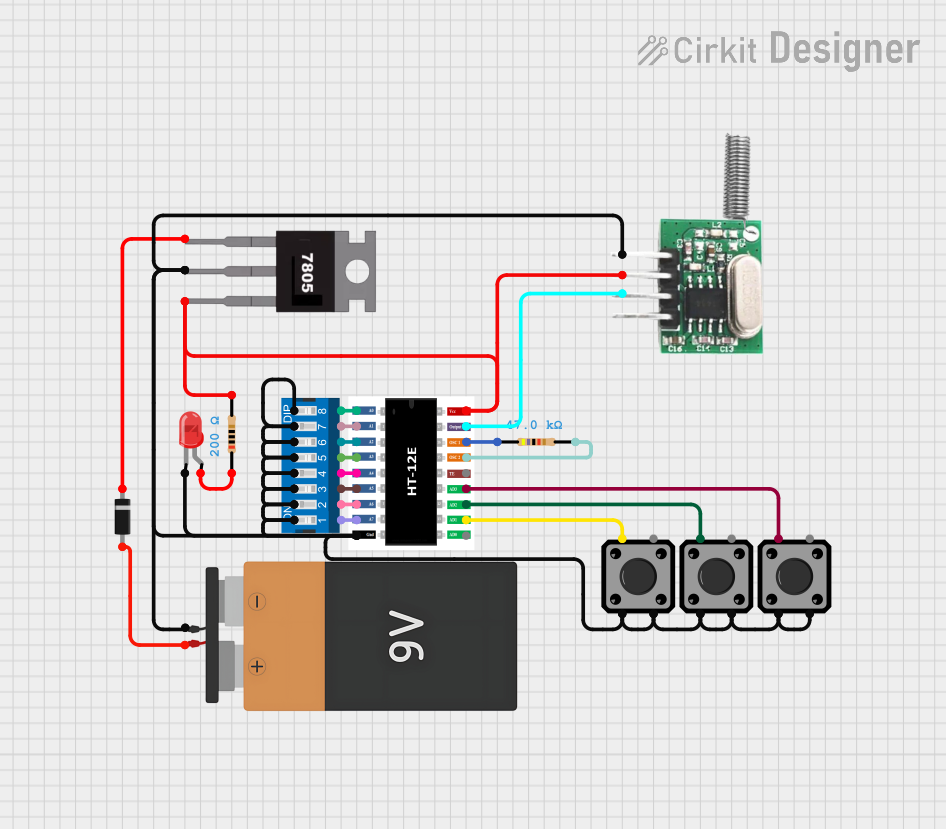

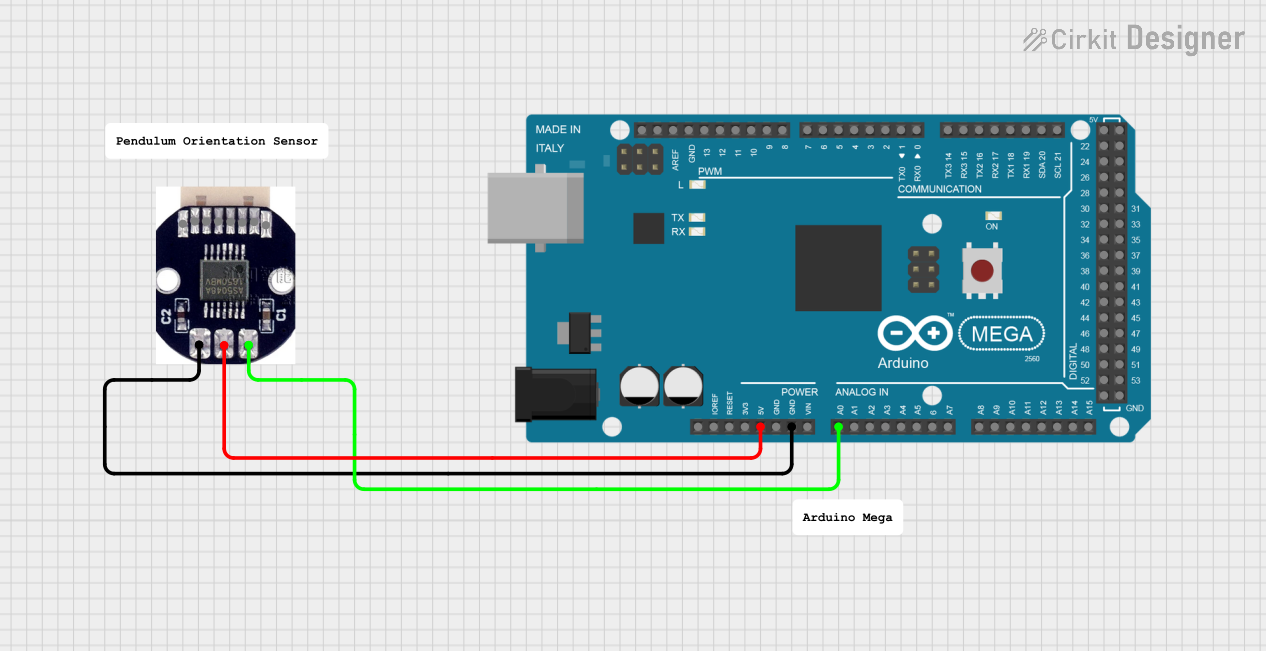

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Supply Voltage (Vdd): 3.3V to 5V

- Measurement Range: 0 to 360 degrees

- Output Interface: Analog (0V to Vdd), PWM, I2C

- Resolution: 12-bit (4096 positions)

- Max Output Update Rate: 1 kHz (PWM), 100 Hz (I2C)

- Operating Temperature Range: -40°C to +125°C

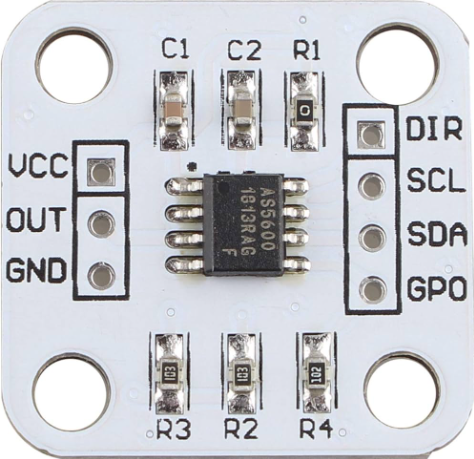

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | VDD | Supply voltage (3.3V to 5V) |

| 3 | SCL | I2C clock line |

| 4 | SDA | I2C data line |

| 5 | OUT | Analog/PWM output |

| 6 | VDD | Supply voltage (duplicate for convenience) |

Usage Instructions

Integration into a Circuit

- Power Supply: Connect the VDD pin to a 3.3V or 5V power supply and the GND pin to the ground.

- Output Selection: For analog output, connect the OUT pin to an analog input on your microcontroller. For PWM or I2C, ensure your microcontroller supports these interfaces and connect accordingly.

- Magnet Placement: Place a diametrically magnetized magnet above the sensor. The magnet's rotation axis should be perpendicular to the sensor surface.

Important Considerations and Best Practices

- Magnet Type: Use a diametrically magnetized magnet for accurate measurements.

- Magnet Distance: Keep the magnet within the recommended distance from the sensor surface as specified in the datasheet.

- Calibration: Perform calibration through the I2C interface to account for magnet misalignment and variations.

- Electromagnetic Interference: Avoid placing the sensor near strong electromagnetic fields to prevent interference.

Example Code for Arduino UNO

#include <Wire.h>

// AS5600 I2C address

#define AS5600_ADDRESS 0x36

// AS5600 register addresses

#define RAW_ANGLE_REG 0x0C

void setup() {

Wire.begin(); // Initialize I2C

Serial.begin(9600); // Start serial communication at 9600 baud

}

void loop() {

unsigned int angle = readAS5600Angle();

Serial.print("Angle: ");

Serial.println(angle);

delay(100); // Delay for readability

}

// Function to read the raw angle from the AS5600

unsigned int readAS5600Angle() {

Wire.beginTransmission(AS5600_ADDRESS);

Wire.write(RAW_ANGLE_REG); // Point to the raw angle register

Wire.endTransmission(false);

Wire.requestFrom(AS5600_ADDRESS, 2); // Request 2 bytes from the sensor

while (Wire.available() < 2); // Wait for the data

unsigned int angle = Wire.read(); // Read the first byte

angle <<= 8; // Shift the first byte

angle |= Wire.read(); // Read the second byte and combine with the first

return angle;

}

Troubleshooting and FAQs

Common Issues

- Inaccurate Readings: Ensure the magnet is properly aligned and within the specified distance from the sensor.

- No Output Signal: Check the power supply and wiring connections. Verify that the magnet is present and correctly oriented.

- Intermittent Signal: Check for loose connections and ensure the magnet is secured in place.

Solutions and Tips

- Calibration: Use the I2C interface to calibrate the sensor for your specific setup.

- Magnet Quality: Use a high-quality magnet to ensure consistent readings.

- Shielding: Implement shielding or move the sensor away from other electronic components that may cause interference.

FAQs

Q: Can the AS5600 measure more than 360 degrees? A: No, the AS5600 is designed for 0 to 360-degree measurements.

Q: How do I calibrate the sensor? A: Calibration can be done through the I2C interface by writing to specific registers. Refer to the datasheet for detailed instructions.

Q: What is the maximum distance the magnet can be from the sensor? A: The maximum distance depends on the magnet strength but typically is a few millimeters. Consult the datasheet for exact specifications.

Q: Is the AS5600 affected by external magnetic fields? A: Yes, external magnetic fields can affect the readings. It is advisable to keep the sensor away from strong magnetic fields.