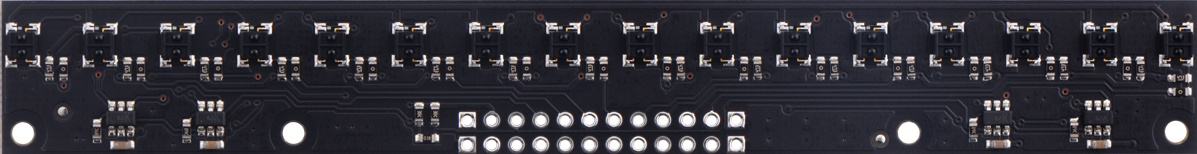

How to Use QTRX-MD-16A Reflectance Sensor Array: Examples, Pinouts, and Specs

Design with QTRX-MD-16A Reflectance Sensor Array in Cirkit Designer

Design with QTRX-MD-16A Reflectance Sensor Array in Cirkit DesignerIntroduction

The QTRX-MD-16A Reflectance Sensor Array, manufactured by Pololu, is a high-performance sensor array designed for detecting surface reflectance. It is commonly used in robotics applications such as line-following robots, edge detection, and obstacle avoidance. The array consists of 16 pairs of infrared emitters and photodetectors, enabling precise and high-resolution surface reflectance measurements. Its compact design and modularity make it suitable for a wide range of projects.

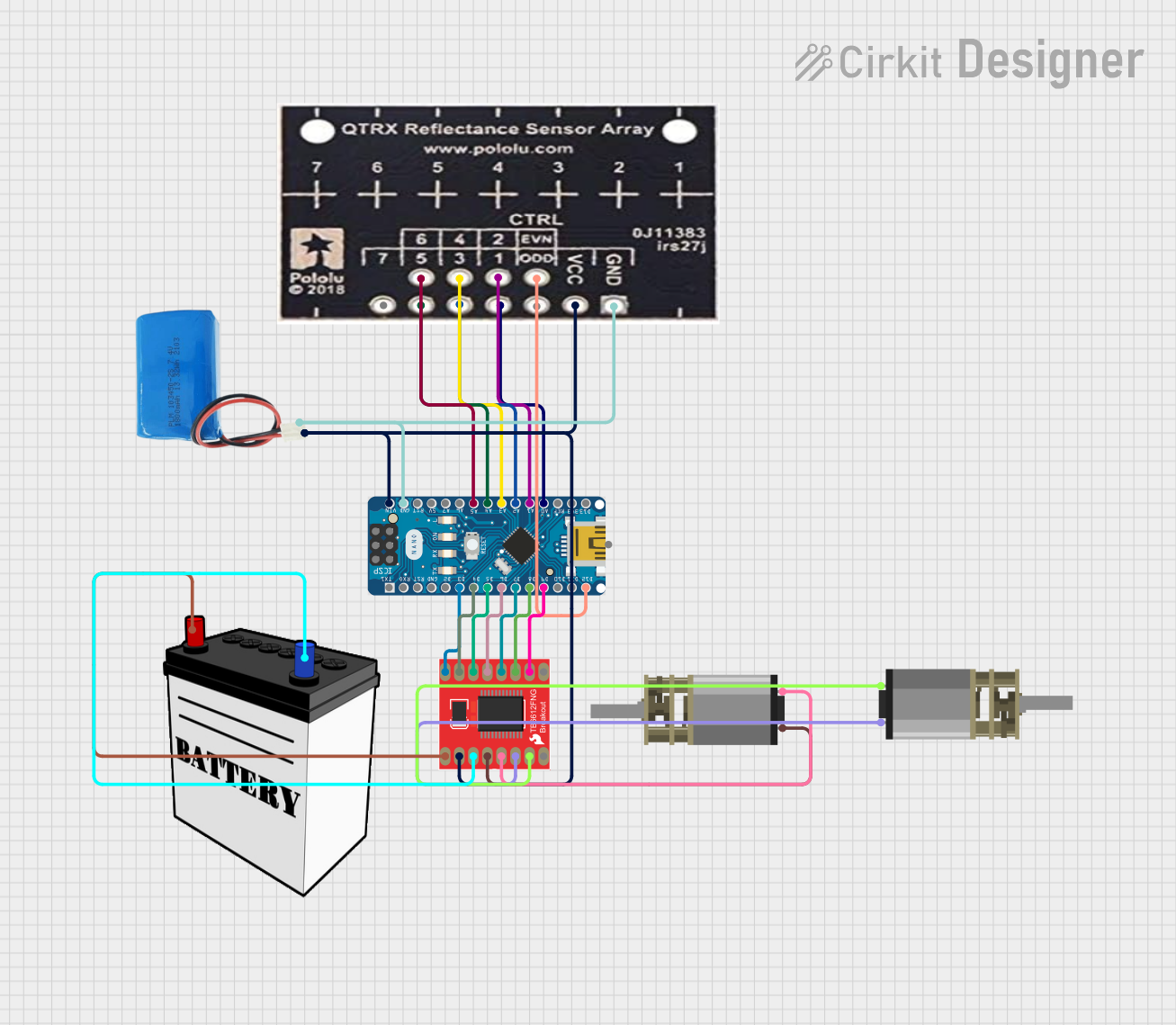

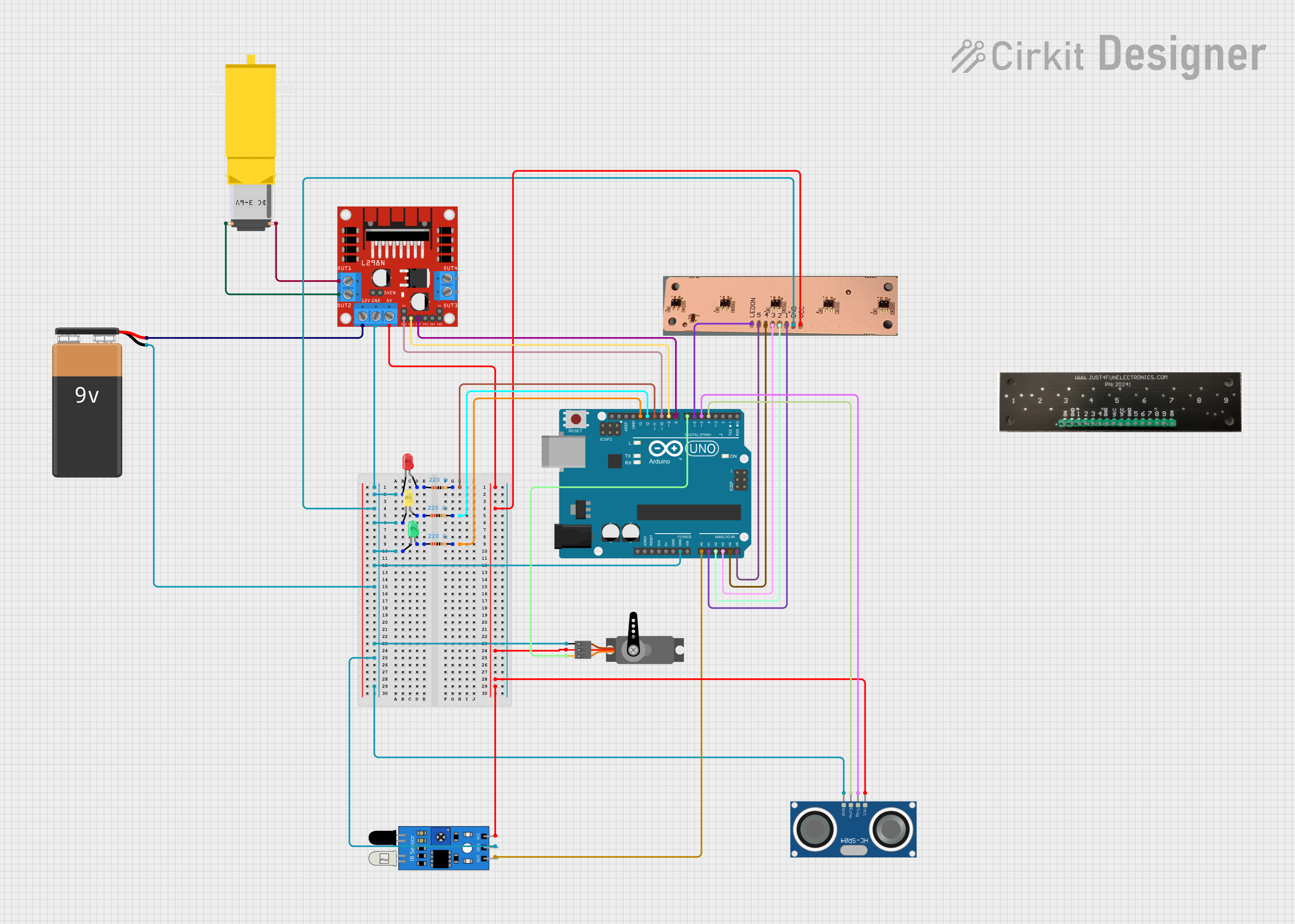

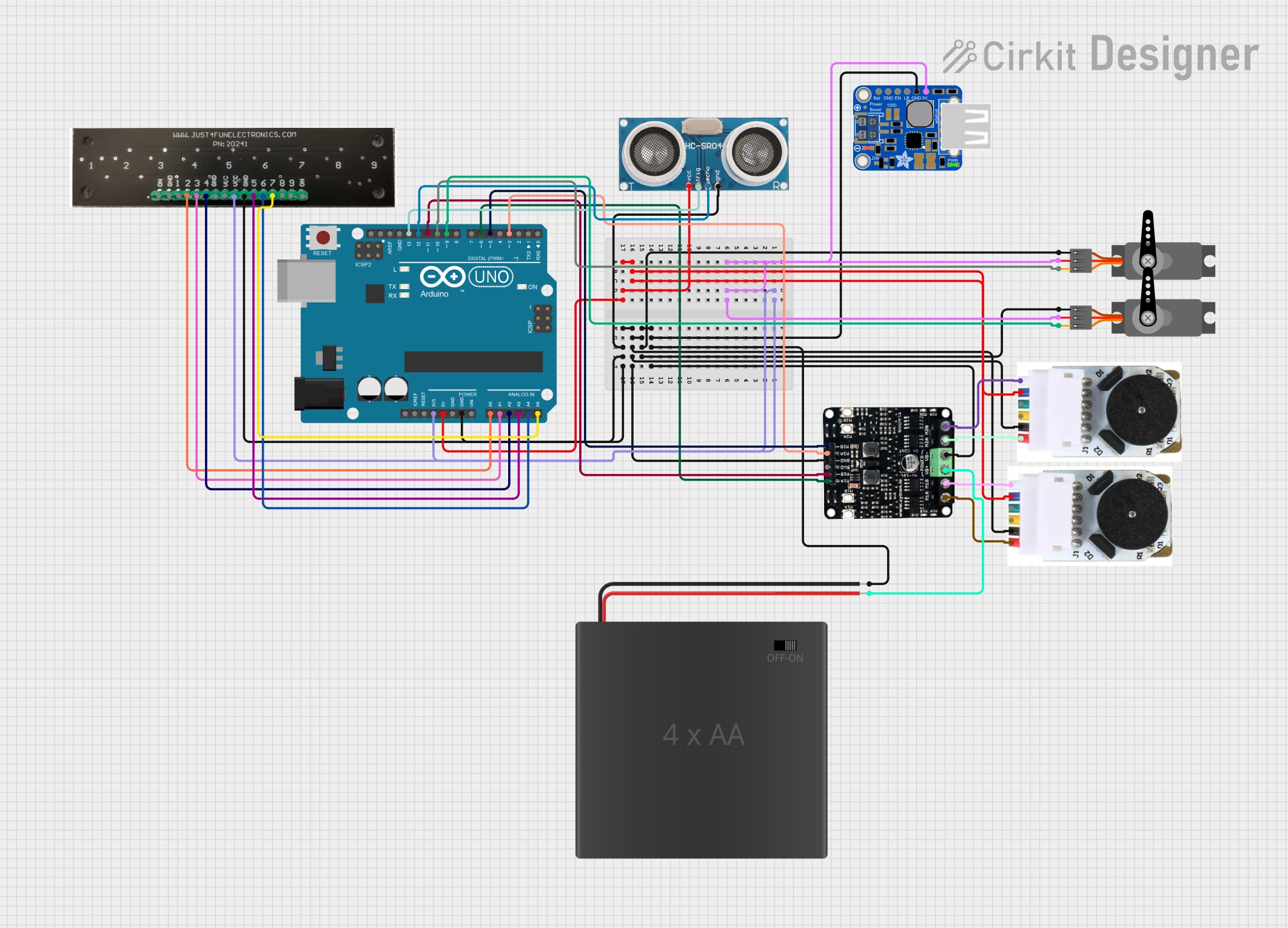

Explore Projects Built with QTRX-MD-16A Reflectance Sensor Array

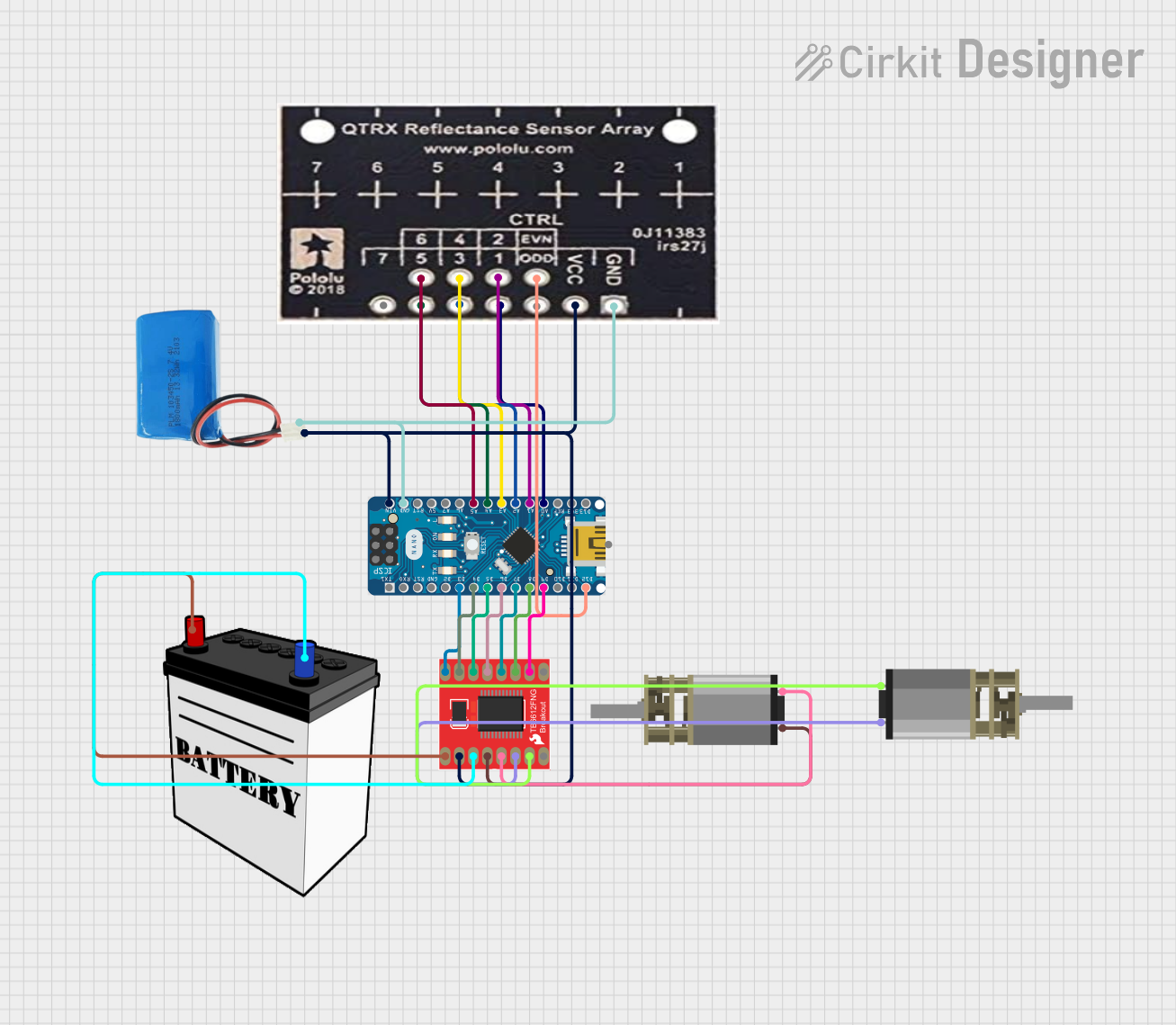

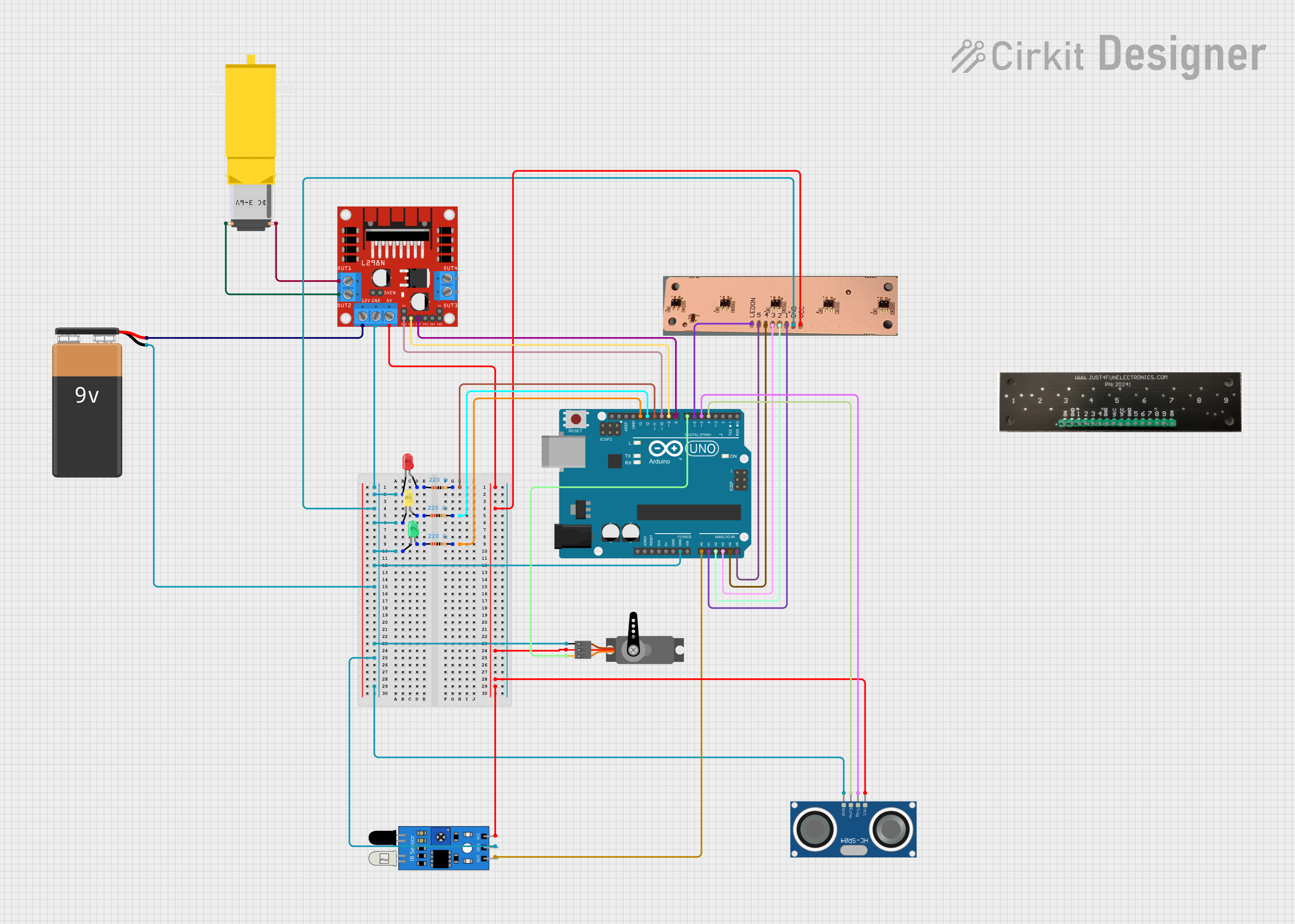

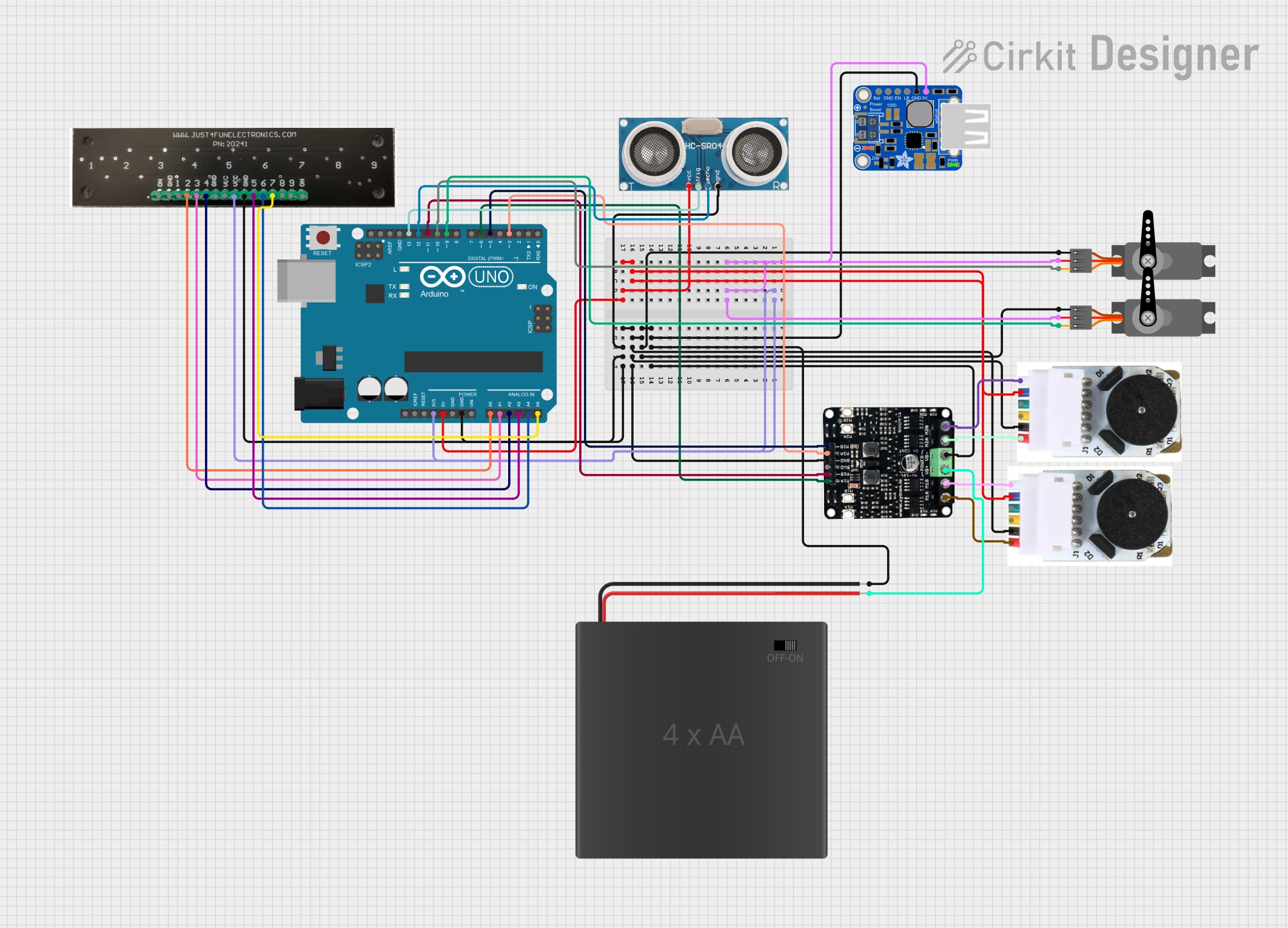

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with QTRX-MD-16A Reflectance Sensor Array

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Line-following robots

- Edge detection in autonomous vehicles

- Obstacle detection and avoidance

- Surface reflectance measurement for industrial automation

- Maze-solving robots

Technical Specifications

The following table outlines the key technical details of the QTRX-MD-16A Reflectance Sensor Array:

| Parameter | Value |

|---|---|

| Manufacturer | Pololu |

| Part Number | QTRX-MD-16A |

| Operating Voltage | 2.9 V to 5.5 V |

| Current Consumption | ~100 mA (typical, all emitters on) |

| Number of Sensors | 16 |

| Sensor Type | Infrared emitter and phototransistor pair |

| Output Type | Analog voltage (0 V to Vcc) |

| Dimensions | 145 mm × 15 mm × 3 mm |

| Weight | 7.5 g |

| Optimal Sensing Distance | 3 mm to 9 mm |

| Operating Temperature | -40°C to 85°C |

Pin Configuration and Descriptions

The QTRX-MD-16A has a 16-pin interface for sensor outputs and additional pins for power and control. The pin configuration is as follows:

| Pin | Name | Description |

|---|---|---|

| 1-16 | OUT1-OUT16 | Analog output for each sensor, corresponding to the reflectance detected. |

| 17 | VCC | Power supply input (2.9 V to 5.5 V). |

| 18 | GND | Ground connection. |

| 19 | LEDON | Control pin for enabling/disabling the IR emitters. High = ON, Low = OFF. |

Usage Instructions

How to Use the QTRX-MD-16A in a Circuit

- Power the Sensor Array: Connect the VCC pin to a regulated power supply (2.9 V to 5.5 V) and the GND pin to the ground of your circuit.

- Connect Outputs: Each sensor output (OUT1 to OUT16) provides an analog voltage proportional to the reflectance detected. Connect these outputs to the analog input pins of a microcontroller or ADC (Analog-to-Digital Converter).

- Enable Emitters: Use the LEDON pin to control the IR emitters. Set the pin HIGH to enable the emitters or LOW to disable them.

- Read Sensor Data: Measure the analog voltage from each output pin. A higher voltage indicates higher reflectance (lighter surfaces), while a lower voltage indicates lower reflectance (darker surfaces).

Important Considerations and Best Practices

- Optimal Sensing Distance: For best results, position the sensor array 3 mm to 9 mm above the surface being measured.

- Emitter Control: To save power, disable the emitters (set LEDON to LOW) when the sensor is not in use.

- Calibration: Calibrate the sensor array for your specific application to account for variations in surface reflectance and ambient lighting.

- Avoid Interference: Ensure that the sensor array is not exposed to direct sunlight or other strong IR sources, as this may affect accuracy.

Example: Using QTRX-MD-16A with Arduino UNO

Below is an example of how to use the QTRX-MD-16A with an Arduino UNO to read reflectance values from the first sensor (OUT1):

// Define the pin connections

#define SENSOR_PIN A0 // Connect OUT1 to Arduino analog pin A0

#define LEDON_PIN 7 // Connect LEDON to Arduino digital pin 7

void setup() {

pinMode(LEDON_PIN, OUTPUT); // Set LEDON pin as output

digitalWrite(LEDON_PIN, HIGH); // Turn on the IR emitters

Serial.begin(9600); // Initialize serial communication

}

void loop() {

int sensorValue = analogRead(SENSOR_PIN); // Read the analog value from OUT1

Serial.print("Sensor Value: ");

Serial.println(sensorValue); // Print the sensor value to the Serial Monitor

delay(100); // Wait for 100 ms before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output from Sensors

- Cause: The IR emitters may be disabled.

- Solution: Ensure the LEDON pin is set HIGH to enable the emitters.

Inconsistent Readings

- Cause: The sensor array may be too far from or too close to the surface.

- Solution: Adjust the distance to fall within the optimal range of 3 mm to 9 mm.

Interference from Ambient Light

- Cause: Strong ambient light or IR sources may interfere with the sensors.

- Solution: Use the sensor in a controlled lighting environment or shield it from external IR sources.

High Power Consumption

- Cause: All emitters are enabled continuously.

- Solution: Disable the emitters (set LEDON to LOW) when the sensor is not actively measuring.

FAQs

Q: Can the QTRX-MD-16A be used with a 3.3 V microcontroller?

A: Yes, the sensor array operates within a voltage range of 2.9 V to 5.5 V, making it compatible with 3.3 V systems.

Q: How do I calibrate the sensor array?

A: Calibration involves reading the sensor outputs for both the darkest and lightest surfaces in your application and mapping the values to a desired range (e.g., 0 to 100).

Q: Can I use fewer than 16 sensors?

A: Yes, you can use only the outputs you need. Unused outputs can be left unconnected.

Q: What is the maximum sampling rate?

A: The sampling rate depends on your microcontroller's ADC speed. Most microcontrollers can sample each sensor at several kHz.