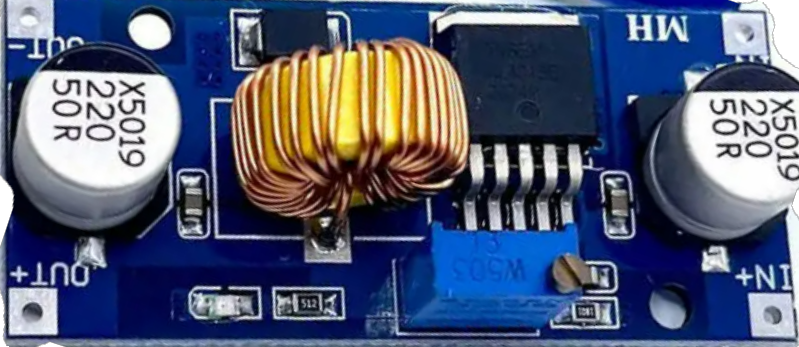

How to Use DC-DC Buck XL4015 5A: Examples, Pinouts, and Specs

Design with DC-DC Buck XL4015 5A in Cirkit Designer

Design with DC-DC Buck XL4015 5A in Cirkit DesignerIntroduction

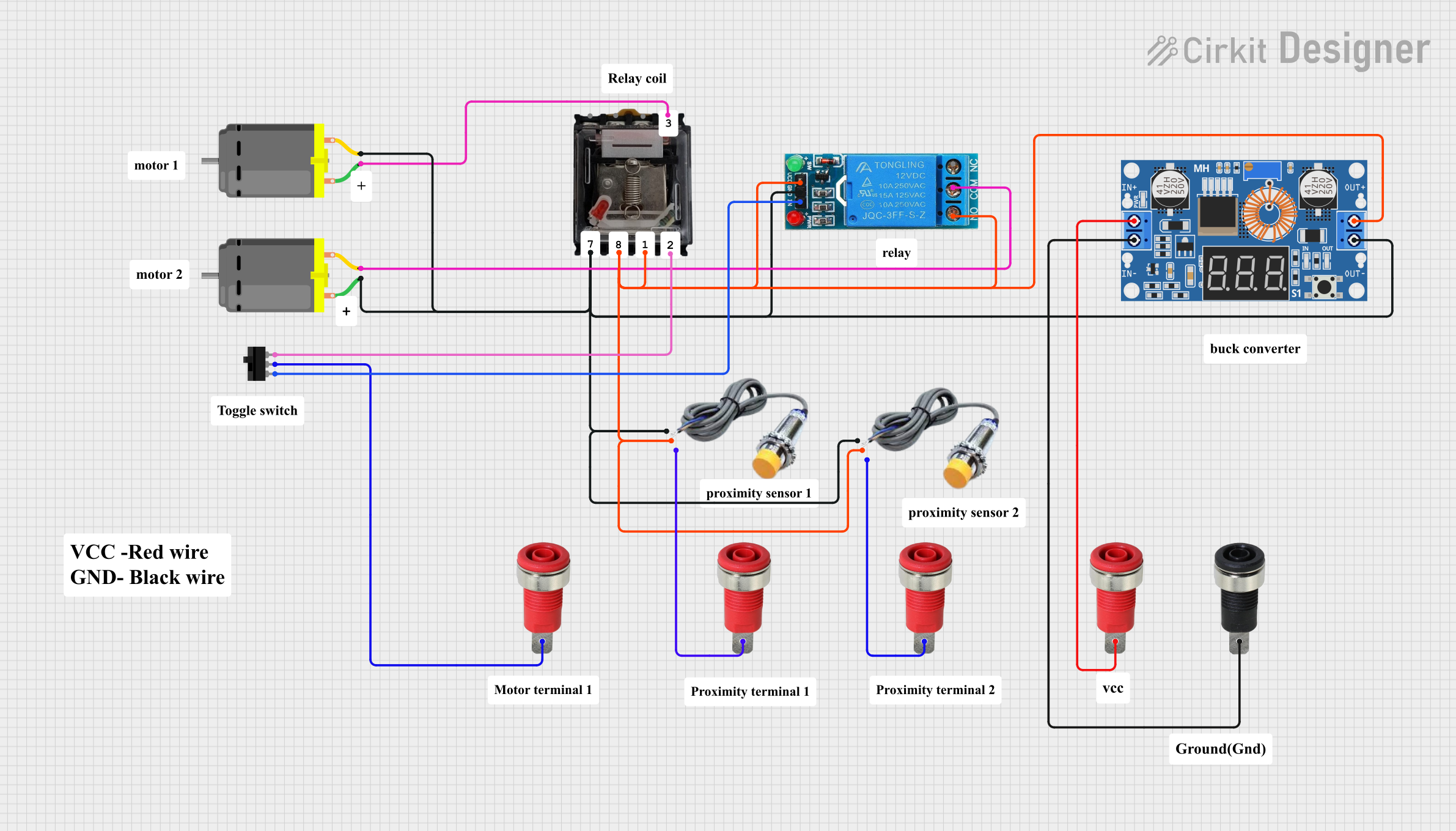

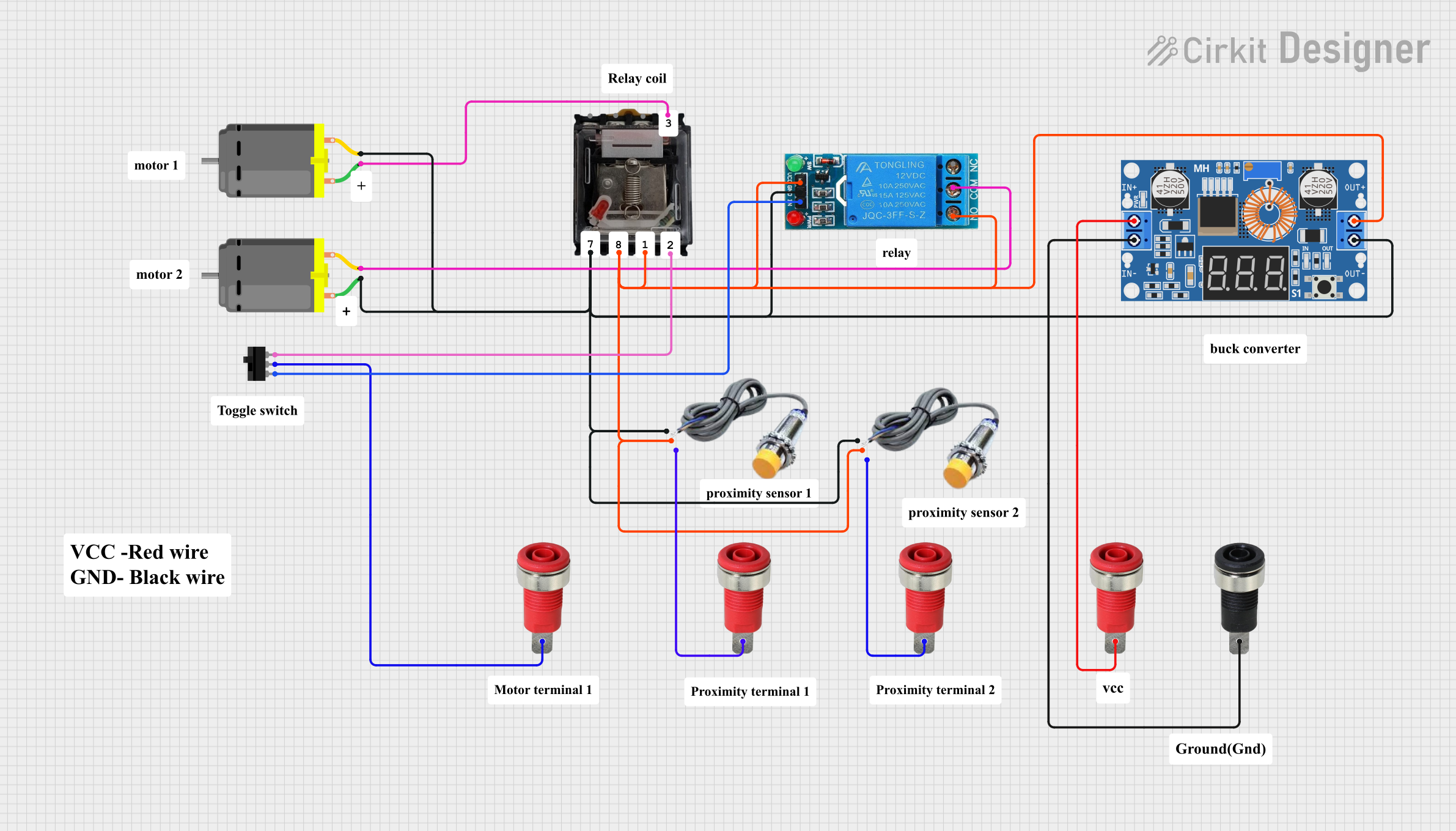

The DC-DC Buck XL4015 5A is a high-performance step-down voltage regulator designed to convert a higher DC input voltage to a lower DC output voltage efficiently. With a maximum output current of 5A, this module is ideal for powering a wide range of electronic devices, including microcontrollers, sensors, and other low-voltage components. Its compact design and adjustable output voltage make it a versatile choice for hobbyists and professionals alike.

Explore Projects Built with DC-DC Buck XL4015 5A

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DC-DC Buck XL4015 5A

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Powering microcontrollers (e.g., Arduino, Raspberry Pi) from higher voltage sources.

- Battery-powered systems requiring regulated voltage.

- LED drivers and lighting systems.

- DIY electronics projects and prototyping.

- Industrial automation and control systems.

Technical Specifications

The following table outlines the key technical details of the DC-DC Buck XL4015 5A:

| Parameter | Value |

|---|---|

| Input Voltage Range | 4V to 38V DC |

| Output Voltage Range | 1.25V to 36V DC (adjustable) |

| Maximum Output Current | 5A (with proper heat dissipation) |

| Output Power | Up to 75W |

| Efficiency | Up to 96% (depending on input/output voltage) |

| Switching Frequency | 180 kHz |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 51mm x 26mm x 14mm |

Pin Configuration and Descriptions

The DC-DC Buck XL4015 5A module has the following pin configuration:

| Pin Name | Description |

|---|---|

| VIN+ | Positive input voltage terminal (connect to the higher DC voltage source). |

| VIN- | Negative input voltage terminal (connect to the ground of the DC voltage source). |

| VOUT+ | Positive output voltage terminal (connect to the load's positive terminal). |

| VOUT- | Negative output voltage terminal (connect to the load's ground terminal). |

Usage Instructions

How to Use the Component in a Circuit

Connect the Input Voltage:

- Connect the positive terminal of your DC power source to the

VIN+pin. - Connect the ground terminal of your DC power source to the

VIN-pin. - Ensure the input voltage is within the range of 4V to 38V DC.

- Connect the positive terminal of your DC power source to the

Adjust the Output Voltage:

- Use the onboard potentiometer to adjust the output voltage.

- Turn the potentiometer clockwise to increase the output voltage and counterclockwise to decrease it.

- Use a multimeter to measure the output voltage across the

VOUT+andVOUT-pins.

Connect the Load:

- Connect the positive terminal of your load to the

VOUT+pin. - Connect the ground terminal of your load to the

VOUT-pin.

- Connect the positive terminal of your load to the

Power On:

- Turn on the input power source and verify the output voltage is as desired before connecting sensitive devices.

Important Considerations and Best Practices

- Heat Dissipation: The module can handle up to 5A of current, but proper heat dissipation (e.g., a heatsink or active cooling) is required for high-current applications.

- Input Voltage: Ensure the input voltage is at least 1.5V higher than the desired output voltage for stable operation.

- Polarity: Double-check the polarity of the input and output connections to avoid damaging the module.

- Load Testing: Gradually increase the load to ensure the module operates within its rated specifications.

Example: Using the XL4015 with an Arduino UNO

The following example demonstrates how to use the DC-DC Buck XL4015 5A to power an Arduino UNO from a 12V DC power source:

- Connect the 12V DC power source to the

VIN+andVIN-pins of the XL4015 module. - Adjust the output voltage to 5V using the potentiometer.

- Connect the

VOUT+pin to the Arduino's 5V input pin. - Connect the

VOUT-pin to the Arduino's GND pin.

Here is a simple Arduino sketch to blink an LED, powered by the XL4015 module:

// Simple LED Blink Example

// Ensure the XL4015 module is set to output 5V before connecting to the Arduino.

const int ledPin = 13; // Pin connected to the onboard LED

void setup() {

pinMode(ledPin, OUTPUT); // Set the LED pin as an output

}

void loop() {

digitalWrite(ledPin, HIGH); // Turn the LED on

delay(1000); // Wait for 1 second

digitalWrite(ledPin, LOW); // Turn the LED off

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Cause: Incorrect input connections or insufficient input voltage.

- Solution: Verify the input voltage is within the specified range and check the polarity of the connections.

Output Voltage Fluctuations:

- Cause: Load exceeds the module's current rating or insufficient input voltage.

- Solution: Reduce the load or increase the input voltage to meet the module's requirements.

Overheating:

- Cause: High current draw without proper heat dissipation.

- Solution: Attach a heatsink or use active cooling to dissipate heat effectively.

Cannot Adjust Output Voltage:

- Cause: Faulty potentiometer or incorrect input voltage.

- Solution: Check the input voltage and ensure it is at least 1.5V higher than the desired output voltage. If the issue persists, inspect the potentiometer for damage.

FAQs

Q1: Can the XL4015 module be used to charge batteries?

A1: Yes, the XL4015 can be used to charge batteries, but you must ensure the output voltage and current are set according to the battery's specifications.

Q2: What is the maximum input voltage for the XL4015?

A2: The maximum input voltage is 38V DC. Exceeding this voltage may damage the module.

Q3: Can I use the XL4015 to power a Raspberry Pi?

A3: Yes, the XL4015 can be used to power a Raspberry Pi. Set the output voltage to 5V and ensure the current rating meets the Raspberry Pi's requirements.

Q4: Is the module protected against reverse polarity?

A4: No, the XL4015 does not have built-in reverse polarity protection. Always double-check your connections before powering the module.