How to Use Motor Driver: Examples, Pinouts, and Specs

Design with Motor Driver in Cirkit Designer

Design with Motor Driver in Cirkit DesignerIntroduction

A motor driver is an electronic circuit that controls the operation of a motor by providing the necessary voltage and current, allowing for direction and speed control. The DfRobot motor driver is a versatile and reliable component designed to interface with various types of DC motors, stepper motors, and servo motors. It is widely used in robotics, automation systems, and other motor-driven applications.

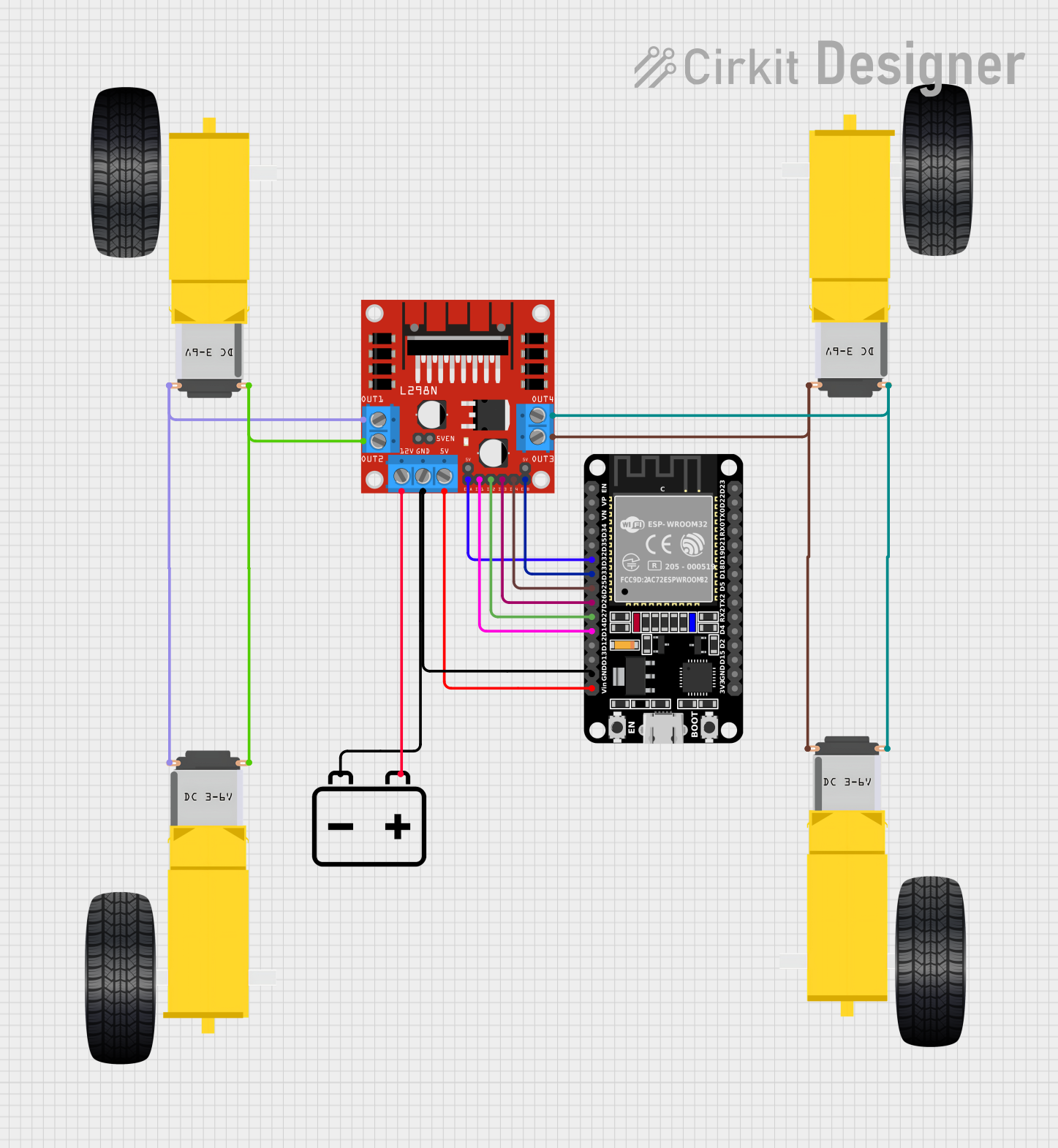

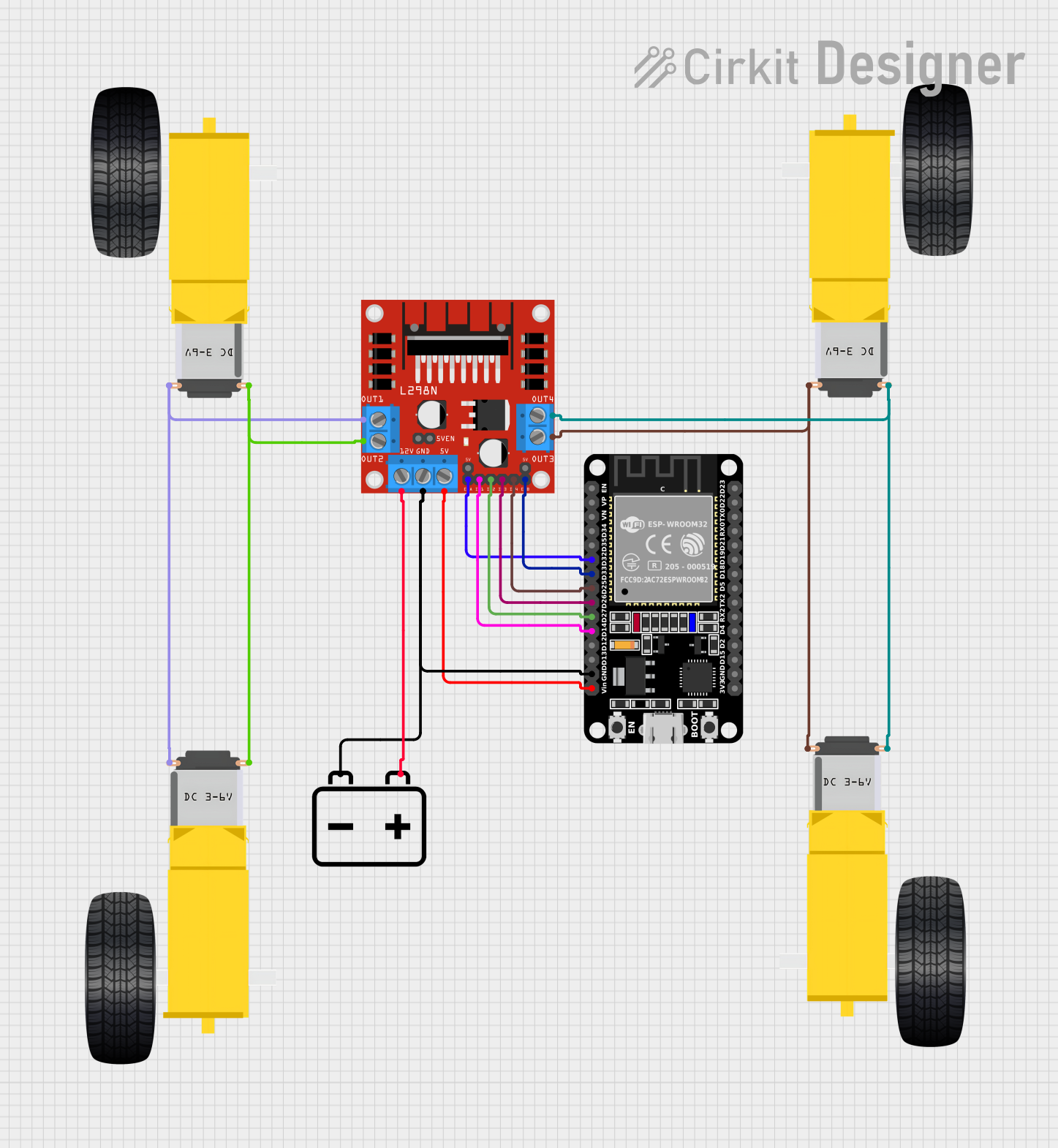

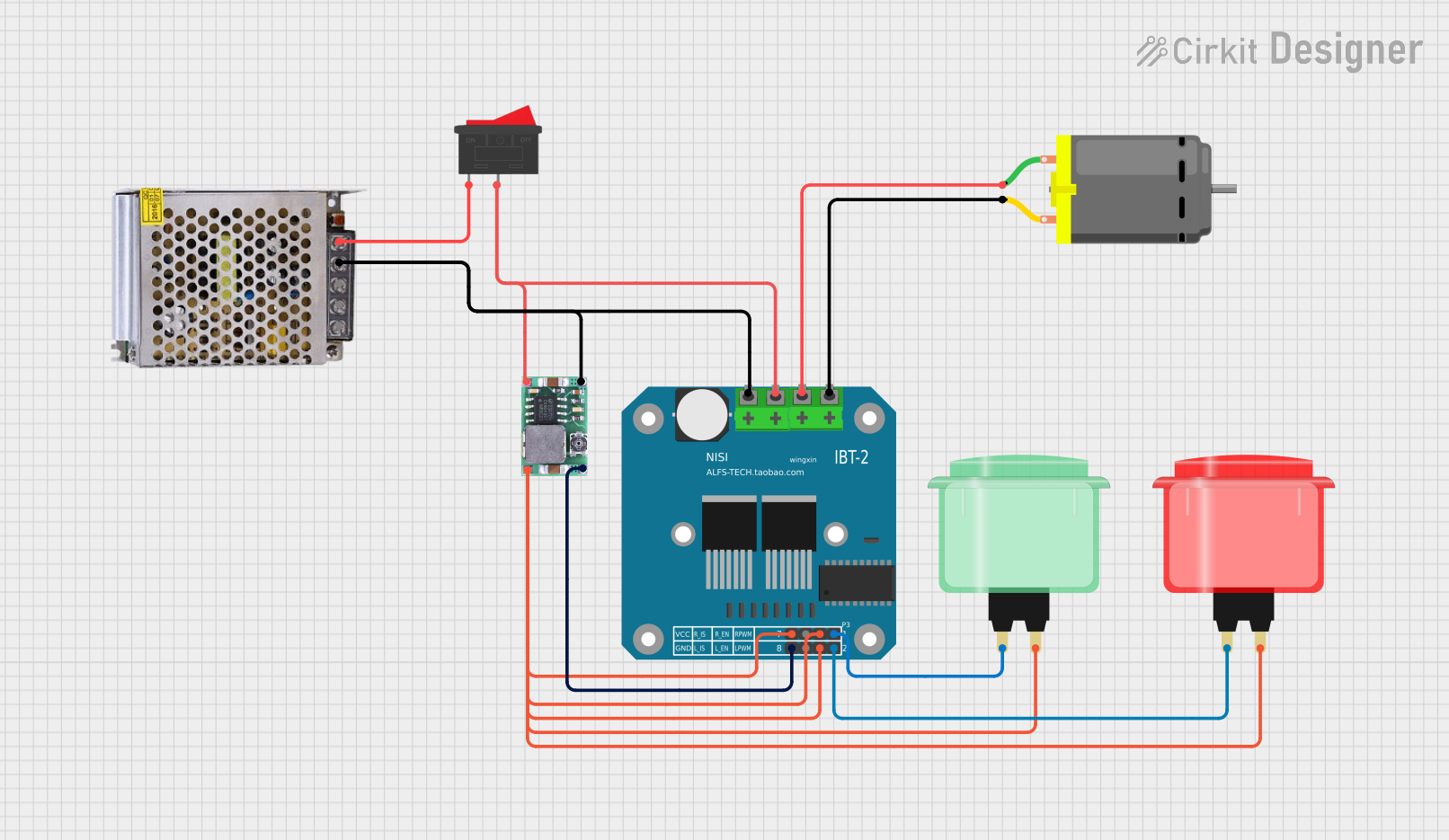

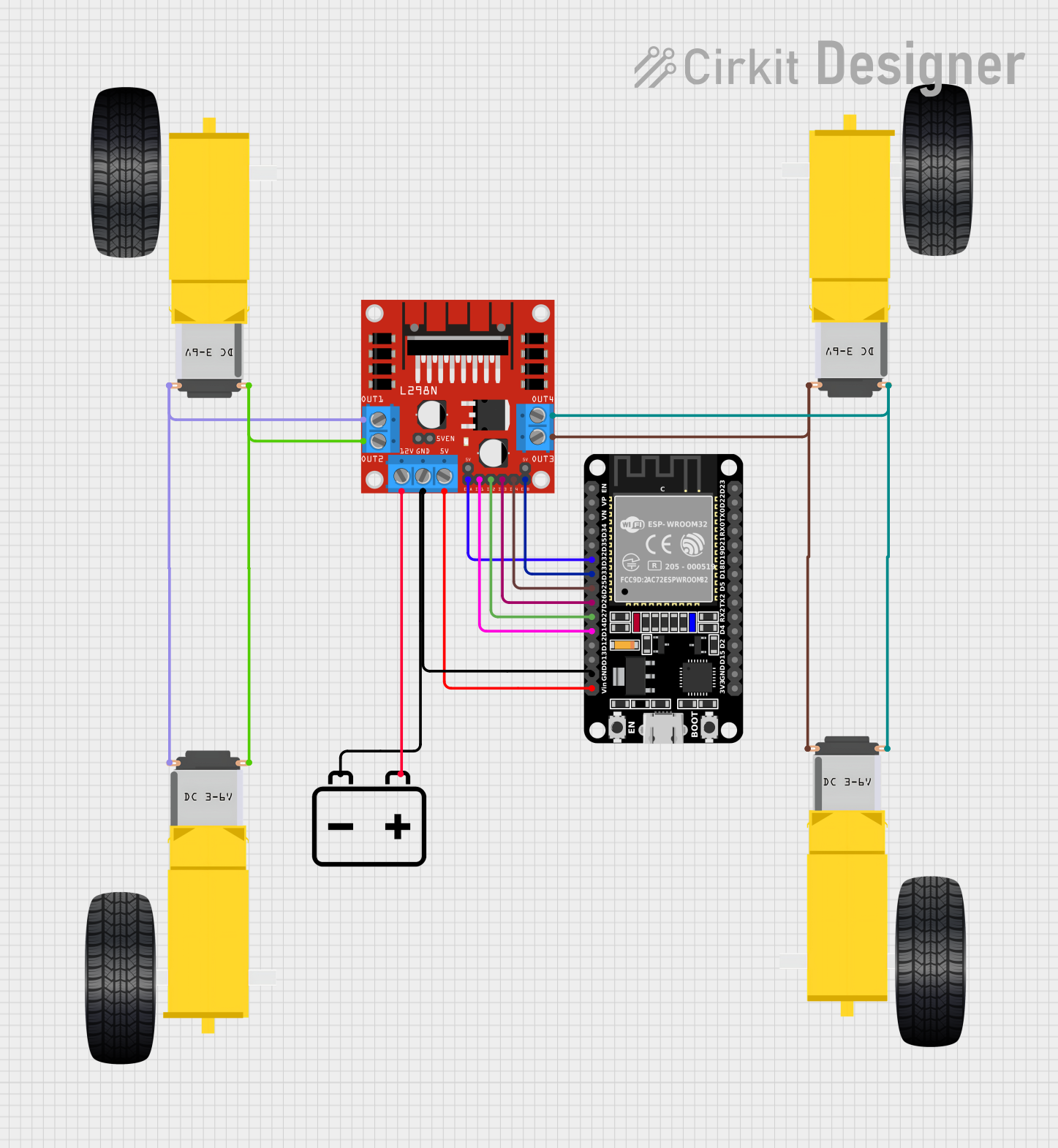

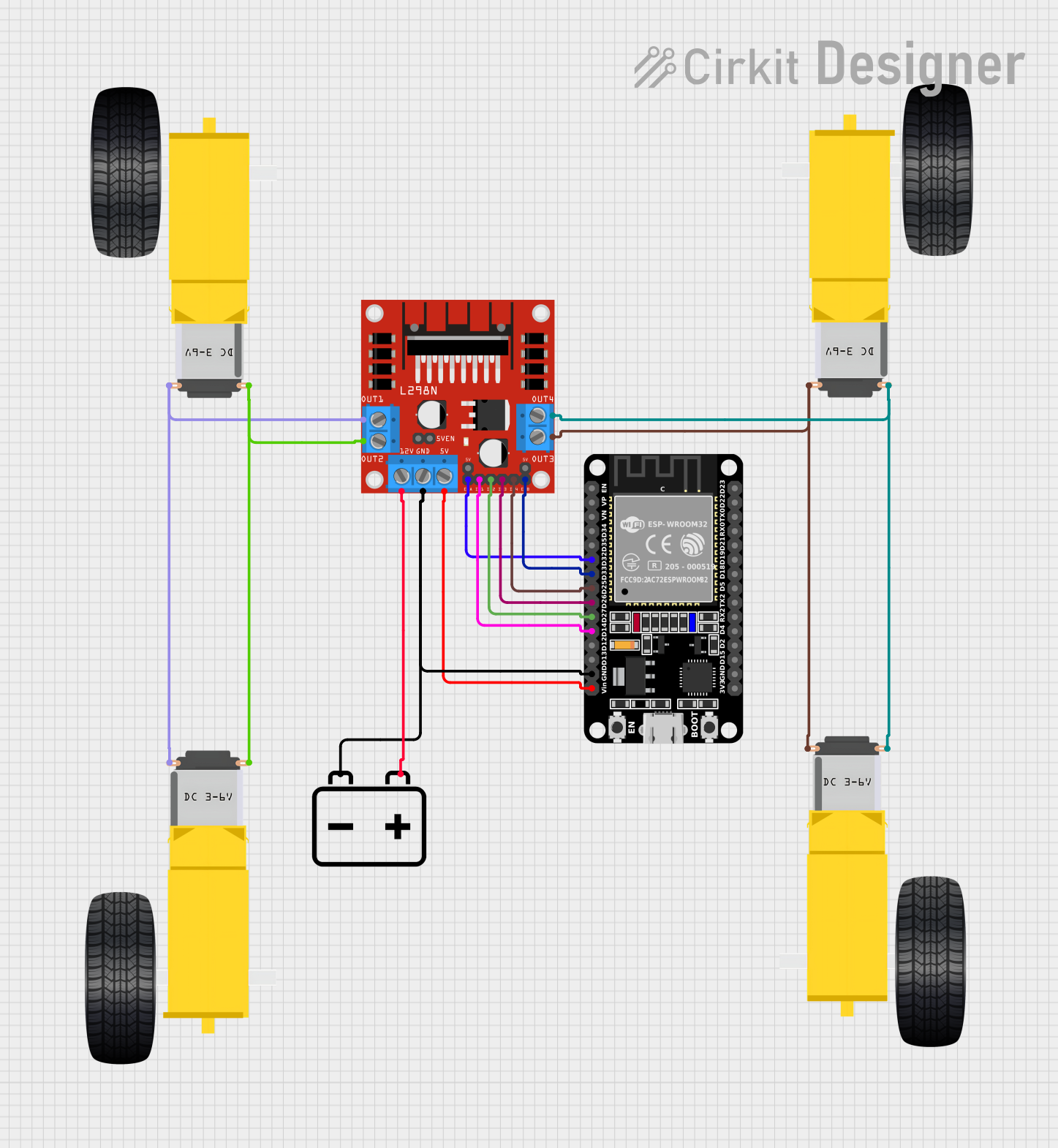

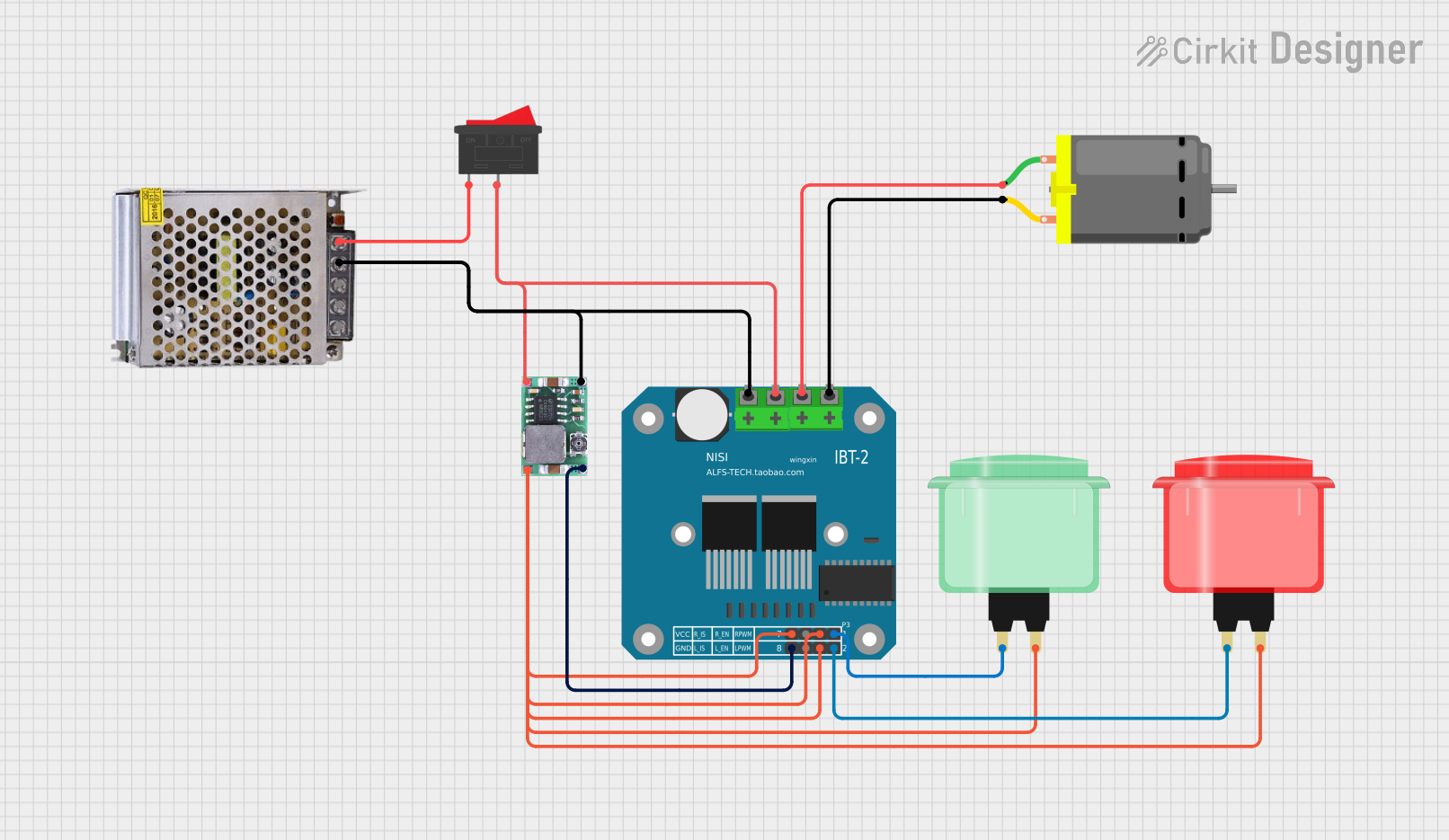

Explore Projects Built with Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Controlling the movement of robot wheels or arms.

- Automation: Driving conveyor belts or automated systems.

- DIY Projects: Building motorized toys or gadgets.

- Industrial Systems: Operating motors in manufacturing or assembly lines.

Technical Specifications

The DfRobot motor driver is designed to handle a wide range of motors and offers robust performance. Below are the key technical details:

General Specifications

- Operating Voltage: 6V to 12V

- Maximum Output Current: 2A per channel

- Number of Channels: 2 (can control two motors simultaneously)

- Control Logic Voltage: 3.3V to 5V (compatible with most microcontrollers)

- PWM Frequency: Up to 20 kHz

- Motor Types Supported: DC motors, stepper motors, and servo motors

- Built-in Protection: Overcurrent and thermal shutdown

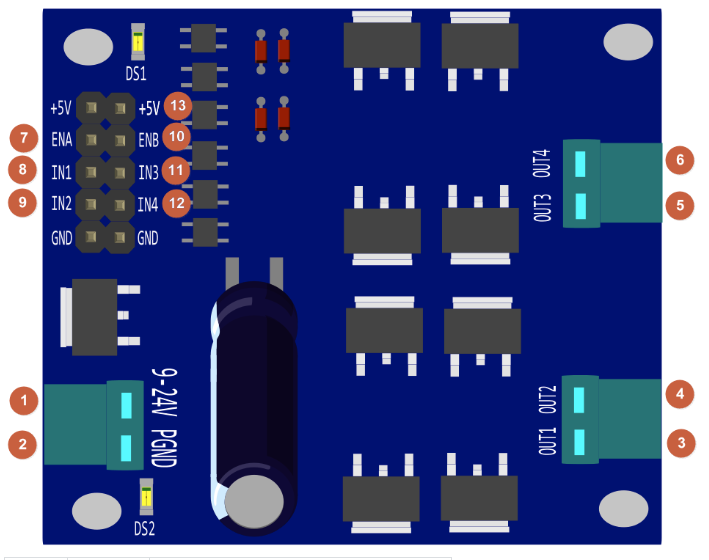

Pin Configuration and Descriptions

The DfRobot motor driver typically comes with a set of pins for control and power connections. Below is the pin configuration:

| Pin Name | Description |

|---|---|

| VCC | Power supply for the motor driver (6V to 12V). |

| GND | Ground connection. |

| IN1 | Input signal for controlling Motor 1 direction (logic HIGH or LOW). |

| IN2 | Input signal for controlling Motor 1 direction (logic HIGH or LOW). |

| IN3 | Input signal for controlling Motor 2 direction (logic HIGH or LOW). |

| IN4 | Input signal for controlling Motor 2 direction (logic HIGH or LOW). |

| ENA | PWM input for speed control of Motor 1. |

| ENB | PWM input for speed control of Motor 2. |

| OUT1 | Output terminal for Motor 1 connection. |

| OUT2 | Output terminal for Motor 1 connection. |

| OUT3 | Output terminal for Motor 2 connection. |

| OUT4 | Output terminal for Motor 2 connection. |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the VCC pin to a power source (6V to 12V) and the GND pin to the ground.

- Motor Connections: Connect the motor terminals to the OUT1/OUT2 pins (for Motor 1) or OUT3/OUT4 pins (for Motor 2).

- Control Signals: Use IN1 and IN2 to control the direction of Motor 1, and IN3 and IN4 for Motor 2. Apply a HIGH or LOW signal to these pins based on the desired direction.

- Speed Control: Connect the ENA and ENB pins to PWM outputs of a microcontroller to control the speed of Motor 1 and Motor 2, respectively.

Important Considerations and Best Practices

- Ensure the power supply voltage matches the motor's operating voltage to avoid damage.

- Use appropriate heat sinks or cooling mechanisms if the motor driver operates at high currents for extended periods.

- Avoid reversing the polarity of the power supply or motor connections.

- Use decoupling capacitors near the power supply pins to reduce noise and improve stability.

Example: Connecting to an Arduino UNO

Below is an example of how to control two DC motors using the DfRobot motor driver and an Arduino UNO:

// Define motor control pins

const int IN1 = 7; // Motor 1 direction control pin

const int IN2 = 6; // Motor 1 direction control pin

const int ENA = 5; // Motor 1 speed control (PWM) pin

const int IN3 = 4; // Motor 2 direction control pin

const int IN4 = 3; // Motor 2 direction control pin

const int ENB = 2; // Motor 2 speed control (PWM) pin

void setup() {

// Set motor control pins as outputs

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENA, OUTPUT);

pinMode(IN3, OUTPUT);

pinMode(IN4, OUTPUT);

pinMode(ENB, OUTPUT);

}

void loop() {

// Motor 1: Forward at 50% speed

digitalWrite(IN1, HIGH); // Set direction

digitalWrite(IN2, LOW);

analogWrite(ENA, 128); // Set speed (0-255)

// Motor 2: Backward at 75% speed

digitalWrite(IN3, LOW); // Set direction

digitalWrite(IN4, HIGH);

analogWrite(ENB, 192); // Set speed (0-255)

delay(2000); // Run motors for 2 seconds

// Stop both motors

analogWrite(ENA, 0);

analogWrite(ENB, 0);

delay(2000); // Wait for 2 seconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motors Not Running:

- Cause: Incorrect wiring or loose connections.

- Solution: Double-check all connections, especially the motor and power supply pins.

Motor Driver Overheating:

- Cause: Excessive current draw or insufficient cooling.

- Solution: Ensure the motor's current rating is within the driver's limits. Add a heat sink or cooling fan if necessary.

Erratic Motor Behavior:

- Cause: Noise or interference in the control signals.

- Solution: Use decoupling capacitors near the power supply and keep control signal wires short.

PWM Speed Control Not Working:

- Cause: Incorrect PWM signal or incompatible microcontroller.

- Solution: Verify the PWM frequency and duty cycle. Ensure the microcontroller's logic voltage matches the motor driver's requirements.

FAQs

Q: Can I use this motor driver with a 24V motor?

A: No, the maximum operating voltage is 12V. Using a higher voltage may damage the driver.Q: How many motors can this driver control?

A: The DfRobot motor driver can control up to two DC motors or one stepper motor.Q: Is it compatible with Raspberry Pi?

A: Yes, as long as the control logic voltage (3.3V) is within the driver's supported range.Q: Can I use this driver for brushless motors?

A: No, this driver is designed for brushed DC motors, stepper motors, and servo motors. Brushless motors require a specialized driver.