How to Use motor ch n20-3: Examples, Pinouts, and Specs

Design with motor ch n20-3 in Cirkit Designer

Design with motor ch n20-3 in Cirkit DesignerIntroduction

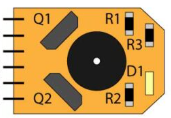

The Motor CH N20-3, manufactured by Motor (Part ID: TCC1), is a compact DC motor designed for high efficiency and low power consumption. Its small size and reliable performance make it an ideal choice for applications requiring precise motion control in limited spaces. This motor is widely used in small robotics, automation projects, and other applications where compact and efficient actuation is required.

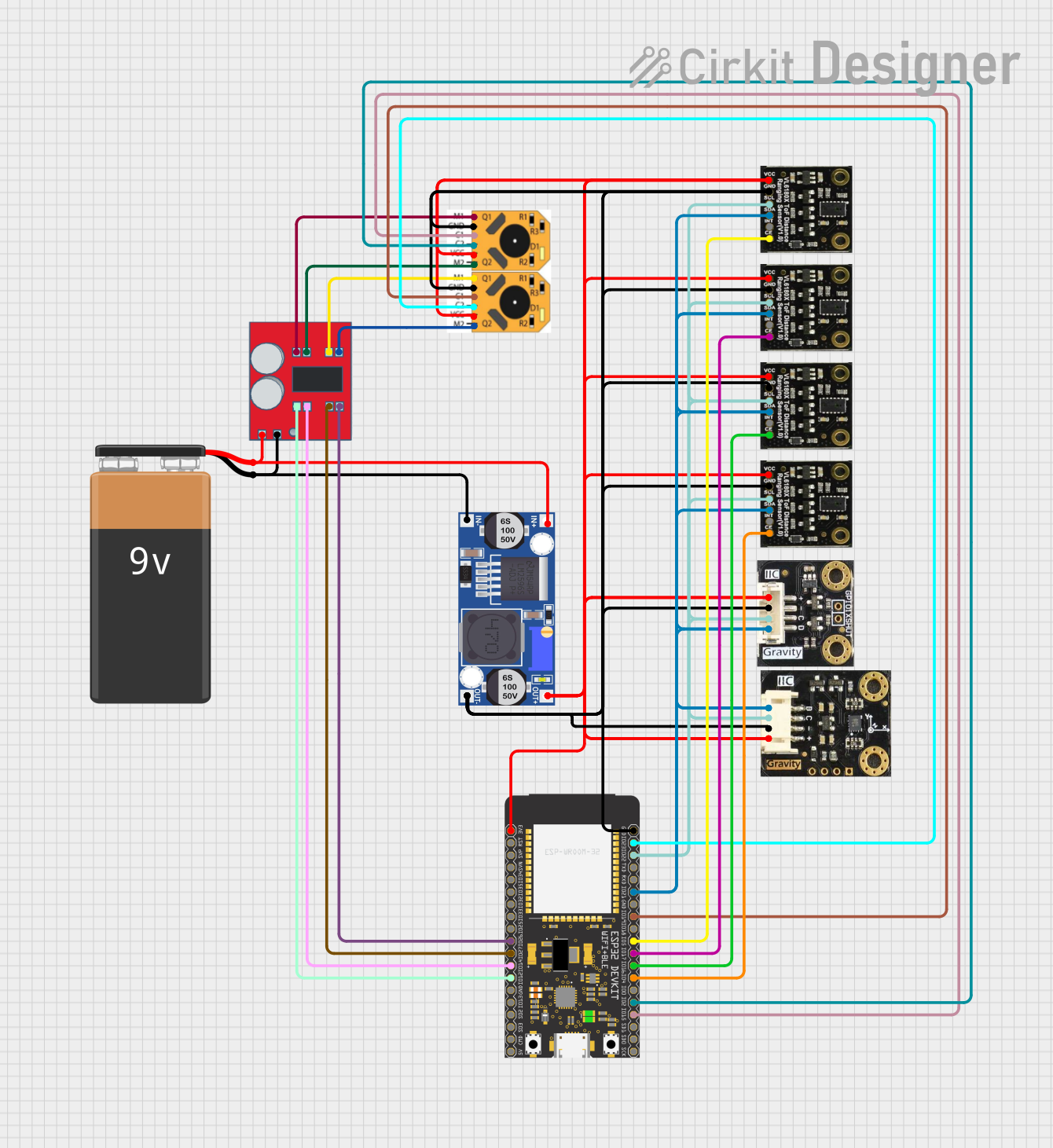

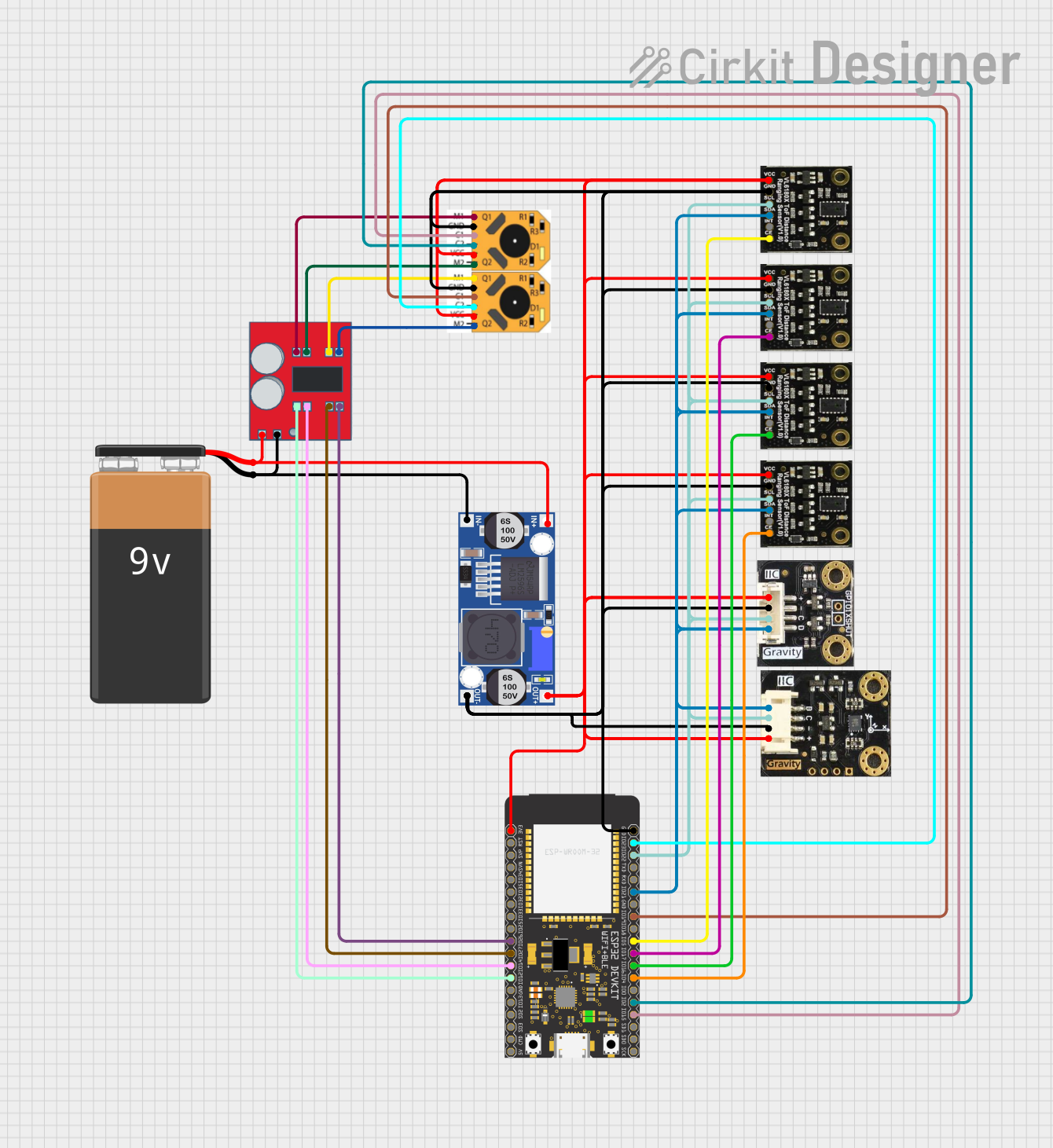

Explore Projects Built with motor ch n20-3

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with motor ch n20-3

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Small robotics (e.g., robotic arms, mobile robots)

- Automation systems

- DIY electronics projects

- Model vehicles and toys

- Precision mechanisms (e.g., camera gimbals, actuators)

Technical Specifications

The following table outlines the key technical specifications of the Motor CH N20-3:

| Parameter | Value |

|---|---|

| Manufacturer | Motor |

| Part ID | TCC1 |

| Operating Voltage | 3V to 12V |

| Rated Voltage | 6V |

| No-Load Current | 40 mA |

| Stall Current | 360 mA |

| No-Load Speed | 300 RPM (at 6V) |

| Stall Torque | 0.1 kg·cm (at 6V) |

| Gear Ratio | 1:30 |

| Motor Dimensions | 12 mm x 10 mm x 15 mm |

| Shaft Diameter | 3 mm |

| Shaft Length | 10 mm |

| Weight | 10 g |

Pin Configuration and Descriptions

The Motor CH N20-3 has two terminals for electrical connections:

| Pin/Terminal | Description |

|---|---|

| Terminal 1 | Positive terminal for power input |

| Terminal 2 | Negative terminal for power input |

Note: The motor's direction of rotation can be reversed by swapping the polarity of the terminals.

Usage Instructions

How to Use the Motor in a Circuit

- Power Supply: Connect the motor to a DC power supply within the operating voltage range (3V to 12V). A 6V supply is recommended for optimal performance.

- Polarity: Ensure the correct polarity of the terminals to achieve the desired direction of rotation. Reversing the polarity will reverse the motor's rotation.

- Motor Driver: For precise control, use a motor driver (e.g., L298N or L293D) to interface the motor with a microcontroller like an Arduino UNO.

- PWM Control: Use Pulse Width Modulation (PWM) to control the motor's speed. This can be achieved using a microcontroller's PWM output pin.

Important Considerations and Best Practices

- Current Limiting: Ensure the power supply or motor driver can handle the stall current (360 mA) to prevent damage.

- Heat Dissipation: Avoid prolonged operation at stall conditions to prevent overheating.

- Mounting: Secure the motor using appropriate brackets or mounts to minimize vibration and ensure stable operation.

- Noise Suppression: Add a capacitor (e.g., 0.1 µF) across the terminals to reduce electrical noise.

Example: Connecting to an Arduino UNO

Below is an example of how to control the Motor CH N20-3 using an Arduino UNO and an L298N motor driver:

// Arduino code to control Motor CH N20-3 using PWM

// Connect the motor to the L298N motor driver

// IN1 and IN2 control the motor direction

// ENA controls the motor speed via PWM

#define IN1 7 // Motor driver IN1 pin connected to Arduino pin 7

#define IN2 8 // Motor driver IN2 pin connected to Arduino pin 8

#define ENA 9 // Motor driver ENA pin connected to Arduino PWM pin 9

void setup() {

pinMode(IN1, OUTPUT); // Set IN1 as output

pinMode(IN2, OUTPUT); // Set IN2 as output

pinMode(ENA, OUTPUT); // Set ENA as output

}

void loop() {

// Rotate motor in one direction

digitalWrite(IN1, HIGH); // Set IN1 high

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 128); // Set speed to 50% (PWM value: 128 out of 255)

delay(2000); // Run for 2 seconds

// Stop the motor

analogWrite(ENA, 0); // Set speed to 0

delay(1000); // Wait for 1 second

// Rotate motor in the opposite direction

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, HIGH); // Set IN2 high

analogWrite(ENA, 200); // Set speed to ~78% (PWM value: 200 out of 255)

delay(2000); // Run for 2 seconds

// Stop the motor

analogWrite(ENA, 0); // Set speed to 0

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power supply voltage and current. Check the wiring for proper connections.

Motor Spins in the Wrong Direction

- Cause: Polarity of the terminals is reversed.

- Solution: Swap the connections to the motor terminals.

Motor Overheats

- Cause: Prolonged operation at stall conditions or excessive load.

- Solution: Reduce the load on the motor and avoid stalling. Use a heat sink if necessary.

Excessive Noise or Vibration

- Cause: Loose mounting or electrical noise.

- Solution: Secure the motor properly and add a capacitor across the terminals to suppress noise.

FAQs

Can the Motor CH N20-3 be used with a battery? Yes, the motor can be powered by batteries within the operating voltage range (e.g., 4x AA batteries for 6V).

What is the maximum load the motor can handle? The motor can handle a maximum torque of 0.1 kg·cm at stall conditions. Avoid exceeding this limit to prevent damage.

Can I control the motor speed without a motor driver? While possible using a variable resistor or direct PWM from a microcontroller, a motor driver is recommended for better control and protection.

Is the motor waterproof? No, the Motor CH N20-3 is not waterproof. Avoid exposing it to water or moisture.