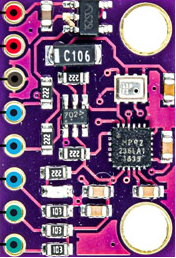

How to Use MPU9250/GY -91: Examples, Pinouts, and Specs

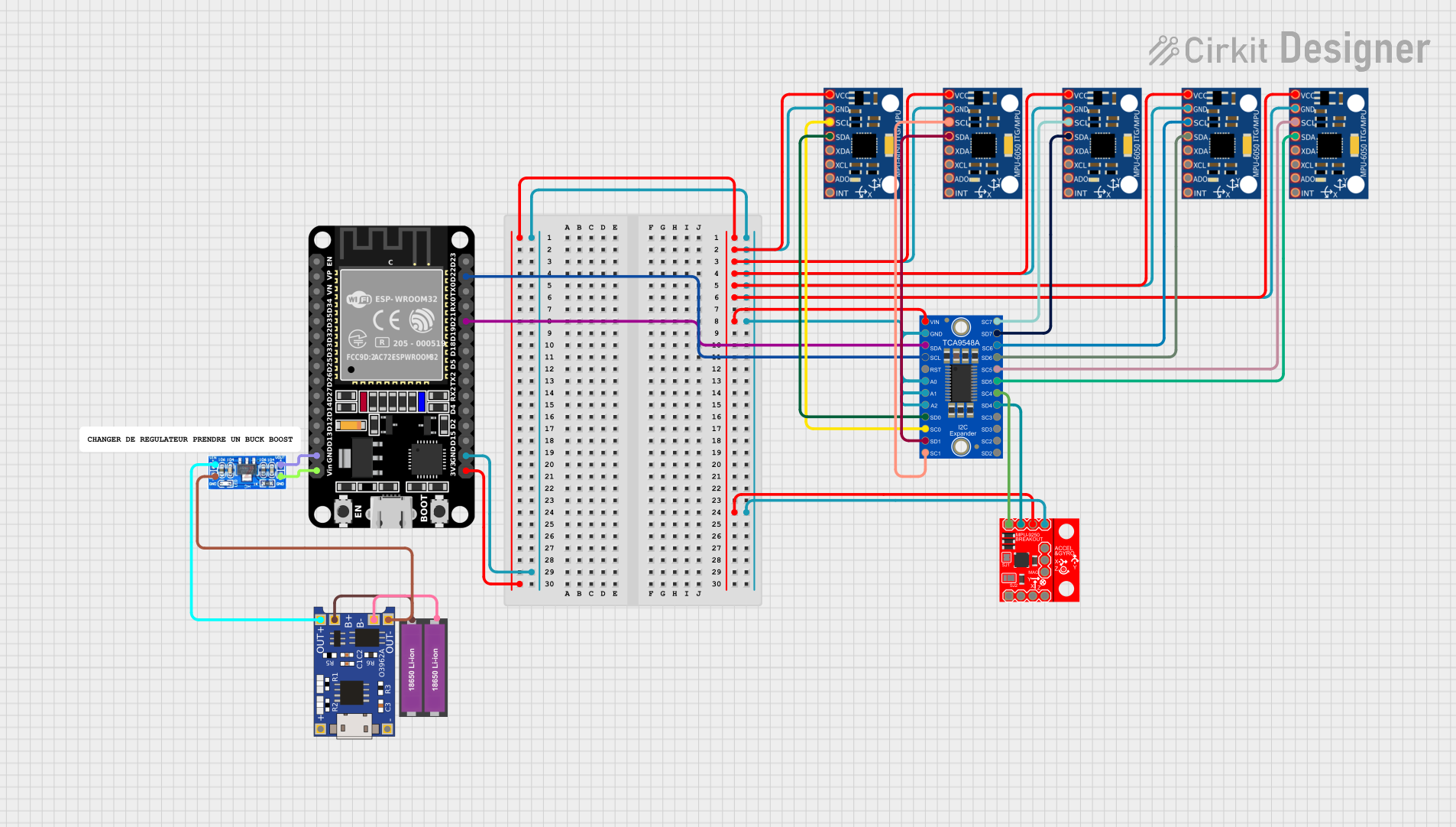

Design with MPU9250/GY -91 in Cirkit Designer

Design with MPU9250/GY -91 in Cirkit DesignerIntroduction

The MPU9250/GY-91 is a multi-faceted motion tracking device that integrates a 3-axis gyroscope, a 3-axis accelerometer, and a 3-axis compass. This 9-axis sensor is widely used in the field of robotics, wearable devices, and motion-based game controllers, providing precise data for orientation and motion sensing.

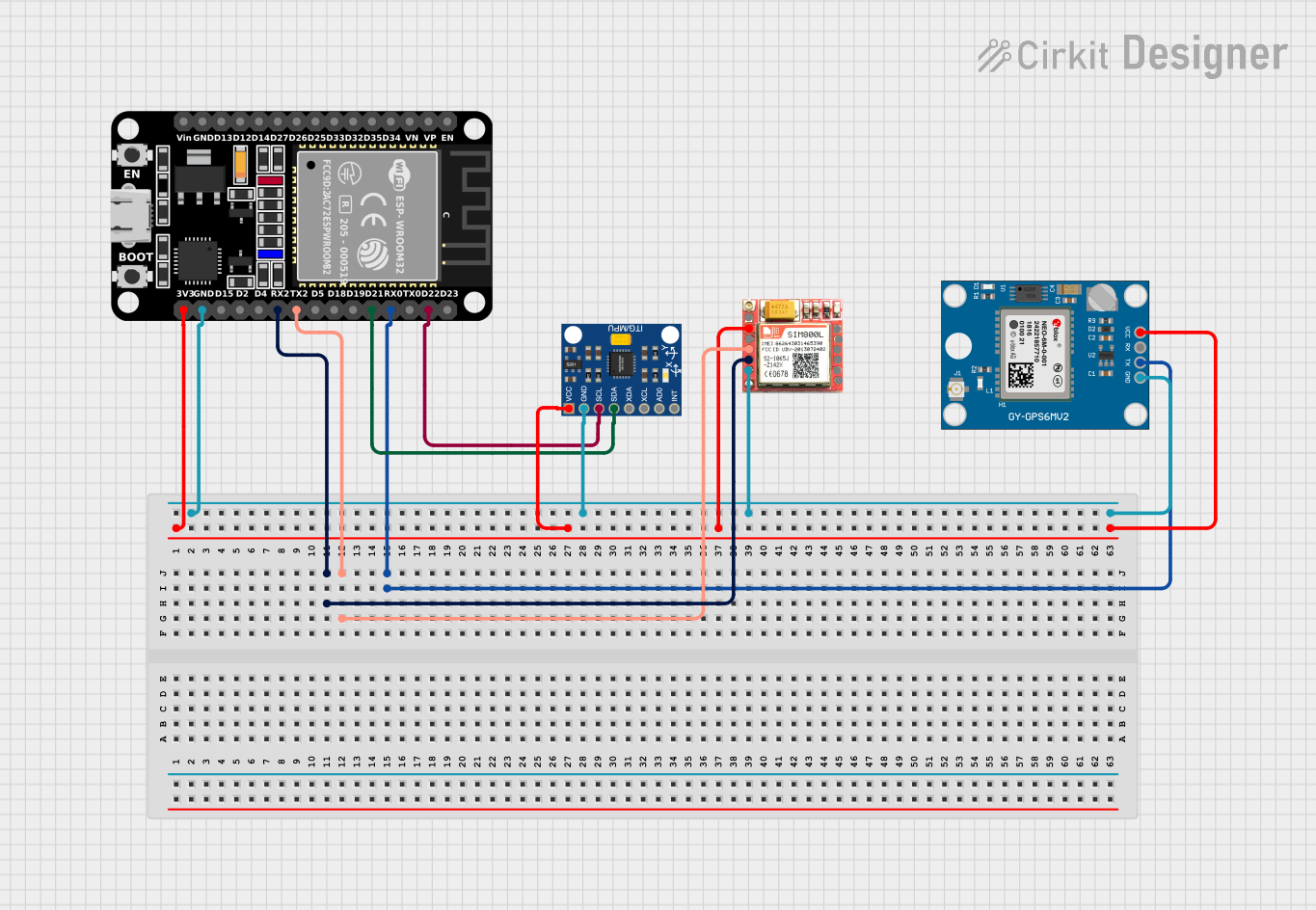

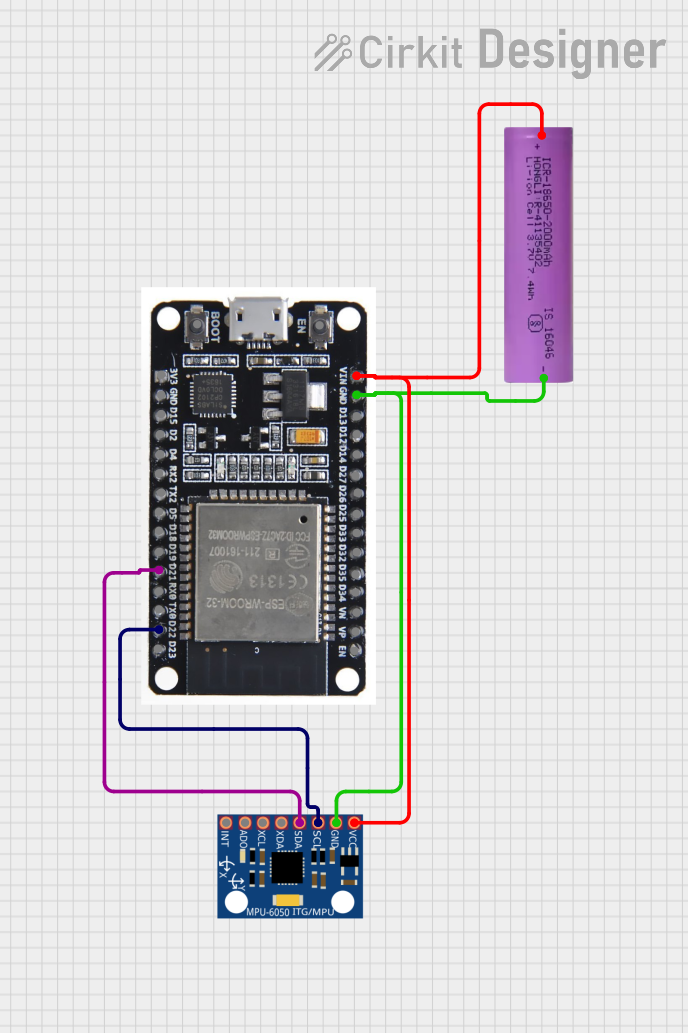

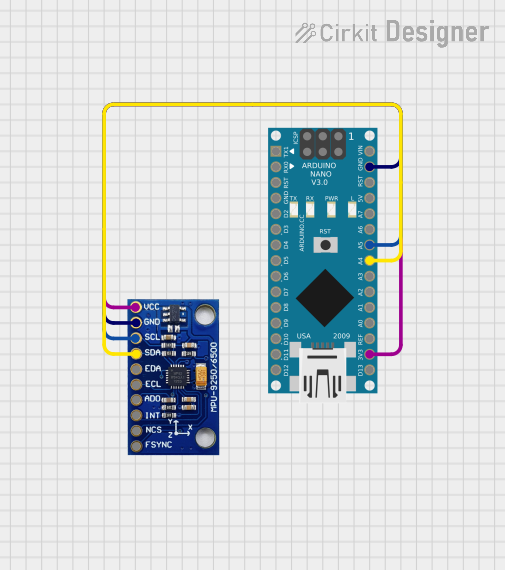

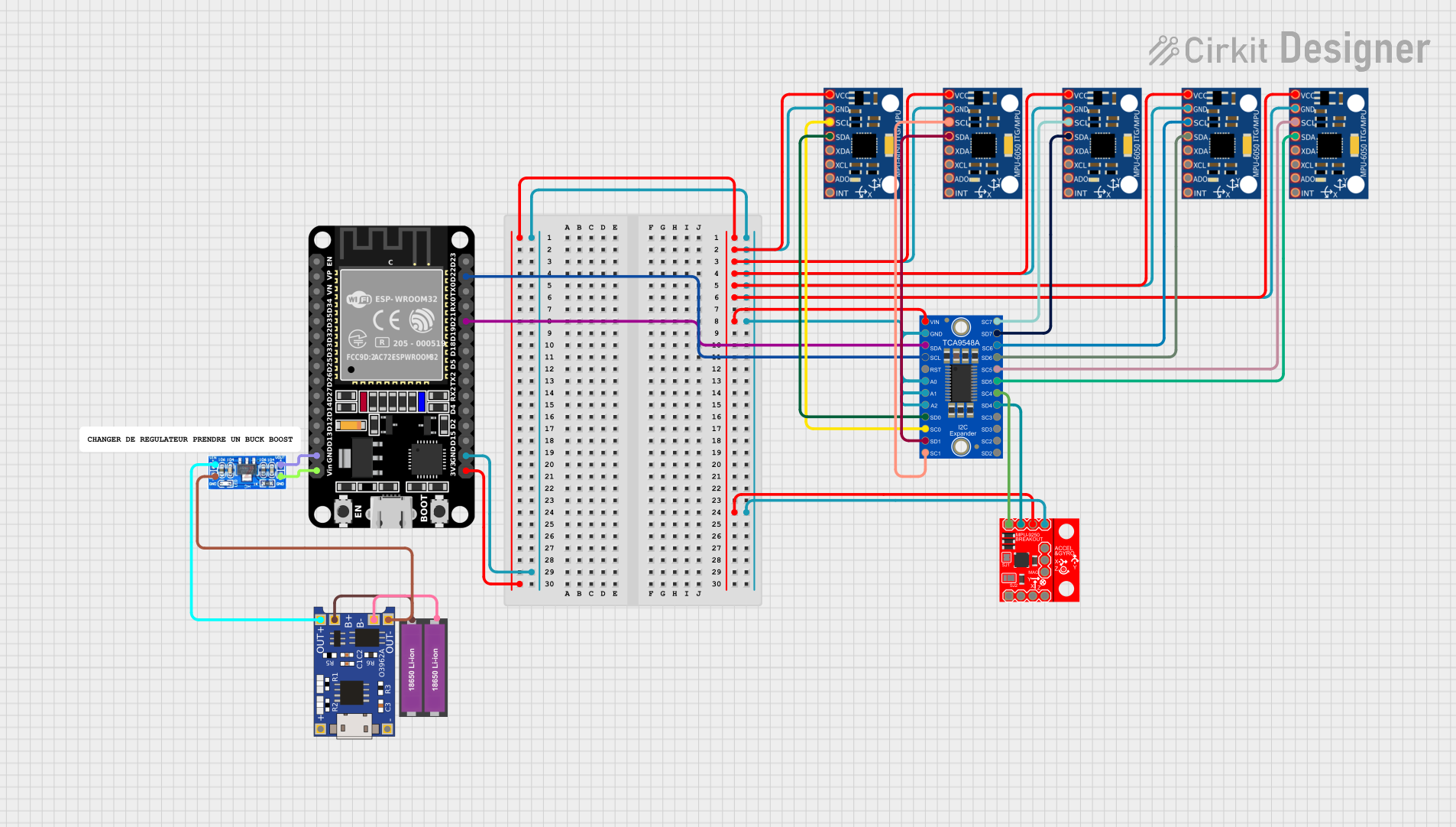

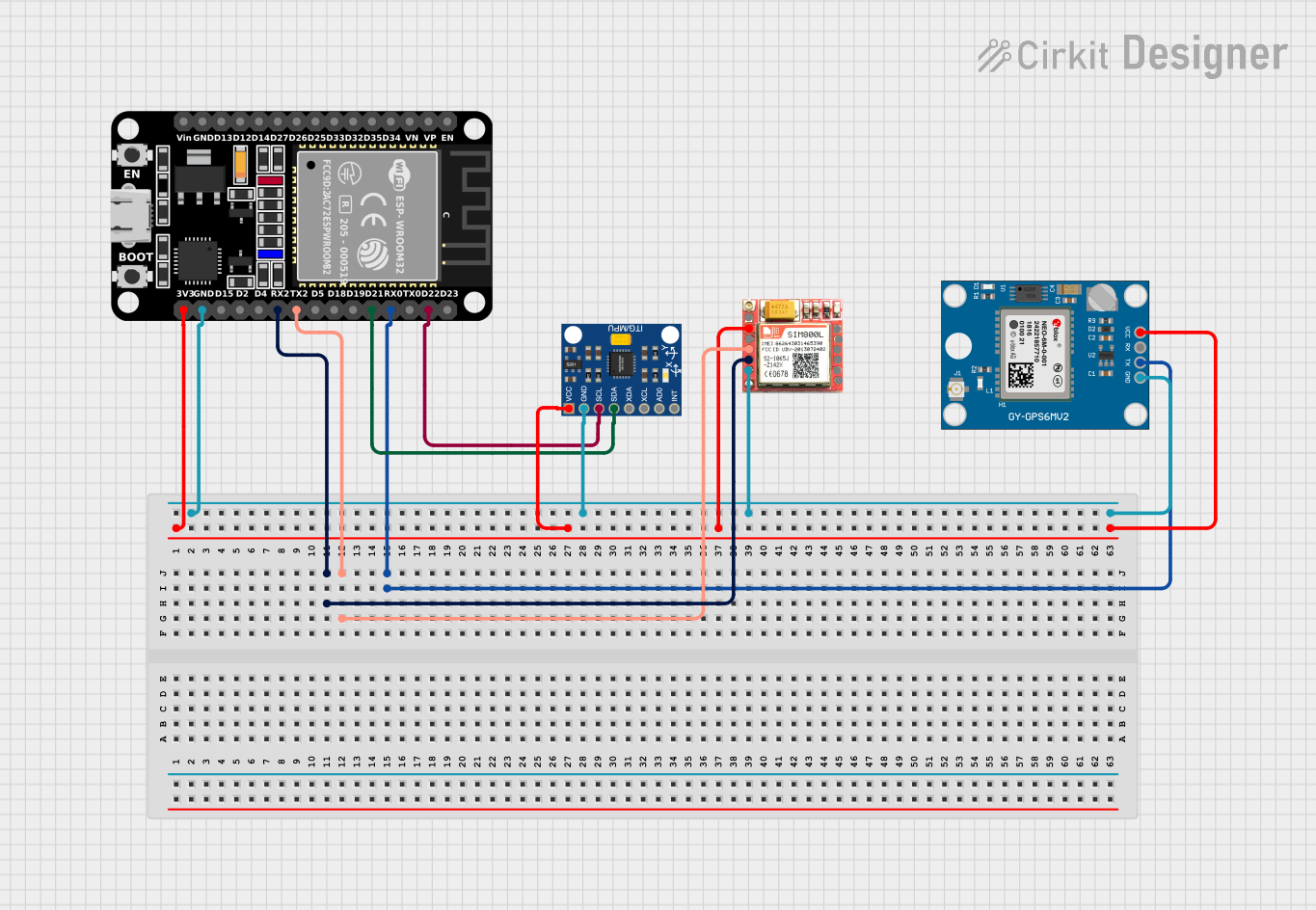

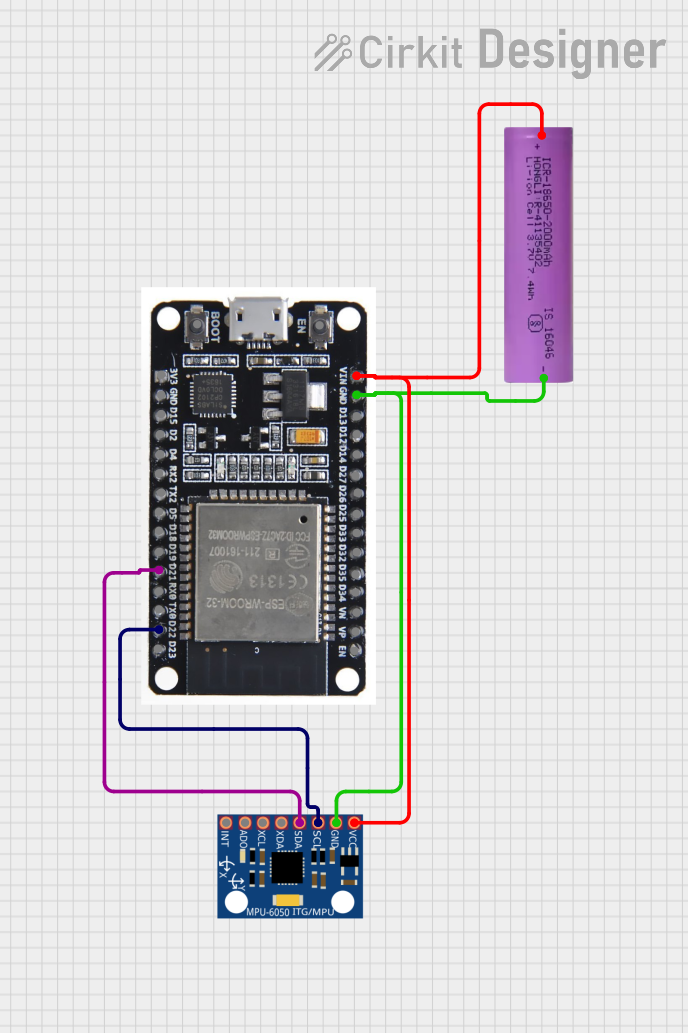

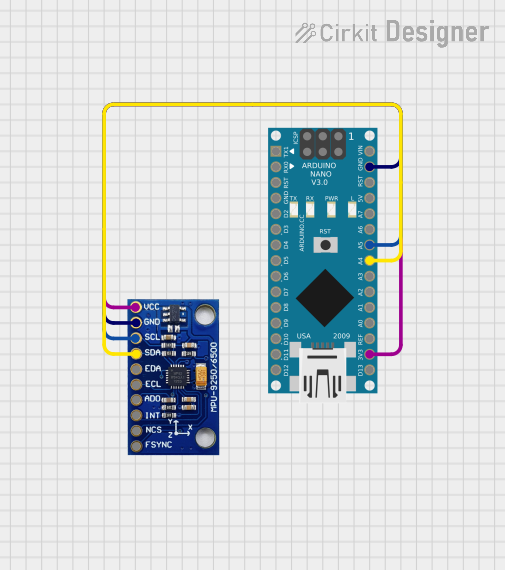

Explore Projects Built with MPU9250/GY -91

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MPU9250/GY -91

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Inertial Measurement Units (IMUs) for robotics

- Orientation tracking for virtual reality (VR) devices

- Motion analysis in sports technology

- Drone stabilization and navigation

- Smartphone and tablet motion features

Technical Specifications

Key Technical Details

- Voltage: 2.4V - 3.6V

- Current: 10μA in low-power accelerometer only mode

- Gyroscope Range: ±250, ±500, ±1000, ±2000°/sec

- Accelerometer Range: ±2g, ±4g, ±8g, ±16g

- Magnetometer Range (Compass): ±4800μT

- Communication: I2C/SPI

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply (2.4V - 3.6V) |

| 2 | GND | Ground |

| 3 | SCL/SCLK | I2C clock/SPI clock |

| 4 | SDA/SDI | I2C data/SPI data input |

| 5 | AD0/SDO | I2C address selection/SPI data output |

| 6 | NCS | SPI chip select (active low) |

| 7 | INT | Interrupt output |

| 8 | FSYNC | Frame synchronization digital input (optional) |

Usage Instructions

How to Use the Component in a Circuit

- Powering the Device: Connect the VCC pin to a 2.4V - 3.6V power source and the GND pin to the ground.

- Communication Setup: For I2C communication, connect SCL to the I2C clock and SDA to the I2C data. For SPI, connect SCLK, SDI, SDO, and NCS accordingly.

- Address Selection: The AD0/SDO pin can be used to set the I2C address. Connect it to VCC or GND to select between the two available addresses.

- Interrupts (Optional): The INT pin can be connected to an external interrupt on a microcontroller to trigger actions when data is ready or other events occur.

Important Considerations and Best Practices

- Ensure that the power supply is within the specified voltage range to prevent damage.

- Use pull-up resistors on the I2C lines if they are not built into the microcontroller.

- For SPI communication, ensure that the NCS pin is kept high when the device is not in use.

- When using the interrupt feature, configure the MPU9250/GY-91 registers to set up the interrupt conditions.

Example Code for Arduino UNO

#include <Wire.h>

// MPU9250 I2C address (depends on AD0 pin, check datasheet)

const int MPU9250_ADDRESS = 0x68;

void setup() {

Wire.begin(); // Initialize I2C

Serial.begin(9600); // Start serial communication at 9600 baud

setupMPU9250(); // Setup MPU9250 registers for operation

}

void loop() {

// Read sensor data and print it

readSensorData();

delay(100); // Delay for readability

}

void setupMPU9250() {

// Write to the power management register to wake up the MPU9250

writeMPU9250Register(MPU9250_ADDRESS, 0x6B, 0x00);

}

void writeMPU9250Register(byte address, byte reg, byte data) {

Wire.beginTransmission(address);

Wire.write(reg);

Wire.write(data);

Wire.endTransmission();

}

void readSensorData() {

Wire.beginTransmission(MPU9250_ADDRESS);

Wire.write(0x3B); // Starting register for accelerometer data

Wire.endTransmission(false);

Wire.requestFrom(MPU9250_ADDRESS, 14, true); // Request 14 bytes from the MPU9250

// Read and process accelerometer, gyroscope, and temperature data

// Accelerometer data

int16_t ax = Wire.read() << 8 | Wire.read();

int16_t ay = Wire.read() << 8 | Wire.read();

int16_t az = Wire.read() << 8 | Wire.read();

// Temperature data (not used in this example)

Wire.read(); Wire.read();

// Gyroscope data

int16_t gx = Wire.read() << 8 | Wire.read();

int16_t gy = Wire.read() << 8 | Wire.read();

int16_t gz = Wire.read() << 8 | Wire.read();

// Print the sensor data

Serial.print("Accel: ");

Serial.print("X="); Serial.print(ax);

Serial.print(" Y="); Serial.print(ay);

Serial.print(" Z="); Serial.println(az);

Serial.print("Gyro: ");

Serial.print("X="); Serial.print(gx);

Serial.print(" Y="); Serial.print(gy);

Serial.print(" Z="); Serial.println(gz);

}

Troubleshooting and FAQs

Common Issues

- No Data Output: Ensure that the device is properly powered and that the I2C/SPI connections are correct.

- Inaccurate Readings: Calibrate the sensor for your specific application environment.

- Intermittent Connection: Check for loose connections and ensure that the pull-up resistors are in place for I2C.

Solutions and Tips for Troubleshooting

- Power Supply Issues: Use a multimeter to verify the voltage at the VCC pin.

- Communication Errors: Use an I2C scanner sketch to check if the MPU9250 is detected on the bus.

- Sensor Calibration: Follow the manufacturer's guidelines for calibrating the gyroscope, accelerometer, and compass.

FAQs

Q: Can the MPU9250/GY-91 be used with both 3.3V and 5V microcontrollers? A: Yes, but ensure that the voltage levels for communication are compatible or use level shifters if necessary.

Q: How can I change the I2C address of the MPU9250? A: The I2C address can be changed by connecting the AD0/SDO pin to either VCC or GND.

Q: What is the default I2C address of the MPU9250? A: The default I2C address is 0x68 when AD0/SDO is connected to GND. It changes to 0x69 when connected to VCC.

Q: How do I interpret the raw data from the MPU9250? A: The raw data needs to be converted using the sensitivity levels specified in the datasheet. This will give you the actual measurements in the appropriate units (e.g., g for acceleration, °/sec for gyroscope, μT for magnetometer).