How to Use Servo DM 15kg: Examples, Pinouts, and Specs

Design with Servo DM 15kg in Cirkit Designer

Design with Servo DM 15kg in Cirkit DesignerIntroduction

The Servo DM 15kg is a high-torque servo motor designed for applications requiring precise control of angular position. With a torque rating of up to 15 kg-cm, this servo is ideal for demanding tasks in robotics, automation, RC vehicles, and industrial machinery. Its robust design and high torque output make it suitable for moving heavy loads with accuracy and reliability.

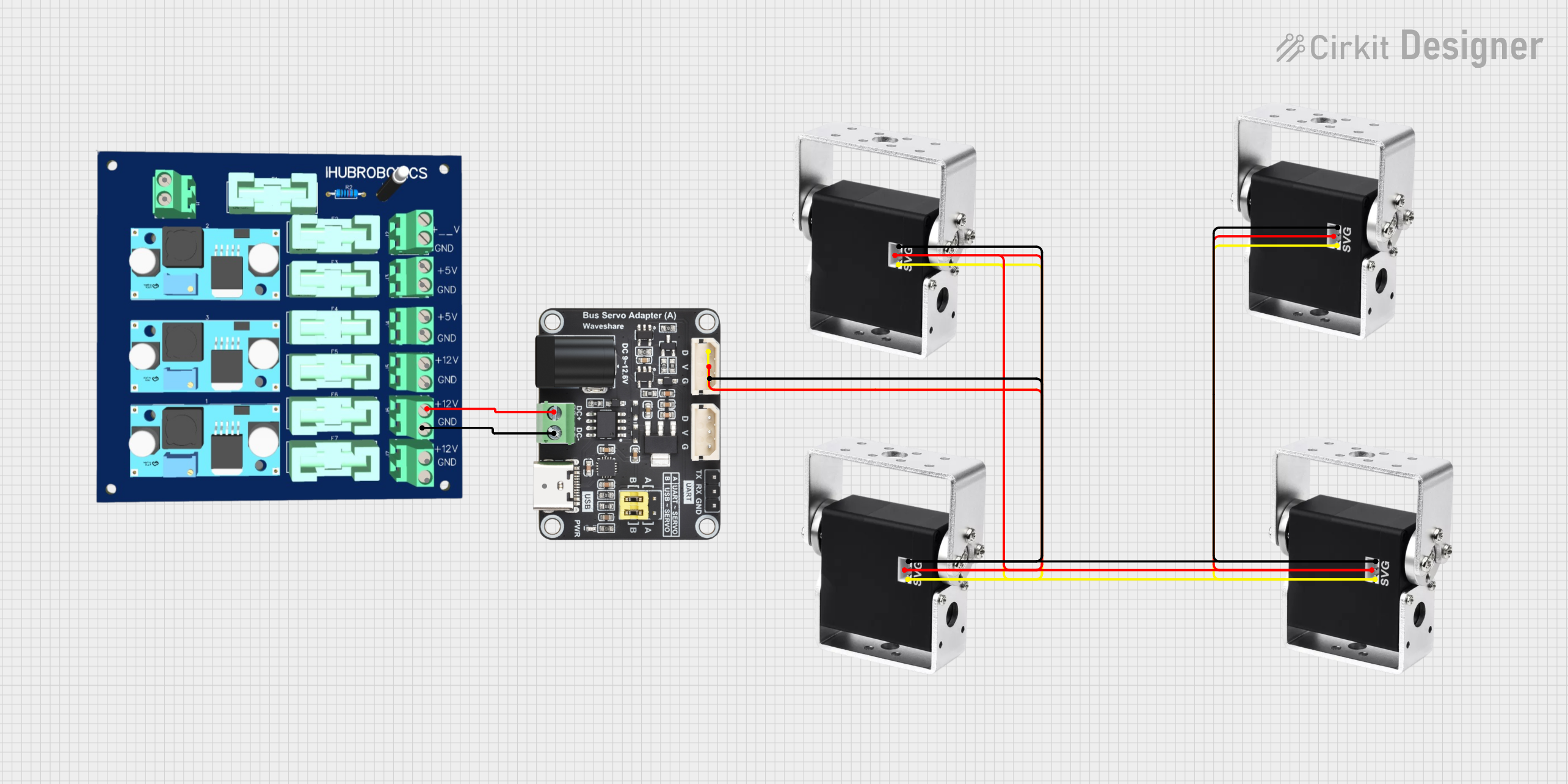

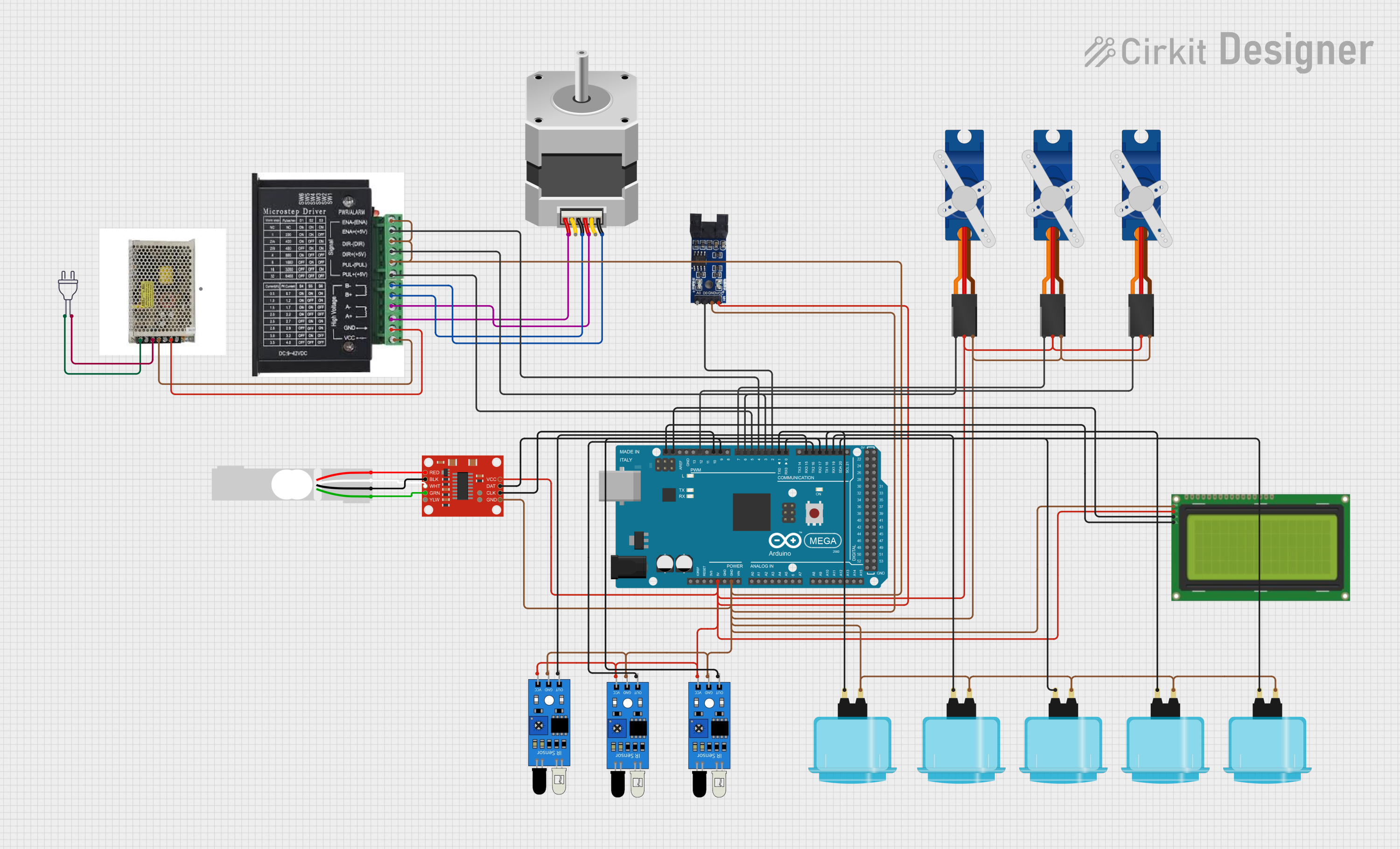

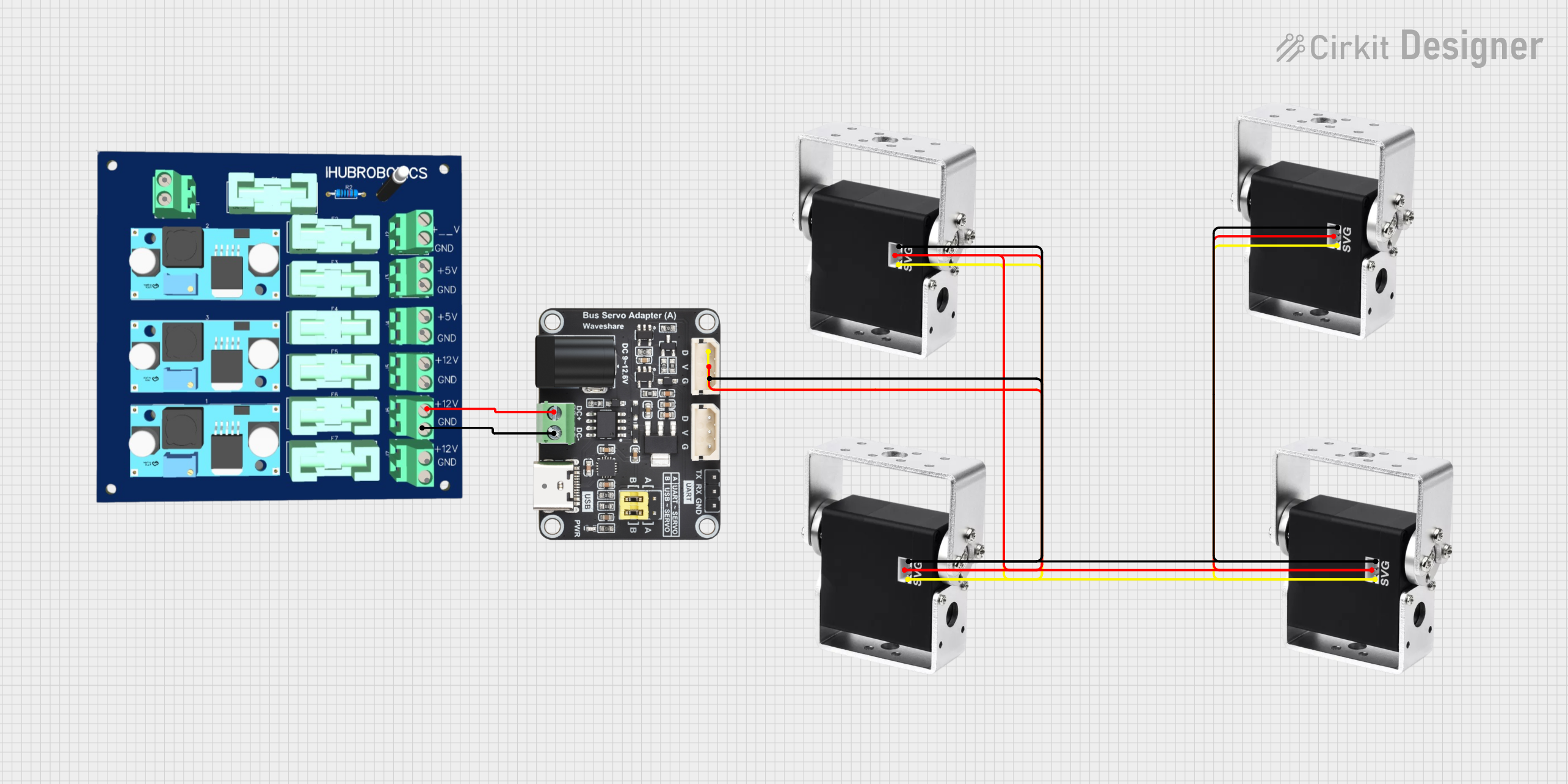

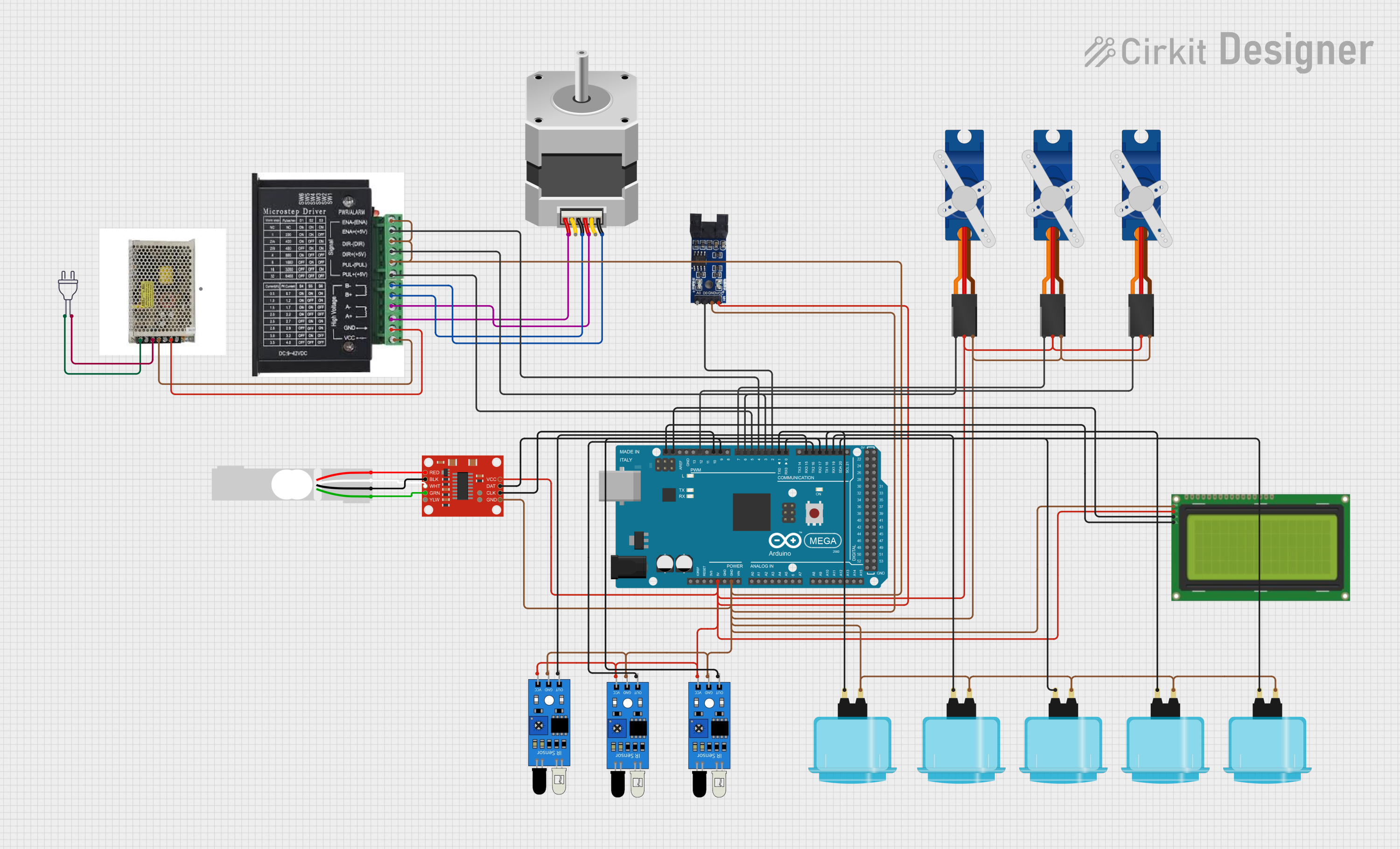

Explore Projects Built with Servo DM 15kg

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Servo DM 15kg

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotic arms and grippers

- RC cars, boats, and planes

- Automated machinery and conveyor systems

- Pan-tilt camera mounts

- DIY projects requiring precise angular motion

Technical Specifications

Below are the key technical details of the Servo DM 15kg:

| Parameter | Value |

|---|---|

| Operating Voltage | 4.8V - 6.8V |

| Stall Torque | 15 kg-cm @ 6.8V |

| Operating Speed | 0.16 sec/60° @ 4.8V, 0.14 sec/60° @ 6.8V |

| Control Signal | PWM (Pulse Width Modulation) |

| PWM Pulse Range | 500 µs - 2500 µs |

| Angle Range | 0° - 180° |

| Gear Material | Metal |

| Motor Type | Coreless |

| Dimensions | 40.5 x 20 x 38 mm |

| Weight | 60 g |

Pin Configuration

The Servo DM 15kg has a standard 3-pin connector. The pinout is as follows:

| Pin | Wire Color | Function |

|---|---|---|

| 1 | Brown | Ground (GND) |

| 2 | Red | Power (VCC) |

| 3 | Orange | Signal (PWM Input) |

Usage Instructions

Connecting the Servo

- Power Supply: Ensure the servo is powered with a voltage between 4.8V and 6.8V. A regulated power supply or a 5V/6V battery pack is recommended.

- Wiring:

- Connect the Brown wire to the ground (GND) of your power source or microcontroller.

- Connect the Red wire to the positive terminal (VCC) of your power source.

- Connect the Orange wire to the PWM output pin of your microcontroller (e.g., Arduino).

Controlling the Servo with Arduino UNO

The Servo DM 15kg can be controlled using the Arduino Servo library. Below is an example code to rotate the servo to specific angles:

#include <Servo.h> // Include the Servo library

Servo myServo; // Create a Servo object

void setup() {

myServo.attach(9); // Attach the servo to pin 9 on the Arduino

}

void loop() {

myServo.write(0); // Move the servo to 0 degrees

delay(1000); // Wait for 1 second

myServo.write(90); // Move the servo to 90 degrees

delay(1000); // Wait for 1 second

myServo.write(180); // Move the servo to 180 degrees

delay(1000); // Wait for 1 second

}

Important Considerations

- Power Supply: Avoid powering the servo directly from the Arduino's 5V pin, as the current draw may exceed the Arduino's capacity. Use an external power source capable of supplying sufficient current (at least 2A).

- PWM Signal: Ensure the PWM signal is within the specified range (500 µs to 2500 µs) to avoid damaging the servo.

- Mechanical Load: Do not exceed the torque rating of 15 kg-cm to prevent overheating or damage to the motor.

Troubleshooting and FAQs

Common Issues and Solutions

Servo Not Moving

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check the wiring and ensure the power supply meets the voltage and current requirements.

Servo Jittering or Vibrating

- Cause: Electrical noise or unstable PWM signal.

- Solution: Use a decoupling capacitor (e.g., 100 µF) across the power supply terminals and ensure the PWM signal is stable.

Servo Overheating

- Cause: Excessive load or prolonged operation at stall torque.

- Solution: Reduce the mechanical load and avoid operating the servo at stall torque for extended periods.

Limited Range of Motion

- Cause: PWM signal out of range or mechanical obstruction.

- Solution: Verify the PWM signal is within the 500 µs to 2500 µs range and check for any physical obstructions.

FAQs

Q: Can I use the Servo DM 15kg with a Raspberry Pi?

A: Yes, but you will need a PWM driver (e.g., PCA9685) or a software PWM library to generate the required signal.

Q: What is the maximum current draw of the servo?

A: The maximum current draw can reach up to 2.5A under heavy load. Ensure your power supply can handle this.

Q: Can the servo rotate beyond 180°?

A: No, the Servo DM 15kg is designed for a range of 0° to 180°. For continuous rotation, consider a continuous rotation servo.

Q: How do I mount the servo?

A: The servo comes with mounting brackets and screws. Use these to securely attach the servo to your project.

By following this documentation, you can effectively integrate the Servo DM 15kg into your projects and troubleshoot common issues with ease.