How to Use GX servo 200: Examples, Pinouts, and Specs

Design with GX servo 200 in Cirkit Designer

Design with GX servo 200 in Cirkit DesignerIntroduction

The GX Servo 200 is a high-performance servo motor manufactured by GX Servo, designed for applications requiring precise control and high torque output. Its robust design makes it ideal for use in robotics, automation systems, and other electromechanical projects. The GX Servo 200 is engineered to deliver reliable performance, even under demanding conditions, making it a popular choice for both hobbyists and professionals.

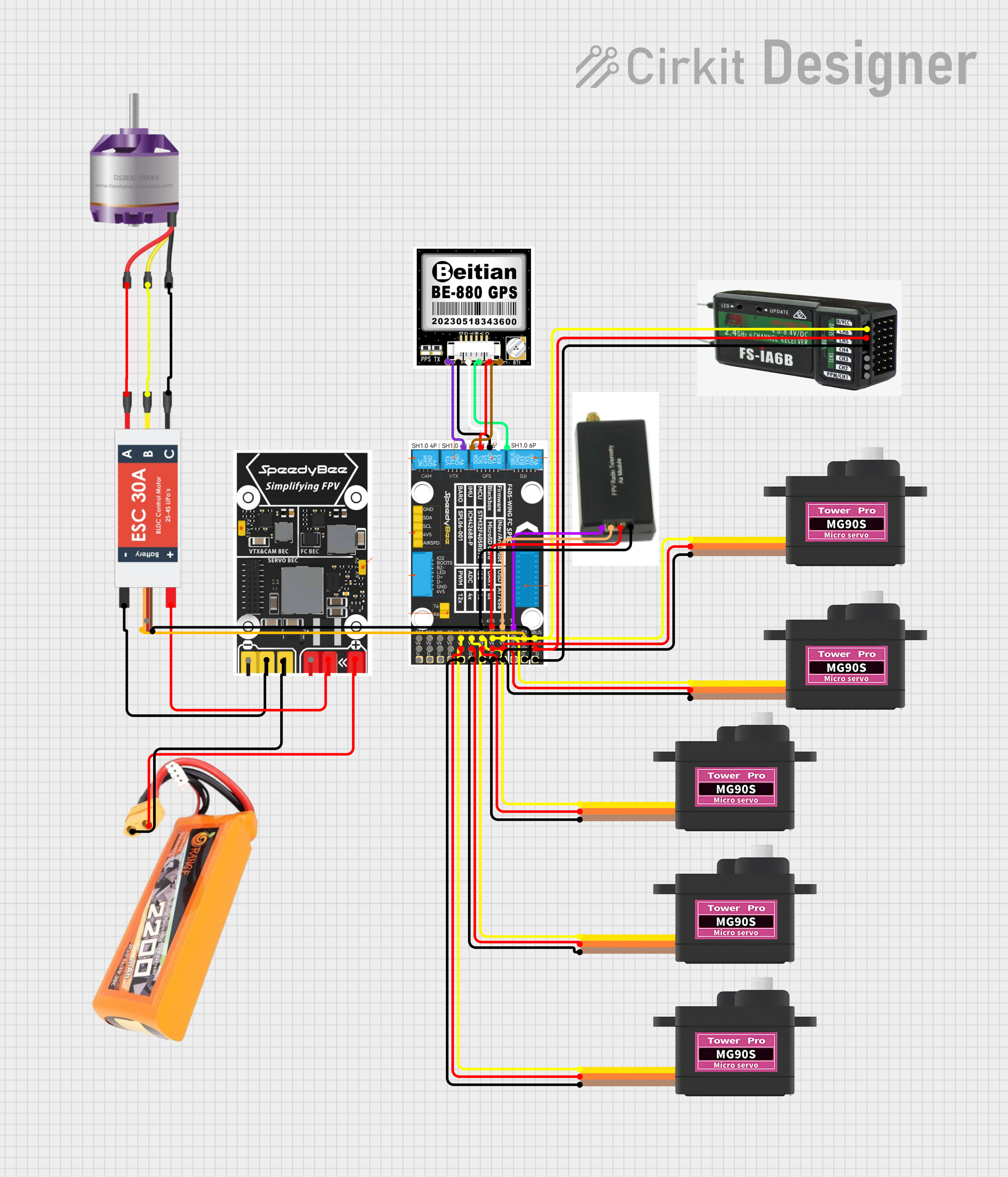

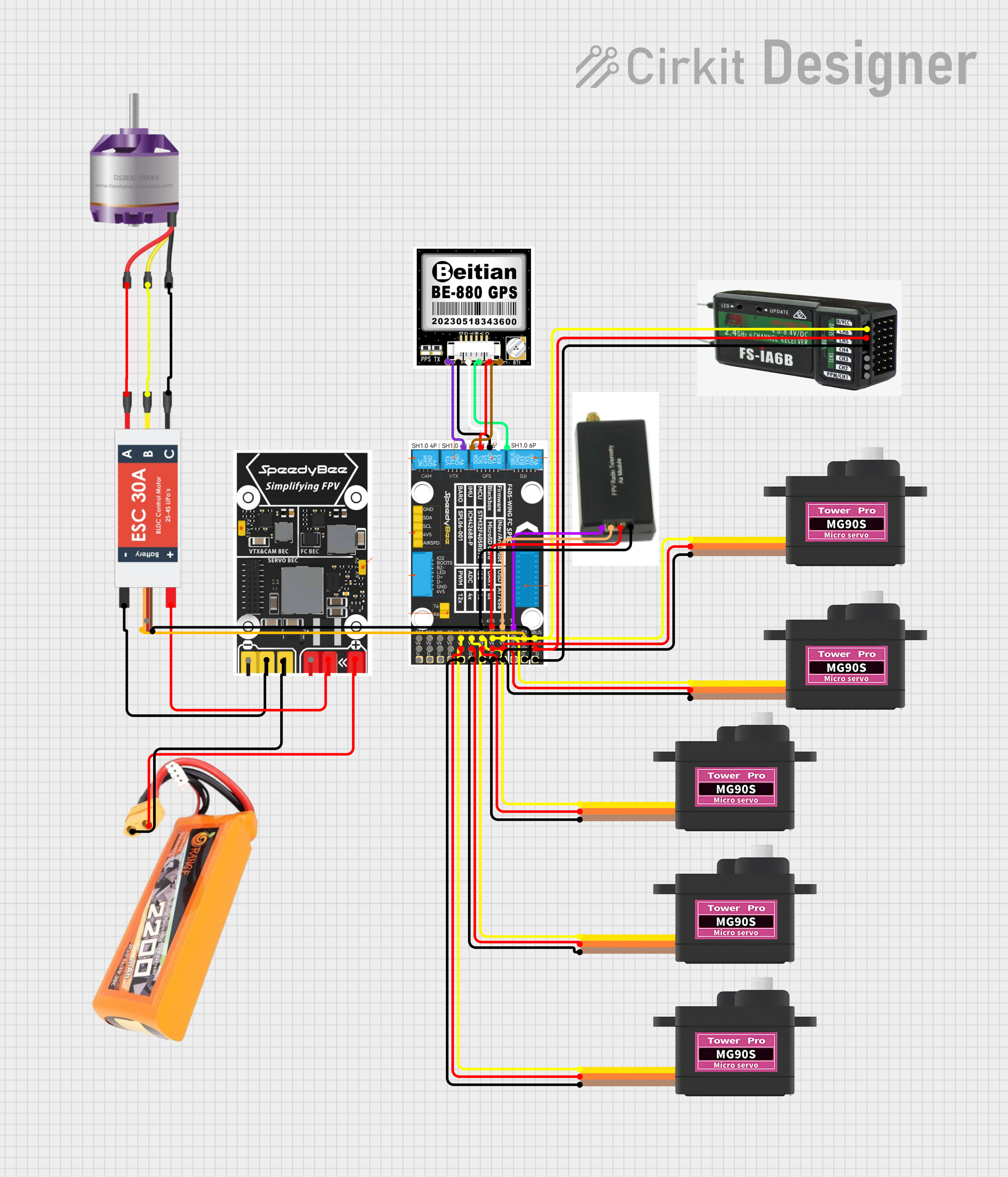

Explore Projects Built with GX servo 200

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with GX servo 200

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotic arms and manipulators

- Automated machinery and conveyor systems

- Remote-controlled vehicles and drones

- Precision positioning systems

- Educational and prototyping projects

Technical Specifications

The following table outlines the key technical details of the GX Servo 200:

| Parameter | Value |

|---|---|

| Operating Voltage | 4.8V to 7.4V |

| Stall Torque | 20 kg·cm @ 6.0V, 25 kg·cm @ 7.4V |

| Operating Speed | 0.16 sec/60° @ 6.0V, 0.14 sec/60° @ 7.4V |

| Control Signal | PWM (Pulse Width Modulation) |

| PWM Pulse Range | 500 µs to 2500 µs |

| Dead Band Width | 3 µs |

| Operating Temperature | -10°C to 50°C |

| Weight | 60 g |

| Dimensions | 40 mm x 20 mm x 40 mm |

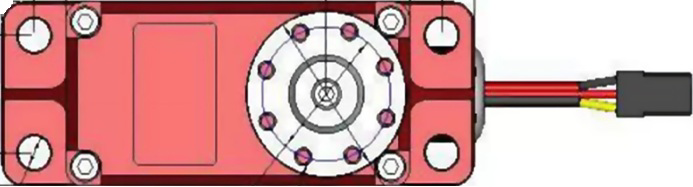

Pin Configuration

The GX Servo 200 has a standard 3-pin connector for interfacing with control systems. The pinout is as follows:

| Pin | Wire Color | Function |

|---|---|---|

| 1 | Brown | Ground (GND) |

| 2 | Red | Power Supply (VCC) |

| 3 | Orange | Signal (PWM Input) |

Usage Instructions

How to Use the GX Servo 200 in a Circuit

- Power Supply: Connect the red wire to a regulated power source within the operating voltage range (4.8V to 7.4V). Ensure the power supply can provide sufficient current for the servo's operation.

- Ground Connection: Connect the brown wire to the ground of your circuit.

- Signal Input: Connect the orange wire to the PWM output pin of your microcontroller or servo controller. The PWM signal controls the servo's position.

Important Considerations

- Voltage Range: Do not exceed the specified voltage range to avoid damaging the servo.

- Current Requirements: Ensure your power supply can handle the peak current draw, especially under high torque conditions.

- PWM Signal: Use a PWM signal with a pulse width between 500 µs (minimum position) and 2500 µs (maximum position). A 1500 µs pulse corresponds to the neutral (center) position.

- Mounting: Secure the servo using appropriate screws and brackets to prevent movement during operation.

- Heat Management: Avoid prolonged operation at stall torque to prevent overheating.

Example: Controlling the GX Servo 200 with an Arduino UNO

Below is an example code snippet to control the GX Servo 200 using an Arduino UNO:

#include <Servo.h> // Include the Servo library

Servo gxServo; // Create a Servo object to control the GX Servo 200

void setup() {

gxServo.attach(9); // Attach the servo to pin 9 on the Arduino

}

void loop() {

gxServo.write(0); // Move the servo to 0 degrees

delay(1000); // Wait for 1 second

gxServo.write(90); // Move the servo to 90 degrees

delay(1000); // Wait for 1 second

gxServo.write(180); // Move the servo to 180 degrees

delay(1000); // Wait for 1 second

}

Code Explanation:

- The

Servolibrary is used to control the GX Servo 200. - The

attach()function links the servo to a specific PWM pin on the Arduino. - The

write()function sets the servo's position in degrees (0° to 180°).

Troubleshooting and FAQs

Common Issues and Solutions

Servo Not Moving:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check the wiring and ensure the power supply meets the voltage and current requirements.

Erratic Movement:

- Cause: Noise or interference in the PWM signal.

- Solution: Use shielded cables for the signal wire and ensure a stable PWM signal from the controller.

Overheating:

- Cause: Prolonged operation at stall torque or excessive load.

- Solution: Reduce the load on the servo and avoid operating it at stall torque for extended periods.

Servo Jittering:

- Cause: Insufficient power supply or unstable voltage.

- Solution: Use a capacitor across the power supply to stabilize the voltage.

FAQs

Q1: Can the GX Servo 200 rotate continuously?

A1: No, the GX Servo 200 is a standard servo designed for angular positioning (0° to 180°). For continuous rotation, a modified or continuous rotation servo is required.

Q2: What is the maximum current draw of the GX Servo 200?

A2: The maximum current draw depends on the load and operating voltage. Under stall conditions, it can draw up to 2.5A. Ensure your power supply can handle this.

Q3: Can I use the GX Servo 200 with a Raspberry Pi?

A3: Yes, but since the Raspberry Pi does not have hardware PWM on all GPIO pins, it is recommended to use a dedicated PWM driver (e.g., PCA9685) for precise control.

Q4: How do I calibrate the servo's neutral position?

A4: The servo's neutral position (1500 µs pulse width) is factory-calibrated. If adjustments are needed, use a servo tester or adjust the PWM signal in your code.

By following this documentation, you can effectively integrate the GX Servo 200 into your projects and achieve precise control for a wide range of applications.