How to Use ECU: Examples, Pinouts, and Specs

Design with ECU in Cirkit Designer

Design with ECU in Cirkit DesignerIntroduction

The Electronic Control Unit (ECU), manufactured by CAR (Part ID: CAR), is a digital computer designed to manage and control various functions in a vehicle. It plays a critical role in modern automotive systems by ensuring optimal performance, efficiency, and safety. The ECU processes data from various sensors and executes commands to control actuators, enabling precise management of systems such as engine performance, transmission, braking, and more.

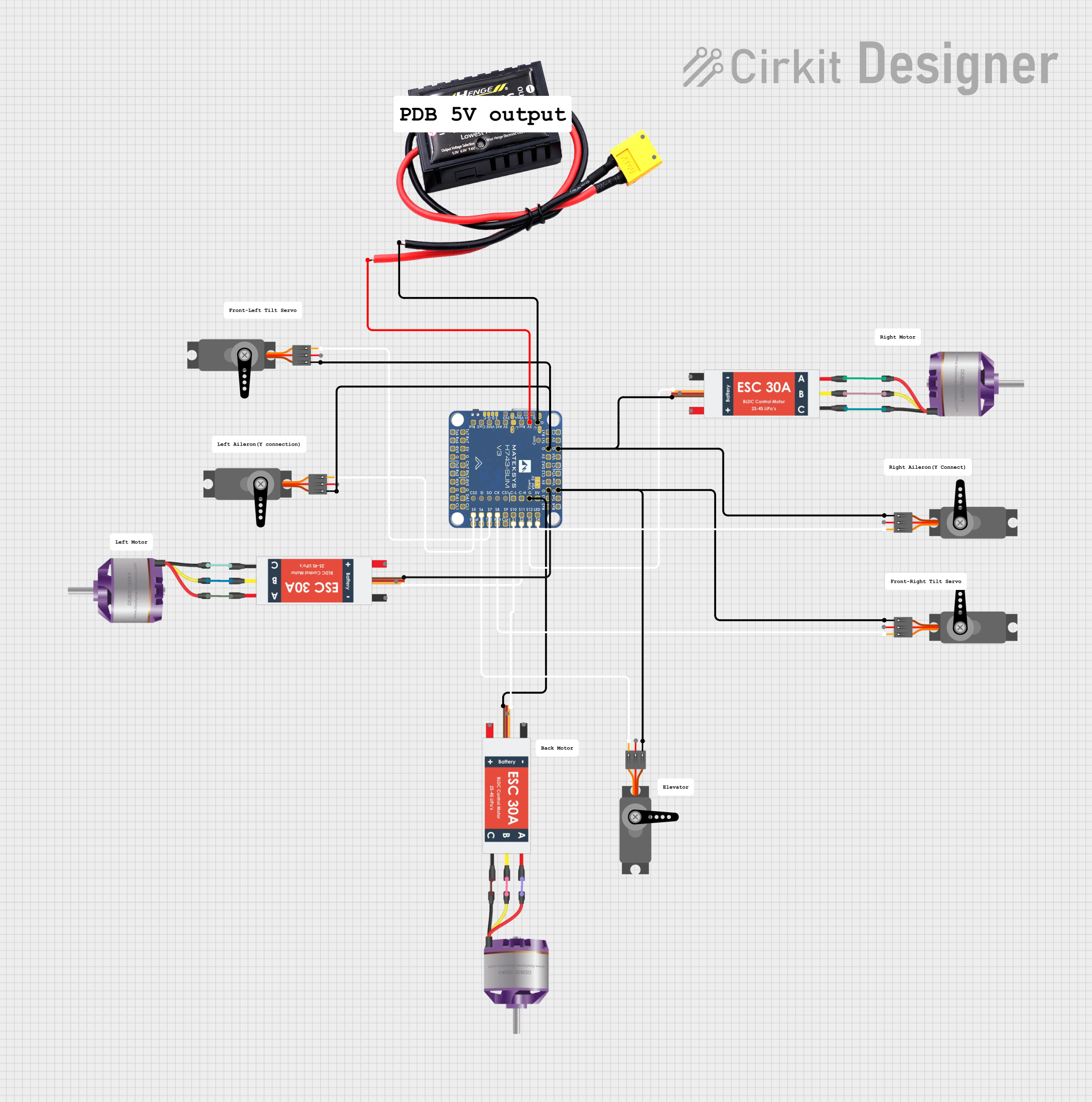

Explore Projects Built with ECU

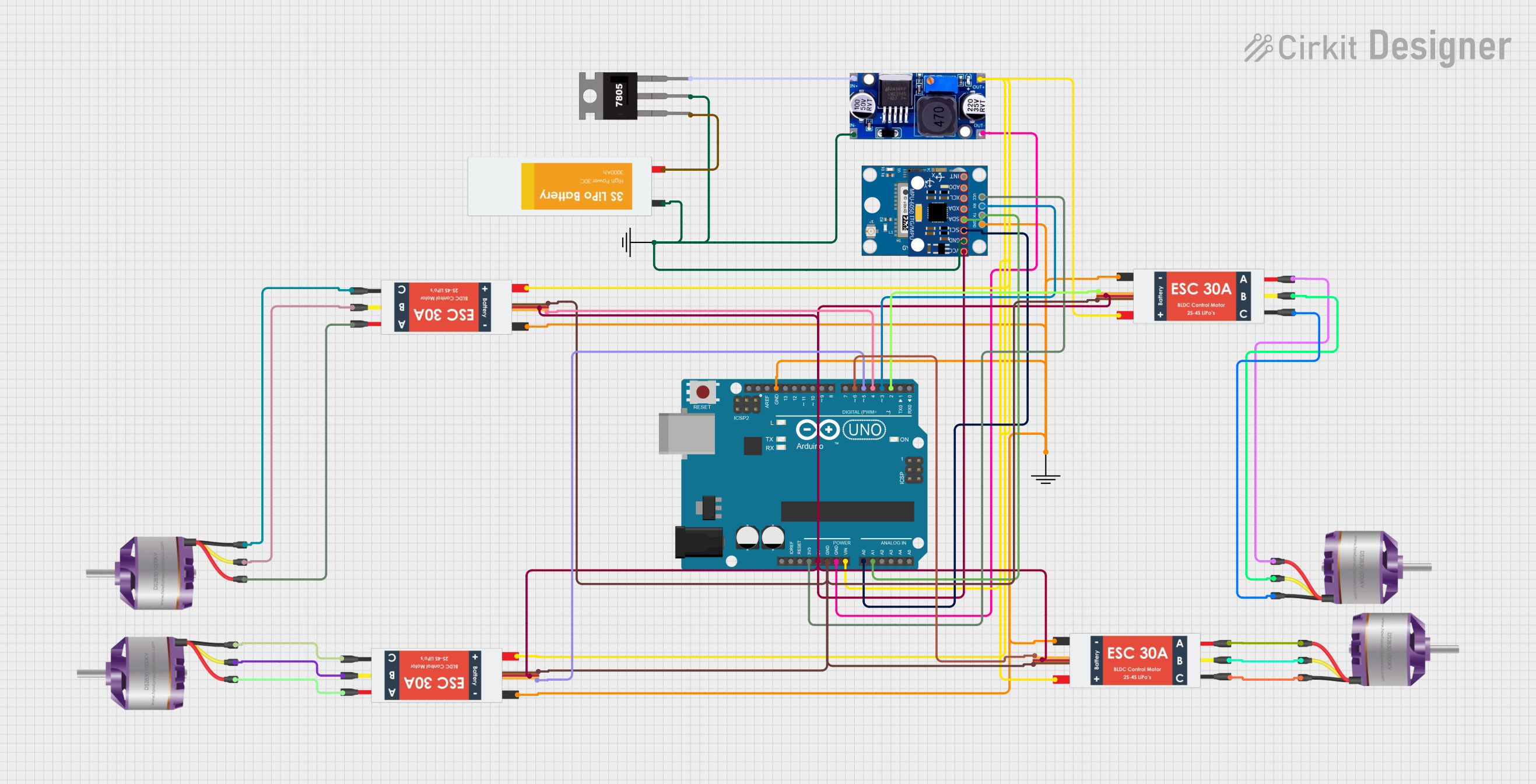

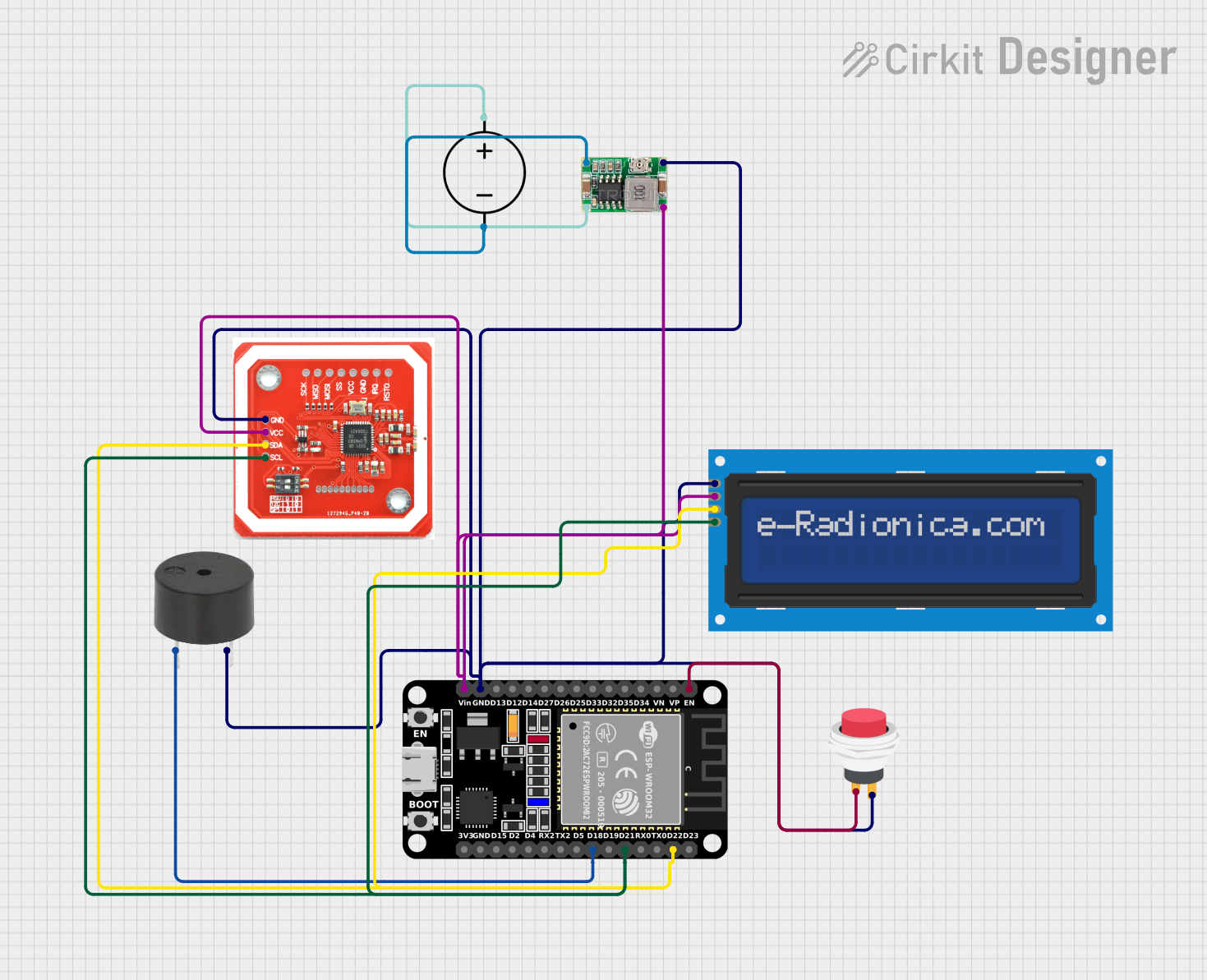

Open Project in Cirkit Designer

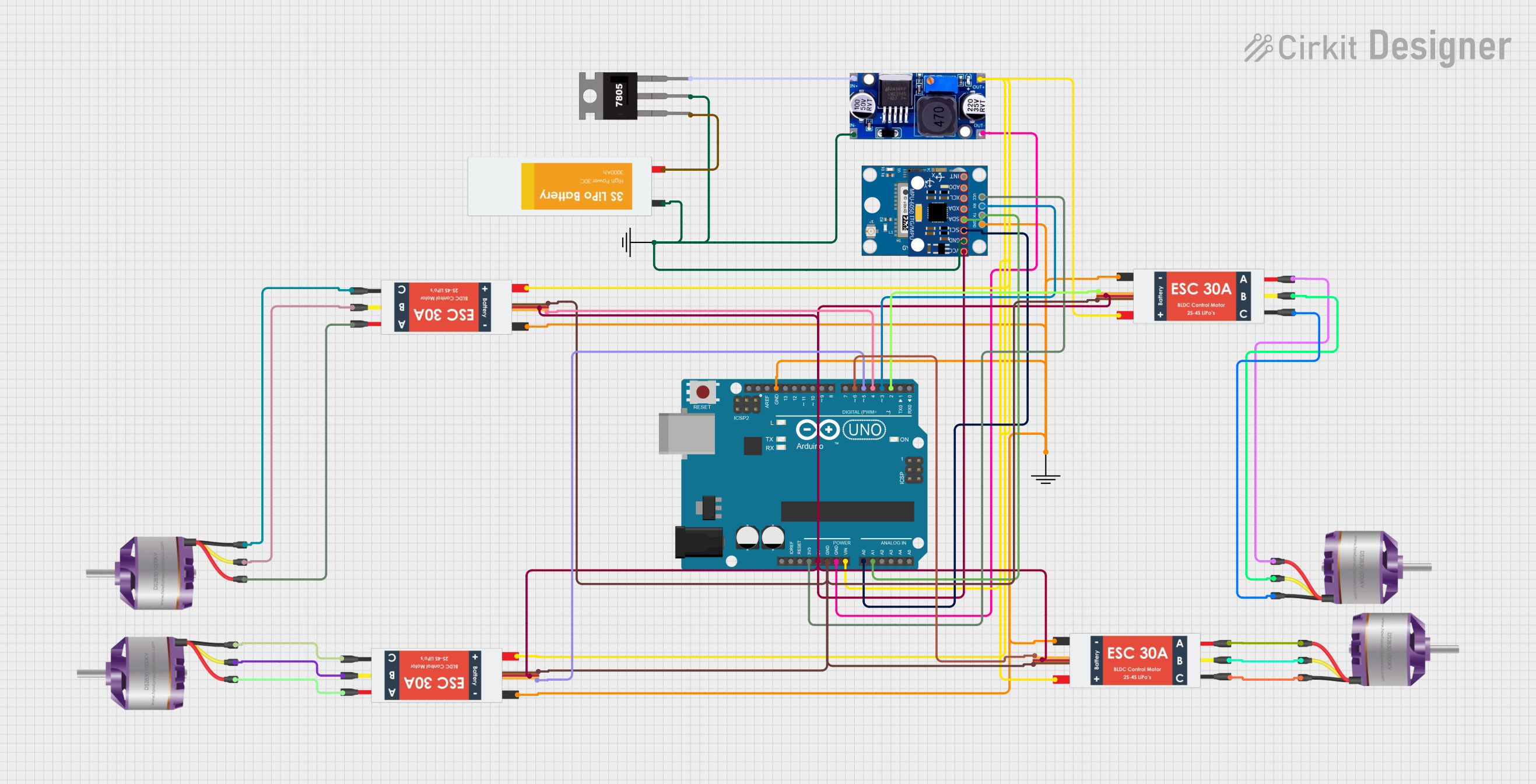

Open Project in Cirkit Designer

Open Project in Cirkit Designer

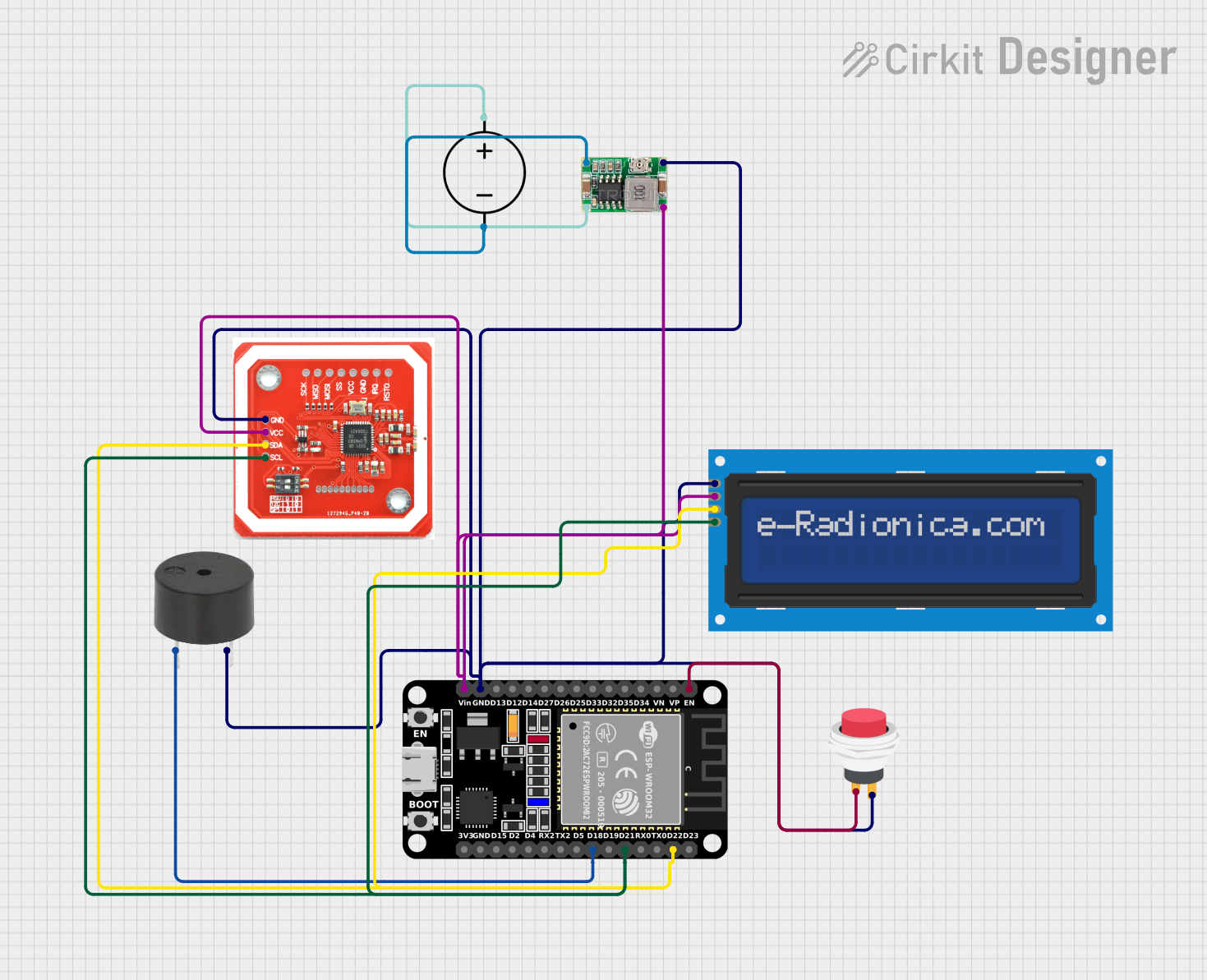

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

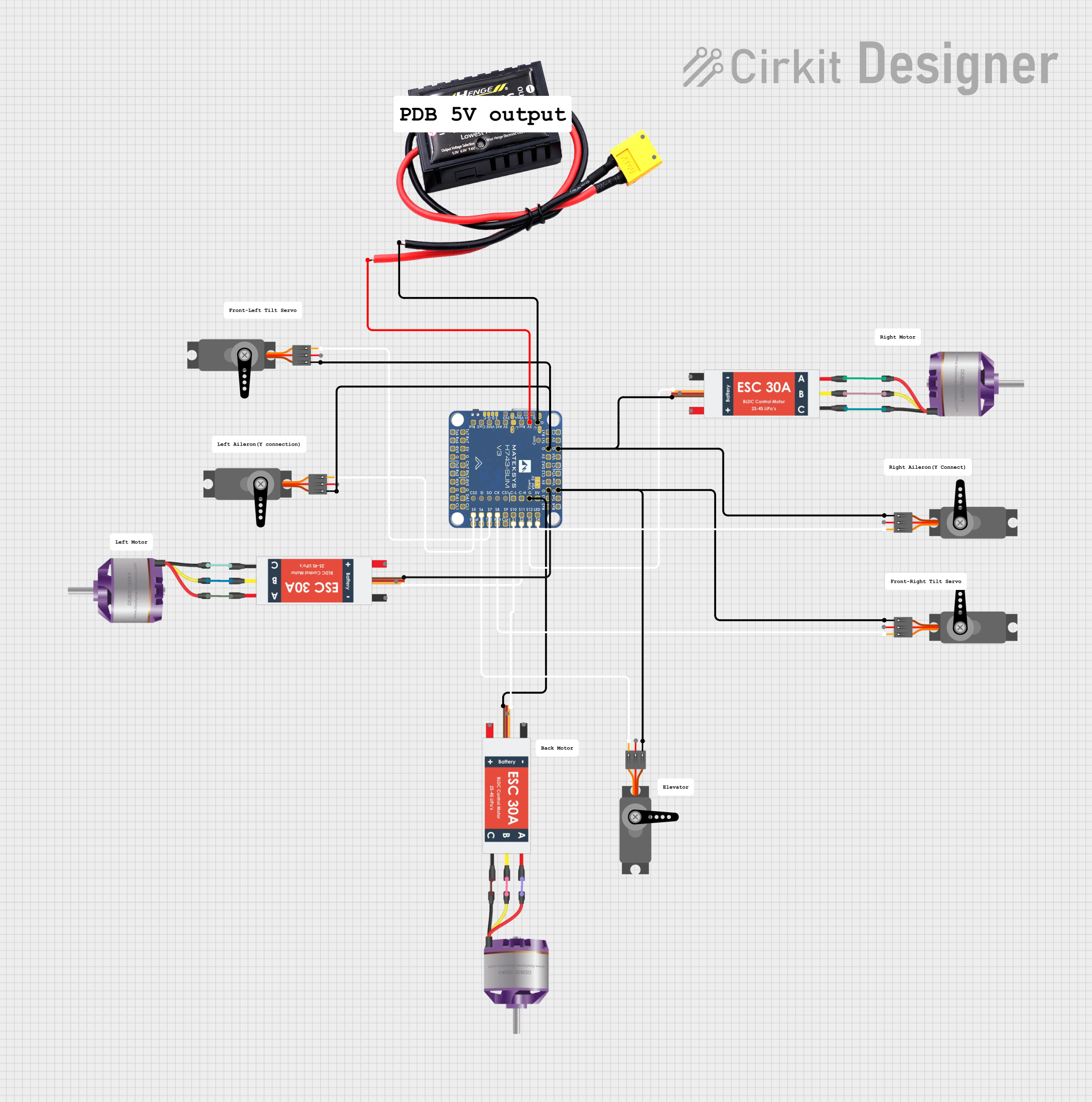

Open Project in Cirkit DesignerExplore Projects Built with ECU

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Engine Management: Controls fuel injection, ignition timing, and air-fuel ratio for optimal engine performance.

- Transmission Control: Manages gear shifting in automatic transmissions for smooth operation.

- Anti-lock Braking System (ABS): Ensures safe braking by preventing wheel lock-up.

- Airbag Deployment: Activates airbags during a collision to protect passengers.

- Climate Control: Regulates cabin temperature and airflow.

- Advanced Driver Assistance Systems (ADAS): Supports features like lane-keeping assist, adaptive cruise control, and parking assistance.

Technical Specifications

The following table outlines the key technical details of the ECU:

| Parameter | Specification |

|---|---|

| Operating Voltage | 12V DC (nominal), 9V-16V range |

| Power Consumption | 5W-50W (depending on system load) |

| Communication Protocols | CAN, LIN, FlexRay, Ethernet |

| Processor Type | 32-bit microcontroller |

| Memory | Flash: 1MB-4MB, RAM: 256KB-1MB |

| Operating Temperature | -40°C to +85°C |

| Dimensions | Varies by model, typically compact |

| Weight | ~500g |

Pin Configuration and Descriptions

The ECU typically features a multi-pin connector for interfacing with sensors, actuators, and other vehicle systems. Below is an example of a generic pin configuration:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | Power (+12V) | Main power supply input |

| 2 | Ground (GND) | Ground connection |

| 3 | CAN_H | High line for CAN bus communication |

| 4 | CAN_L | Low line for CAN bus communication |

| 5 | Sensor Input 1 | Analog input from a connected sensor |

| 6 | Sensor Input 2 | Analog input from another sensor |

| 7 | Actuator Output 1 | Output signal to control an actuator |

| 8 | Actuator Output 2 | Output signal to control another actuator |

| 9 | Diagnostic Port | Interface for diagnostics and programming |

| 10 | Reserved | Reserved for future use |

Note: Pin configurations may vary depending on the specific ECU model and application.

Usage Instructions

How to Use the ECU in a Circuit

- Power Connection: Connect the ECU's power pin to a stable 12V DC source and the ground pin to the vehicle's chassis or a common ground.

- Sensor Inputs: Wire the appropriate sensors (e.g., temperature, pressure, or speed sensors) to the designated input pins.

- Actuator Outputs: Connect actuators (e.g., fuel injectors, solenoids, or motors) to the output pins as specified in the vehicle's wiring diagram.

- Communication: Use the CAN_H and CAN_L pins to connect the ECU to the vehicle's CAN bus for data exchange with other modules.

- Diagnostics: Connect a diagnostic tool to the diagnostic port for programming, troubleshooting, or firmware updates.

Important Considerations and Best Practices

- Voltage Stability: Ensure the power supply is stable and within the specified range (9V-16V) to prevent damage to the ECU.

- Wiring Integrity: Use high-quality automotive-grade wires and connectors to avoid signal loss or interference.

- Grounding: Proper grounding is essential to prevent electrical noise and ensure reliable operation.

- Firmware Updates: Regularly update the ECU firmware to benefit from performance improvements and bug fixes.

- Environmental Protection: Install the ECU in a location protected from excessive heat, moisture, and vibration.

Example: Connecting the ECU to an Arduino UNO

While the ECU is primarily designed for automotive systems, it can be interfaced with an Arduino UNO for testing or prototyping purposes. Below is an example of how to read data from the ECU using the CAN bus:

Required Components

- Arduino UNO

- CAN bus shield

- ECU

- Jumper wires

Sample Code

#include <SPI.h>

#include <mcp_can.h>

// Define the CAN bus shield's CS pin

#define CAN_CS_PIN 10

// Initialize the CAN bus object

MCP_CAN CAN(CAN_CS_PIN);

void setup() {

Serial.begin(9600); // Initialize serial communication for debugging

// Initialize the CAN bus at 500 kbps

if (CAN.begin(MCP_ANY, 500000, MCP_8MHZ) == CAN_OK) {

Serial.println("CAN bus initialized successfully!");

} else {

Serial.println("Error initializing CAN bus. Check connections.");

while (1); // Halt execution if initialization fails

}

CAN.setMode(MCP_NORMAL); // Set CAN bus to normal mode

Serial.println("CAN bus set to normal mode.");

}

void loop() {

unsigned char len = 0;

unsigned char buf[8];

// Check if data is available on the CAN bus

if (CAN.checkReceive() == CAN_MSGAVAIL) {

CAN.readMsgBuf(&len, buf); // Read the received message

Serial.print("Received data: ");

for (int i = 0; i < len; i++) {

Serial.print(buf[i], HEX); // Print each byte in hexadecimal format

Serial.print(" ");

}

Serial.println();

}

delay(100); // Add a small delay to avoid flooding the serial monitor

}

Note: This code assumes the use of an MCP2515-based CAN bus shield. Adjust the settings as needed for your specific hardware.

Troubleshooting and FAQs

Common Issues and Solutions

ECU Not Powering On

- Cause: Insufficient or unstable power supply.

- Solution: Verify the power source and ensure it provides a stable 12V DC.

No Communication with Other Modules

- Cause: Faulty CAN bus wiring or incorrect termination.

- Solution: Check the CAN_H and CAN_L connections and ensure proper termination resistors (120Ω) are in place.

Sensor Data Not Detected

- Cause: Loose or damaged sensor connections.

- Solution: Inspect the wiring and connectors for damage or poor contact.

Actuator Not Responding

- Cause: Incorrect wiring or faulty actuator.

- Solution: Verify the actuator's wiring and test it independently to confirm functionality.

FAQs

Q: Can the ECU be used in non-automotive applications?

A: Yes, the ECU can be adapted for use in other systems requiring real-time control, such as industrial automation or robotics.Q: How do I update the ECU firmware?

A: Use a compatible diagnostic tool or programming interface to upload the latest firmware provided by the manufacturer.Q: What happens if the ECU overheats?

A: Most ECUs have built-in thermal protection and will shut down or reduce performance to prevent damage. Ensure proper ventilation and avoid exposure to excessive heat.Q: Can I repair a damaged ECU?

A: Repairs should only be performed by qualified technicians with access to the necessary tools and replacement components.

For additional support, refer to the manufacturer's documentation or contact their technical support team.