How to Use Motor Driver Expansion Board Bottom side: Examples, Pinouts, and Specs

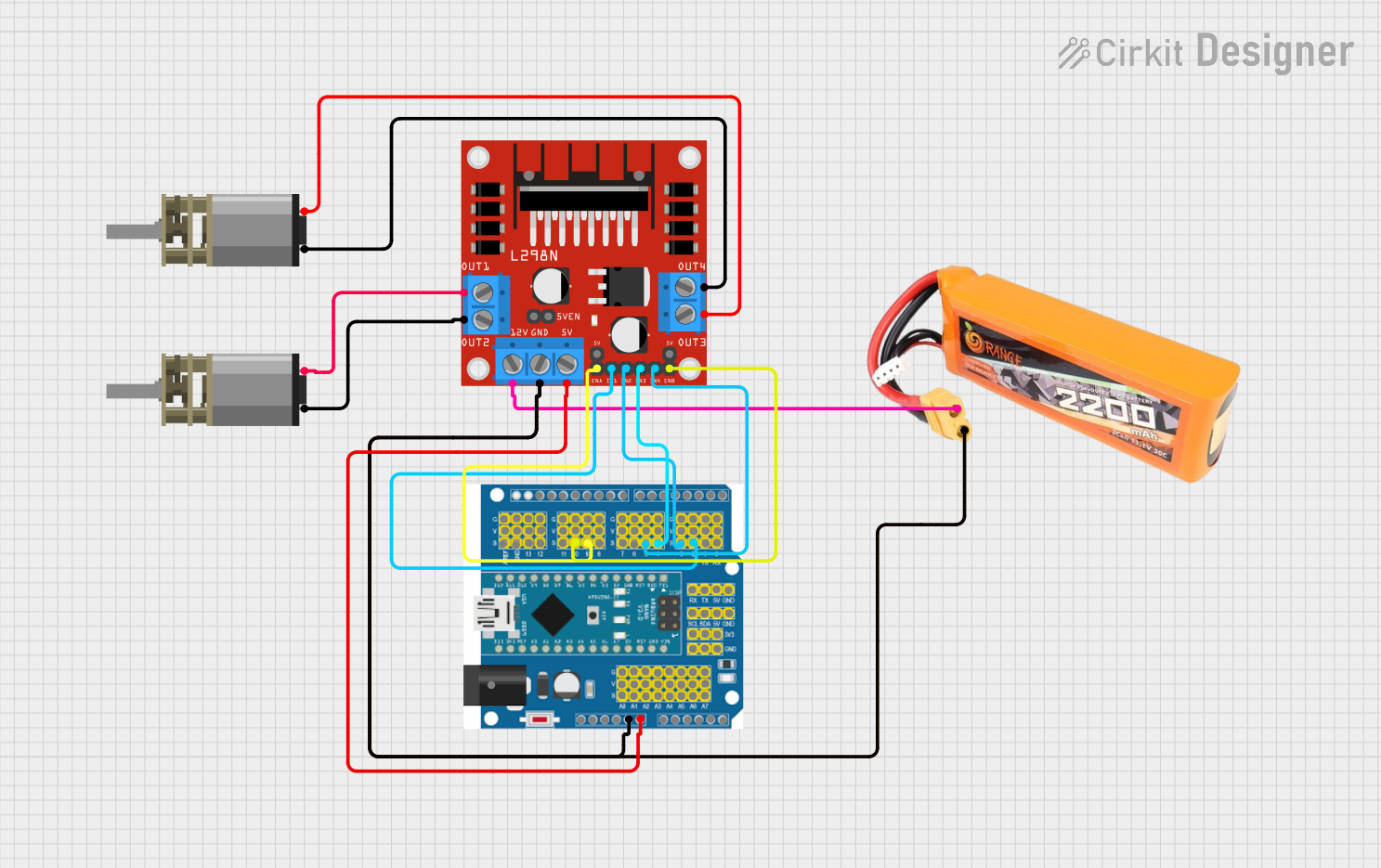

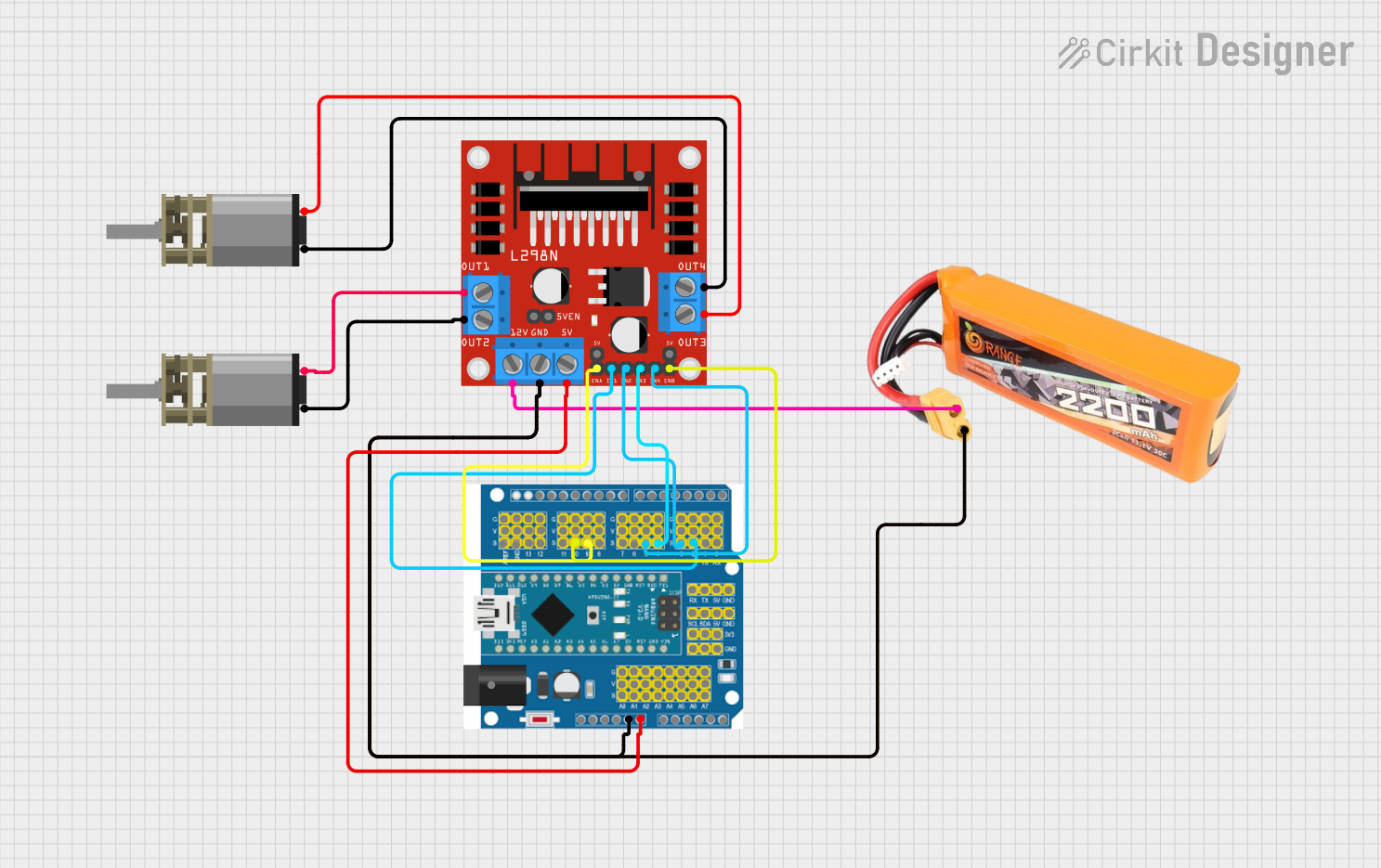

Design with Motor Driver Expansion Board Bottom side in Cirkit Designer

Design with Motor Driver Expansion Board Bottom side in Cirkit DesignerIntroduction

The Keyestudio 8833 Motor Driver Expansion Board is an electronic module designed to facilitate the control of motors in various applications such as robotics, automation, and custom projects. It is compatible with microcontroller platforms like Arduino UNO, making it an ideal choice for hobbyists and professionals alike. The board is capable of driving multiple motors simultaneously and offers features such as speed control and direction control.

Explore Projects Built with Motor Driver Expansion Board Bottom side

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Motor Driver Expansion Board Bottom side

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving wheels or tracks on robotic vehicles.

- Automation: Controlling conveyor belts, actuators, or other machinery.

- Educational Projects: Teaching motor control principles in STEM education.

- DIY Projects: Custom builds requiring motor control, such as automated plant watering systems.

Technical Specifications

Key Technical Details

- Operating Voltage: 6V to 12V

- Continuous Current per Channel: 1.2A

- Peak Current per Channel: 3.2A (for a few milliseconds)

- Logic Control Voltage: 5V (from Arduino UNO)

- Motor Driver: Dual H-Bridge configuration

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VM | Motor power supply input (6V-12V) |

| 2 | GND | Ground connection |

| 3 | V5 | 5V output (from Arduino UNO) |

| 4 | D2 | Direction control for Motor A |

| 5 | D3 | Speed control for Motor A (PWM) |

| 6 | D4 | Direction control for Motor B |

| 7 | D5 | Speed control for Motor B (PWM) |

| 8 | D6 | Brake for Motor A |

| 9 | D7 | Brake for Motor B |

| 10 | A+ | Motor A output positive |

| 11 | A- | Motor A output negative |

| 12 | B+ | Motor B output positive |

| 13 | B- | Motor B output negative |

Usage Instructions

How to Use the Component in a Circuit

- Connect the VM pin to your motor power supply (6V-12V).

- Connect the GND pin to the ground of your power supply and Arduino.

- Connect the V5 pin to the 5V output on the Arduino if additional 5V supply is needed.

- Connect the D2-D7 pins to the corresponding digital pins on the Arduino for control signals.

- Connect the motor terminals to the A+/A- and B+/B- outputs for Motor A and Motor B, respectively.

Important Considerations and Best Practices

- Ensure the power supply voltage and current do not exceed the board's ratings.

- Use PWM signals on D3 and D5 for speed control.

- Use digital HIGH/LOW signals on D2 and D4 to set the direction of the motors.

- Utilize D6 and D7 for braking functionality.

- Always double-check wiring to prevent short circuits or incorrect connections.

- Implement proper decoupling techniques to minimize noise and voltage spikes.

Troubleshooting and FAQs

Common Issues

- Motor not running: Check power supply connections and ensure the control signals are being sent from the Arduino.

- Overheating: Ensure the current draw is within the board's limits and provide adequate cooling if necessary.

- Inconsistent motor speed: Verify PWM signal integrity and check for any loose connections.

Solutions and Tips for Troubleshooting

- Double-check all connections, especially power and ground.

- Use a multimeter to verify voltage levels at various points in the circuit.

- Ensure the Arduino code is correctly generating PWM and digital control signals.

- If the board is not functioning, disconnect all power and inspect for any signs of damage or burnt components.

FAQs

Q: Can I control stepper motors with this board? A: No, this board is designed for DC motors. Stepper motors require a different type of driver.

Q: What is the maximum number of motors I can control with this board? A: You can control up to two motors independently with this board.

Q: Can I use this board without an Arduino? A: While designed for use with an Arduino, any microcontroller capable of providing the correct logic signals can be used.

Example Arduino Code

// Example code to control Motor A on the Keyestudio 8833 Motor Driver Expansion Board

const int motorASpeedPin = 3; // D3 for PWM speed control

const int motorADirectionPin = 2; // D2 for direction control

const int motorABrakePin = 6; // D6 for brake control

void setup() {

pinMode(motorASpeedPin, OUTPUT);

pinMode(motorADirectionPin, OUTPUT);

pinMode(motorABrakePin, OUTPUT);

}

void loop() {

// Set motor A direction to forward

digitalWrite(motorADirectionPin, HIGH);

// Disable motor A brake

digitalWrite(motorABrakePin, LOW);

// Ramp up the speed of motor A

for (int speed = 0; speed <= 255; speed++) {

analogWrite(motorASpeedPin, speed);

delay(10);

}

// Engage motor A brake

digitalWrite(motorABrakePin, HIGH);

delay(1000);

// Repeat the process for reverse direction and braking

}

Remember to keep the code comments concise and within the 80 character line length limit. This example demonstrates basic motor control including direction, speed, and braking.