How to Use Johnson motor: Examples, Pinouts, and Specs

Design with Johnson motor in Cirkit Designer

Design with Johnson motor in Cirkit DesignerIntroduction

The Johnson Motor by Johnson & Johnson (Part ID: Johnson Motor) is a high-performance DC motor renowned for its high torque and efficiency. This motor is widely used in various applications, including robotics, automotive systems, and industrial machinery. Its robust design and reliable performance make it a popular choice for both hobbyists and professionals.

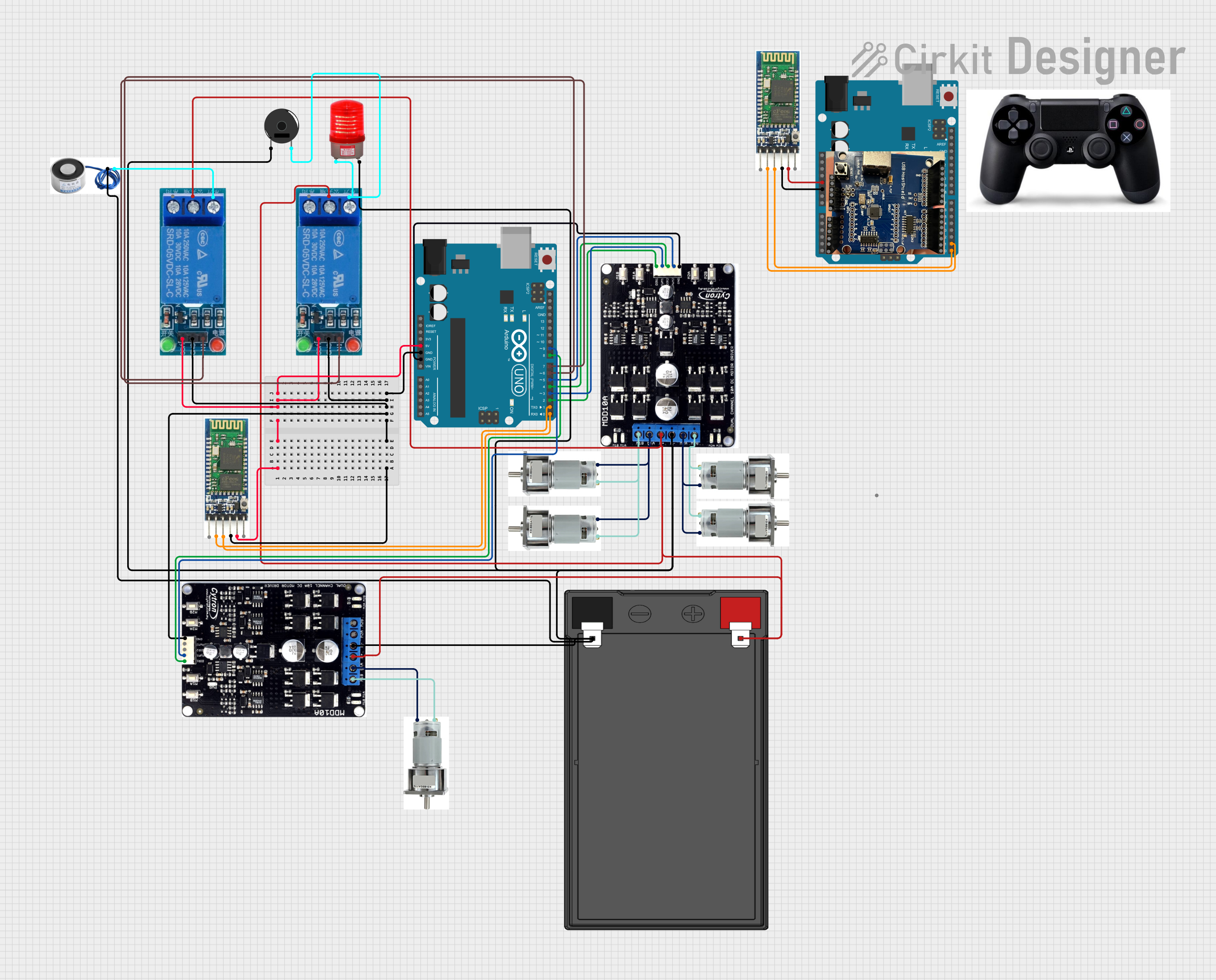

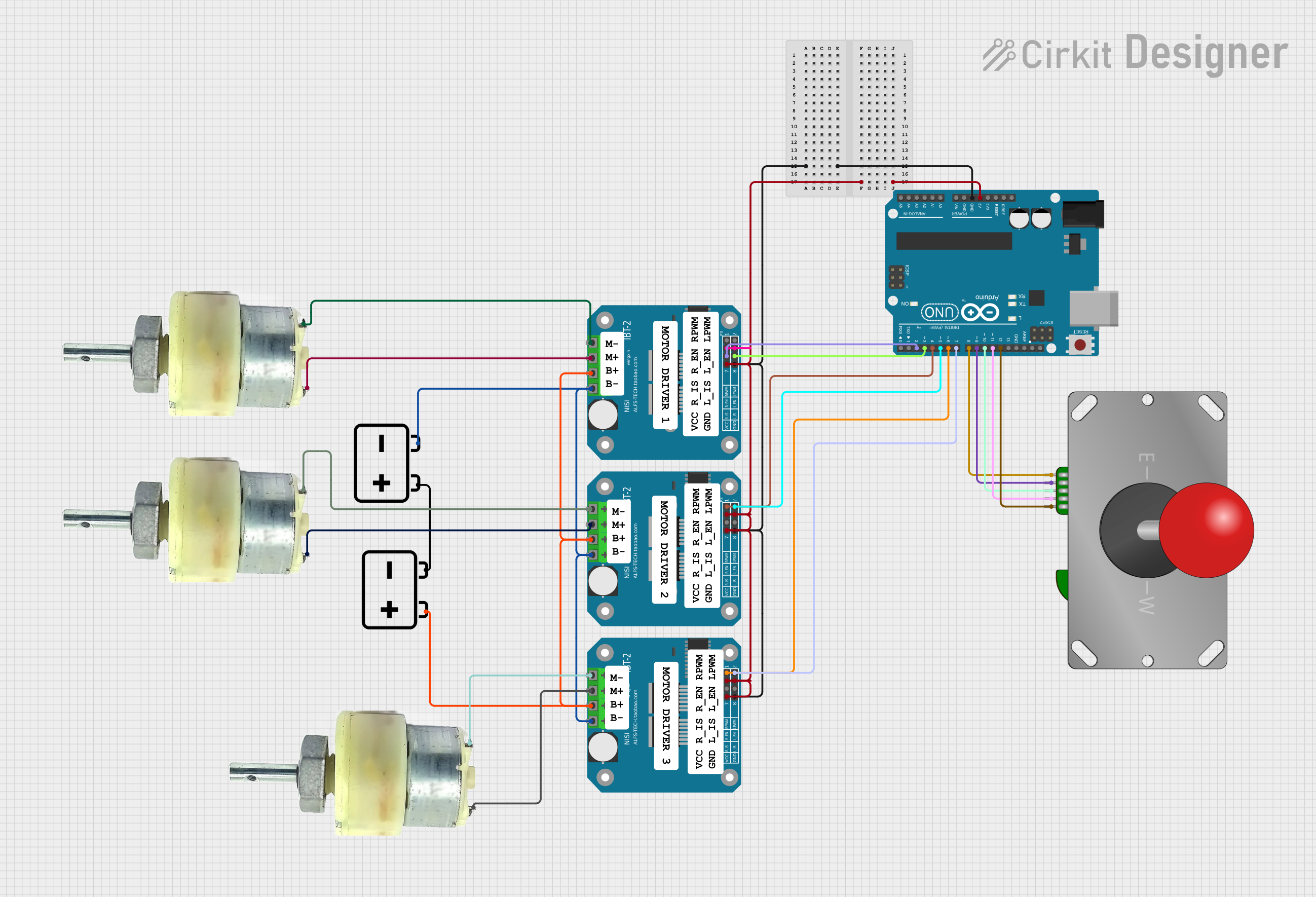

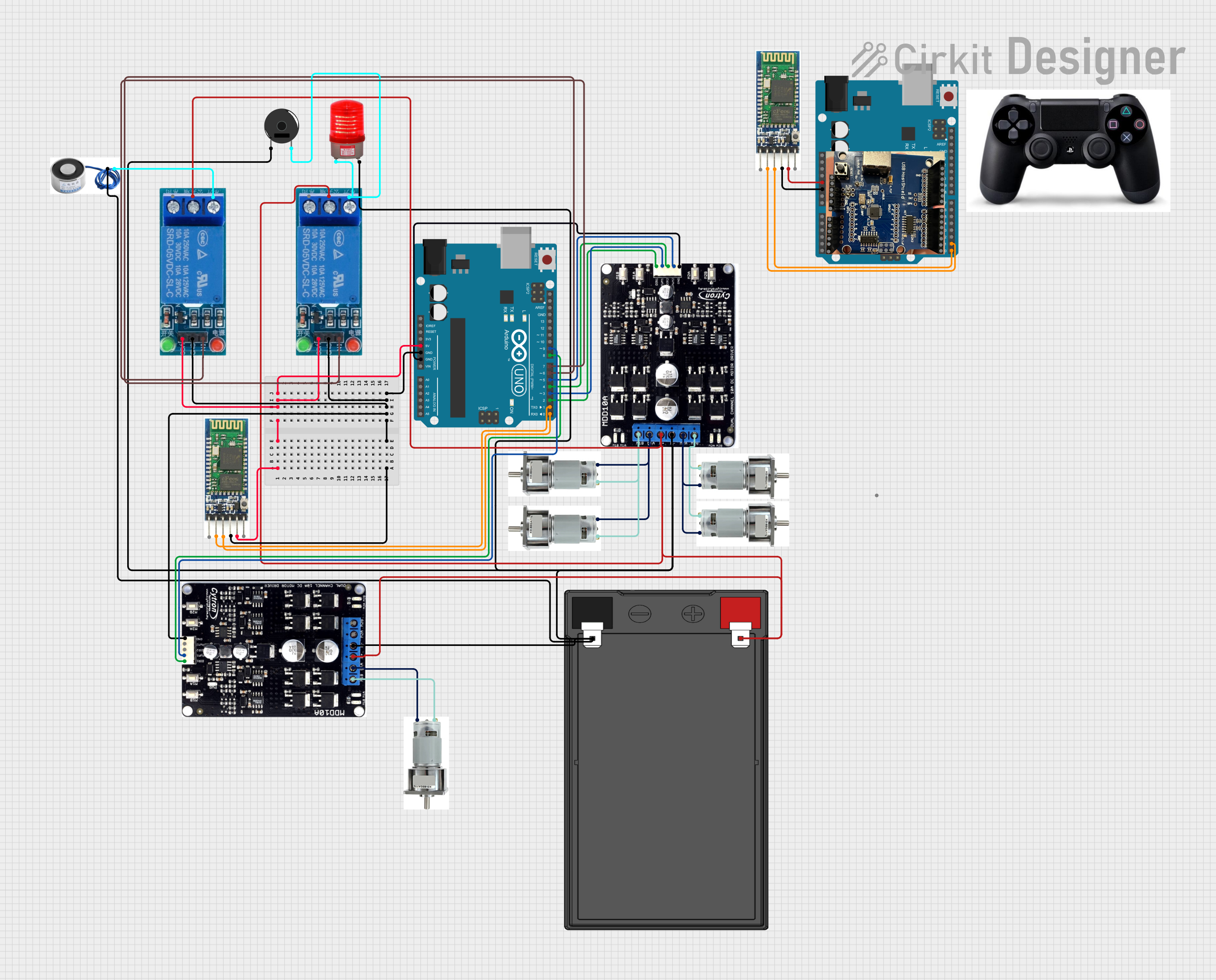

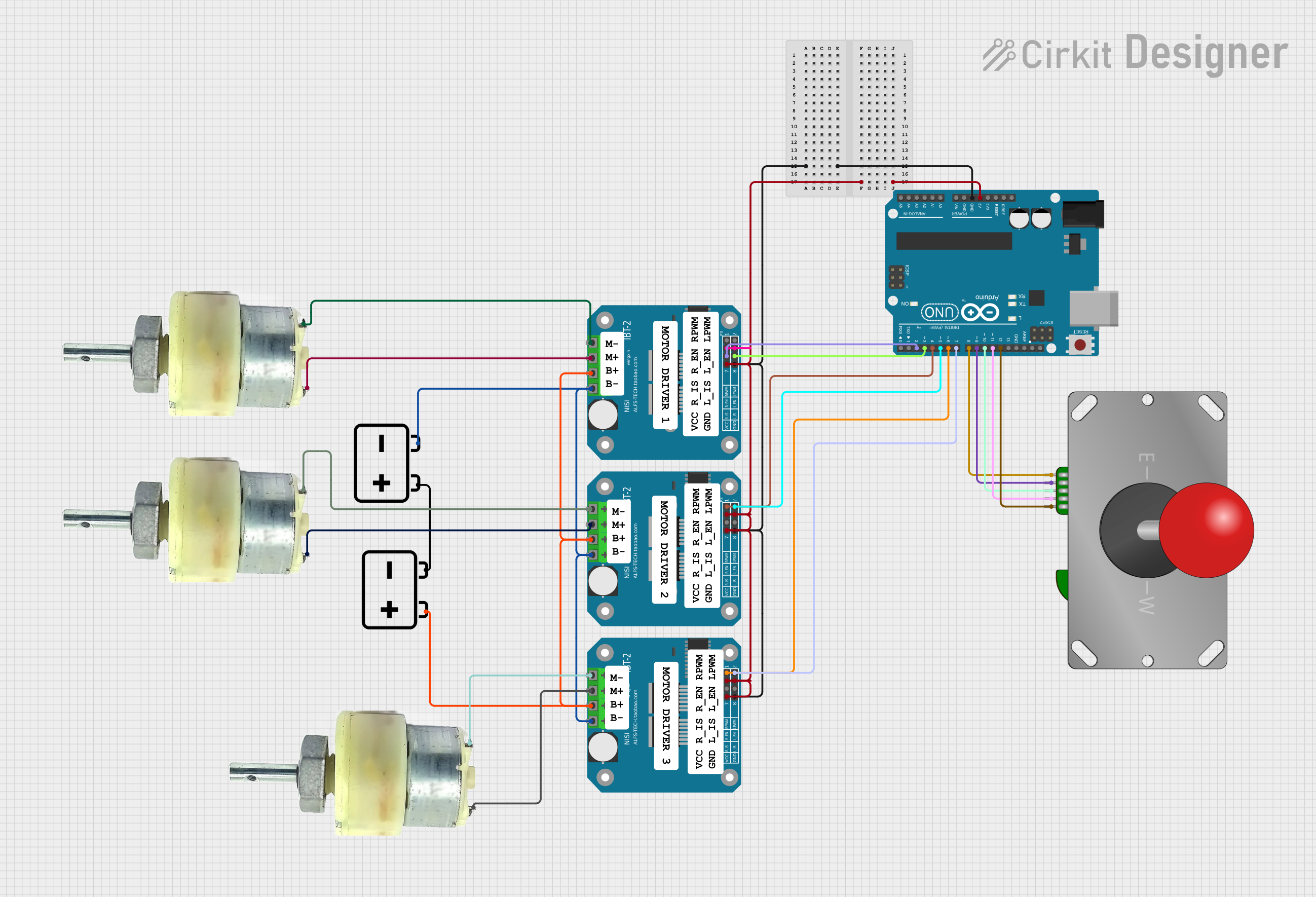

Explore Projects Built with Johnson motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Johnson motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Voltage Rating | 6V - 12V |

| Current Rating | 1.5A (no load) |

| Stall Current | 6A |

| Power Rating | 18W |

| Torque | 0.5 Nm |

| Speed | 3000 RPM (at 12V) |

| Shaft Diameter | 5mm |

| Motor Dimensions | 35mm x 50mm |

| Weight | 200g |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | V+ | Positive Voltage Input (6V - 12V) |

| 2 | V- | Ground (0V) |

| 3 | NC | Not Connected |

Usage Instructions

How to Use the Johnson Motor in a Circuit

- Power Supply: Connect the V+ pin to a power supply ranging from 6V to 12V. Ensure the power supply can provide sufficient current, especially considering the stall current of 6A.

- Ground Connection: Connect the V- pin to the ground of your power supply.

- Motor Driver: It is recommended to use a motor driver (e.g., L298N) to control the motor, especially if you are using a microcontroller like Arduino.

Important Considerations and Best Practices

- Heat Dissipation: Ensure proper heat dissipation as the motor can get hot during operation. Use heat sinks or cooling fans if necessary.

- Current Limiting: Use a current limiting circuit or fuse to protect the motor from overcurrent conditions.

- Mounting: Securely mount the motor to prevent vibrations and mechanical stress.

- Polarity: Ensure correct polarity when connecting the motor to avoid damage.

Example: Connecting to Arduino UNO

Circuit Diagram

Sample Code

// Johnson Motor Control with Arduino UNO

// This example demonstrates how to control the Johnson Motor using an L298N motor driver

const int motorPin1 = 9; // IN1 on the L298N

const int motorPin2 = 10; // IN2 on the L298N

const int enablePin = 11; // ENA on the L298N

void setup() {

// Set all the motor control pins to outputs

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

pinMode(enablePin, OUTPUT);

// Enable the motor

digitalWrite(enablePin, HIGH);

}

void loop() {

// Rotate the motor clockwise

digitalWrite(motorPin1, HIGH);

digitalWrite(motorPin2, LOW);

delay(2000); // Run for 2 seconds

// Stop the motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

delay(1000); // Stop for 1 second

// Rotate the motor counterclockwise

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, HIGH);

delay(2000); // Run for 2 seconds

// Stop the motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

delay(1000); // Stop for 1 second

}

Troubleshooting and FAQs

Common Issues

Motor Not Spinning:

- Solution: Check the power supply connections and ensure the voltage is within the specified range. Verify the motor driver connections and code.

Motor Overheating:

- Solution: Ensure proper ventilation and cooling. Check for overcurrent conditions and use a current limiting circuit if necessary.

Noisy Operation:

- Solution: Securely mount the motor and check for any loose connections. Use rubber mounts to reduce vibrations.

FAQs

Q1: Can I run the Johnson Motor at 5V?

- A1: It is not recommended to run the motor below 6V as it may not perform optimally and could lead to insufficient torque.

Q2: How can I reverse the motor direction?

- A2: To reverse the motor direction, swap the connections of the motor pins (V+ and V-) or use a motor driver to control the direction programmatically.

Q3: What is the maximum load the motor can handle?

- A3: The motor can handle a maximum torque of 0.5 Nm. Ensure the load does not exceed this limit to avoid damage.

This documentation provides a comprehensive guide to using the Johnson Motor by Johnson & Johnson. Whether you are a beginner or an experienced user, following these guidelines will help you effectively integrate this motor into your projects.