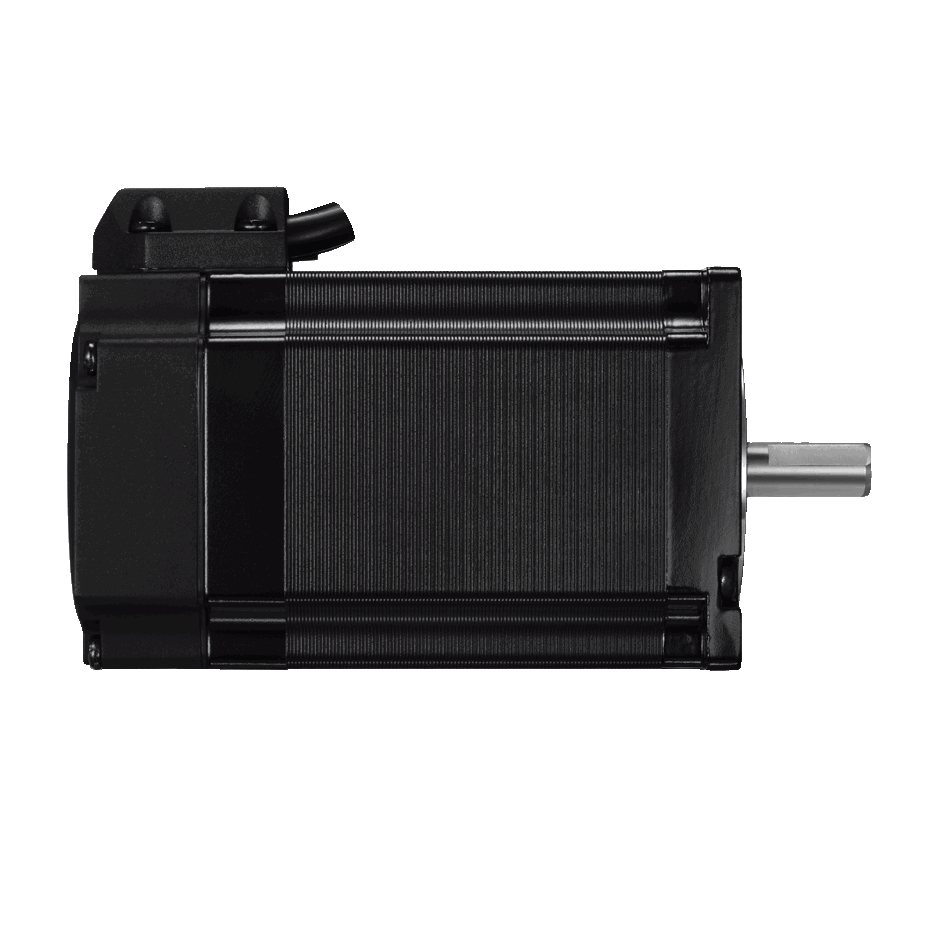

How to Use NEMA 23 Closed Loop Stepper System: Examples, Pinouts, and Specs

Design with NEMA 23 Closed Loop Stepper System in Cirkit Designer

Design with NEMA 23 Closed Loop Stepper System in Cirkit DesignerIntroduction

The NEMA 23 Closed Loop Stepper System (Leadshine CS-M22323) is a high-performance stepper motor system designed for precision motion control applications. This system integrates a NEMA 23 stepper motor with a closed-loop control mechanism, which ensures improved accuracy, reduced vibration, and enhanced torque performance compared to traditional open-loop stepper systems. The closed-loop feedback eliminates issues such as missed steps and provides smoother operation, making it ideal for demanding applications.

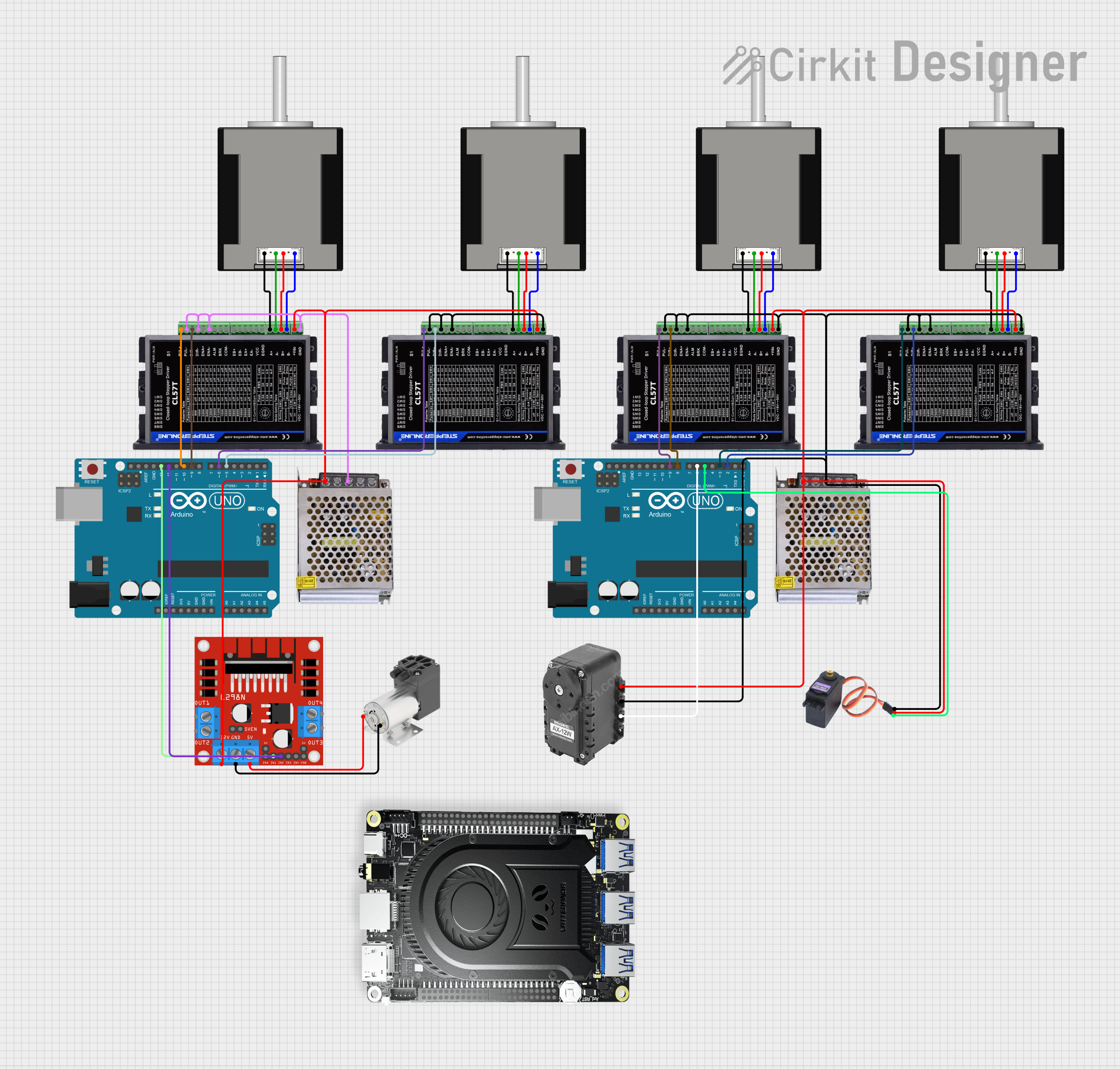

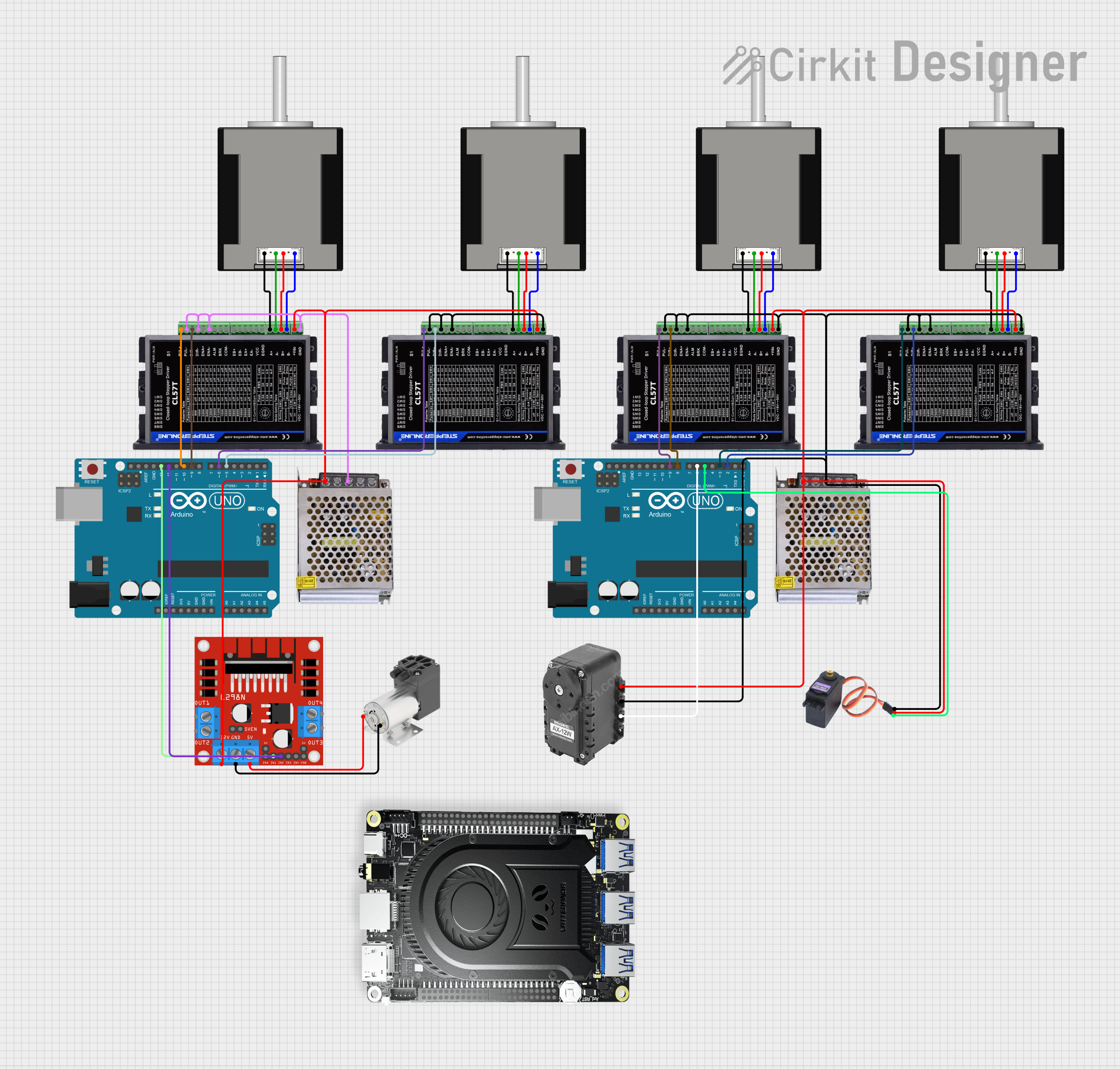

Explore Projects Built with NEMA 23 Closed Loop Stepper System

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with NEMA 23 Closed Loop Stepper System

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- CNC machines and 3D printers

- Robotics and automation systems

- Conveyor systems

- Medical devices requiring precise motion control

- Industrial equipment for positioning and actuation

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Motor Frame Size | NEMA 23 (57 x 57 mm) |

| Manufacturer Part ID | CS-M22323 |

| Control Type | Closed-loop (with encoder feedback) |

| Step Angle | 1.8° |

| Holding Torque | 2.3 Nm (325 oz-in) |

| Rated Current | 3.5 A |

| Voltage Range | 24 VDC to 50 VDC |

| Encoder Resolution | 1000 lines/rev (4000 counts/rev) |

| Communication Interface | Pulse/Direction or Step/Dir signals |

| Operating Temperature | -20°C to +50°C |

| Insulation Class | Class B |

Pin Configuration and Descriptions

The system includes a motor and a driver. Below is the pin configuration for the driver:

Driver Input Signals

| Pin Number | Signal Name | Description |

|---|---|---|

| 1 | PUL+ | Pulse signal input (positive) |

| 2 | PUL- | Pulse signal input (negative) |

| 3 | DIR+ | Direction signal input (positive) |

| 4 | DIR- | Direction signal input (negative) |

| 5 | ENA+ | Enable signal input (positive) |

| 6 | ENA- | Enable signal input (negative) |

Power and Motor Connections

| Pin Number | Signal Name | Description |

|---|---|---|

| 7 | V+ | Power supply positive (24-50 VDC) |

| 8 | V- | Power supply negative (GND) |

| 9 | A+ | Motor winding A+ |

| 10 | A- | Motor winding A- |

| 11 | B+ | Motor winding B+ |

| 12 | B- | Motor winding B- |

Encoder Feedback Signals

| Pin Number | Signal Name | Description |

|---|---|---|

| 13 | EA+ | Encoder A+ signal |

| 14 | EA- | Encoder A- signal |

| 15 | EB+ | Encoder B+ signal |

| 16 | EB- | Encoder B- signal |

| 17 | VCC | Encoder power supply (5 VDC) |

| 18 | GND | Encoder ground |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect a DC power supply (24-50 VDC) to the V+ and V- terminals of the driver. Ensure the power supply can provide sufficient current for the motor (at least 3.5 A).

- Motor Connections: Connect the motor windings to the A+, A-, B+, and B- terminals of the driver. Follow the wiring diagram provided in the manufacturer's datasheet to avoid incorrect connections.

- Control Signals:

- Connect the PUL+, PUL-, DIR+, and DIR- pins to a microcontroller or motion controller capable of generating pulse and direction signals.

- If using an Arduino UNO, use digital pins to generate the required signals.

- Encoder Feedback: Connect the encoder signals (EA+, EA-, EB+, EB-) to the corresponding pins on the driver. Ensure the encoder power supply (VCC and GND) is properly connected.

- Enable Signal: Optionally, connect the ENA+ and ENA- pins to enable or disable the motor driver via an external signal.

Important Considerations and Best Practices

- Power Supply: Use a regulated DC power supply within the specified voltage range to avoid damage to the driver or motor.

- Signal Integrity: Use shielded cables for control and encoder signals to minimize noise interference.

- Heat Dissipation: Ensure proper ventilation or heat sinking for the driver to prevent overheating during operation.

- Step Resolution: Configure the microstepping settings on the driver (if applicable) to achieve the desired resolution and smoothness.

- Wiring: Double-check all connections before powering on the system to prevent short circuits or incorrect wiring.

Example Code for Arduino UNO

Below is an example Arduino sketch to control the NEMA 23 Closed Loop Stepper System using pulse and direction signals:

// Define pin connections for the stepper driver

const int pulsePin = 2; // Pulse signal connected to digital pin 2

const int dirPin = 3; // Direction signal connected to digital pin 3

void setup() {

// Set pin modes

pinMode(pulsePin, OUTPUT);

pinMode(dirPin, OUTPUT);

// Set initial direction

digitalWrite(dirPin, HIGH); // HIGH for clockwise, LOW for counterclockwise

}

void loop() {

// Generate pulses to move the motor

digitalWrite(pulsePin, HIGH); // Set pulse pin HIGH

delayMicroseconds(500); // Pulse width (500 µs)

digitalWrite(pulsePin, LOW); // Set pulse pin LOW

delayMicroseconds(500); // Pulse interval (500 µs)

}

Note: Adjust the

delayMicrosecondsvalues to control the motor speed. A shorter delay results in higher speed, while a longer delay reduces speed.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Verify the power supply voltage and current are within the specified range.

- Check the pulse and direction signal connections.

- Ensure the enable signal (ENA+ and ENA-) is active (if used).

Missed Steps or Erratic Movement:

- Ensure the encoder feedback signals are properly connected.

- Use shielded cables to reduce noise interference.

- Verify the microstepping settings on the driver.

Overheating:

- Check for proper ventilation or heat sinking for the driver.

- Reduce the motor current setting if possible.

No Encoder Feedback:

- Verify the encoder power supply (VCC and GND) connections.

- Check the encoder signal wiring (EA+, EA-, EB+, EB-).

FAQs

Can I use this system with an Arduino? Yes, the system can be controlled using an Arduino or any microcontroller capable of generating pulse and direction signals.

What is the advantage of closed-loop control? Closed-loop control provides higher accuracy, eliminates missed steps, and improves torque performance compared to open-loop systems.

What is the maximum speed of the motor? The maximum speed depends on the pulse frequency and load conditions. Refer to the manufacturer's datasheet for detailed performance curves.

Can I use a higher voltage power supply? No, the power supply voltage must not exceed 50 VDC to avoid damaging the driver.