How to Use vibration motor module: Examples, Pinouts, and Specs

Design with vibration motor module in Cirkit Designer

Design with vibration motor module in Cirkit DesignerIntroduction

A vibration motor module is a small device that converts electrical energy into mechanical vibrations. It typically consists of a motor with an unbalanced weight attached to its shaft, which creates vibrations when the motor spins. These modules are widely used in applications requiring haptic feedback, such as mobile devices, wearables, and robotics. They are also employed in alert systems, gaming controllers, and other interactive devices to provide tactile feedback to users.

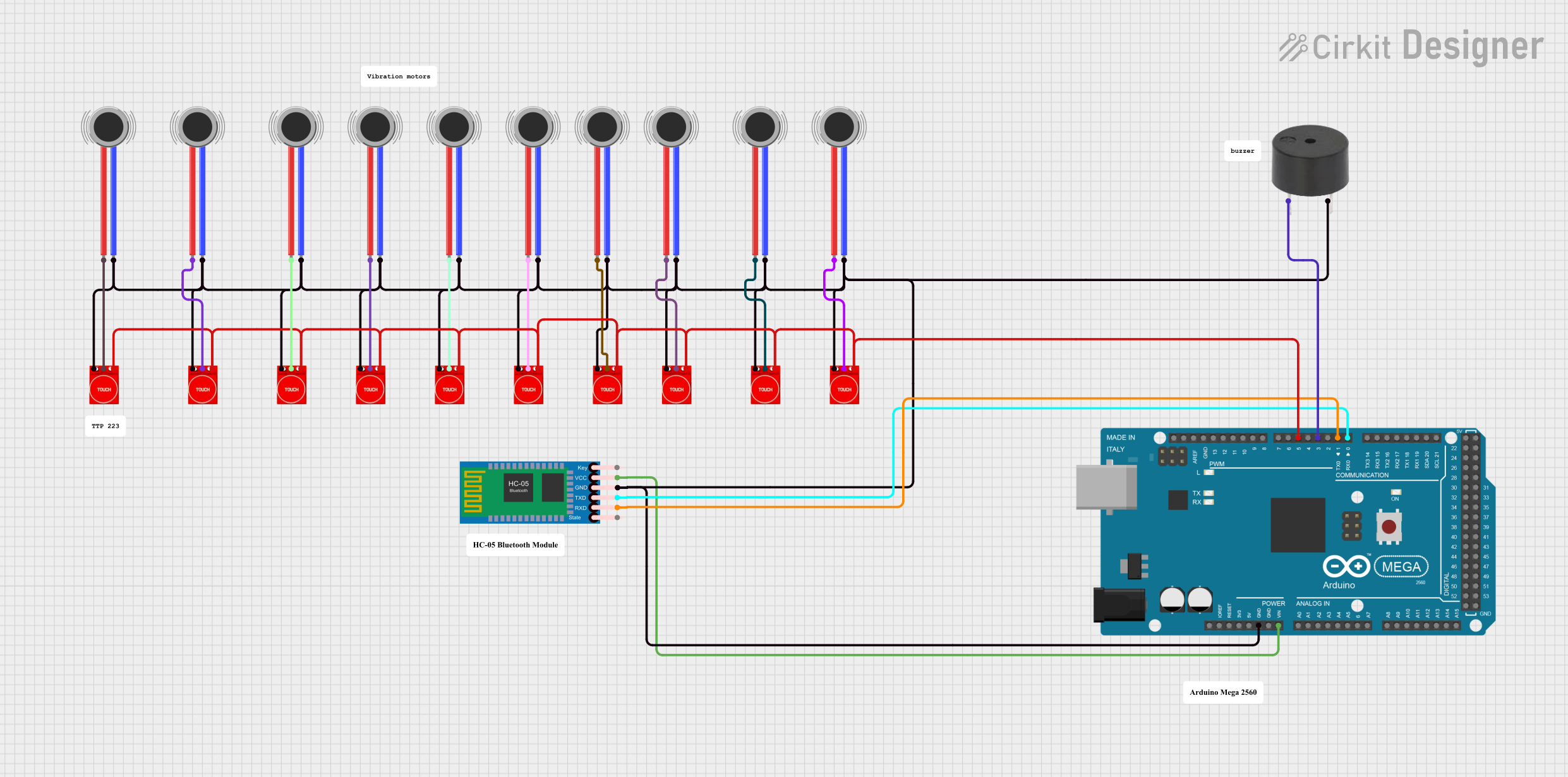

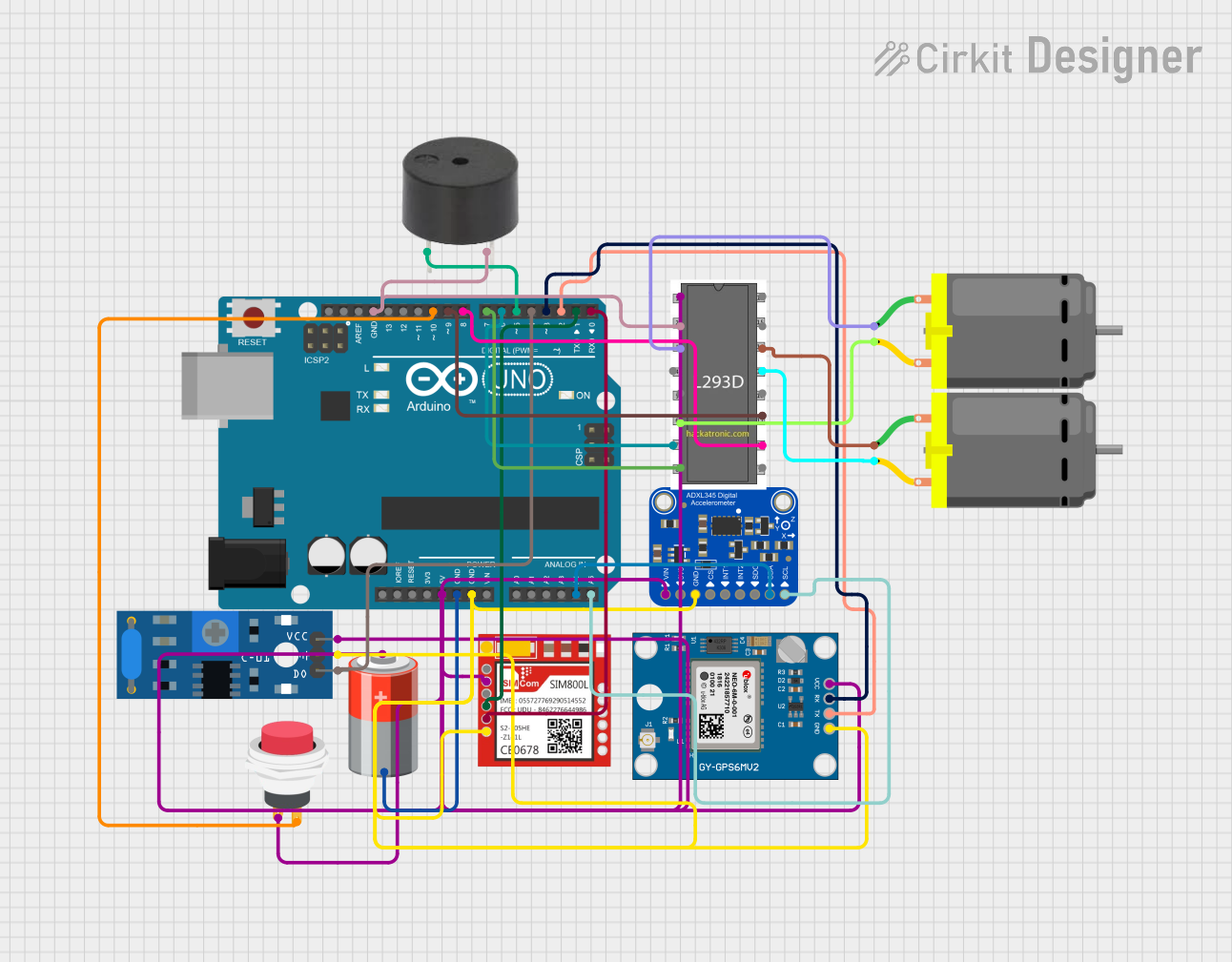

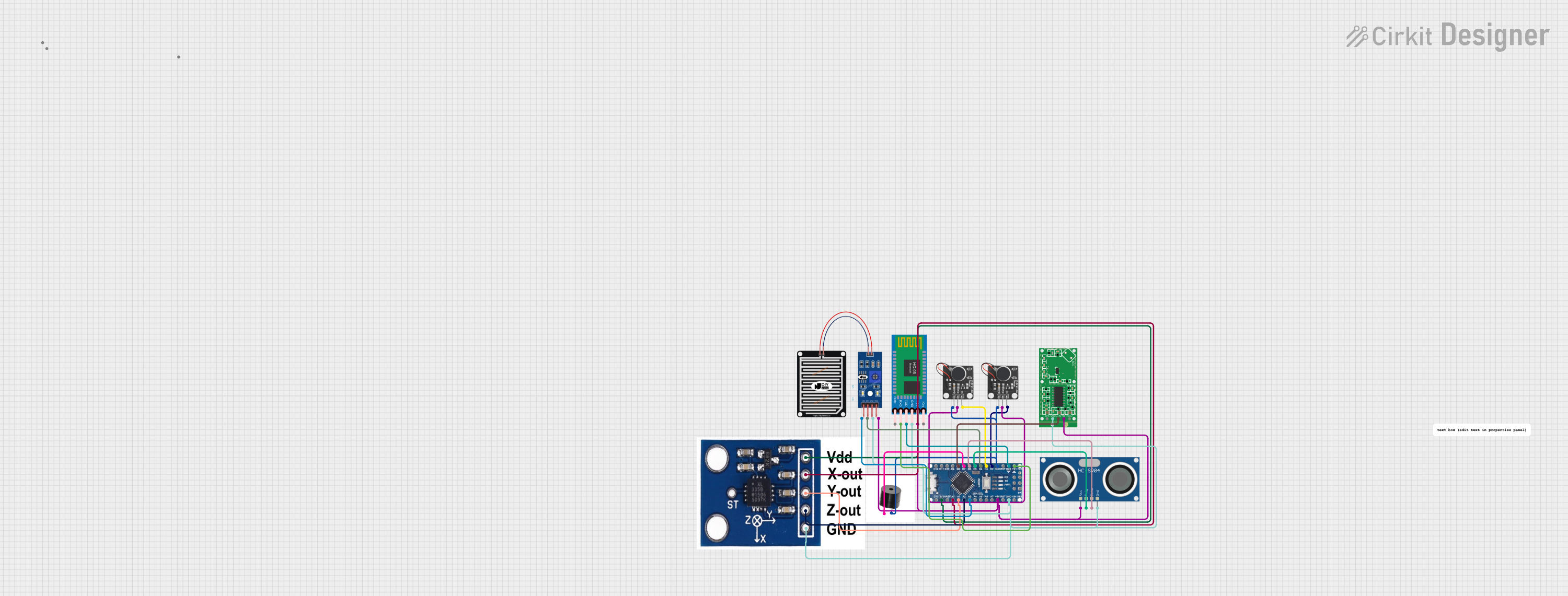

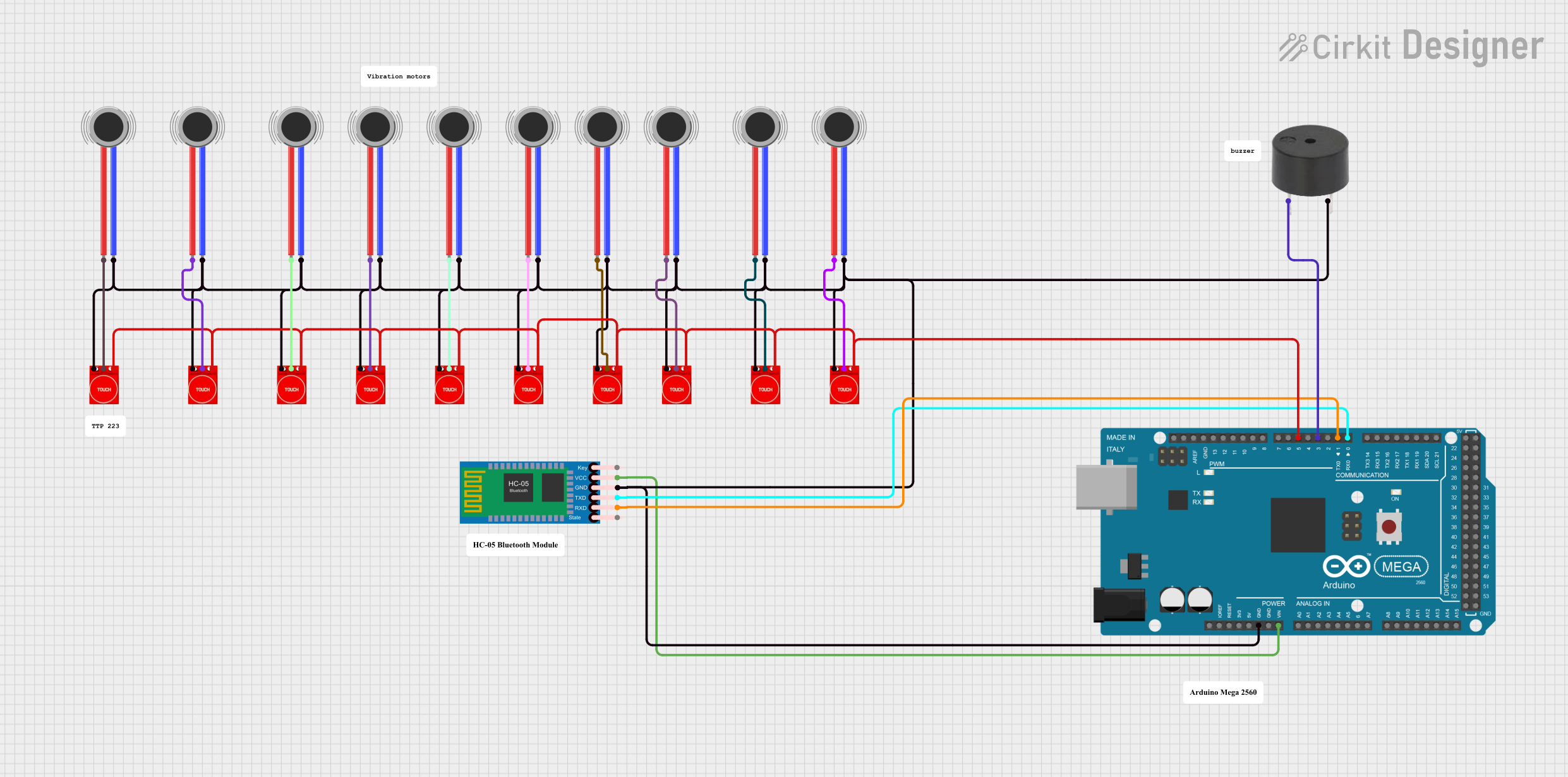

Explore Projects Built with vibration motor module

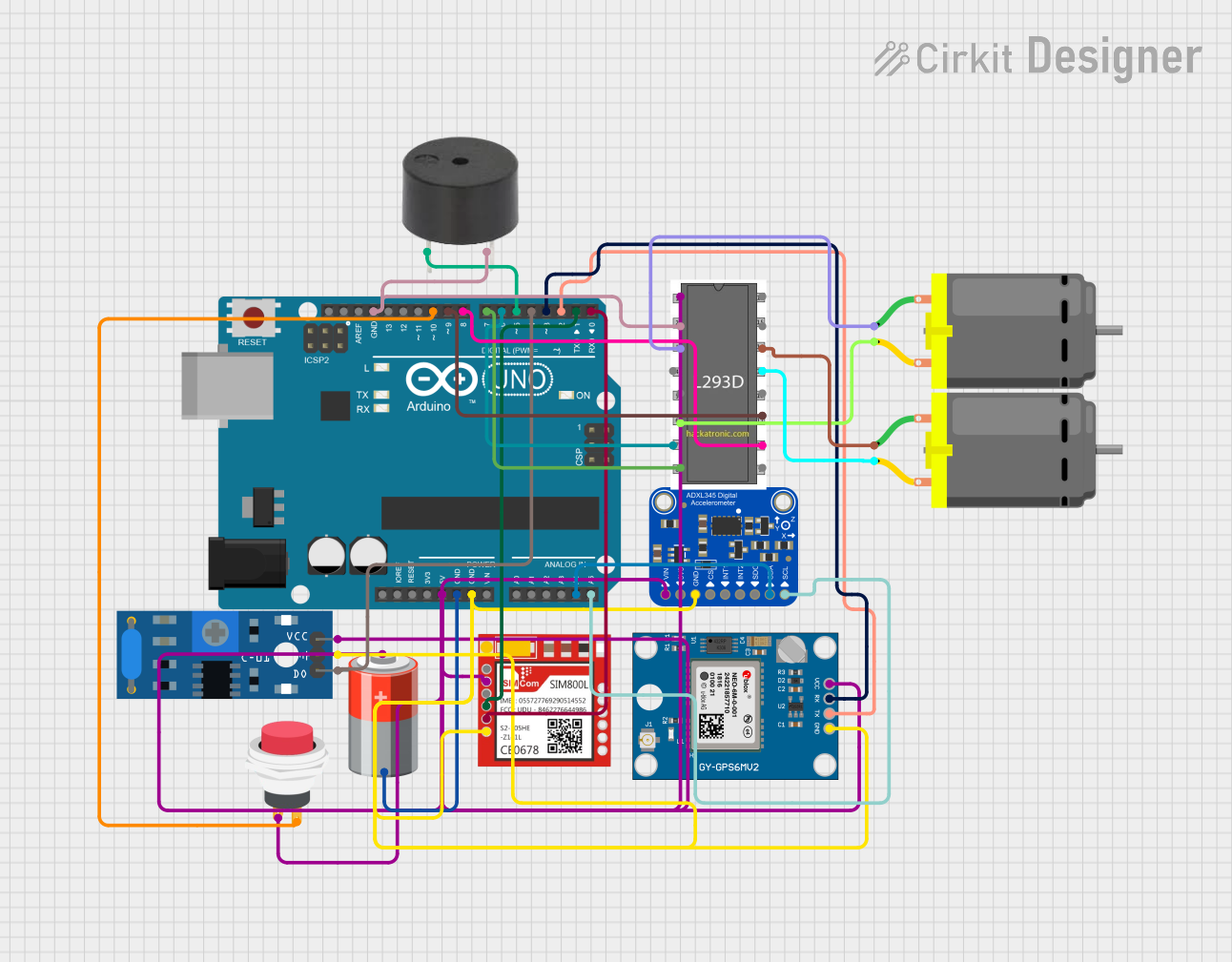

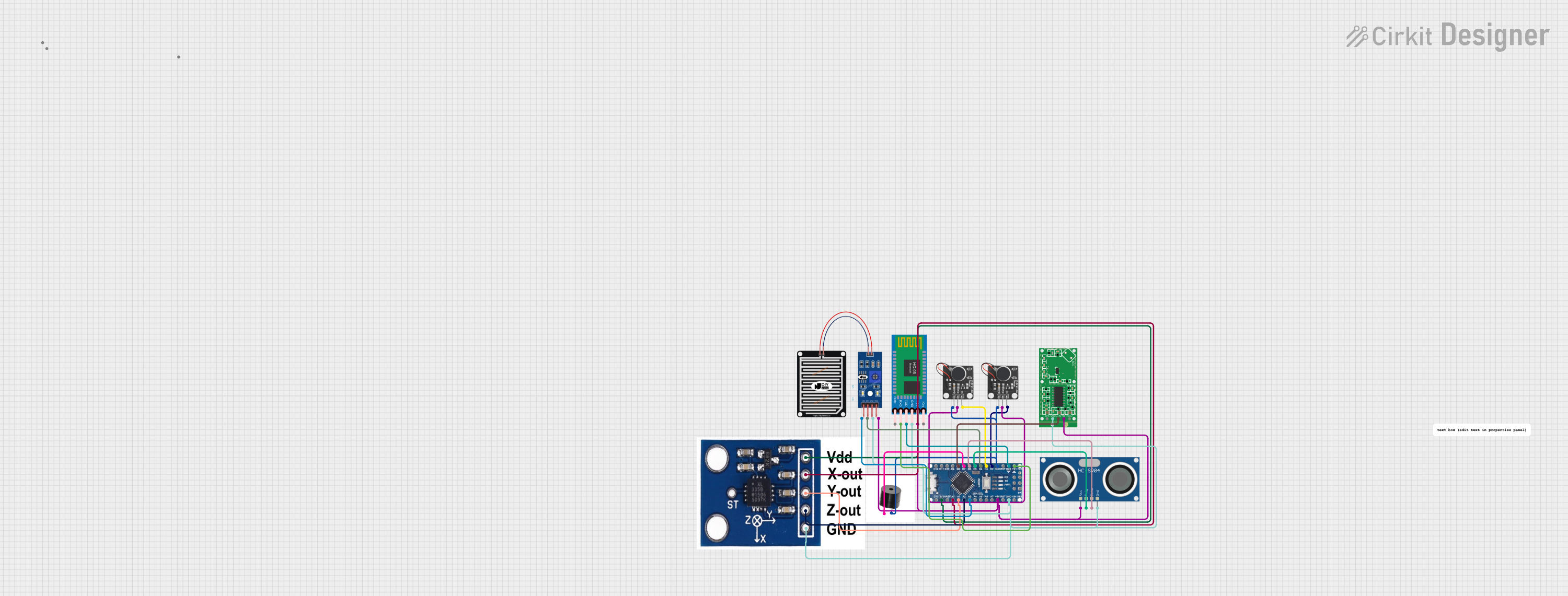

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with vibration motor module

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications:

- Haptic feedback in mobile phones and wearables

- Robotics for tactile signaling

- Gaming controllers for immersive experiences

- Alert systems in industrial or medical devices

- Educational and DIY electronics projects

Technical Specifications

Key Technical Details:

- Operating Voltage: 3.3V to 5V DC

- Operating Current: ~80mA (typical)

- Motor Type: DC motor with an eccentric rotating mass (ERM)

- Vibration Frequency: ~100 Hz (varies with voltage)

- Dimensions: ~27mm x 12mm x 10mm (module size)

- Weight: ~5g

- Control Type: Digital (ON/OFF) or PWM for intensity control

Pin Configuration and Descriptions:

| Pin Name | Description |

|---|---|

| VCC | Power supply input (3.3V to 5V DC) |

| GND | Ground connection |

| IN | Control signal input (Digital or PWM) |

Usage Instructions

How to Use the Vibration Motor Module in a Circuit:

- Power the Module: Connect the

VCCpin to a 3.3V or 5V power source and theGNDpin to the ground of your circuit. - Control the Motor: Use the

INpin to control the motor. A HIGH signal (3.3V or 5V) will activate the motor, while a LOW signal (0V) will turn it off. - PWM Control (Optional): To adjust the vibration intensity, provide a PWM signal to the

INpin. The duty cycle of the PWM signal determines the motor's speed and, consequently, the vibration intensity.

Important Considerations and Best Practices:

- Power Supply: Ensure the power supply can provide sufficient current (~80mA) to drive the motor.

- Signal Voltage: Match the control signal voltage to the module's operating voltage (3.3V or 5V).

- Decoupling Capacitor: Add a small decoupling capacitor (e.g., 0.1µF) across the power pins to reduce noise.

- Mounting: Secure the module firmly to prevent unwanted movement during operation.

- Prolonged Use: Avoid running the motor continuously for extended periods to prevent overheating.

Example: Connecting to an Arduino UNO

Below is an example of how to connect and control the vibration motor module using an Arduino UNO:

Circuit Connections:

- Connect the

VCCpin of the module to the 5V pin on the Arduino. - Connect the

GNDpin of the module to the GND pin on the Arduino. - Connect the

INpin of the module to digital pin 9 on the Arduino.

Arduino Code:

// Vibration Motor Module Example Code

// This code demonstrates how to control the vibration motor module

// using an Arduino UNO. The motor will vibrate for 1 second, then stop

// for 1 second, in a loop.

#define MOTOR_PIN 9 // Define the pin connected to the IN pin of the module

void setup() {

pinMode(MOTOR_PIN, OUTPUT); // Set the motor pin as an output

}

void loop() {

digitalWrite(MOTOR_PIN, HIGH); // Turn the motor ON

delay(1000); // Wait for 1 second

digitalWrite(MOTOR_PIN, LOW); // Turn the motor OFF

delay(1000); // Wait for 1 second

}

Adjusting Vibration Intensity with PWM:

To control the vibration intensity, replace digitalWrite() with analogWrite() in the code. For example:

analogWrite(MOTOR_PIN, 128); // Set motor intensity to 50% (128 out of 255)

Troubleshooting and FAQs

Common Issues and Solutions:

Motor Not Vibrating:

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power supply voltage and current. Check all connections.

Weak or No Vibration:

- Cause: Low PWM duty cycle or insufficient voltage.

- Solution: Increase the PWM duty cycle or ensure the supply voltage is within the specified range.

Overheating:

- Cause: Prolonged continuous operation or excessive voltage.

- Solution: Limit the motor's runtime and ensure the supply voltage does not exceed 5V.

Noise in Circuit:

- Cause: Motor operation causing electrical noise.

- Solution: Add a decoupling capacitor across the power pins and use proper grounding.

FAQs:

Q: Can I use the module with a 3.3V microcontroller?

A: Yes, the module is compatible with 3.3V systems. Ensure the control signal matches the operating voltage.Q: How do I reduce vibration intensity?

A: Use a PWM signal on theINpin to control the motor speed and vibration intensity.Q: Can I run the motor continuously?

A: While the motor can run continuously, it is recommended to allow periodic rest to prevent overheating.Q: Is the module polarity-sensitive?

A: Yes, ensure correct polarity when connecting the power supply to avoid damage.

This documentation provides a comprehensive guide to understanding, using, and troubleshooting the vibration motor module.