How to Use 3s bms: Examples, Pinouts, and Specs

Design with 3s bms in Cirkit Designer

Design with 3s bms in Cirkit DesignerIntroduction

A 3S BMS (Battery Management System) is a circuit protection and monitoring device designed specifically for a 3-cell lithium-ion or lithium-polymer battery pack. It ensures the safe operation of the battery pack by balancing cell voltages, preventing overcharging, overdischarging, and overcurrent situations. This component is crucial for maintaining the longevity and safety of battery packs used in various applications.

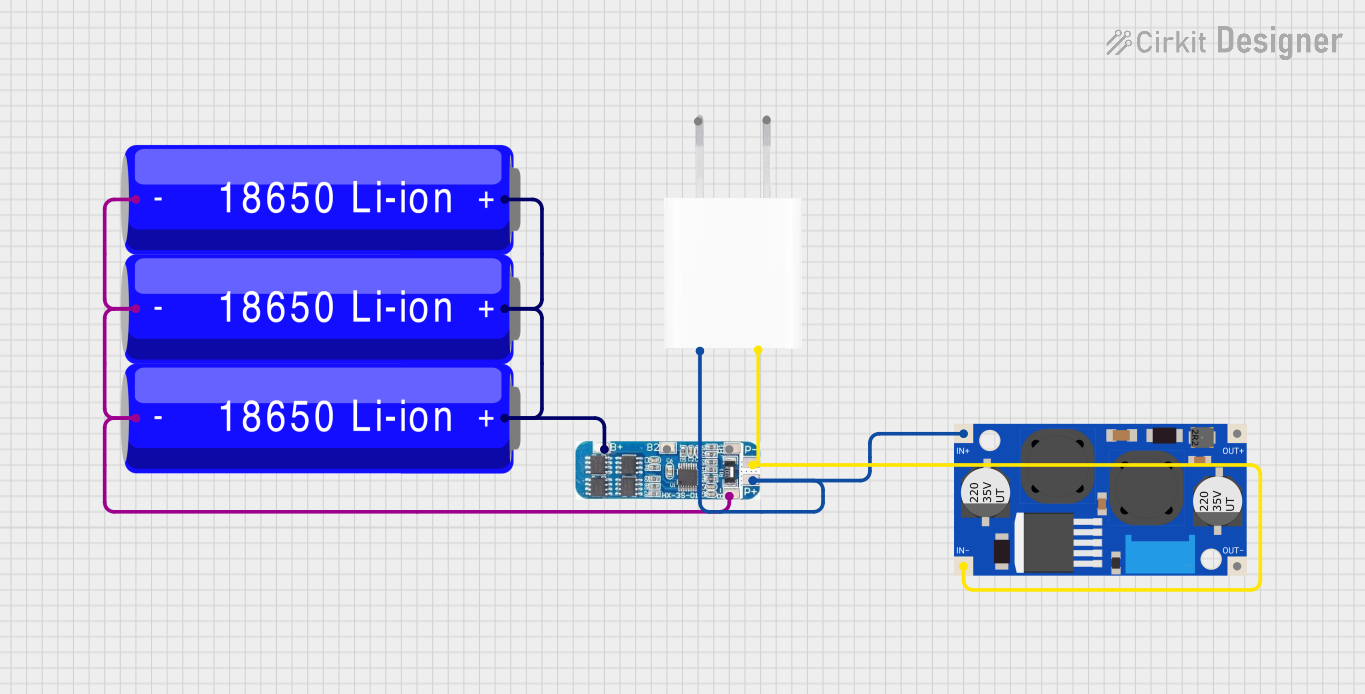

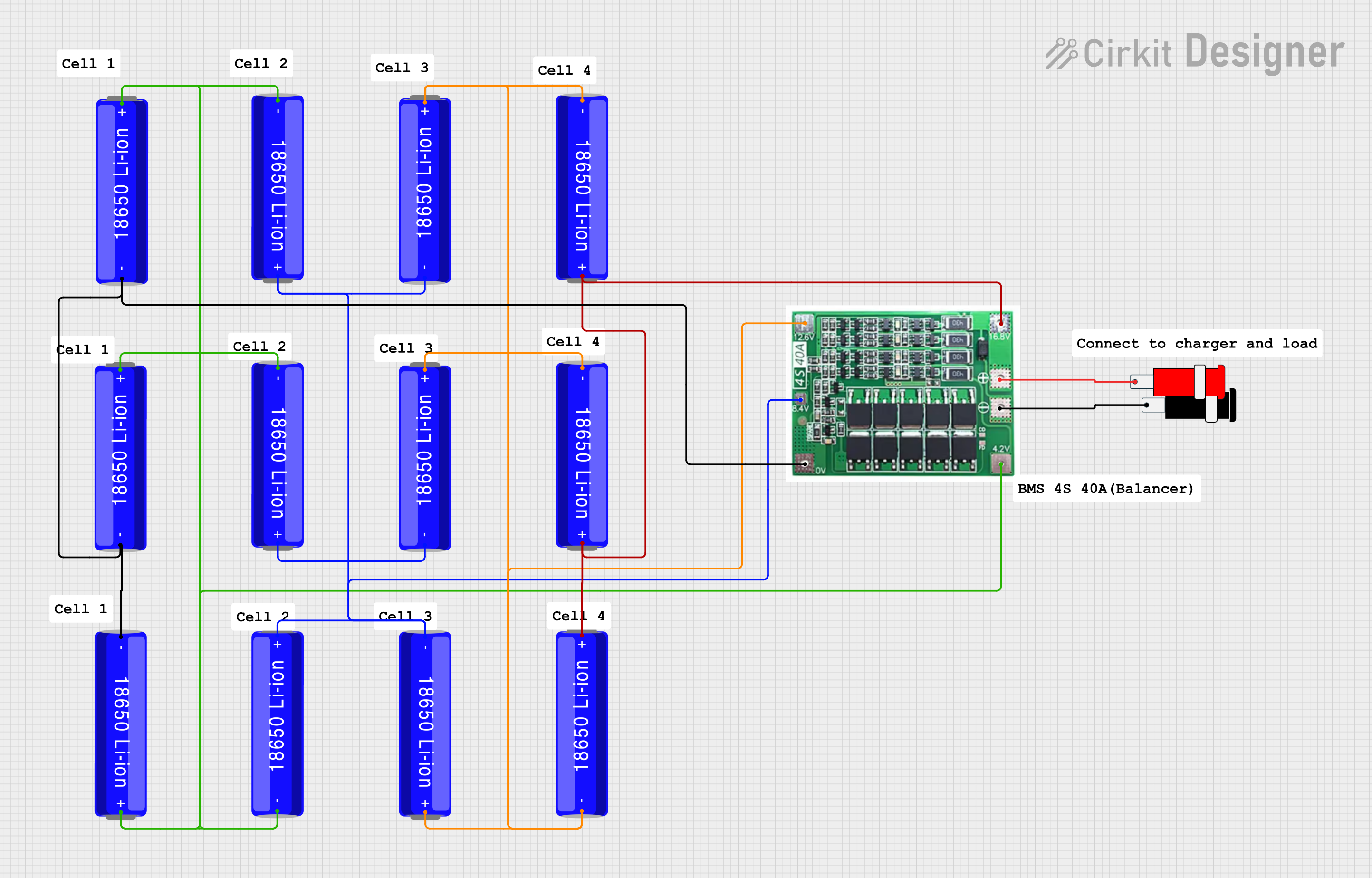

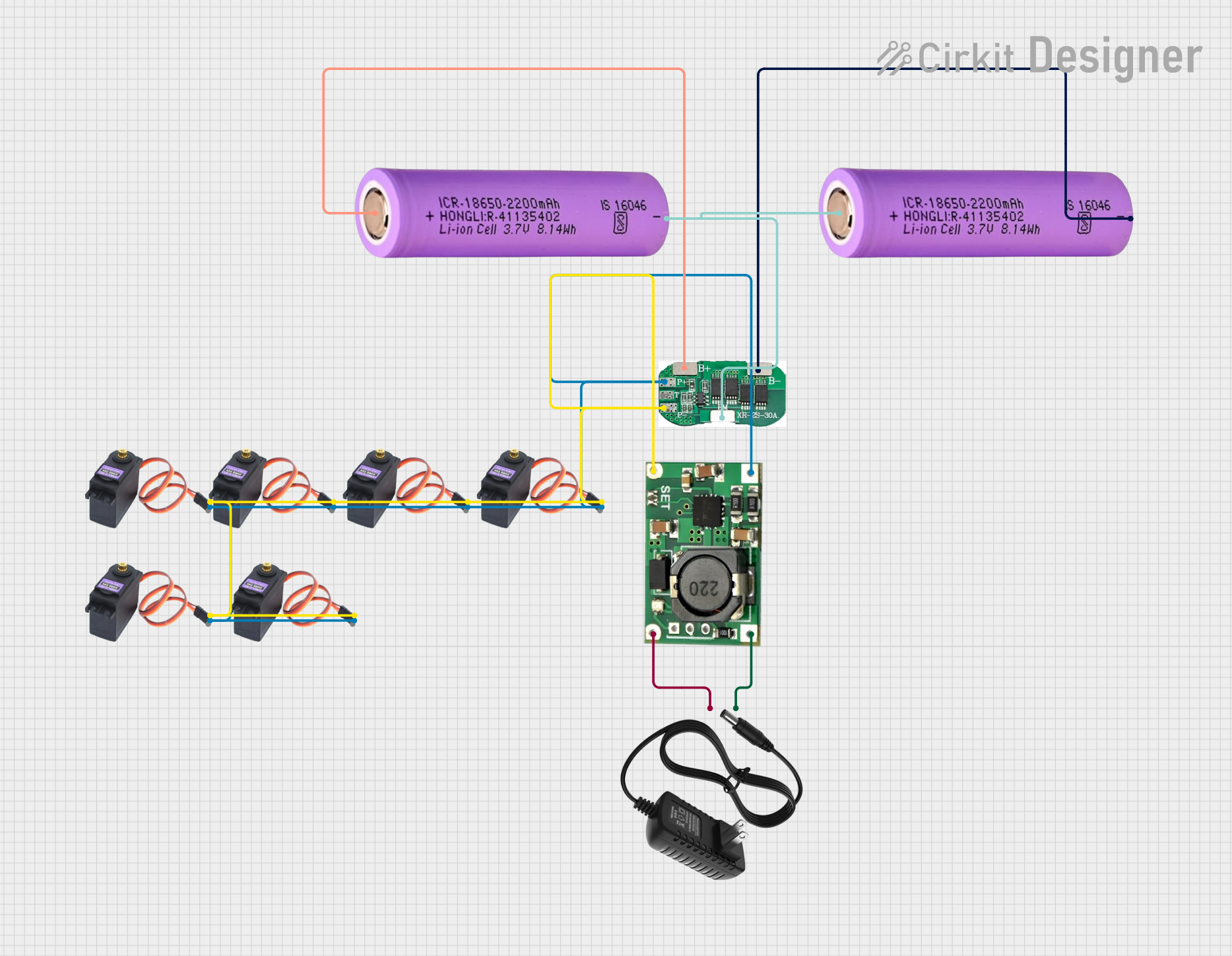

Explore Projects Built with 3s bms

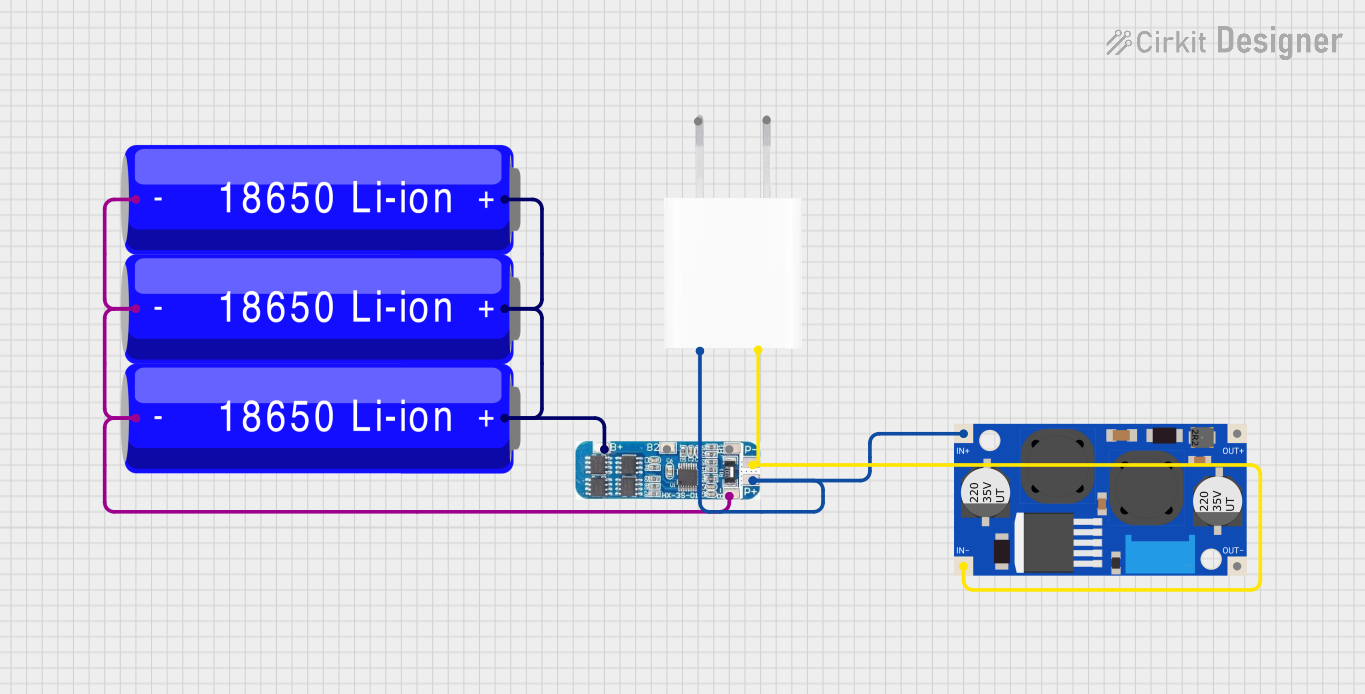

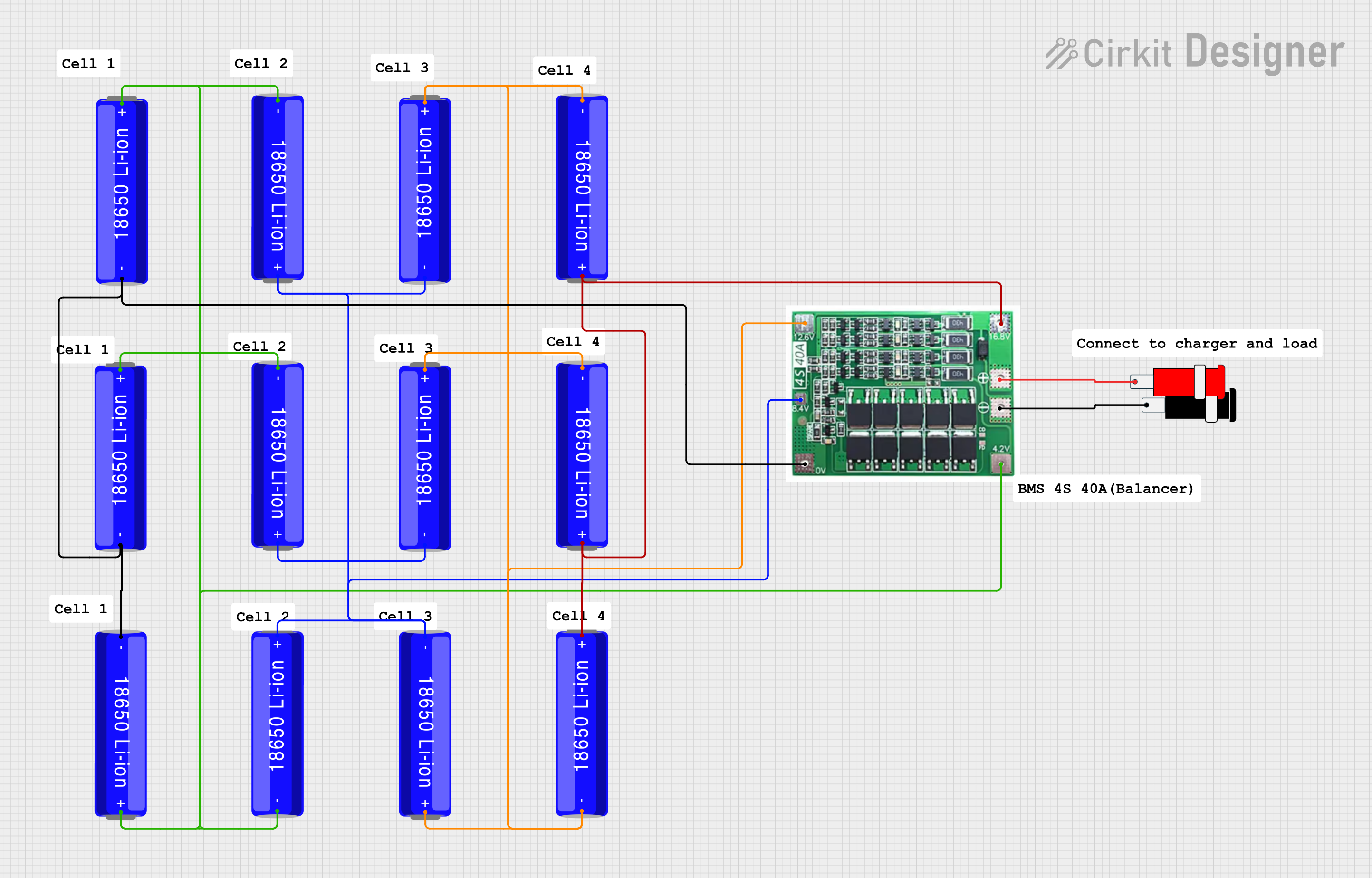

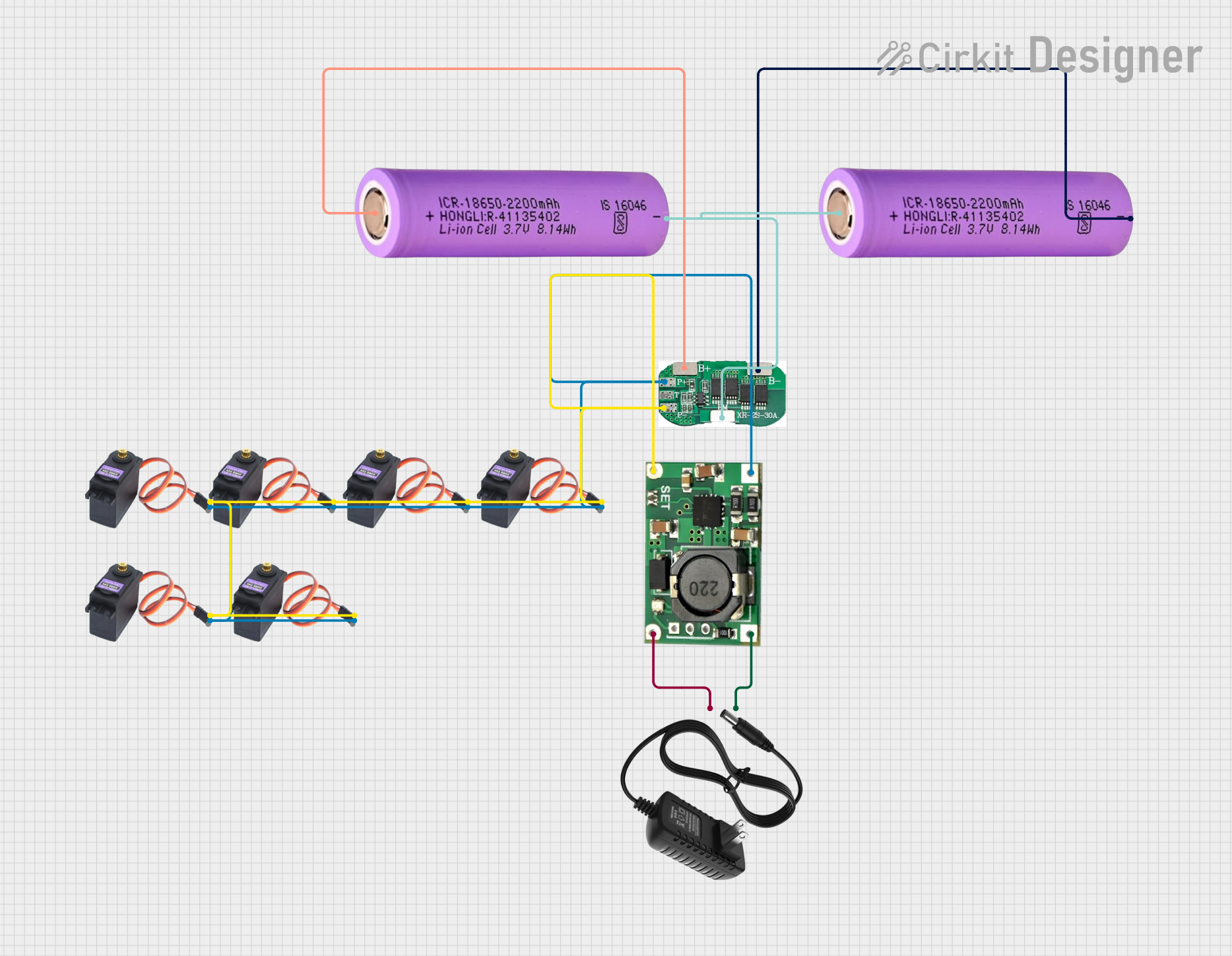

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 3s bms

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Electric vehicles (e-bikes, e-scooters)

- Portable power banks

- Solar energy storage systems

- Uninterruptible power supplies (UPS)

- Remote-controlled devices (drones, RC cars)

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Battery Configuration | 3S (3 cells in series) |

| Overcharge Protection | 4.25V ± 0.05V per cell |

| Overdischarge Protection | 2.5V ± 0.1V per cell |

| Overcurrent Protection | 20A (typical) |

| Balancing Current | 42mA ± 5mA |

| Operating Temperature | -40°C to 85°C |

| Storage Temperature | -40°C to 125°C |

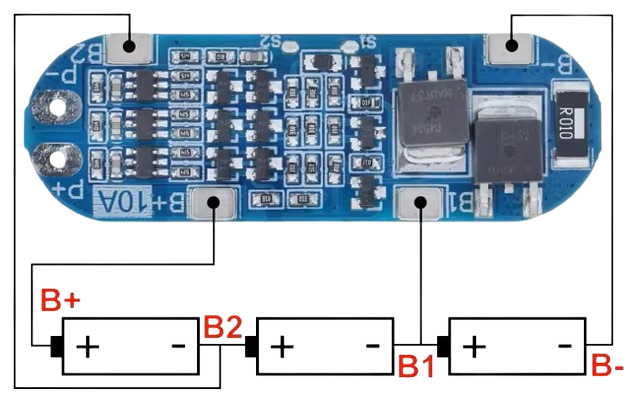

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | B- | Battery negative terminal |

| 2 | B1 | Connection to the positive terminal of cell 1 |

| 3 | B2 | Connection to the positive terminal of cell 2 |

| 4 | B3 | Connection to the positive terminal of cell 3 |

| 5 | P- | Power output negative terminal |

| 6 | P+ | Power output positive terminal |

Usage Instructions

How to Use the Component in a Circuit

Connect the Battery Pack:

- Connect the negative terminal of the battery pack to the B- pin.

- Connect the positive terminal of the first cell to the B1 pin.

- Connect the positive terminal of the second cell to the B2 pin.

- Connect the positive terminal of the third cell to the B3 pin.

Connect the Load/Charger:

- Connect the negative terminal of the load/charger to the P- pin.

- Connect the positive terminal of the load/charger to the P+ pin.

Important Considerations and Best Practices

- Ensure Proper Connections: Double-check all connections to avoid short circuits or incorrect wiring.

- Use Appropriate Wire Gauges: Use wires that can handle the current rating of the BMS to prevent overheating.

- Monitor Temperature: Ensure the BMS operates within the specified temperature range to avoid damage.

- Avoid Overloading: Do not exceed the overcurrent protection limit to maintain the safety and longevity of the BMS.

Troubleshooting and FAQs

Common Issues Users Might Face

BMS Not Balancing Cells:

- Solution: Ensure all cell connections are secure and the cells are within the voltage range for balancing.

Overcurrent Protection Triggering Frequently:

- Solution: Check for short circuits or reduce the load to stay within the BMS's current rating.

Overcharge/Overdischarge Protection Activating:

- Solution: Verify the charger and load specifications to ensure they are compatible with the BMS settings.

FAQs

Q1: Can I use the 3S BMS with a different battery configuration?

- A1: No, the 3S BMS is specifically designed for a 3-cell series configuration. Using it with a different configuration may result in improper operation and potential damage.

Q2: How do I know if the BMS is balancing the cells?

- A2: You can measure the voltage of each cell. If the voltages are close to each other, the BMS is balancing the cells correctly.

Q3: Can I connect the 3S BMS to an Arduino UNO for monitoring?

- A3: Yes, you can use an Arduino UNO to monitor the cell voltages and overall battery pack status. Below is an example code snippet for reading cell voltages using an Arduino UNO:

// Example code to read cell voltages using Arduino UNO

// Connect B1, B2, B3 to analog pins A0, A1, A2 respectively

const int cell1Pin = A0; // Pin connected to B1

const int cell2Pin = A1; // Pin connected to B2

const int cell3Pin = A2; // Pin connected to B3

void setup() {

Serial.begin(9600); // Initialize serial communication

}

void loop() {

float cell1Voltage = analogRead(cell1Pin) * (5.0 / 1023.0) * 2; // Read and convert voltage

float cell2Voltage = analogRead(cell2Pin) * (5.0 / 1023.0) * 2; // Read and convert voltage

float cell3Voltage = analogRead(cell3Pin) * (5.0 / 1023.0) * 2; // Read and convert voltage

Serial.print("Cell 1 Voltage: ");

Serial.print(cell1Voltage);

Serial.println(" V");

Serial.print("Cell 2 Voltage: ");

Serial.print(cell2Voltage);

Serial.println(" V");

Serial.print("Cell 3 Voltage: ");

Serial.print(cell3Voltage);

Serial.println(" V");

delay(1000); // Wait for 1 second before next reading

}

This code reads the voltages of the three cells and prints them to the serial monitor. Ensure that the voltage divider resistors are used if the cell voltages exceed the Arduino's analog input range.

By following this documentation, users can effectively utilize the 3S BMS in their projects, ensuring safe and efficient battery management.