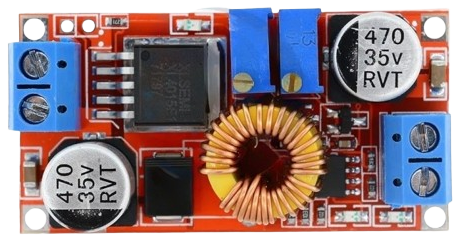

How to Use Regulator Stepdown DC XL4015 CC CV (Biggest): Examples, Pinouts, and Specs

Design with Regulator Stepdown DC XL4015 CC CV (Biggest) in Cirkit Designer

Design with Regulator Stepdown DC XL4015 CC CV (Biggest) in Cirkit DesignerIntroduction

The XL4015 is a buck converter module that steps down DC voltage while maintaining a constant current (CC) and constant voltage (CV). This electronic component is widely used in battery charging, power supplies, LED drivers, and other applications where voltage and current regulation are critical.

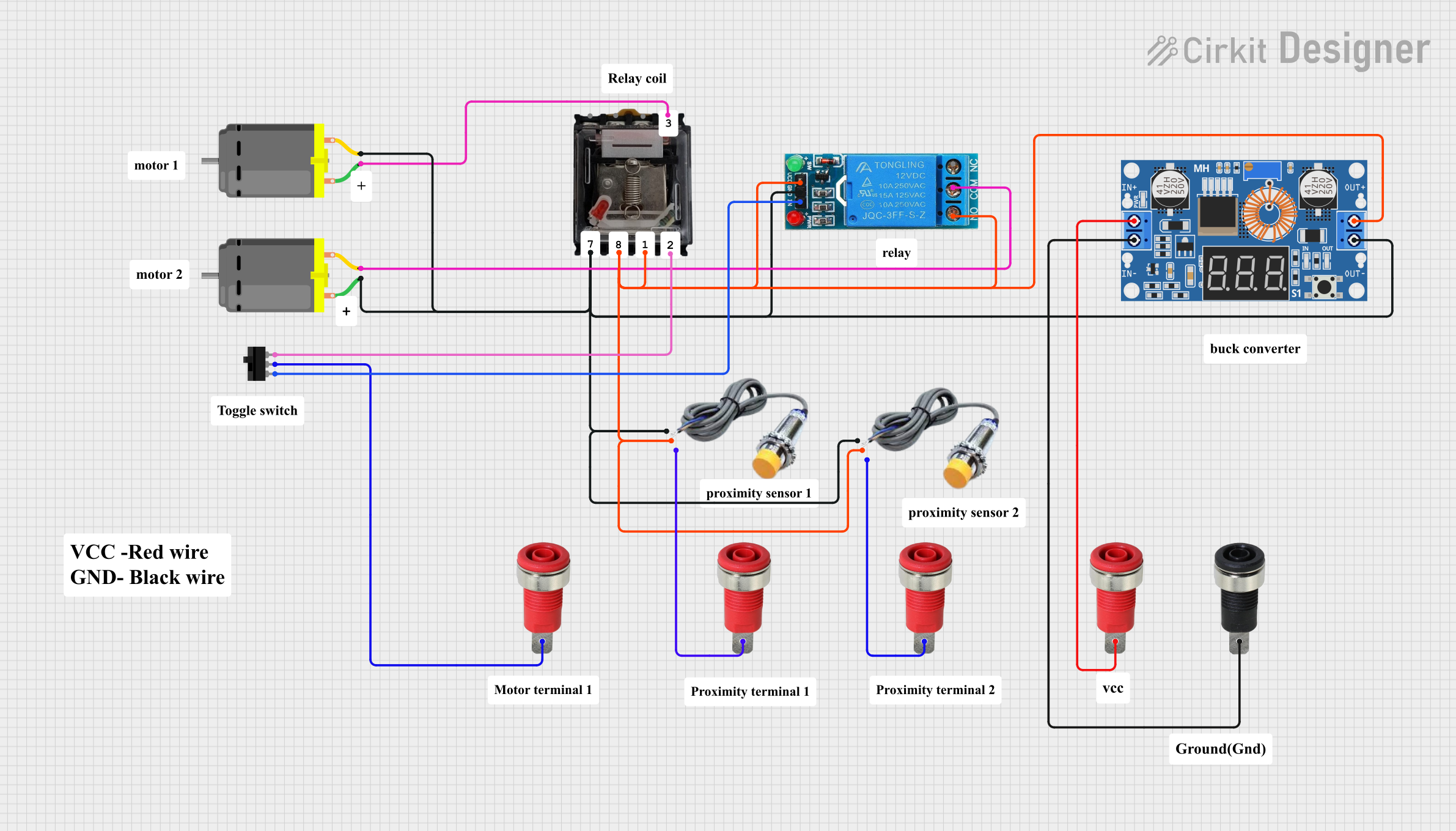

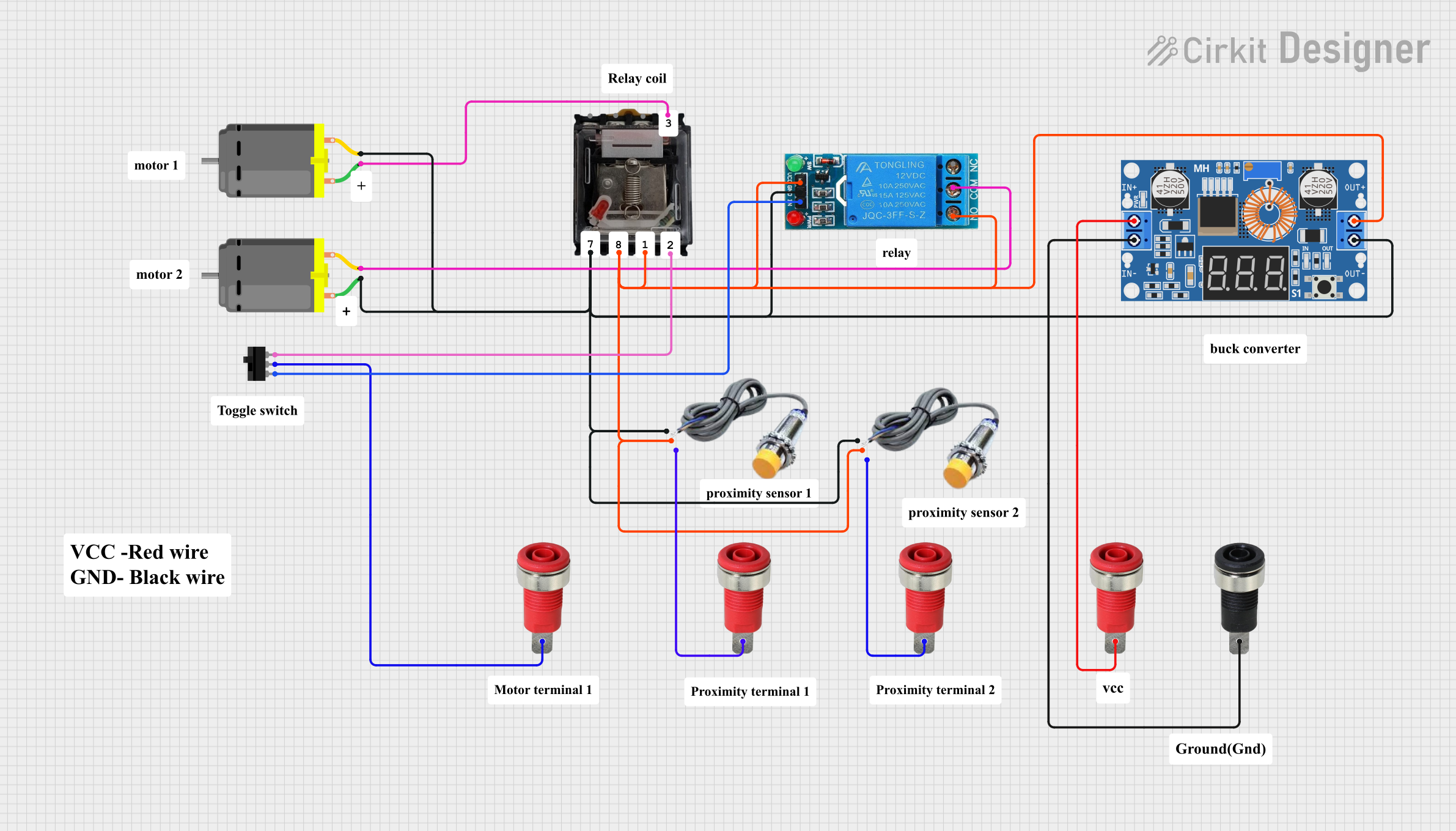

Explore Projects Built with Regulator Stepdown DC XL4015 CC CV (Biggest)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Regulator Stepdown DC XL4015 CC CV (Biggest)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Input Voltage: 4V to 38V DC

- Output Voltage: 1.25V to 36V DC (adjustable)

- Output Current: Up to 5A (with proper heat sinking)

- Maximum Power: 75W (with proper heat sinking)

- Switching Frequency: 180kHz

- Efficiency: Up to 96%

- Operating Temperature: -40°C to +85°C

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | IN+ | Input positive |

| 2 | IN- | Input negative |

| 3 | OUT+ | Output positive |

| 4 | OUT- | Output negative |

| 5 | CV | Constant voltage adjustment |

| 6 | CC | Constant current adjustment |

Usage Instructions

Integration into a Circuit

- Connection: Connect the input power supply to the IN+ and IN- pins, ensuring the voltage is within the specified range. Connect the load to the OUT+ and OUT- pins.

- Adjustment: Use a multimeter to monitor the output voltage and current. Adjust the CV and CC potentiometers to set the desired output voltage and current limits.

- Heat Management: For currents above 2A, or when the module is dissipating significant power, attach a heatsink to the XL4015 chip to prevent overheating.

Best Practices

- Always verify input voltage before connecting to the module to avoid damage.

- Start with the CV and CC potentiometers turned fully counterclockwise before powering up.

- Incrementally adjust the CV and CC settings while monitoring the output to prevent overshooting the desired values.

- Use a fuse on the input side as a safety precaution against overcurrent conditions.

Troubleshooting and FAQs

Common Issues

- No Output Voltage: Ensure input power is within the specified range and connections are secure. Check for any short circuits on the output side.

- Inaccurate Output Voltage or Current: Recalibrate the CV and CC potentiometers. Ensure that the load does not exceed the module's maximum ratings.

- Overheating: Attach a heatsink to the XL4015 chip and ensure adequate ventilation around the module.

FAQs

Q: Can I use the XL4015 to charge batteries? A: Yes, the XL4015 can be used for battery charging, but ensure to set the CC and CV correctly according to the battery's specifications.

Q: What is the difference between CC and CV modes? A: CC mode limits the output current to a preset level, while CV mode maintains a constant output voltage regardless of changes in load.

Q: How do I know if I need a heatsink? A: If the module is running hot to the touch or if you are running it near the maximum output current for extended periods, a heatsink is recommended.

Example Arduino UNO Connection

// No direct code is used to control the XL4015 with an Arduino UNO

// as it is a standalone module. However, you can monitor the output

// voltage and current using an Arduino if you have the appropriate

// sensors and circuitry to do so safely.

// Always ensure that any connections to the Arduino are within its

// voltage and current specifications to avoid damaging the board.

Remember, the XL4015 is a powerful module that requires careful handling, especially when dealing with high currents and voltages. Always follow safety protocols and consult an expert if you are unsure about your setup.