How to Use 100:1 Metal Gearmotor 37Dx73L mm 24V with 64 CPR Encoder (Helical Pinion): Examples, Pinouts, and Specs

Design with 100:1 Metal Gearmotor 37Dx73L mm 24V with 64 CPR Encoder (Helical Pinion) in Cirkit Designer

Design with 100:1 Metal Gearmotor 37Dx73L mm 24V with 64 CPR Encoder (Helical Pinion) in Cirkit DesignerIntroduction

The 100:1 Metal Gearmotor 37Dx73L mm 24V with 64 CPR Encoder, manufactured by Pololu (Part ID: 4695), is a compact and efficient gearmotor designed for high-torque applications. It features a 100:1 gear ratio, operates at 24V, and includes a built-in quadrature encoder with 64 counts per revolution (CPR) for precise position and speed feedback. The helical pinion design ensures smoother operation and reduced noise compared to traditional straight-cut gears.

Explore Projects Built with 100:1 Metal Gearmotor 37Dx73L mm 24V with 64 CPR Encoder (Helical Pinion)

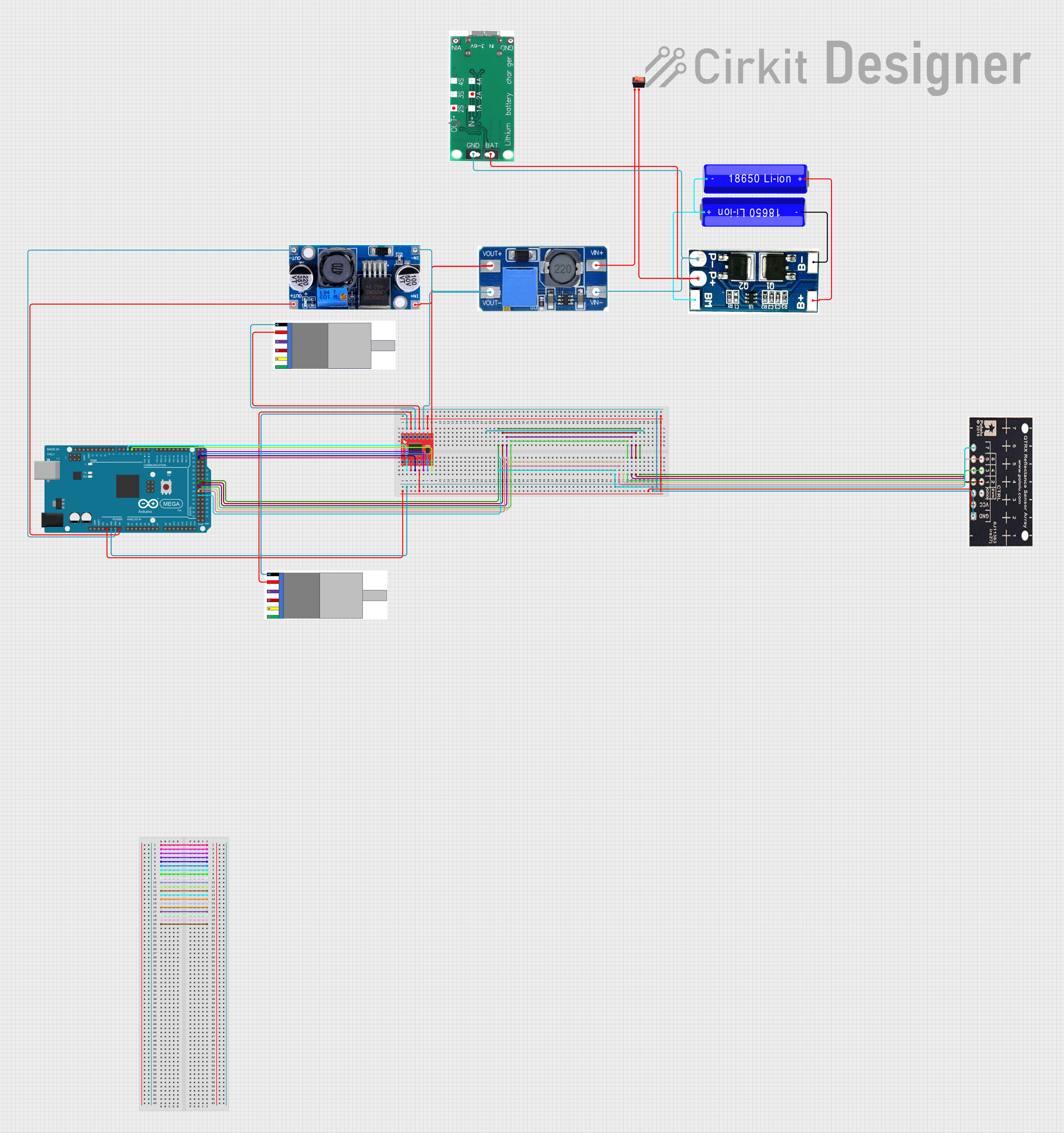

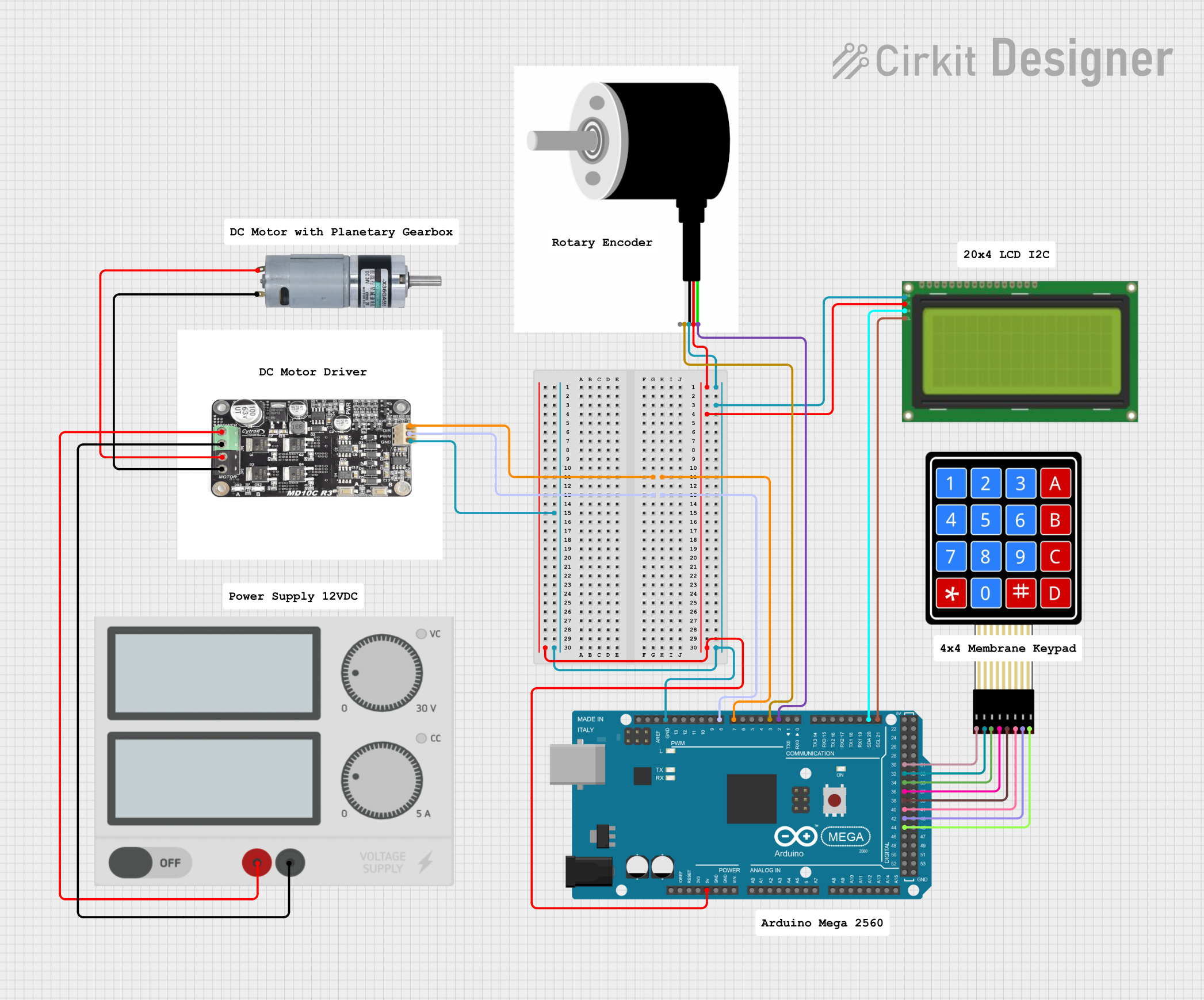

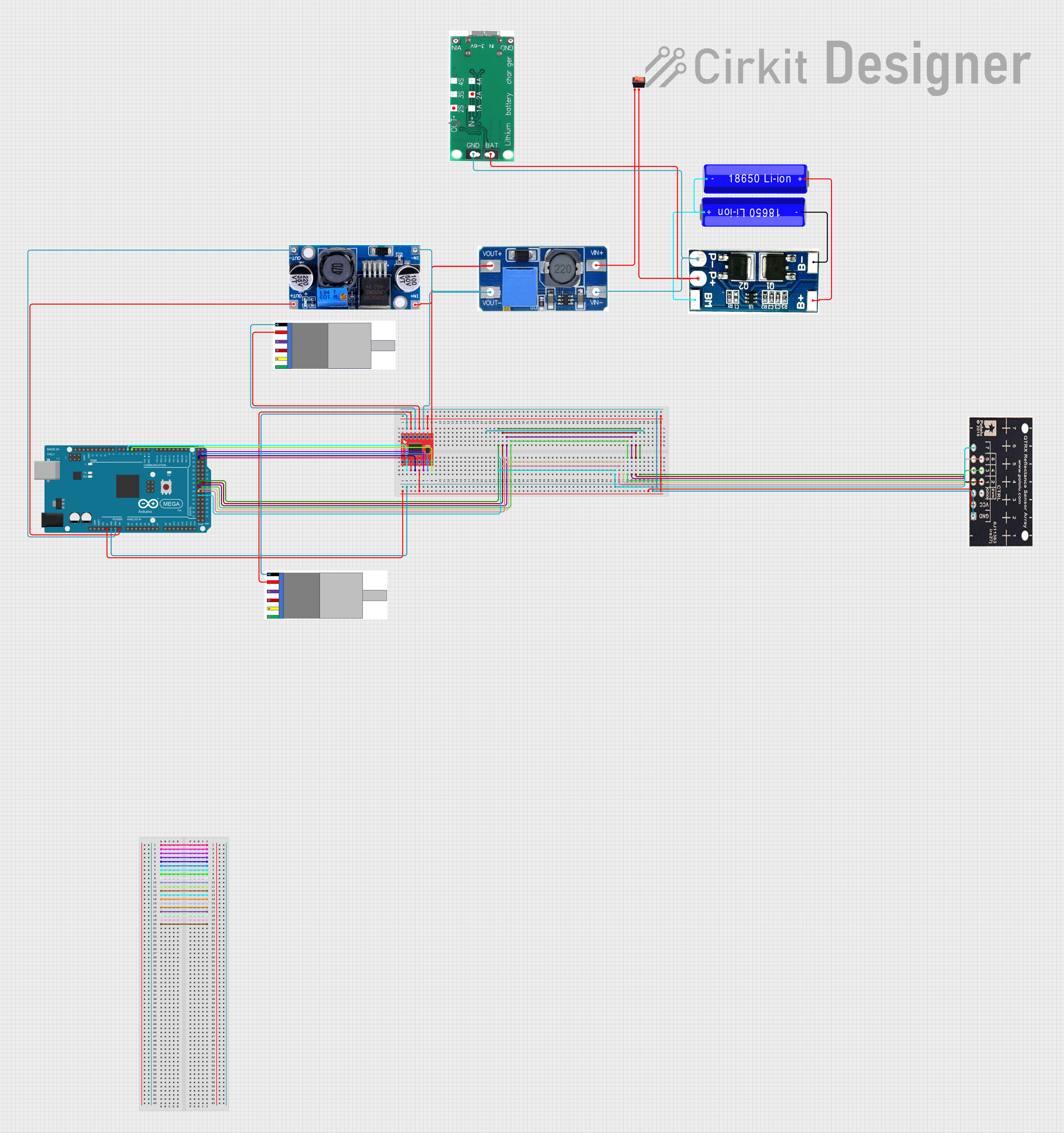

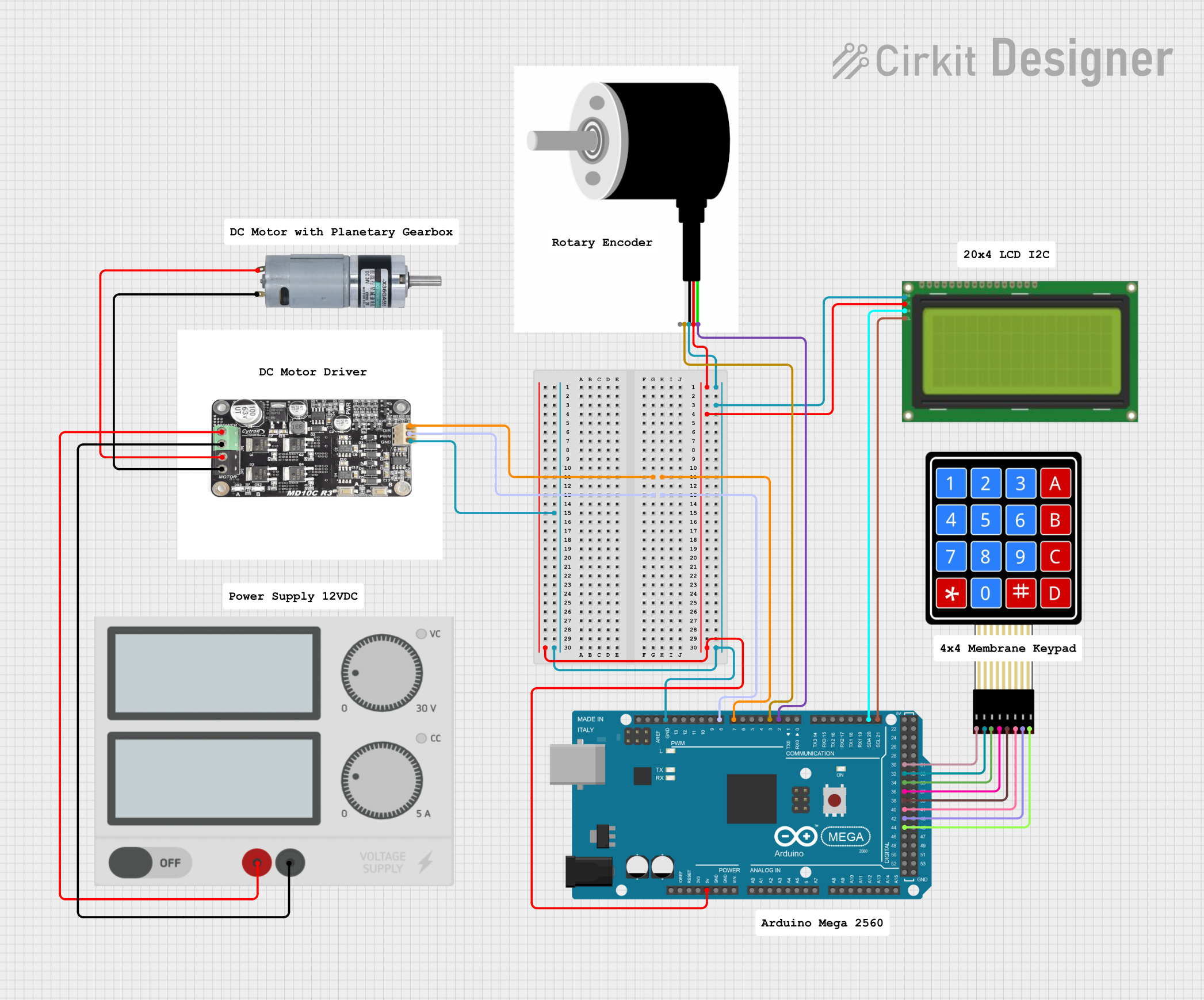

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 100:1 Metal Gearmotor 37Dx73L mm 24V with 64 CPR Encoder (Helical Pinion)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics (e.g., mobile robots, robotic arms)

- Automated systems (e.g., conveyor belts, actuators)

- Precision motion control

- Industrial machinery

- Hobbyist and DIY projects requiring high torque and precise feedback

Technical Specifications

Key Specifications

| Parameter | Value |

|---|---|

| Gear Ratio | 100:1 |

| Operating Voltage | 24V |

| No-Load Speed | ~100 RPM |

| Stall Torque | ~11 kg·cm (at 24V) |

| Stall Current | ~5.5 A (at 24V) |

| Encoder Type | Quadrature Encoder |

| Encoder Resolution | 64 CPR (counts per revolution) |

| Shaft Diameter | 6 mm |

| Motor Dimensions | 37 mm diameter, 73 mm length |

| Weight | ~300 g |

Pin Configuration and Descriptions

The motor has two main terminals for power and four additional pins for the encoder. The pinout is as follows:

Motor Power Terminals

| Terminal | Description |

|---|---|

| M+ | Motor positive lead |

| M- | Motor negative lead |

Encoder Pinout

| Pin | Wire Color | Description |

|---|---|---|

| VCC | Red | Encoder power supply (3.5V–20V) |

| GND | Black | Ground |

| A | Yellow | Encoder channel A output |

| B | White | Encoder channel B output |

Note: The encoder outputs are open-drain and require pull-up resistors for proper operation.

Usage Instructions

How to Use the Component in a Circuit

Powering the Motor:

- Connect the motor terminals (M+ and M-) to a motor driver capable of handling the motor's voltage (24V) and current (up to 5.5A).

- Use a motor driver with PWM control for speed regulation.

Connecting the Encoder:

- Supply power to the encoder by connecting the VCC pin to a voltage source (3.5V–20V) and the GND pin to ground.

- Connect the A and B pins to microcontroller GPIO pins configured as digital inputs.

- Add pull-up resistors (e.g., 10 kΩ) to the A and B lines if not already provided by the microcontroller.

Controlling the Motor:

- Use a motor driver or H-bridge to control the motor's direction and speed.

- For precise position or speed control, read the encoder signals (A and B) to determine the motor's rotation and direction.

Important Considerations and Best Practices

- Power Supply: Ensure the power supply can provide sufficient current (up to 5.5A) to avoid voltage drops or motor stalling.

- Heat Dissipation: Prolonged operation at high loads may cause the motor to heat up. Allow adequate ventilation or use a heat sink if necessary.

- Encoder Signal Noise: Use shielded cables for the encoder connections to minimize noise interference.

- Mounting: Secure the motor using the mounting holes to prevent vibration or misalignment during operation.

Example: Using with Arduino UNO

Below is an example of how to read the encoder signals using an Arduino UNO:

// Define encoder pins

const int encoderPinA = 2; // Channel A connected to digital pin 2

const int encoderPinB = 3; // Channel B connected to digital pin 3

volatile int encoderCount = 0; // Variable to store encoder count

int lastEncoded = 0; // Tracks the last encoder state

void setup() {

pinMode(encoderPinA, INPUT_PULLUP); // Enable pull-up resistor on pin A

pinMode(encoderPinB, INPUT_PULLUP); // Enable pull-up resistor on pin B

// Attach interrupts to encoder pins

attachInterrupt(digitalPinToInterrupt(encoderPinA), updateEncoder, CHANGE);

attachInterrupt(digitalPinToInterrupt(encoderPinB), updateEncoder, CHANGE);

Serial.begin(9600); // Initialize serial communication

}

void loop() {

// Print the encoder count to the serial monitor

Serial.print("Encoder Count: ");

Serial.println(encoderCount);

delay(100); // Delay for readability

}

void updateEncoder() {

// Read the current state of the encoder pins

int MSB = digitalRead(encoderPinA); // Most significant bit

int LSB = digitalRead(encoderPinB); // Least significant bit

int encoded = (MSB << 1) | LSB; // Combine the two bits

int sum = (lastEncoded << 2) | encoded; // Track state changes

// Update encoder count based on state transitions

if (sum == 0b1101 || sum == 0b0100 || sum == 0b0010 || sum == 0b1011) encoderCount++;

if (sum == 0b1110 || sum == 0b0111 || sum == 0b0001 || sum == 0b1000) encoderCount--;

lastEncoded = encoded; // Update the last state

}

Note: This code assumes the encoder outputs are connected to pins 2 and 3 on the Arduino UNO. Adjust the pin numbers as needed for your setup.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin:

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power supply voltage and current. Check the motor driver connections.

Encoder Signals Are Unstable:

- Cause: Electrical noise or missing pull-up resistors.

- Solution: Use shielded cables for the encoder and add pull-up resistors to the A and B lines.

Motor Overheats:

- Cause: Prolonged operation at high loads or insufficient ventilation.

- Solution: Reduce the load or provide better cooling.

Incorrect Encoder Readings:

- Cause: Misaligned wiring or incorrect interrupt configuration.

- Solution: Double-check the encoder pin connections and ensure the microcontroller is configured correctly.

FAQs

Q: Can I use this motor with a 12V power supply?

- A: While the motor is designed for 24V, it can operate at lower voltages with reduced performance (e.g., lower speed and torque).

Q: What is the maximum RPM of this motor?

- A: The no-load speed is approximately 100 RPM at 24V.

Q: Do I need external pull-up resistors for the encoder?

- A: Yes, the encoder outputs are open-drain and require pull-up resistors for proper operation.

Q: Can I use this motor for continuous operation?

- A: Yes, but ensure proper cooling and avoid exceeding the motor's rated load to prevent overheating.