How to Use AMT22: Examples, Pinouts, and Specs

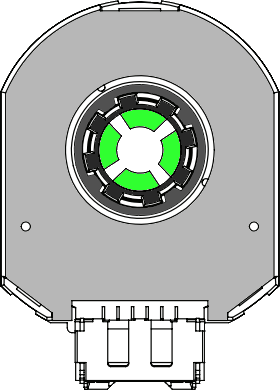

Design with AMT22 in Cirkit Designer

Design with AMT22 in Cirkit DesignerIntroduction

The AMT22 is a high-resolution rotary encoder manufactured by Same Sky (formerly CUI). It is designed for precise position sensing in a wide range of applications, including robotics, industrial automation, motor control, and more. The encoder provides digital output signals that represent the angle of rotation, making it an ideal choice for systems requiring accurate and reliable position feedback.

The AMT22 uses a proprietary capacitive sensing technology, which offers high durability, resistance to environmental factors such as dust and moisture, and exceptional accuracy. Its compact design and versatile mounting options make it suitable for integration into various mechanical systems.

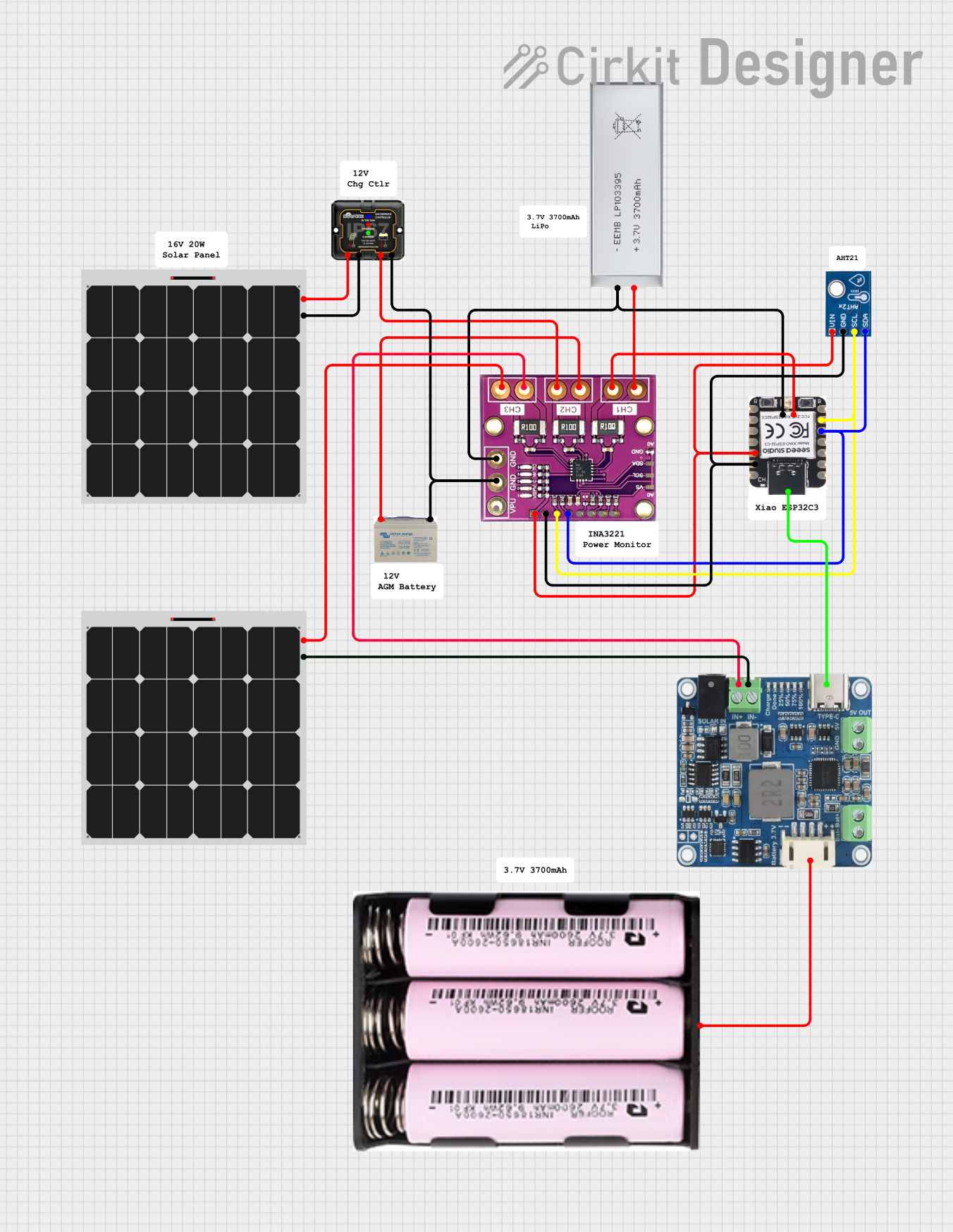

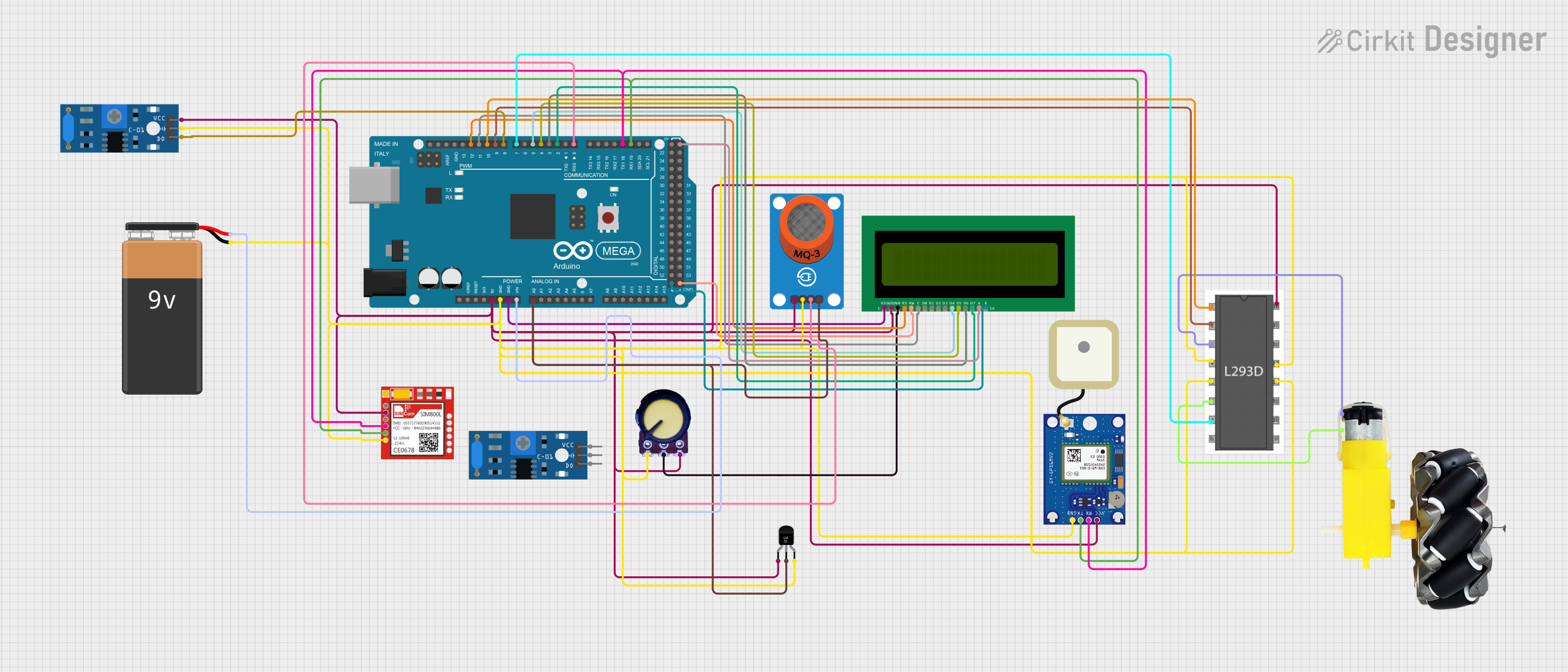

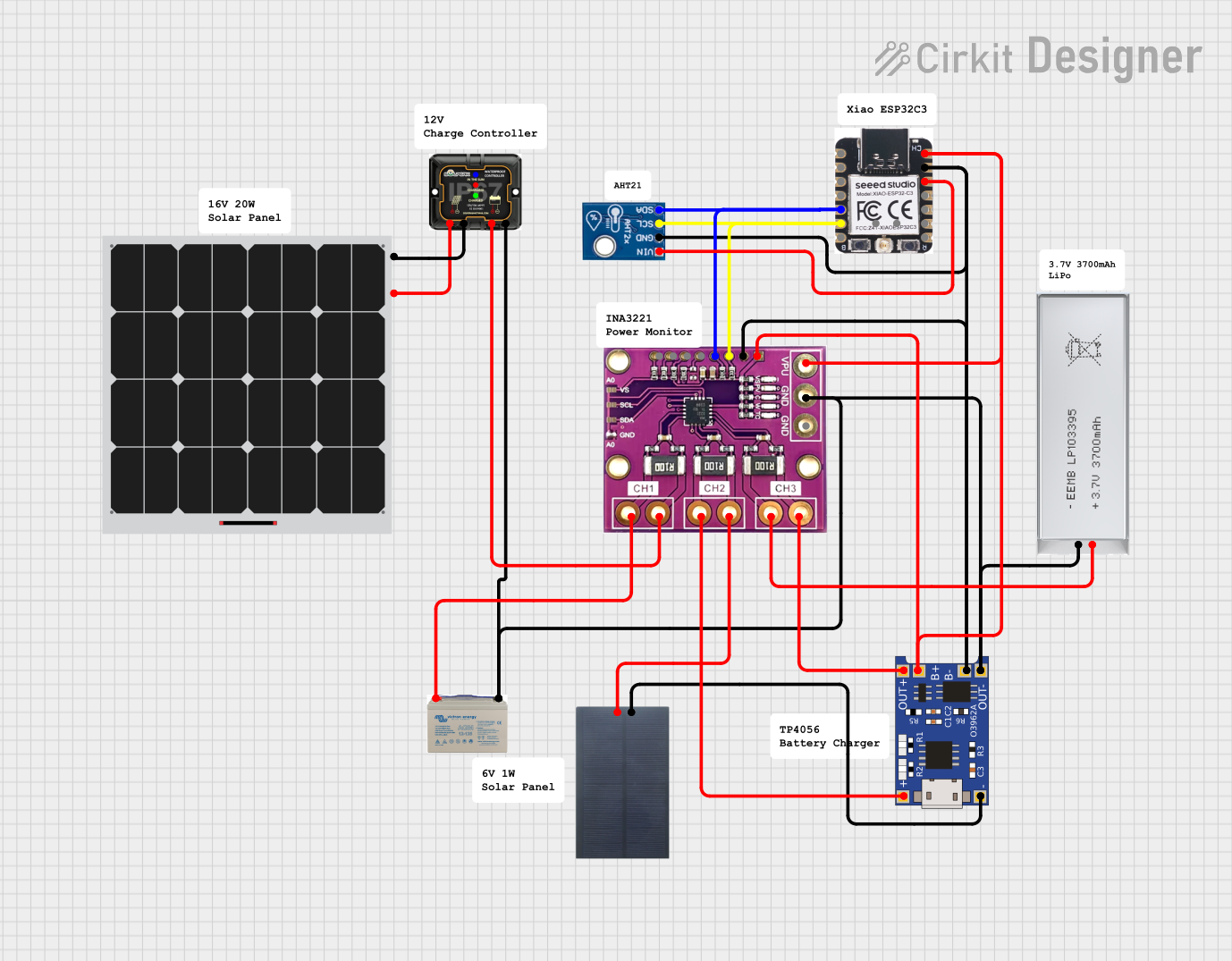

Explore Projects Built with AMT22

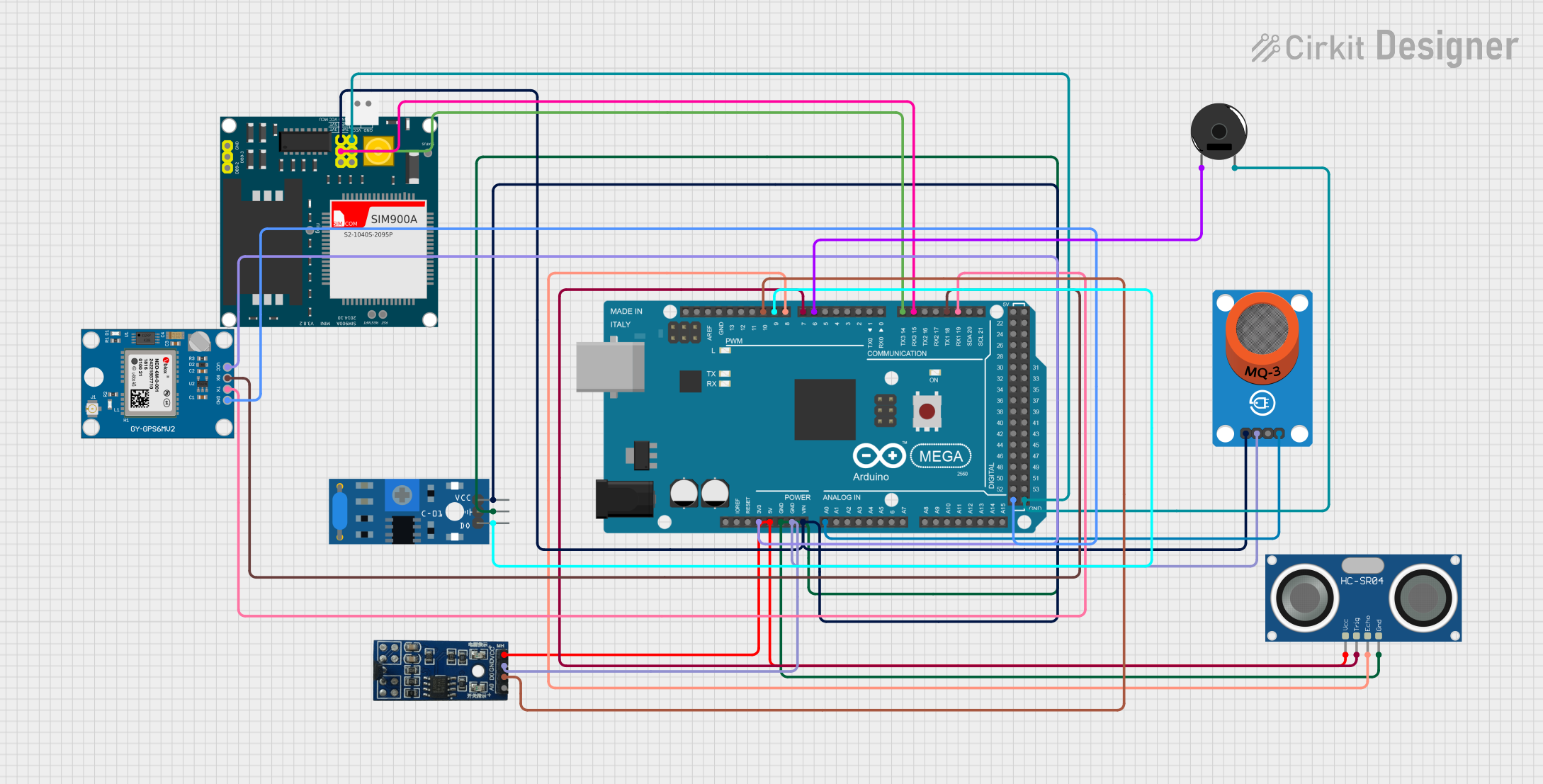

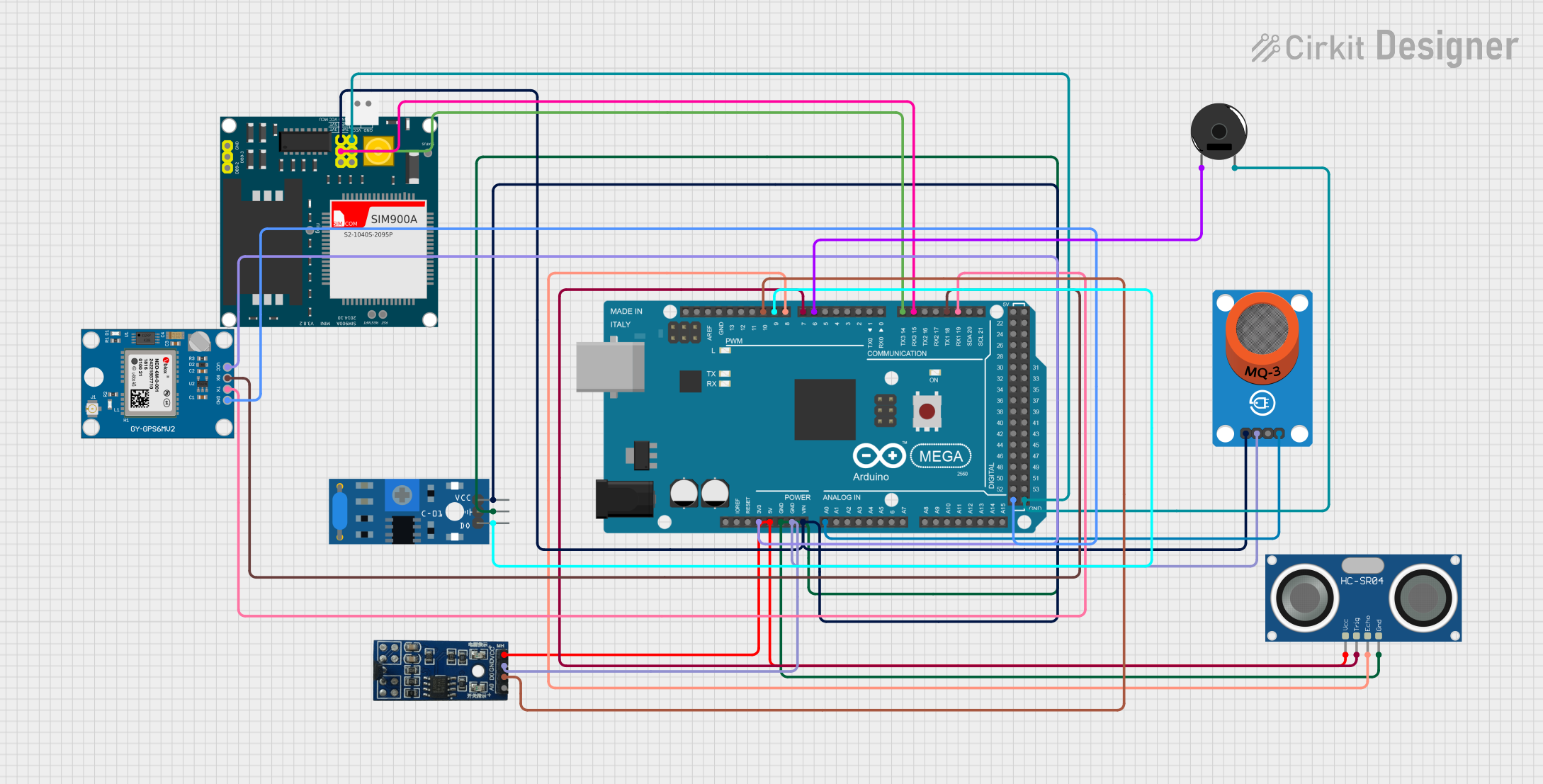

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

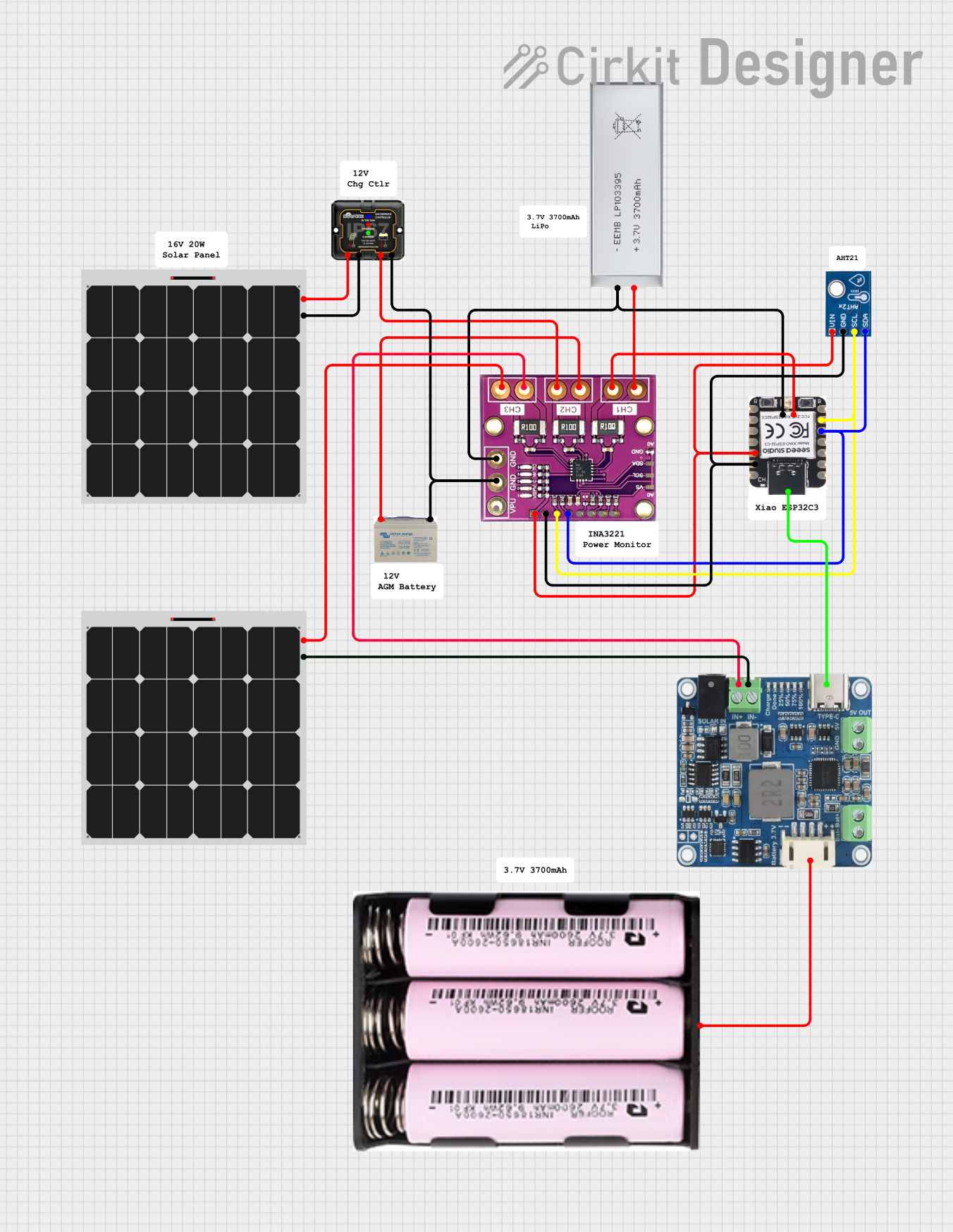

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with AMT22

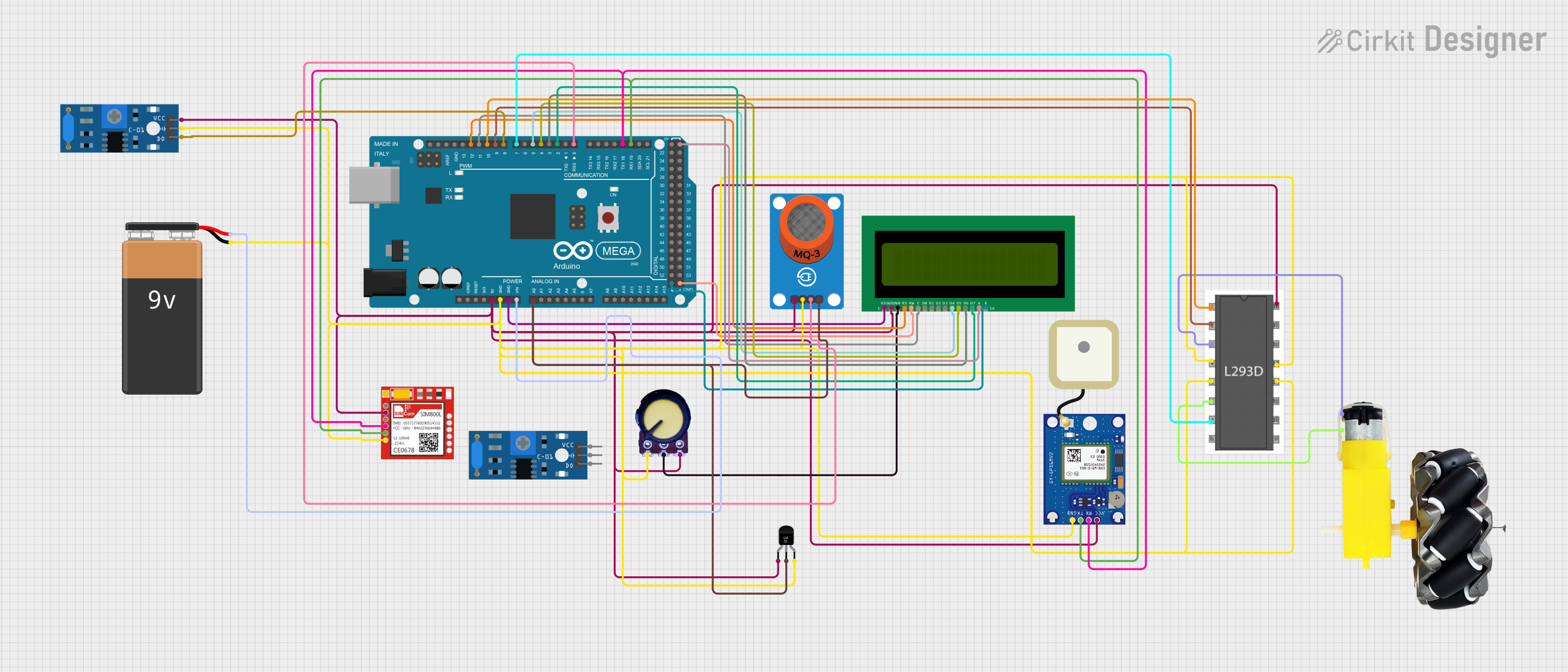

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

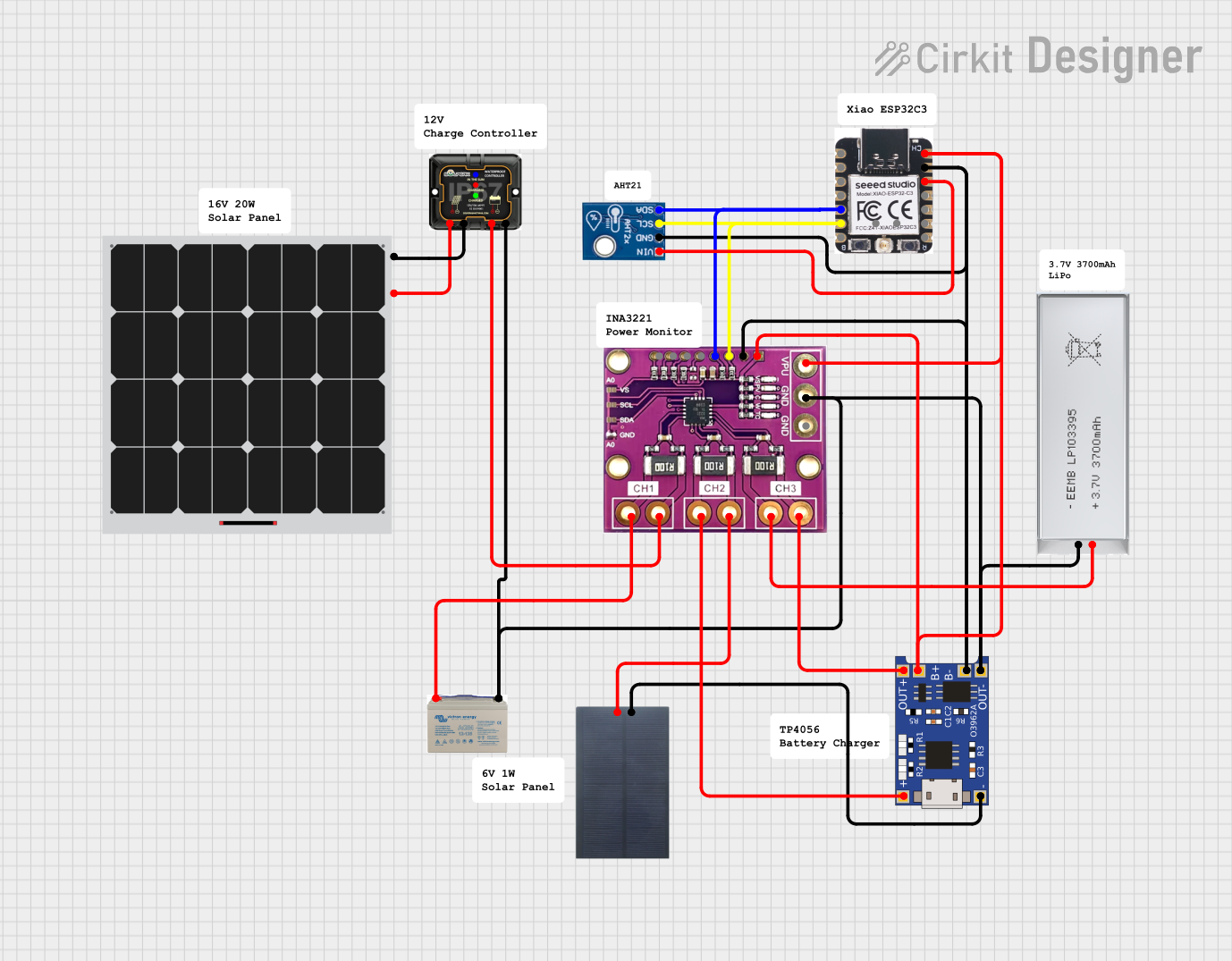

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

The following table outlines the key technical specifications of the AMT22 rotary encoder:

| Parameter | Value |

|---|---|

| Resolution | Up to 14 bits (16,384 steps) |

| Output Protocol | SPI (Serial Peripheral Interface) |

| Supply Voltage | 5 V DC |

| Current Consumption | 8 mA (typical) |

| Operating Temperature | -40°C to +125°C |

| Maximum Rotational Speed | 10,000 RPM |

| Accuracy | ±0.2° |

| Communication Speed | Up to 1 MHz |

| Mounting Options | Multiple shaft sizes supported |

Pin Configuration and Descriptions

The AMT22 encoder has a 6-pin interface for power, communication, and control. The pinout is as follows:

| Pin Number | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (5 V DC) |

| 2 | GND | Ground connection |

| 3 | SCK | SPI clock signal input |

| 4 | MOSI | Master Out Slave In (data input to the encoder) |

| 5 | MISO | Master In Slave Out (data output from the encoder) |

| 6 | CS | Chip Select (active low) |

Usage Instructions

How to Use the AMT22 in a Circuit

- Power Supply: Connect the VCC pin to a stable 5 V DC power source and the GND pin to the ground of your circuit.

- SPI Communication: Connect the SCK, MOSI, MISO, and CS pins to the corresponding SPI pins on your microcontroller or development board (e.g., Arduino UNO).

- Initialization: Configure the SPI interface on your microcontroller to communicate with the AMT22. The encoder operates with SPI mode 0 (CPOL = 0, CPHA = 0).

- Data Reading: Send a command to the encoder via the MOSI line to request position data. The encoder will respond with the current position on the MISO line.

Important Considerations and Best Practices

- Mounting: Ensure the encoder is securely mounted to the shaft to avoid misalignment or slippage, which can affect accuracy.

- Noise Reduction: Use proper decoupling capacitors near the VCC and GND pins to minimize electrical noise.

- Cable Length: Keep the SPI communication lines as short as possible to reduce signal degradation, especially at higher communication speeds.

- Environmental Protection: While the AMT22 is resistant to dust and moisture, additional protection may be necessary in harsh environments.

Example Code for Arduino UNO

Below is an example of how to interface the AMT22 with an Arduino UNO to read position data:

#include <SPI.h>

// Define SPI pins for the AMT22

const int CS_PIN = 10; // Chip Select pin connected to Arduino pin 10

void setup() {

// Initialize serial communication for debugging

Serial.begin(9600);

// Configure the Chip Select pin as output

pinMode(CS_PIN, OUTPUT);

digitalWrite(CS_PIN, HIGH); // Set CS high (inactive)

// Initialize SPI communication

SPI.begin();

SPI.setDataMode(SPI_MODE0); // Set SPI mode 0 (CPOL = 0, CPHA = 0)

SPI.setClockDivider(SPI_CLOCK_DIV16); // Set SPI clock speed

}

uint16_t readAMT22Position() {

uint16_t position = 0;

// Activate the encoder by pulling CS low

digitalWrite(CS_PIN, LOW);

// Send the command to request position data (0x10)

SPI.transfer(0x10);

// Read the high byte of the position

position = SPI.transfer(0x00) << 8;

// Read the low byte of the position

position |= SPI.transfer(0x00);

// Deactivate the encoder by pulling CS high

digitalWrite(CS_PIN, HIGH);

// Return the 14-bit position value

return position & 0x3FFF; // Mask to keep only the lower 14 bits

}

void loop() {

// Read the position from the AMT22

uint16_t position = readAMT22Position();

// Print the position to the serial monitor

Serial.print("Position: ");

Serial.println(position);

// Add a small delay for stability

delay(100);

}

Troubleshooting and FAQs

Common Issues and Solutions

No Position Data Received

- Cause: Incorrect SPI configuration or wiring.

- Solution: Verify the SPI mode (mode 0) and ensure all connections are secure.

Inconsistent Readings

- Cause: Electrical noise or poor grounding.

- Solution: Add decoupling capacitors near the encoder and ensure a solid ground connection.

Encoder Not Responding

- Cause: Incorrect Chip Select (CS) handling.

- Solution: Ensure the CS pin is pulled low before sending commands and high after communication.

Position Jumps or Drifts

- Cause: Shaft misalignment or slippage.

- Solution: Check the mechanical mounting and ensure the encoder is securely attached to the shaft.

FAQs

Q: Can the AMT22 be used with 3.3 V systems?

A: The AMT22 requires a 5 V power supply, but its SPI lines can often tolerate 3.3 V logic. Use level shifters if needed for compatibility.

Q: What is the maximum cable length for SPI communication?

A: The maximum cable length depends on the communication speed and environmental noise. For reliable operation, keep the cable length under 1 meter at high speeds.

Q: How do I reset the encoder?

A: The AMT22 does not have a dedicated reset pin. Power cycling the encoder will reset it.

Q: Can I use multiple AMT22 encoders on the same SPI bus?

A: Yes, you can connect multiple encoders by assigning each a unique Chip Select (CS) pin.