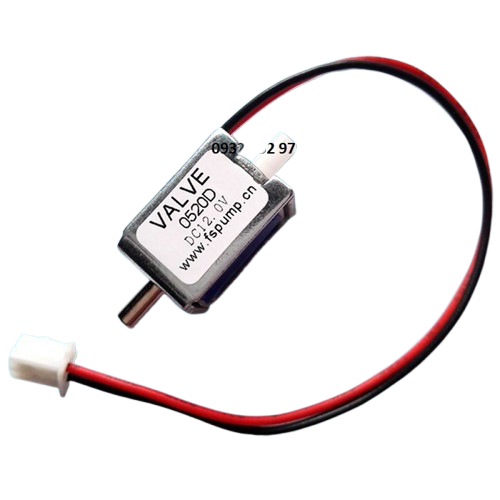

How to Use valve 052f: Examples, Pinouts, and Specs

Design with valve 052f in Cirkit Designer

Design with valve 052f in Cirkit DesignerIntroduction

The Valve 052F is a specialized component designed for precise regulation of fluid flow and pressure in various control systems. Manufactured with high-quality materials, it ensures reliable performance in demanding environments. This valve is commonly used in industrial automation, HVAC systems, water treatment plants, and other fluid control applications where accuracy and durability are critical.

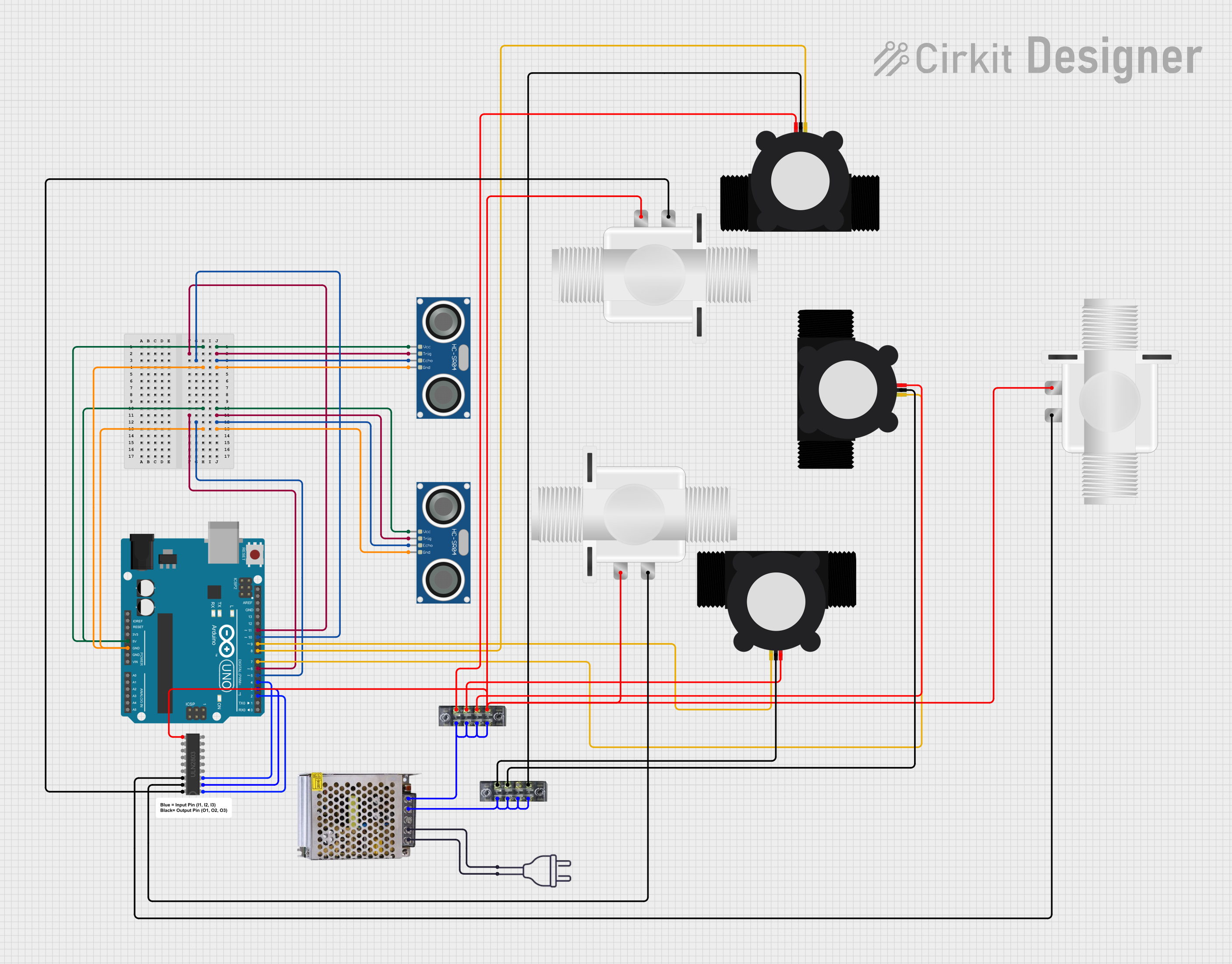

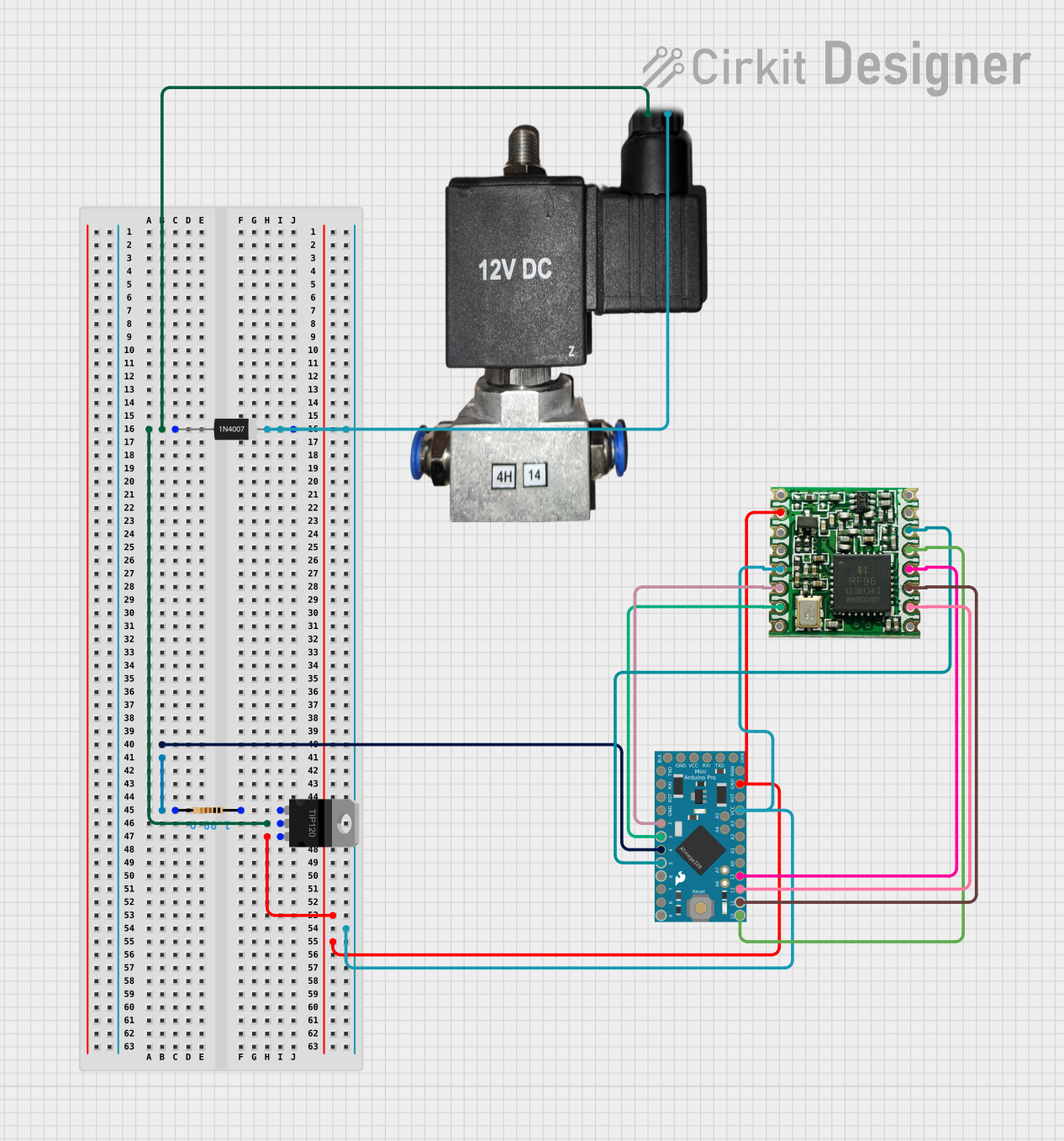

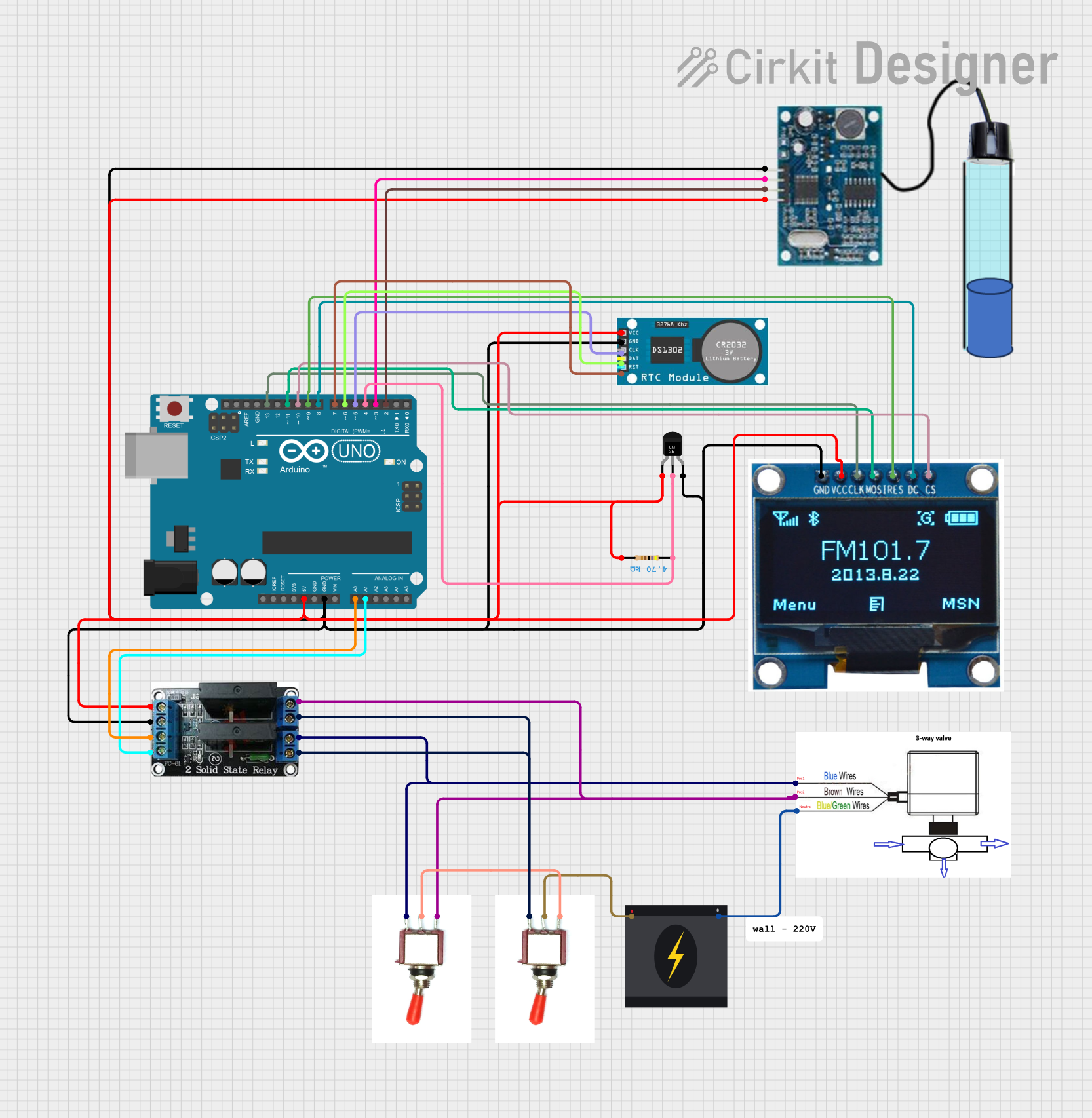

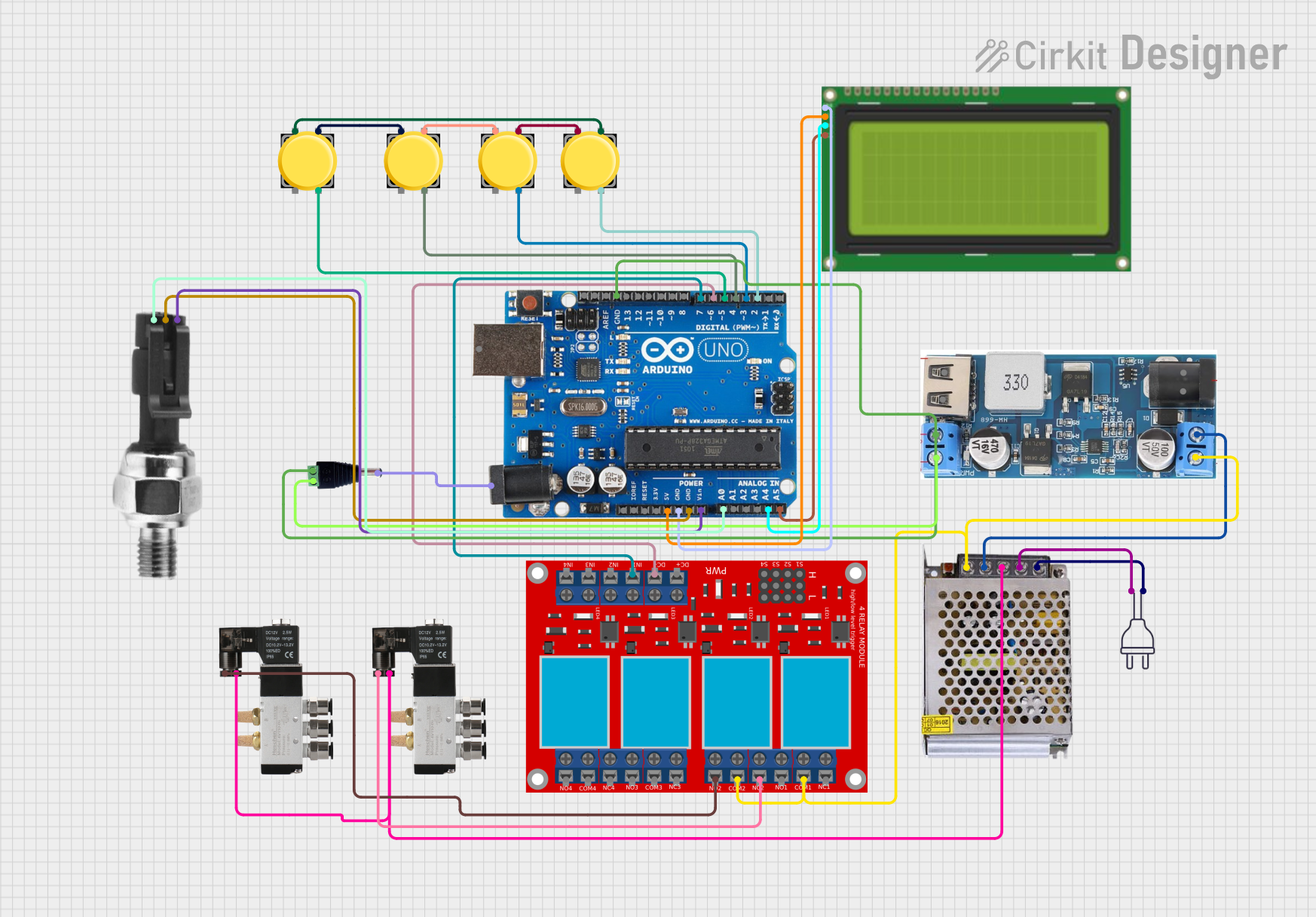

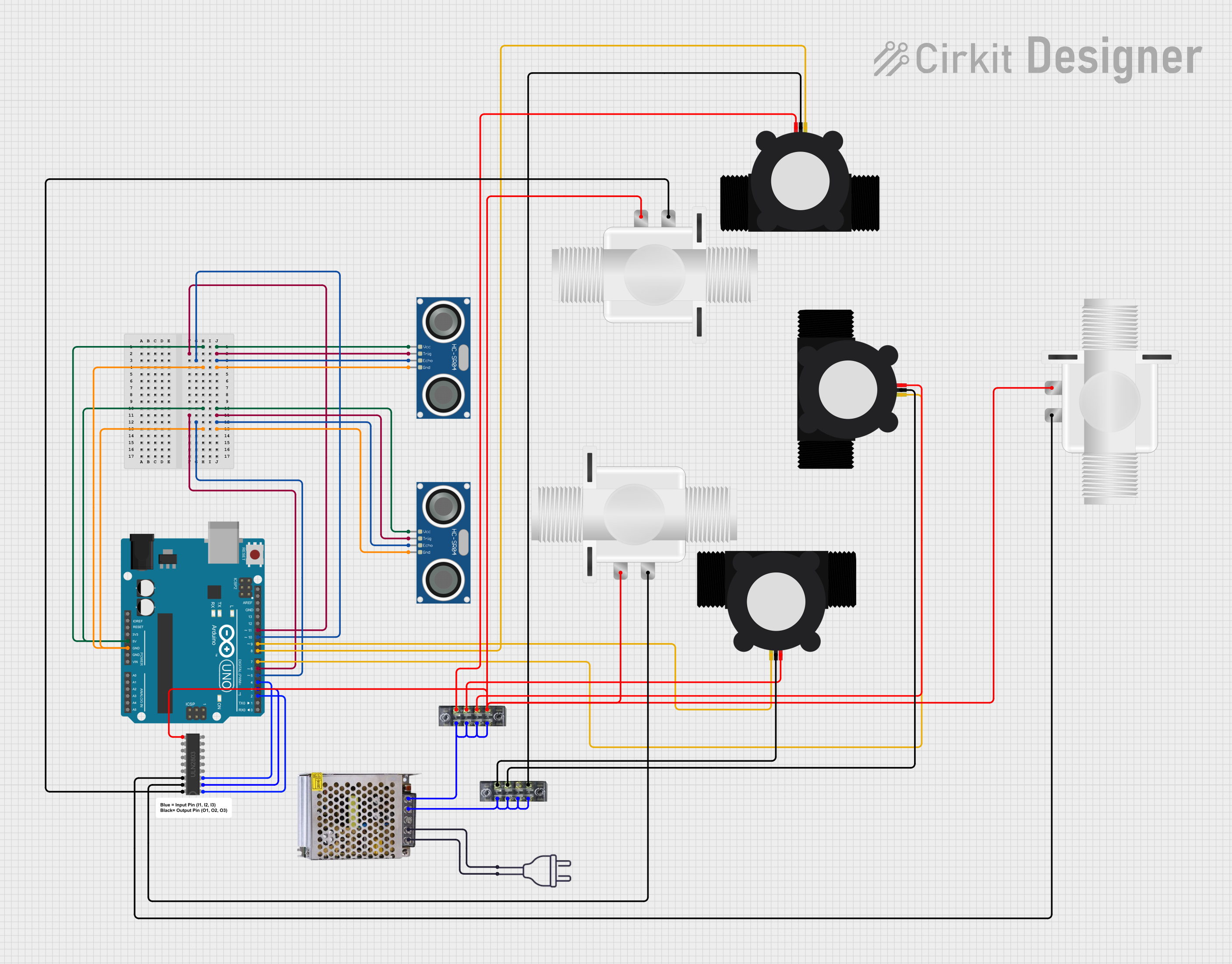

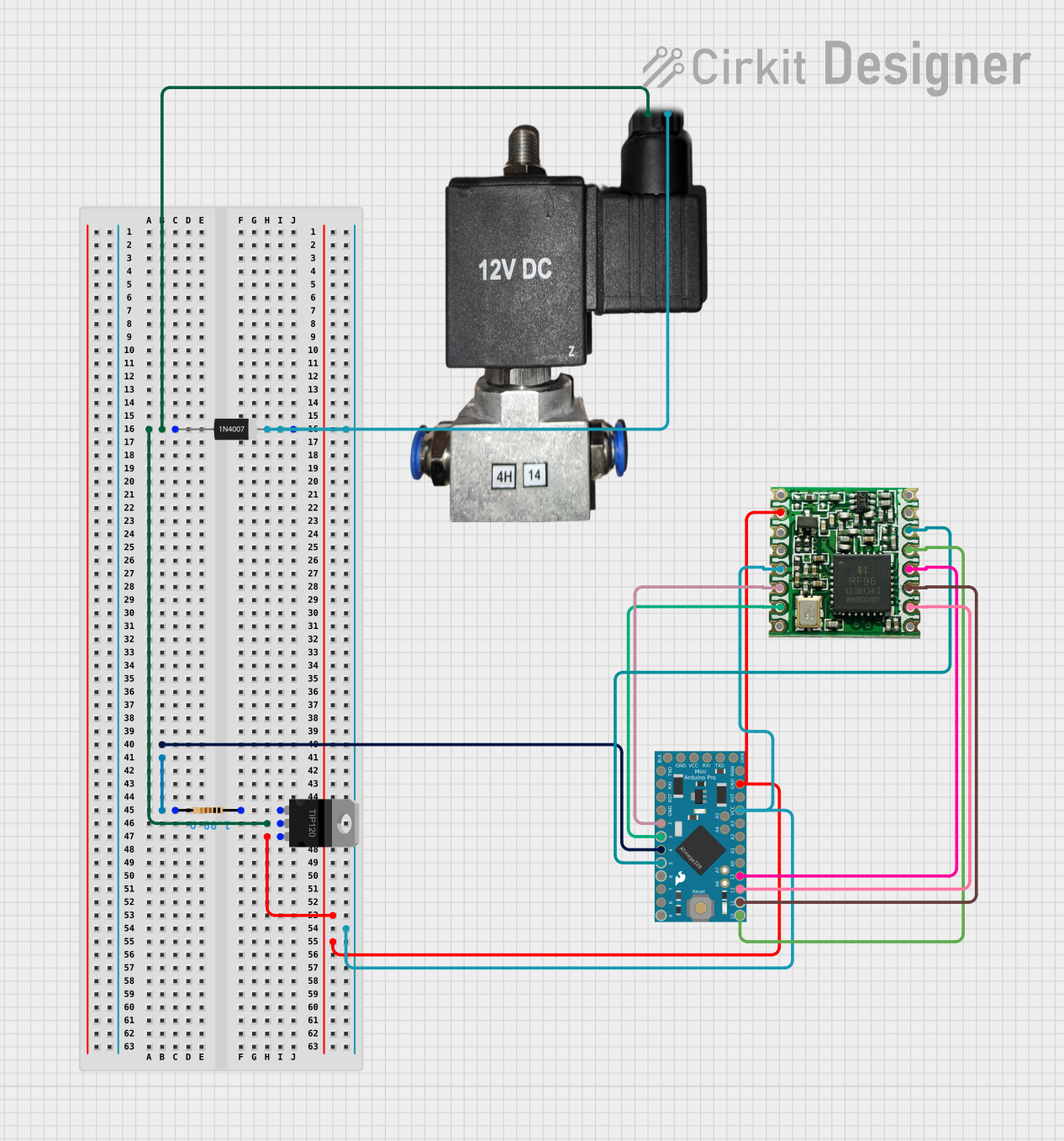

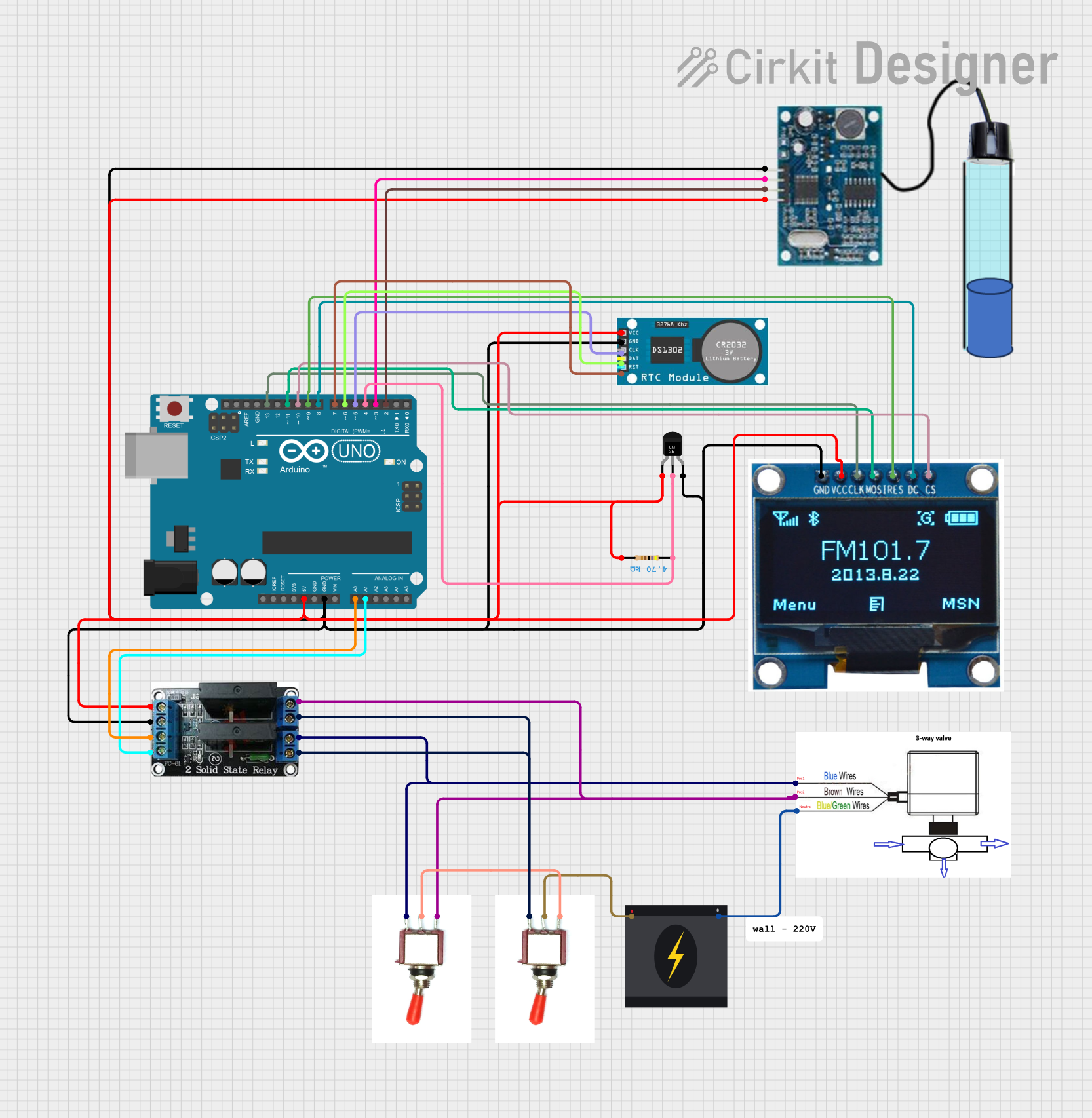

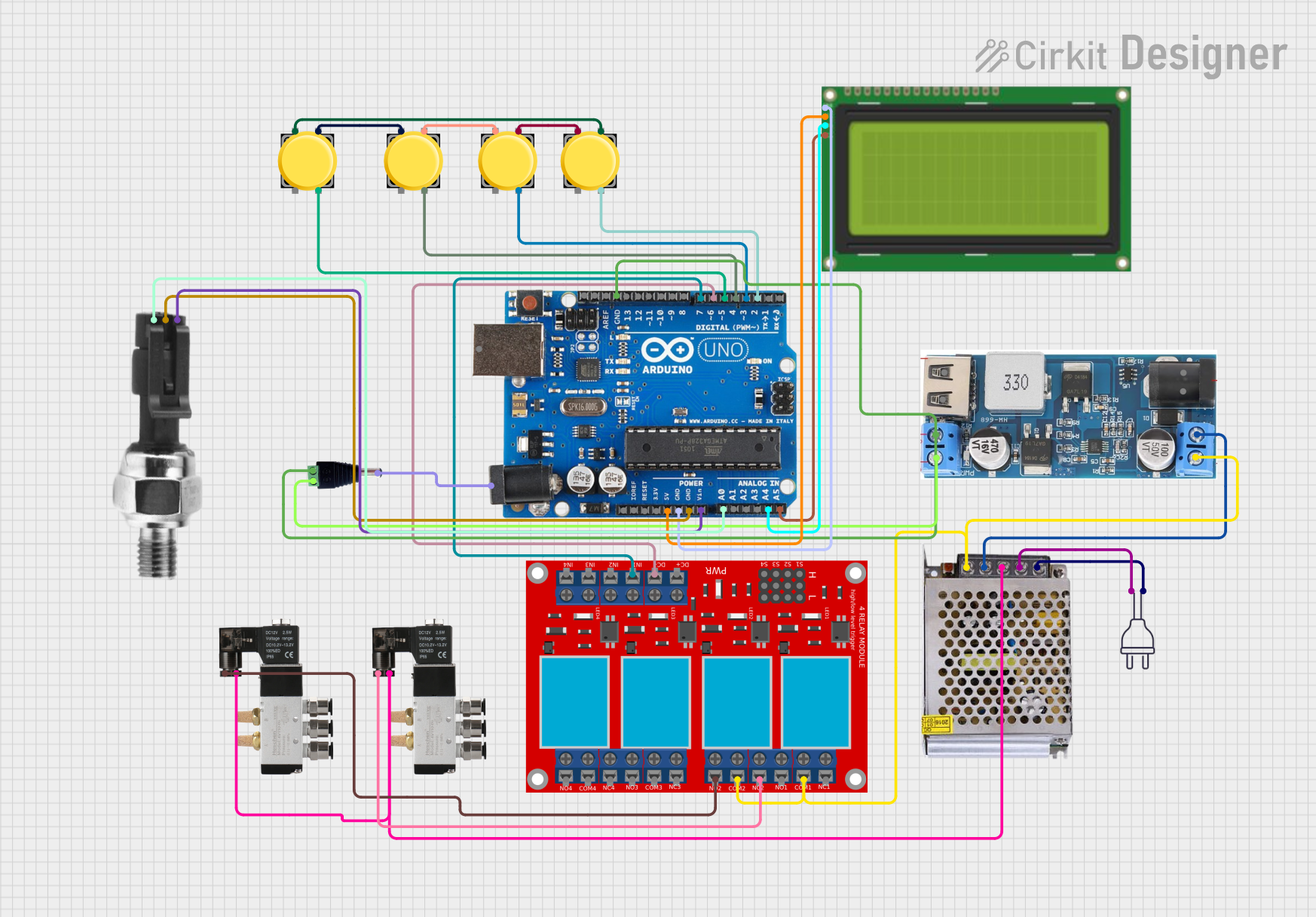

Explore Projects Built with valve 052f

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with valve 052f

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

The Valve 052F is engineered to meet the needs of modern fluid control systems. Below are its key technical details:

General Specifications

- Manufacturer: Valve 052F

- Part ID: Valve 052F

- Type: Fluid control valve

- Material: Corrosion-resistant alloy

- Operating Medium: Liquid or gas

- Control Type: Manual or automated (via actuator)

Electrical and Mechanical Specifications

| Parameter | Value |

|---|---|

| Operating Voltage | 24V DC / 110V AC / 220V AC |

| Power Consumption | 5W (typical) |

| Maximum Operating Pressure | 10 bar (145 psi) |

| Flow Rate Range | 0.1 to 10 liters per minute (LPM) |

| Temperature Range | -10°C to 80°C (14°F to 176°F) |

| Connection Type | Threaded (1/4", 1/2", or 3/4") |

| Actuation Time | < 1 second |

Pin Configuration and Descriptions

For automated operation, the Valve 052F can be connected to an electrical control system. Below is the pin configuration for the actuator:

| Pin Number | Name | Description |

|---|---|---|

| 1 | V+ | Positive voltage input (24V DC or AC supply) |

| 2 | V- | Ground (negative terminal) |

| 3 | Signal Input | Control signal (PWM or ON/OFF for valve actuation) |

| 4 | Feedback | Optional feedback signal for valve position status |

Usage Instructions

The Valve 052F is versatile and can be integrated into a variety of fluid control systems. Follow these steps and best practices for optimal performance:

Installation

- Mounting: Secure the valve to the pipeline using the appropriate threaded connection size (1/4", 1/2", or 3/4"). Ensure the flow direction matches the arrow marked on the valve body.

- Electrical Connection: Connect the actuator pins to the control system as per the pin configuration table. Use proper insulation and connectors to avoid short circuits.

- Sealing: Use Teflon tape or a suitable sealant on the threads to prevent leaks.

Operation

- For manual operation, use the handle or knob to adjust the flow rate.

- For automated systems, provide a control signal (e.g., PWM or ON/OFF) to the signal input pin. The valve will open or close based on the signal.

Arduino UNO Example Code

The Valve 052F can be controlled using an Arduino UNO. Below is an example code snippet for operating the valve with a PWM signal:

// Define the pin connected to the valve's signal input

const int valvePin = 9;

void setup() {

// Set the valve pin as an output

pinMode(valvePin, OUTPUT);

}

void loop() {

// Open the valve (PWM signal at 50% duty cycle)

analogWrite(valvePin, 128); // 128 corresponds to 50% of 255

delay(5000); // Keep the valve open for 5 seconds

// Close the valve (PWM signal at 0% duty cycle)

analogWrite(valvePin, 0); // 0 corresponds to fully closed

delay(5000); // Keep the valve closed for 5 seconds

}

Best Practices

- Ensure the operating medium is clean and free of debris to prevent clogging.

- Do not exceed the maximum operating pressure or temperature limits.

- Periodically inspect the valve for wear and tear, especially in high-pressure applications.

Troubleshooting and FAQs

Common Issues and Solutions

Valve does not open or close:

- Check the electrical connections and ensure the correct voltage is supplied.

- Verify the control signal is being sent to the signal input pin.

- Inspect the valve for physical obstructions or damage.

Leakage around the valve:

- Ensure the threads are properly sealed with Teflon tape or a suitable sealant.

- Check for cracks or damage to the valve body.

Inconsistent flow rate:

- Clean the valve to remove any debris or buildup.

- Verify the control signal is stable and within the specified range.

FAQs

Q: Can the Valve 052F handle corrosive fluids?

A: The valve is made of a corrosion-resistant alloy, but compatibility with specific corrosive fluids should be verified with the manufacturer.

Q: Is the valve suitable for high-temperature applications?

A: The valve can operate within a temperature range of -10°C to 80°C (14°F to 176°F). For higher temperatures, consult the manufacturer.

Q: Can I use the Valve 052F with a 12V power supply?

A: No, the valve requires a 24V DC or 110V/220V AC power supply for proper operation.

By following this documentation, users can effectively integrate and maintain the Valve 052F in their fluid control systems.