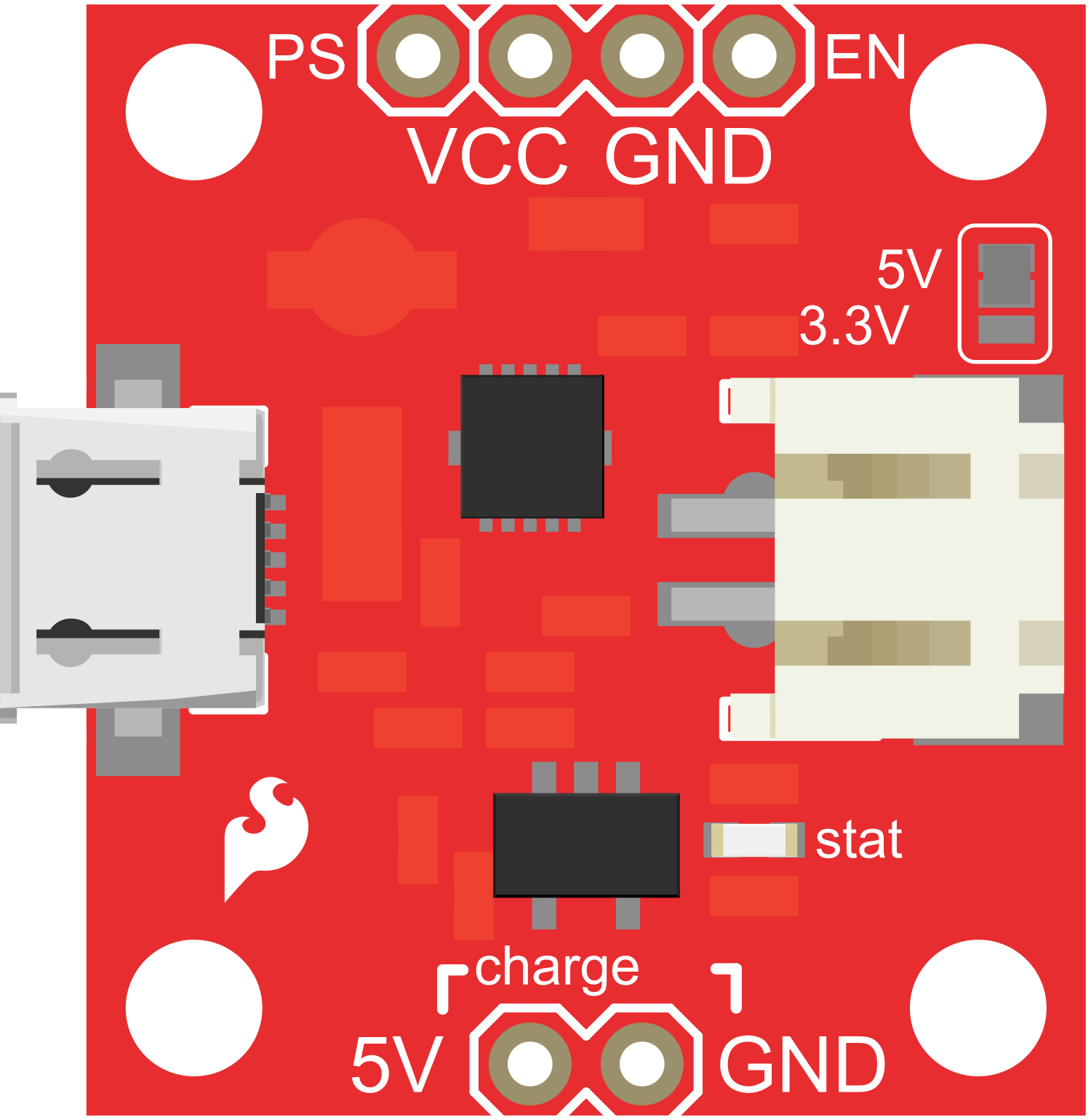

How to Use Power Cell - LiPo Charger/Booster: Examples, Pinouts, and Specs

Design with Power Cell - LiPo Charger/Booster in Cirkit Designer

Design with Power Cell - LiPo Charger/Booster in Cirkit DesignerIntroduction

The Power Cell - LiPo Charger/Booster is a sophisticated electronic module designed to charge single-cell Lithium Polymer (LiPo) batteries and boost the output voltage to a higher, selectable level. This component is ideal for portable, wearable, and IoT devices where a stable power supply is crucial. It integrates a micro-USB port for charging and provides a convenient solution for powering projects that require a compact energy source.

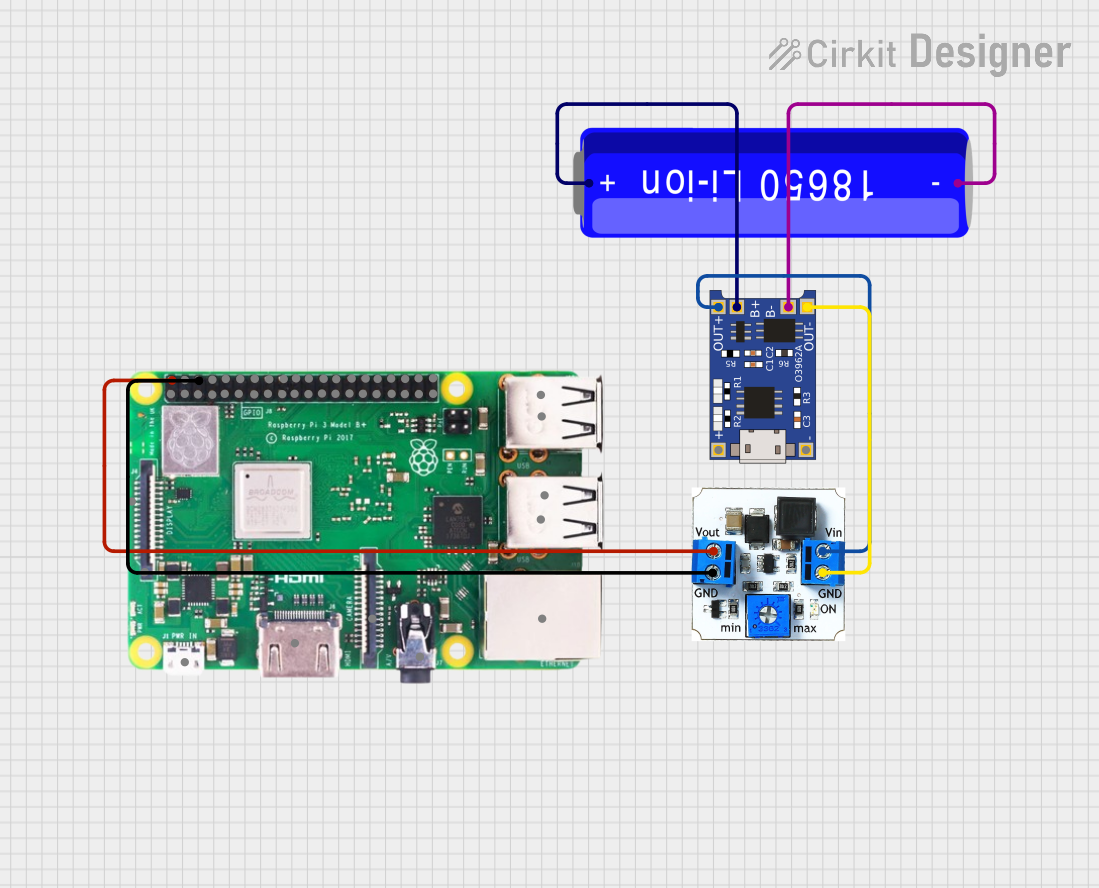

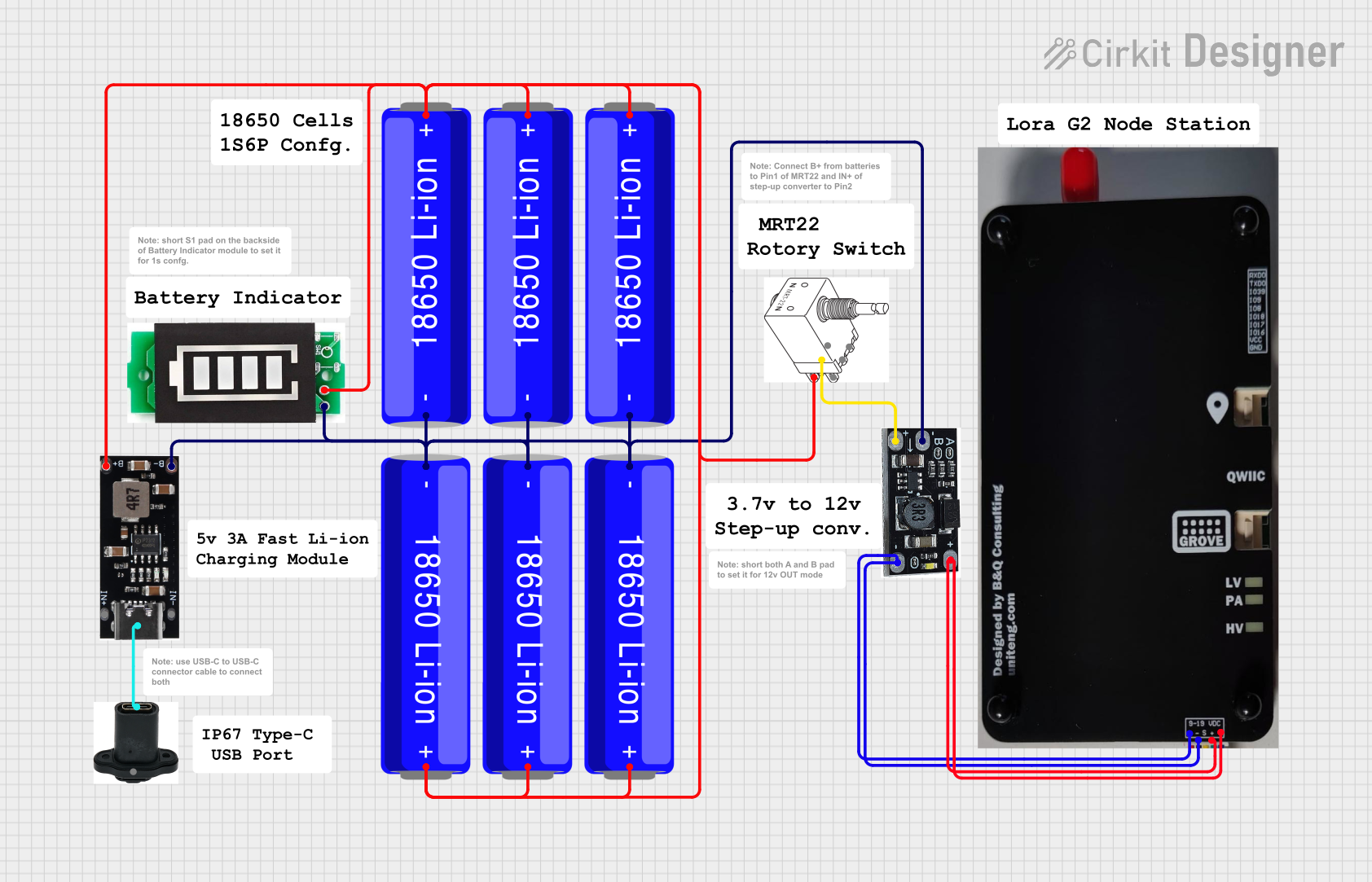

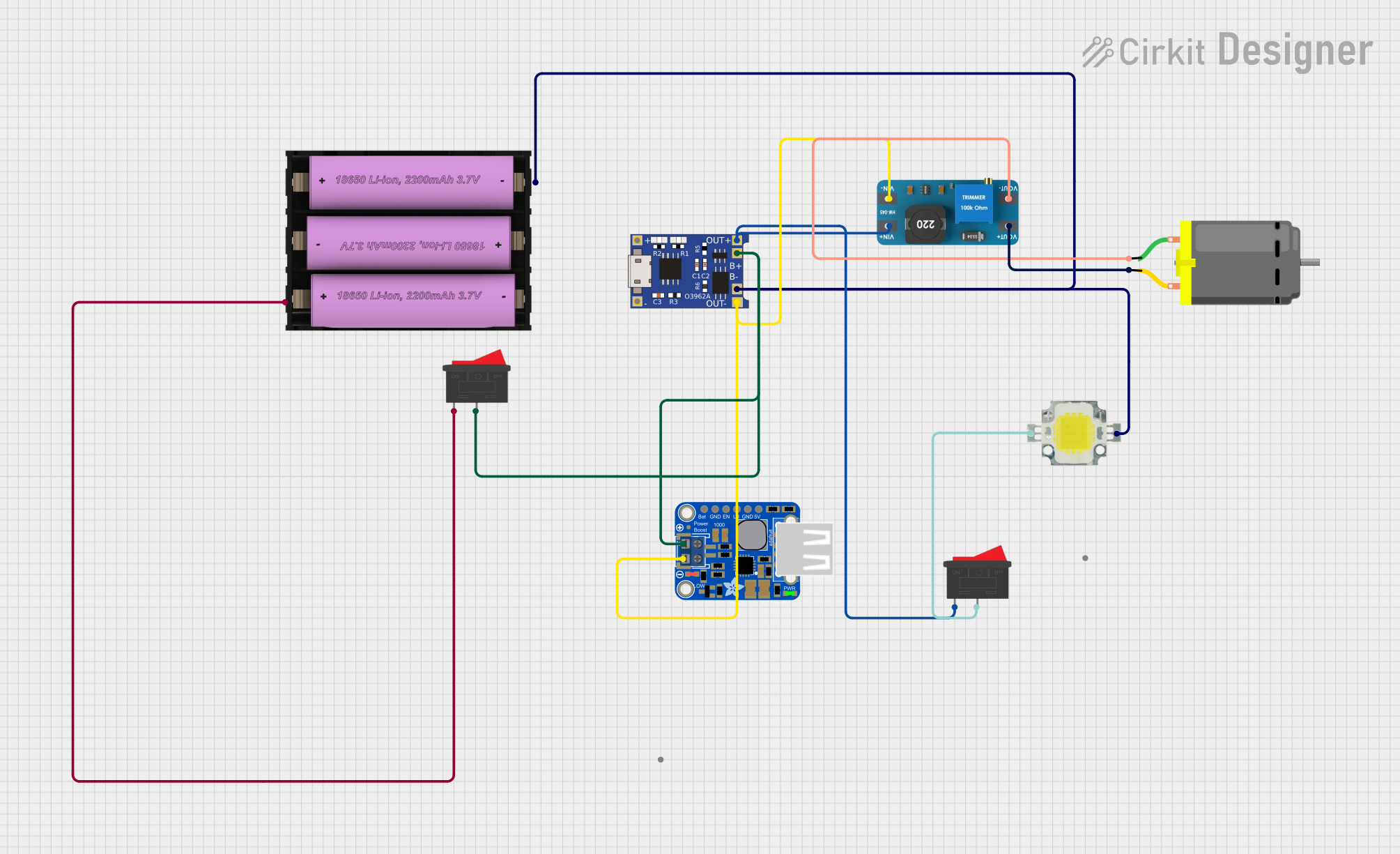

Explore Projects Built with Power Cell - LiPo Charger/Booster

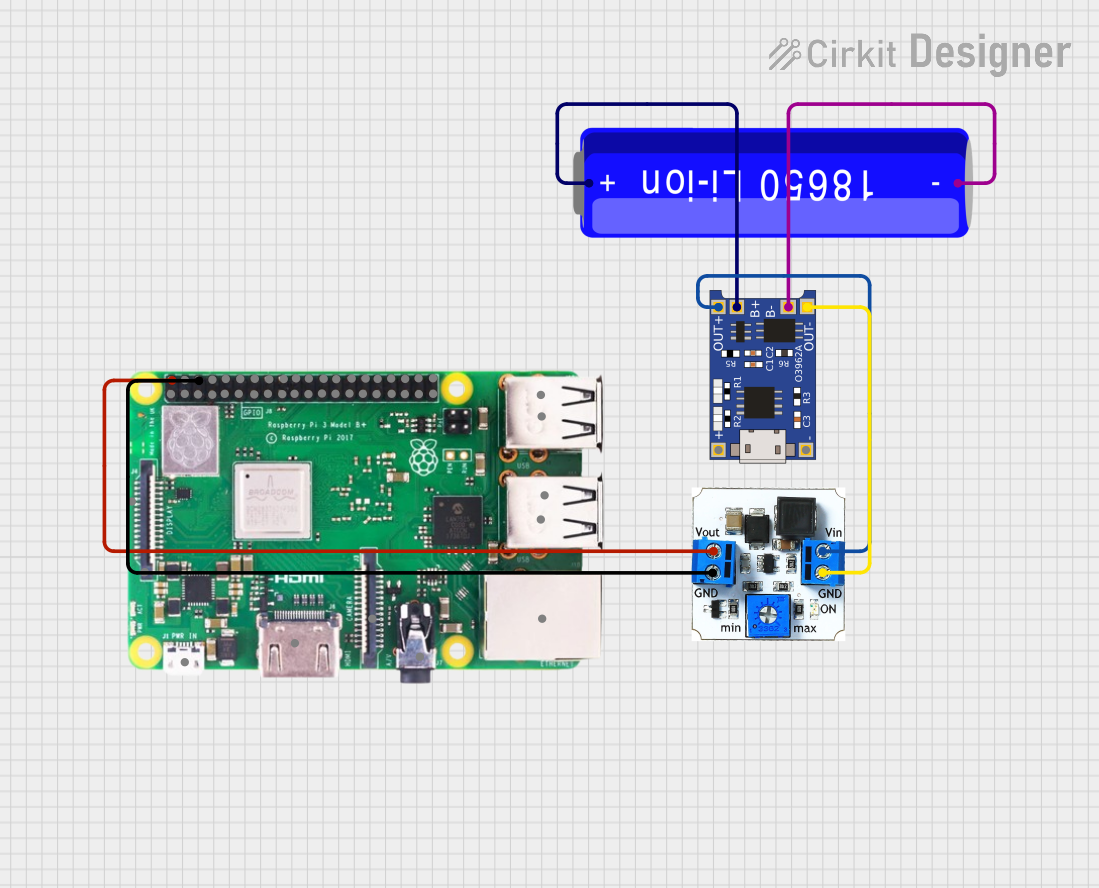

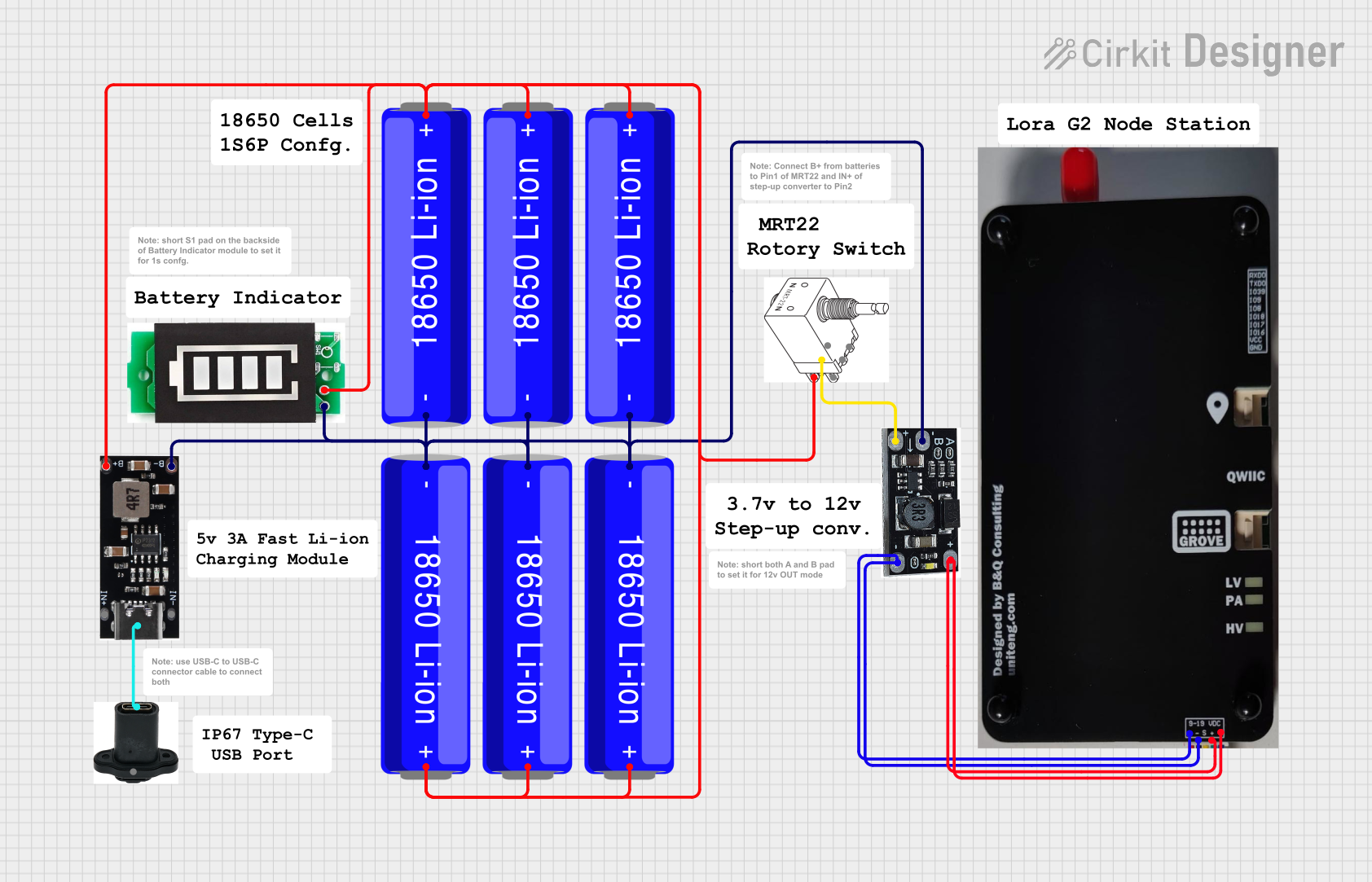

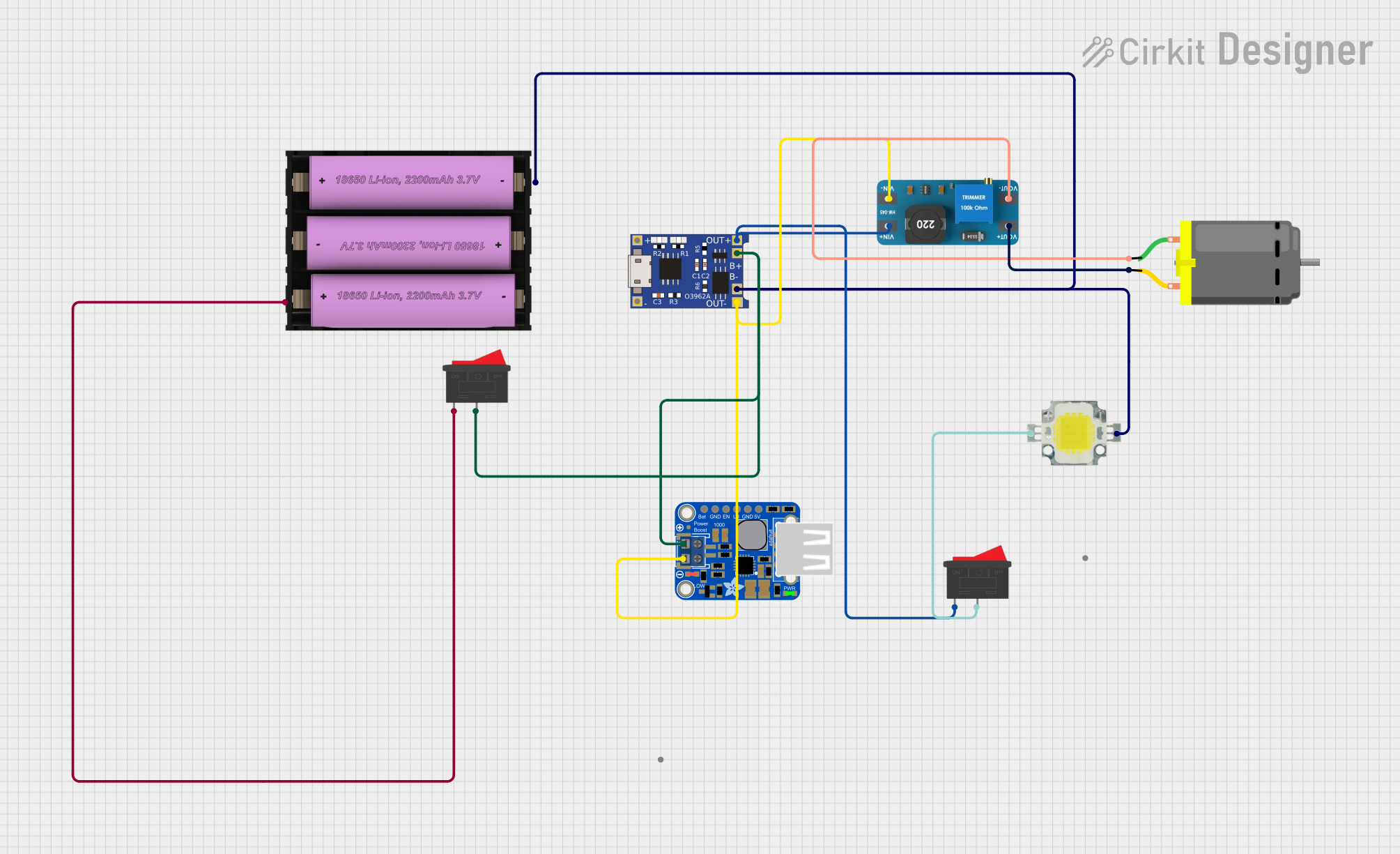

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Power Cell - LiPo Charger/Booster

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Portable electronic devices

- Wearable technology

- IoT devices

- DIY projects requiring a rechargeable power source

- Robotics

Technical Specifications

Key Technical Details

- Input Voltage (via micro-USB): 5V

- Battery Charging Voltage: 4.2V (for single-cell LiPo batteries)

- Selectable Output Voltages: Typically 3.3V and 5V

- Maximum Charging Current: 1A (adjustable)

- Output Current: Depends on the input and output voltage settings

- Efficiency: Up to 95% (depends on input and output voltages)

- Operating Temperature: -40°C to +85°C

Pin Configuration and Descriptions

| Pin Name | Description |

|---|---|

| BAT+ | Positive terminal for LiPo battery connection |

| BAT- | Negative terminal for LiPo battery connection |

| GND | Ground connection |

| VOUT | Regulated output voltage |

| USB+ | Positive input from micro-USB port |

| USB- | Negative input from micro-USB port |

| EN | Enable pin for the booster circuit (active high) |

| SEL | Voltage selection pin (logic level determines output voltage) |

Usage Instructions

How to Use the Component in a Circuit

Connecting the Battery:

- Connect the LiPo battery to the BAT+ and BAT- terminals, ensuring correct polarity.

Charging the Battery:

- Plug a micro-USB cable into the module and a 5V USB power source.

- The onboard charging circuit will safely charge the connected LiPo battery.

Selecting Output Voltage:

- Use the SEL pin to select the desired output voltage. A logic high will typically select 5V, and a logic low will select 3.3V.

Enabling the Booster:

- Apply a logic high signal to the EN pin to enable the booster circuit.

Drawing Power:

- Connect your load to the VOUT and GND pins, ensuring it does not exceed the module's maximum output current rating.

Important Considerations and Best Practices

- Always verify the polarity of the LiPo battery before connecting it to the module.

- Do not exceed the recommended charging current by adjusting the onboard potentiometer without proper knowledge.

- Ensure the input power source does not exceed 5V to avoid damaging the module.

- Avoid placing the module in environments that exceed its operating temperature range.

- When selecting the output voltage, ensure that your load can tolerate the selected voltage.

Troubleshooting and FAQs

Common Issues

Battery Not Charging:

- Check the micro-USB cable and power source.

- Ensure the battery polarity is correct.

- Verify that the battery is not damaged.

No Output Voltage:

- Ensure the EN pin is set high to enable the booster.

- Check if the SEL pin is correctly set for the desired output voltage.

- Verify that the load does not exceed the maximum output current.

Solutions and Tips for Troubleshooting

- If the battery is not charging, try a different USB cable or power source.

- For no output voltage, double-check the connections to the EN and SEL pins.

- If the module is overheating, reduce the load or improve ventilation around the module.

FAQs

Q: Can I charge multiple LiPo batteries at once? A: No, this module is designed to charge a single-cell LiPo battery.

Q: What should I do if the module gets hot during operation? A: Ensure that the load is within the module's limits and that there is adequate ventilation. If the issue persists, reduce the load.

Q: Can I use this module with batteries other than LiPo? A: This module is specifically designed for single-cell LiPo batteries and may not be suitable for other battery types.

Q: How do I adjust the charging current? A: The charging current can be adjusted via an onboard potentiometer, but this should only be done by those with the appropriate knowledge and experience.

Example Code for Arduino UNO

// Example code to enable the Power Cell - LiPo Charger/Booster with an Arduino UNO

const int enablePin = 7; // Connect to the EN pin on the module

const int selectPin = 8; // Connect to the SEL pin on the module

void setup() {

pinMode(enablePin, OUTPUT);

pinMode(selectPin, OUTPUT);

// Enable the booster circuit

digitalWrite(enablePin, HIGH);

// Select output voltage (HIGH for 5V, LOW for 3.3V)

digitalWrite(selectPin, HIGH); // Set this to LOW for 3.3V

}

void loop() {

// Your code here to interact with the powered circuit

}

Remember to ensure that the Arduino pins used in the code are correctly connected to the EN and SEL pins on the Power Cell module. Adjust the selectPin logic level according to the required output voltage for your project.