How to Use DOUBLE SOLENOID: Examples, Pinouts, and Specs

Design with DOUBLE SOLENOID in Cirkit Designer

Design with DOUBLE SOLENOID in Cirkit DesignerIntroduction

The Double Solenoid by FESTO (Manufacturer Part ID: DOUBLE SOLENOID) is an electromechanical device equipped with two coils. These coils can move a plunger or armature in two directions, making it ideal for controlling the flow of fluids or gases in various systems. Double solenoids are commonly used in automation, pneumatic systems, and hydraulic systems to achieve precise control over fluid or gas flow.

Explore Projects Built with DOUBLE SOLENOID

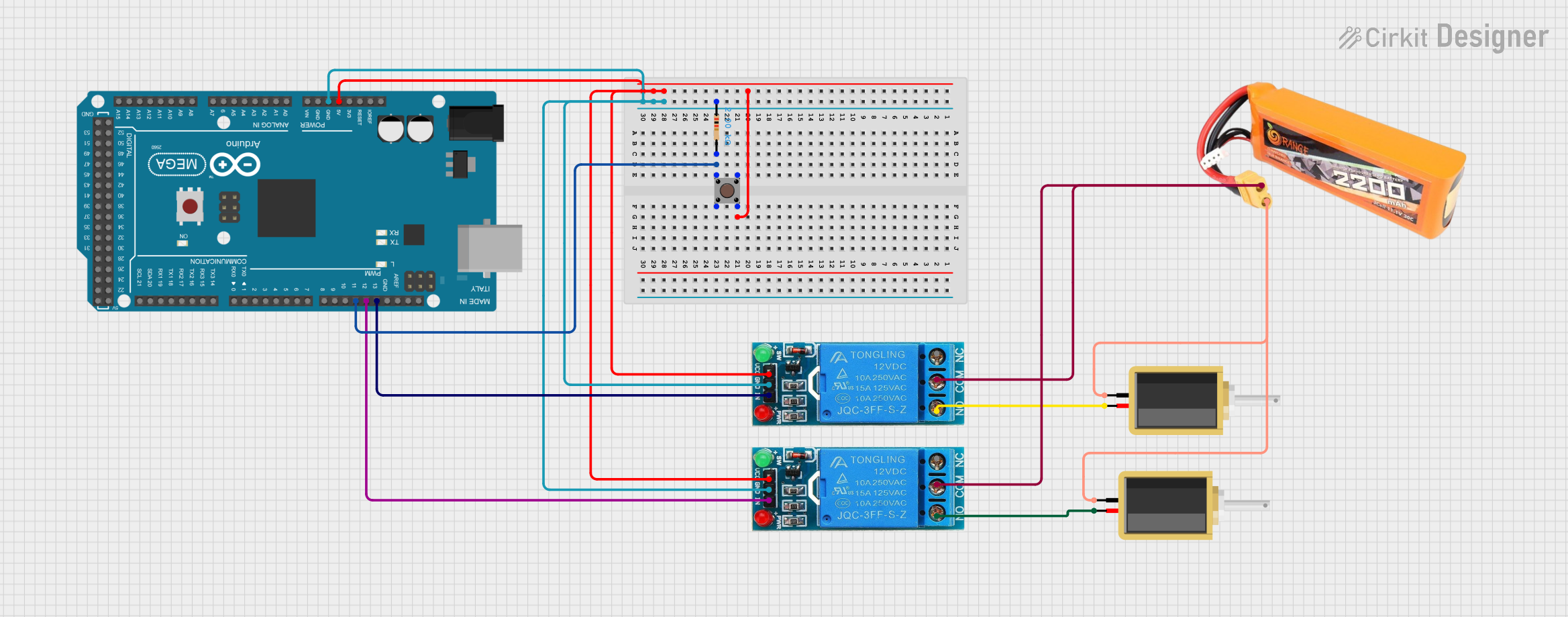

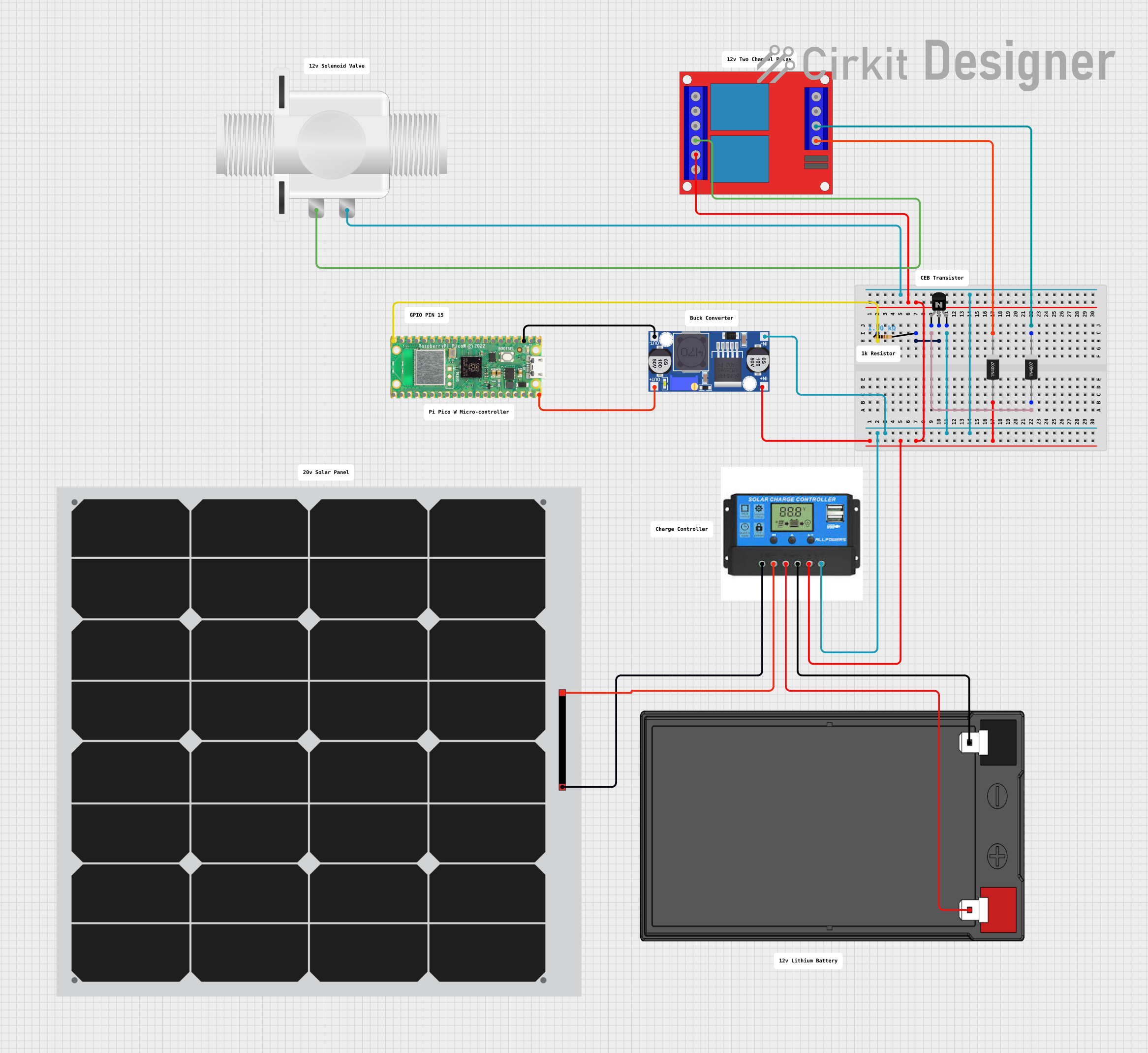

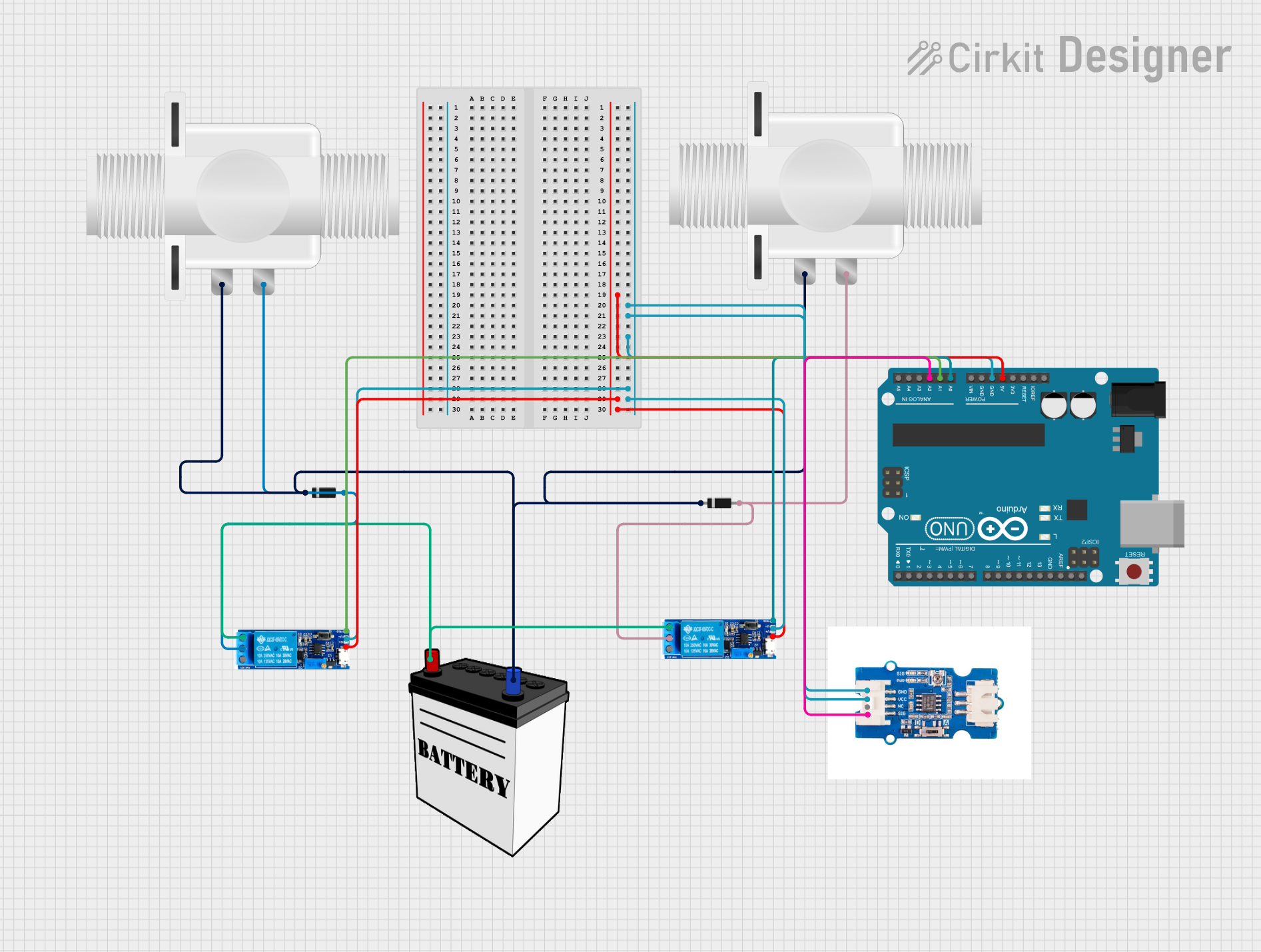

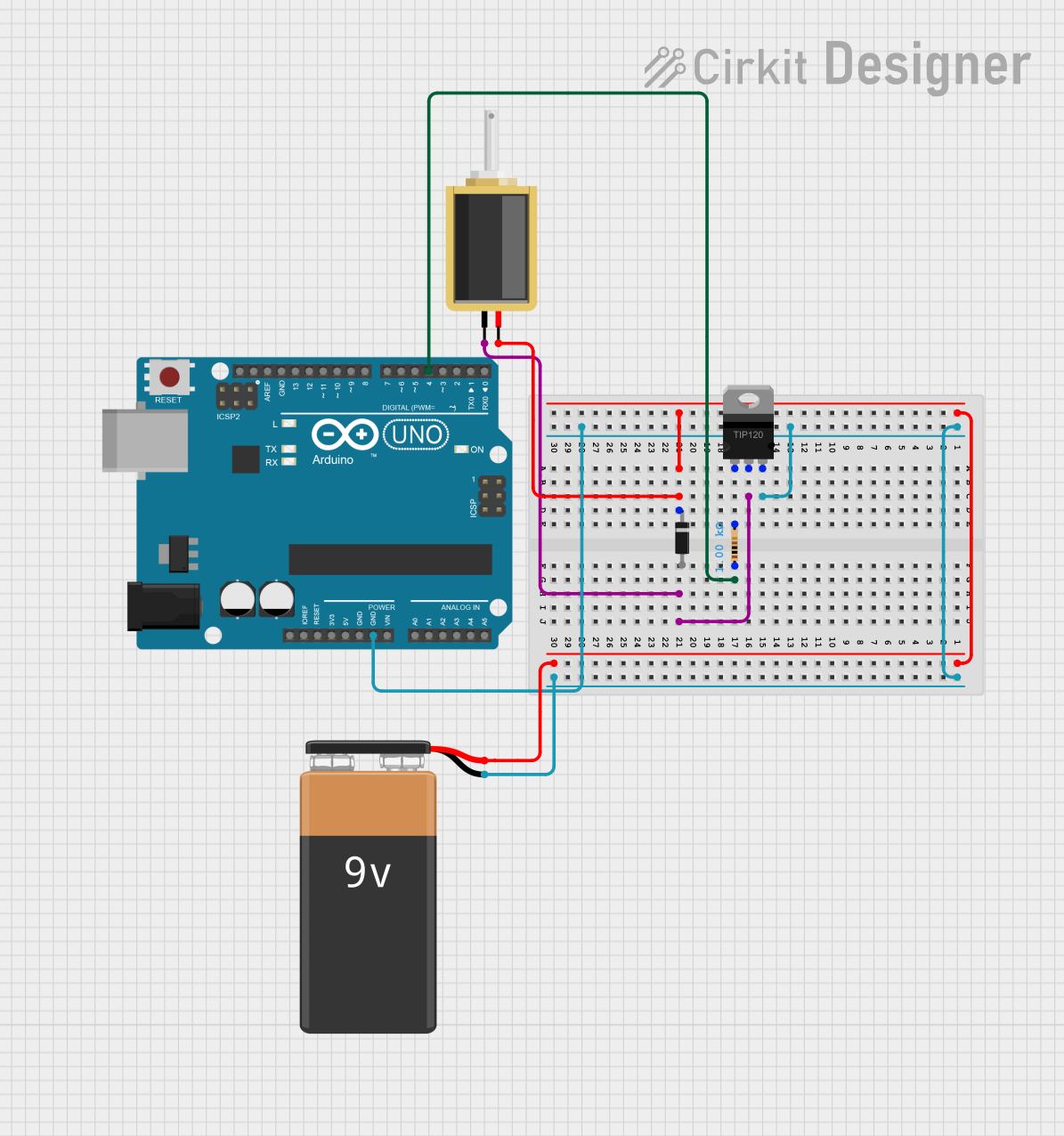

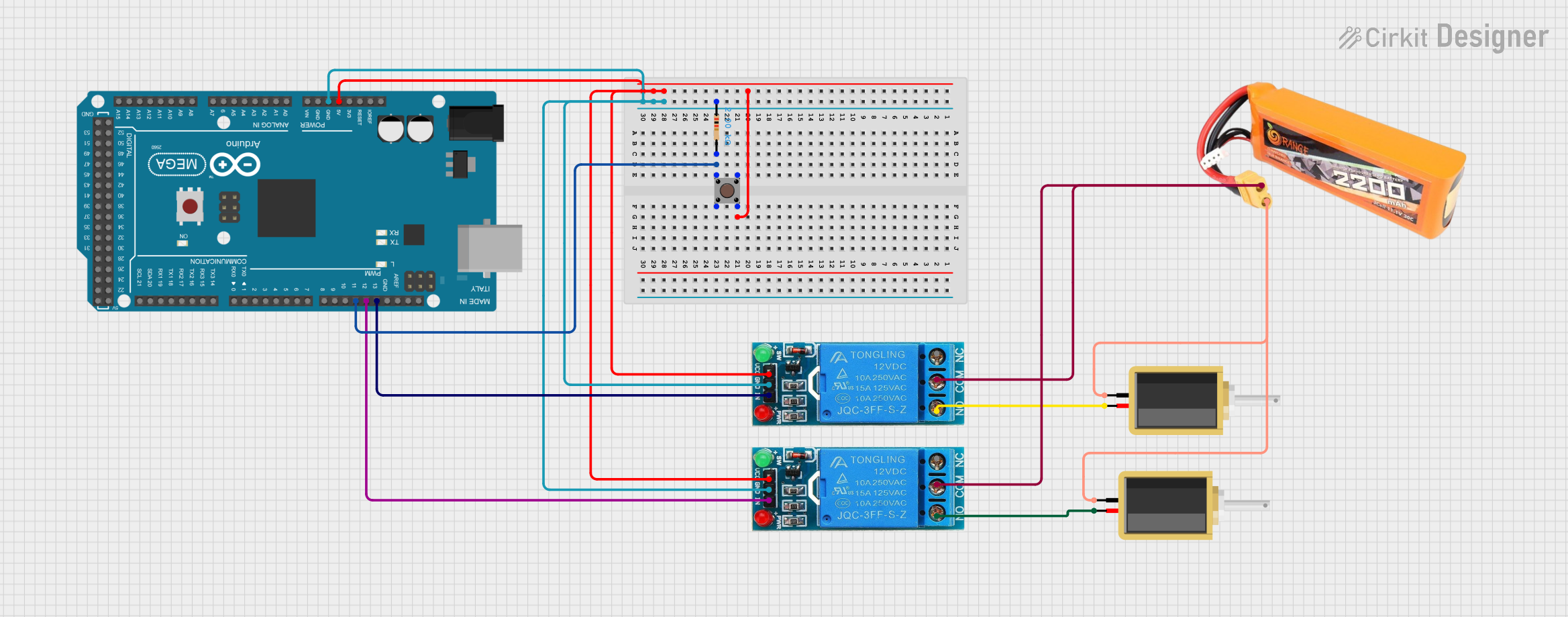

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

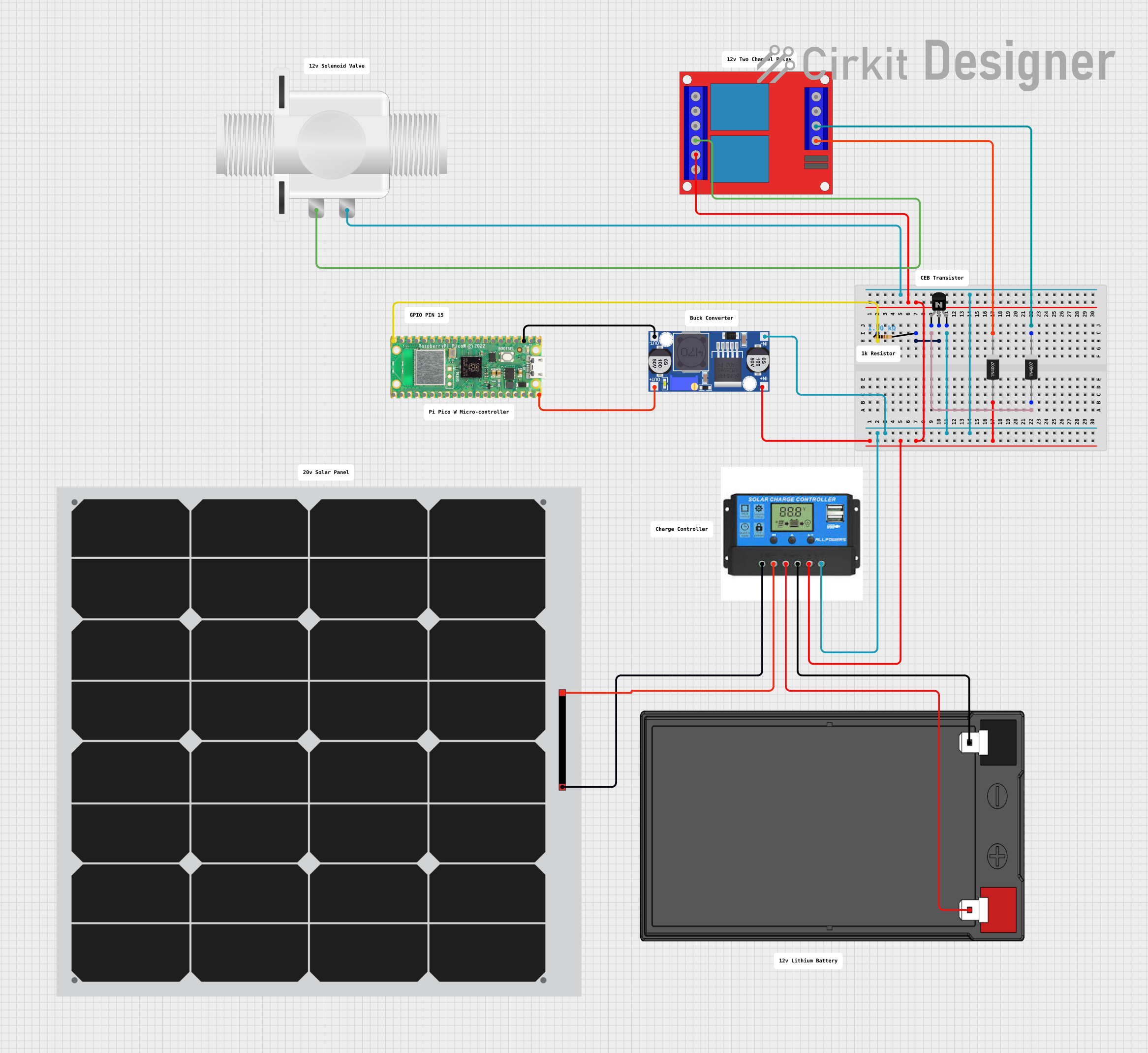

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DOUBLE SOLENOID

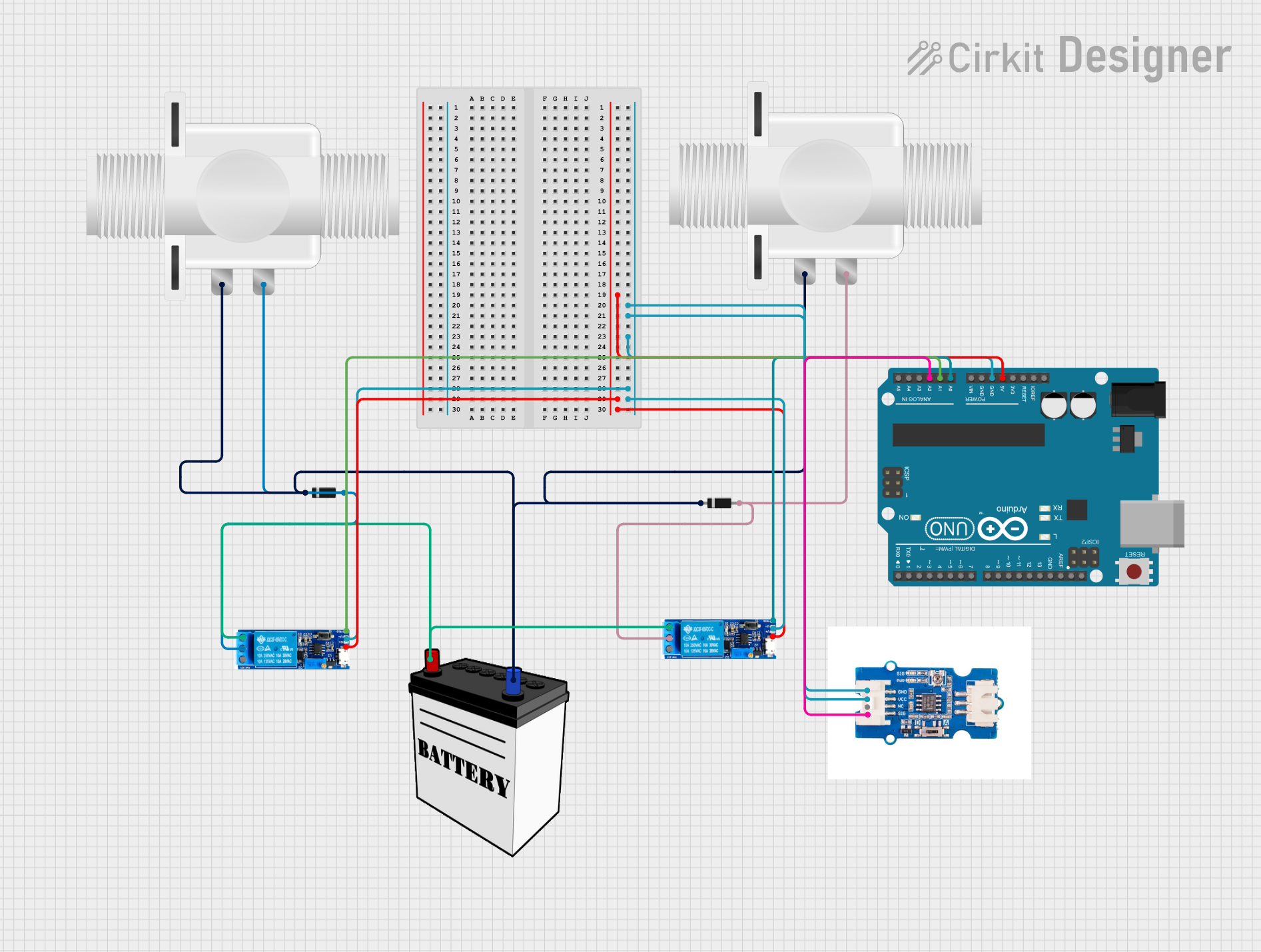

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

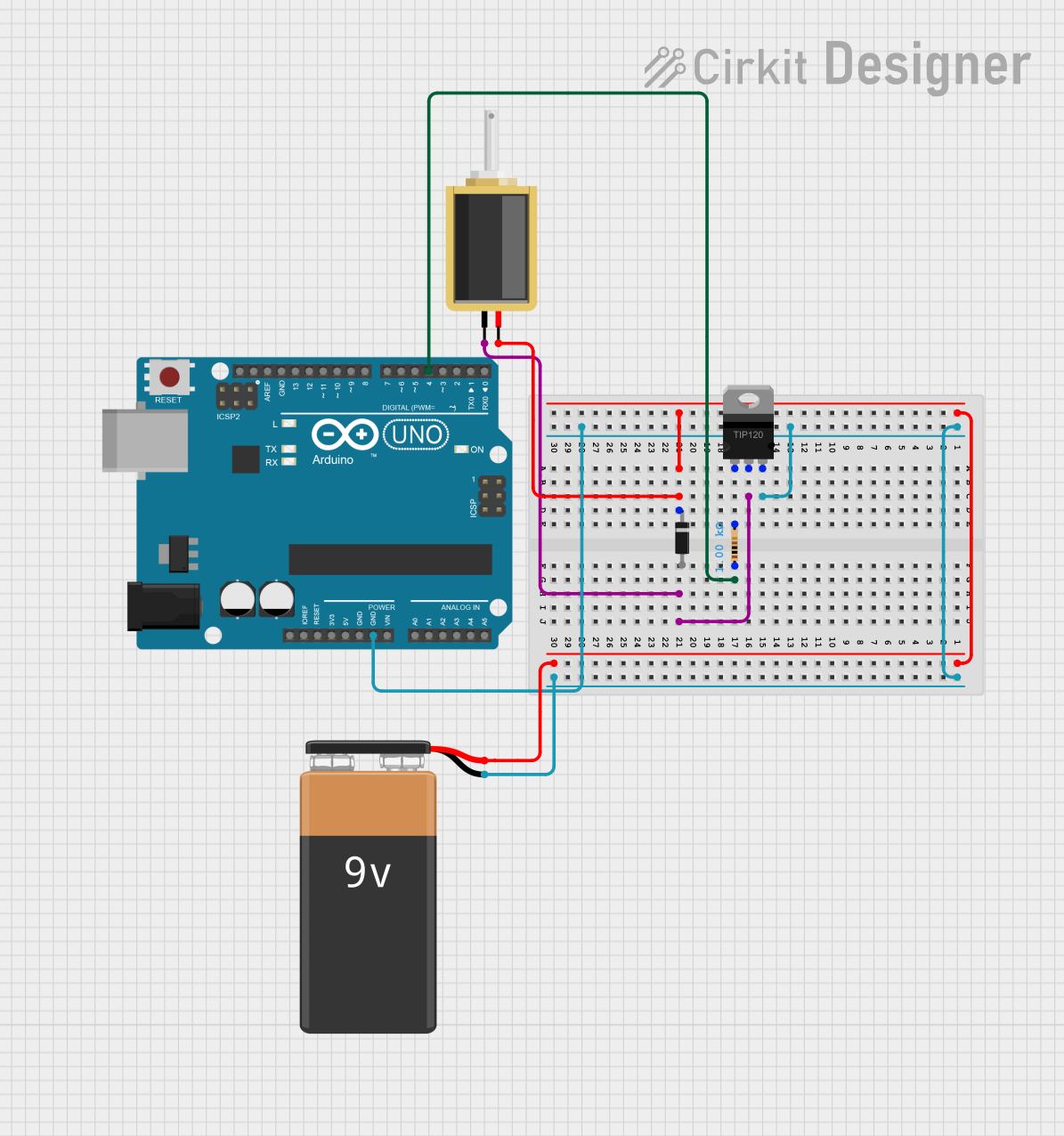

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Voltage | 24V DC |

| Current | 0.5A per coil |

| Power Rating | 12W per coil |

| Actuation Time | 20 ms |

| Operating Pressure | 0 to 10 bar |

| Temperature Range | -10°C to 50°C |

| Duty Cycle | 100% |

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Coil A Positive |

| 2 | Coil A Negative |

| 3 | Coil B Positive |

| 4 | Coil B Negative |

| 5 | Common Ground |

| 6 | Not Connected (NC) |

Usage Instructions

How to Use the Component in a Circuit

To use the double solenoid in a circuit, follow these steps:

- Power Supply: Ensure you have a 24V DC power supply capable of providing at least 1A of current.

- Connections:

- Connect Pin 1 to the positive terminal of the power supply for Coil A.

- Connect Pin 2 to the negative terminal of the power supply for Coil A.

- Connect Pin 3 to the positive terminal of the power supply for Coil B.

- Connect Pin 4 to the negative terminal of the power supply for Coil B.

- Connect Pin 5 to the common ground of your circuit.

- Control: Use a microcontroller or relay to control the activation of each coil. Activating Coil A will move the plunger in one direction, while activating Coil B will move it in the opposite direction.

Important Considerations and Best Practices

- Power Supply: Ensure the power supply is stable and within the specified voltage range to avoid damaging the solenoid.

- Heat Dissipation: Double solenoids can generate heat during operation. Ensure proper ventilation or heat dissipation mechanisms are in place.

- Duty Cycle: Although the solenoid is rated for 100% duty cycle, avoid continuous activation for extended periods to prolong the lifespan of the coils.

- Debouncing: When using a microcontroller, implement debouncing techniques to avoid rapid switching that can cause wear and tear.

Example Code for Arduino UNO

Below is an example code to control the double solenoid using an Arduino UNO:

// Define pin connections

const int coilAPin = 8; // Pin connected to Coil A

const int coilBPin = 9; // Pin connected to Coil B

void setup() {

// Set pin modes

pinMode(coilAPin, OUTPUT);

pinMode(coilBPin, OUTPUT);

}

void loop() {

// Activate Coil A

digitalWrite(coilAPin, HIGH);

delay(1000); // Keep Coil A activated for 1 second

// Deactivate Coil A

digitalWrite(coilAPin, LOW);

delay(500); // Wait for 0.5 seconds

// Activate Coil B

digitalWrite(coilBPin, HIGH);

delay(1000); // Keep Coil B activated for 1 second

// Deactivate Coil B

digitalWrite(coilBPin, LOW);

delay(500); // Wait for 0.5 seconds

}

Troubleshooting and FAQs

Common Issues Users Might Face

Solenoid Not Activating:

- Solution: Check the power supply voltage and current. Ensure connections are secure and correct.

Overheating:

- Solution: Ensure proper ventilation and avoid continuous activation for extended periods.

Erratic Behavior:

- Solution: Implement debouncing in your control logic to avoid rapid switching.

Solutions and Tips for Troubleshooting

- Check Connections: Ensure all connections are secure and correctly configured according to the pin configuration table.

- Measure Voltage and Current: Use a multimeter to verify that the solenoid is receiving the correct voltage and current.

- Inspect for Damage: Check the solenoid and wiring for any signs of physical damage or wear.

By following this documentation, users can effectively integrate and troubleshoot the FESTO Double Solenoid in their projects, ensuring reliable and efficient operation.