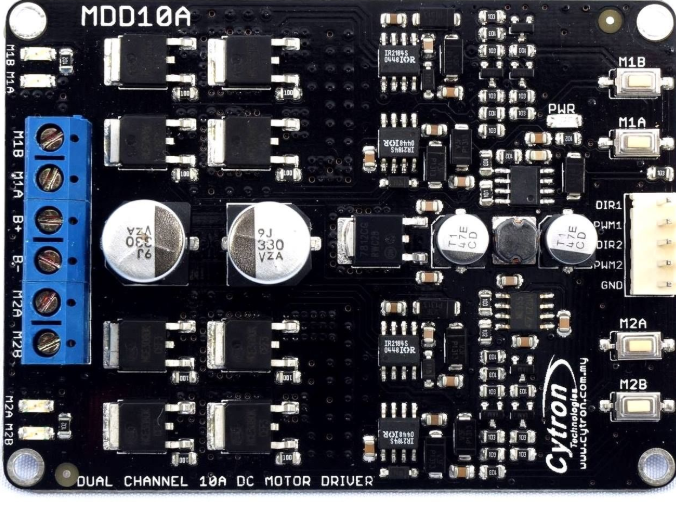

How to Use cytron: Examples, Pinouts, and Specs

Design with cytron in Cirkit Designer

Design with cytron in Cirkit DesignerIntroduction

Cytron Technologies is a company that specializes in creating electronic components for robotics and automation projects. Among their products, motor drivers are some of the most prominent and widely used. These drivers are essential for controlling the speed, direction, and torque of motors in various applications, from hobbyist projects to industrial automation systems.

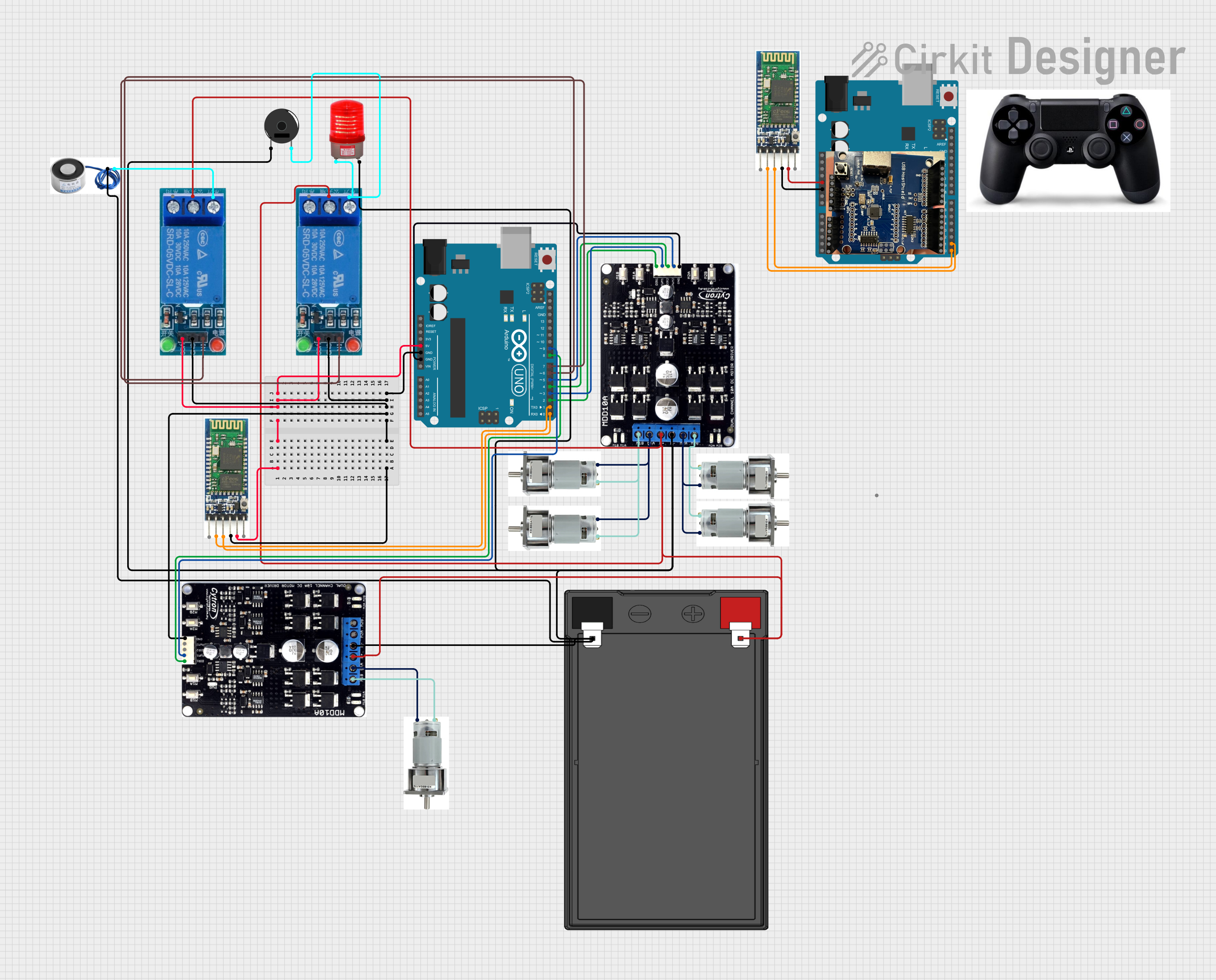

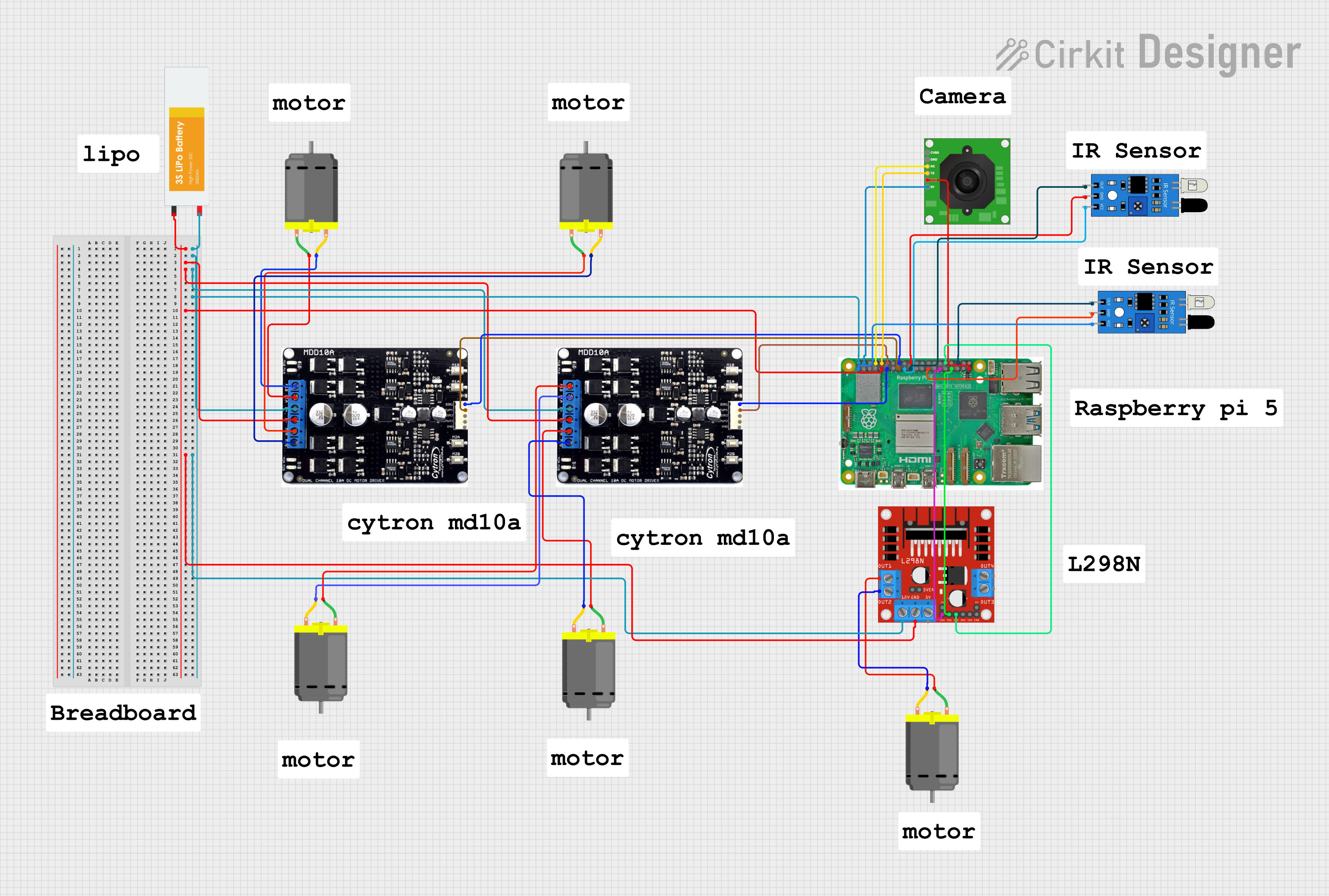

Explore Projects Built with cytron

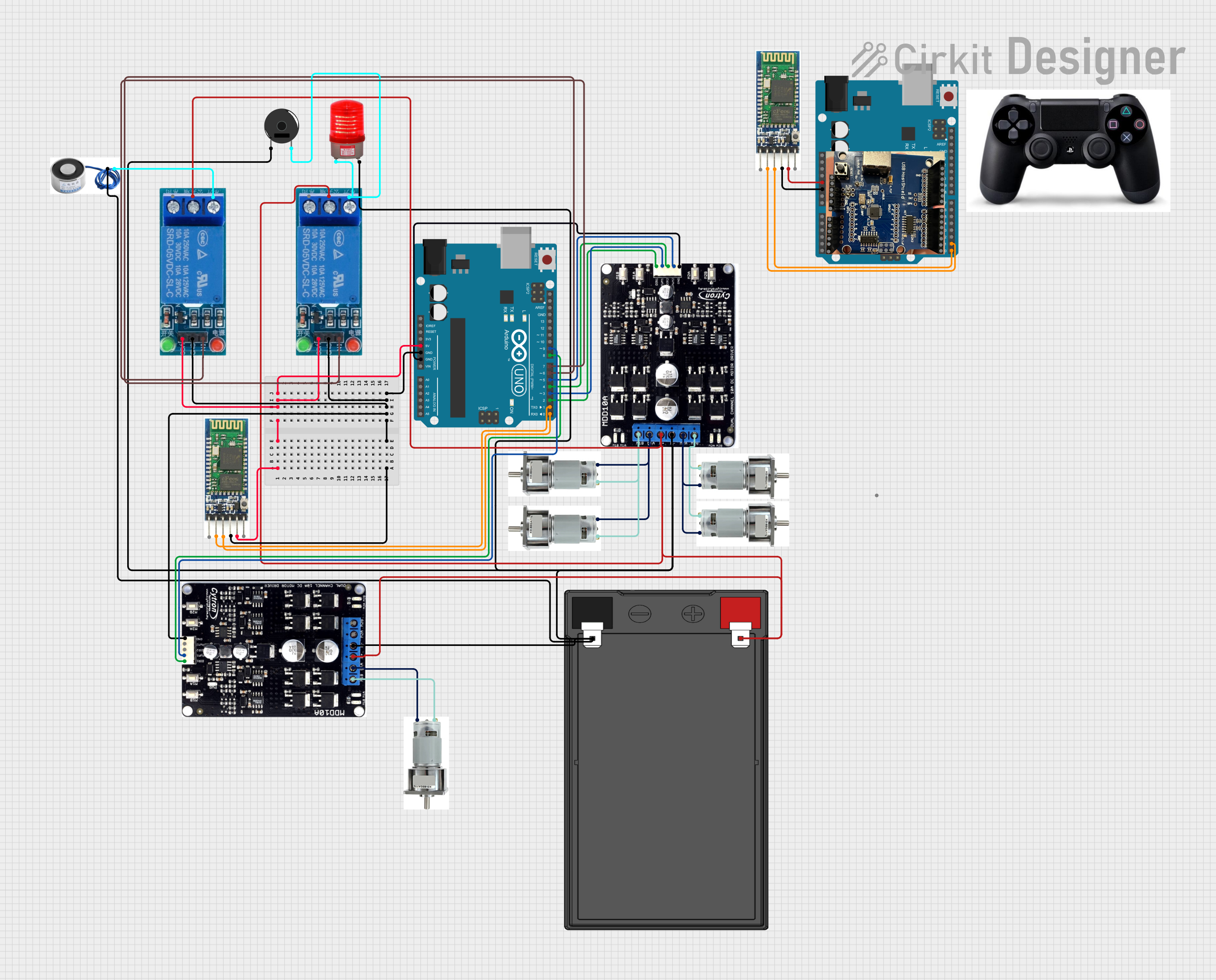

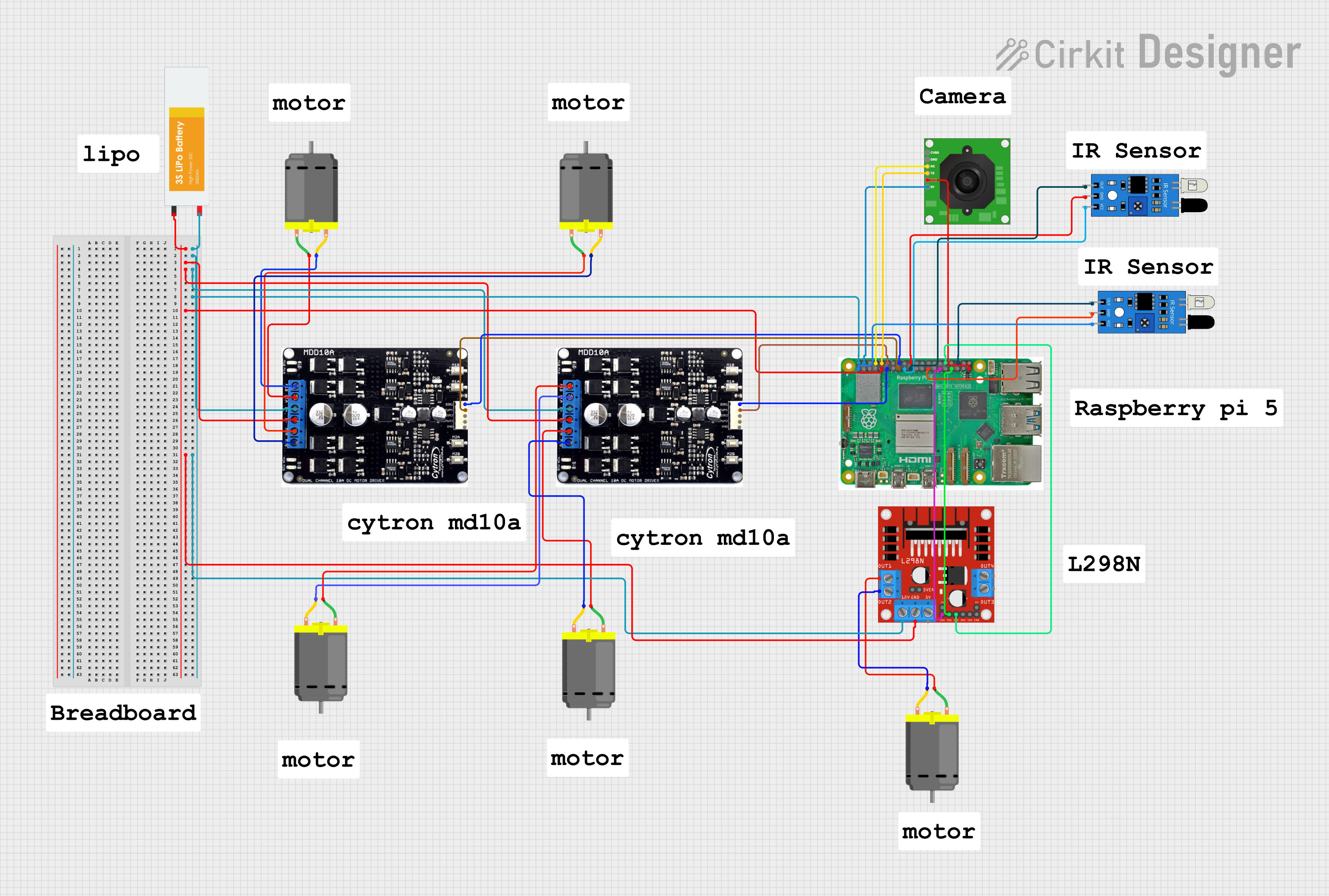

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with cytron

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Controlling DC, stepper, or servo motors for movement and positioning.

- Automation: Driving conveyor belts, actuators, and other machinery.

- Educational Projects: Used in teaching electronics and robotics.

- Hobby Projects: DIY projects such as remote-controlled vehicles and home automation.

Technical Specifications

Key Technical Details

- Voltage Range: Typically from 5V to 30V, depending on the model.

- Current Rating: Varies, with some models supporting up to several amps of continuous current.

- Power Ratings: Dependent on voltage and current specifications.

Pin Configuration and Descriptions

| Pin Name | Description |

|---|---|

| VCC | Power supply for the motor driver (5V to 30V) |

| GND | Ground connection |

| IN1 | Input control pin 1 |

| IN2 | Input control pin 2 |

| PWM | Pulse Width Modulation input for speed control |

| OUT1 | Output to motor terminal A |

| OUT2 | Output to motor terminal B |

Note: The actual pin configuration may vary depending on the specific Cytron motor driver model. Always refer to the datasheet of the specific model you are using.

Usage Instructions

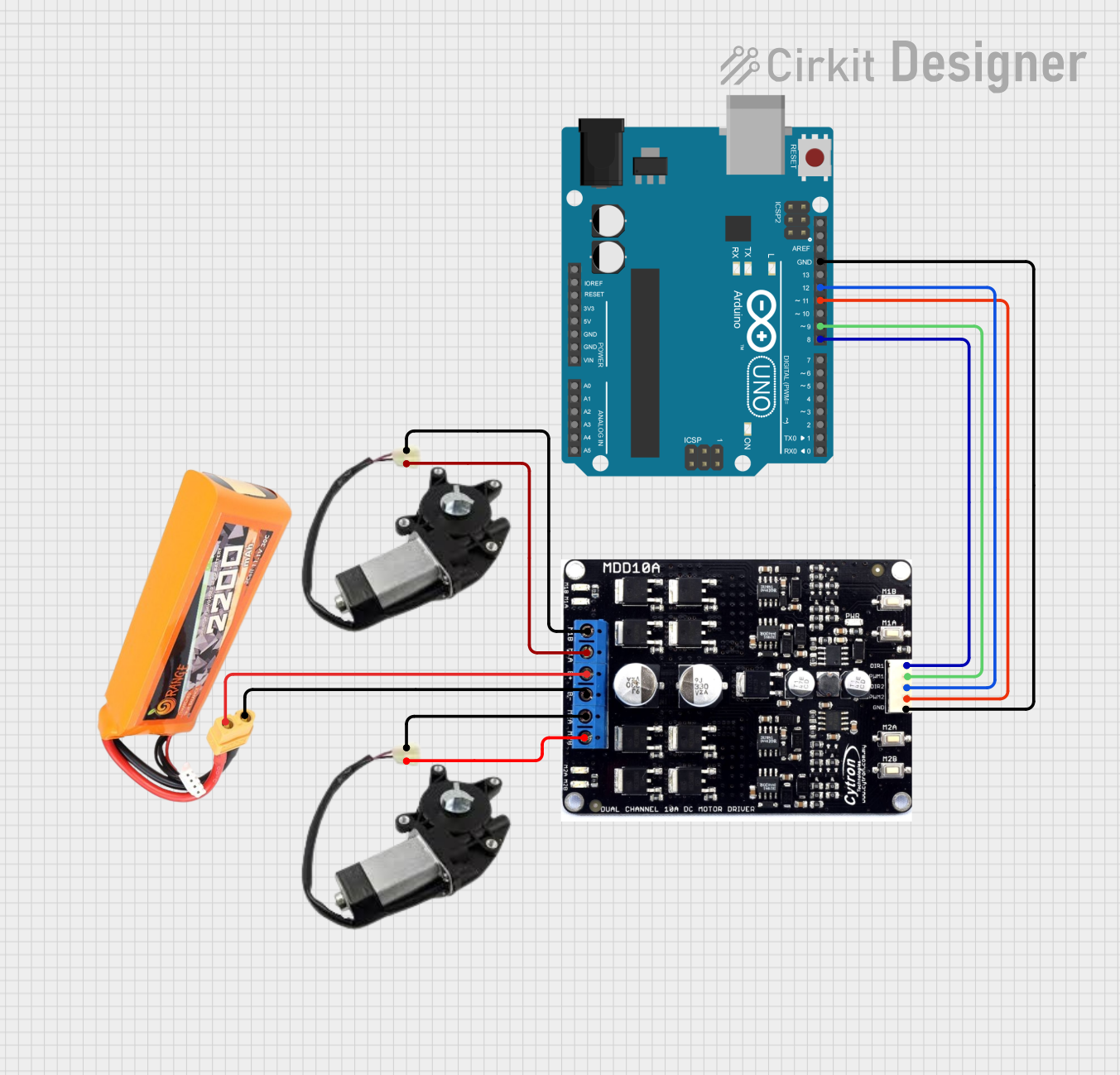

How to Use the Component in a Circuit

- Connect the motor terminals to the OUT1 and OUT2 pins.

- Supply the motor voltage to the VCC pin and connect the ground.

- Apply control signals to IN1 and IN2 to set the motor direction.

- Use the PWM pin to control the speed of the motor by varying the duty cycle.

Important Considerations and Best Practices

- Ensure the power supply matches the motor driver's voltage requirements.

- Do not exceed the current rating of the motor driver.

- Use appropriate decoupling capacitors to minimize voltage spikes.

- Implement proper heat dissipation techniques if the driver is expected to handle high currents.

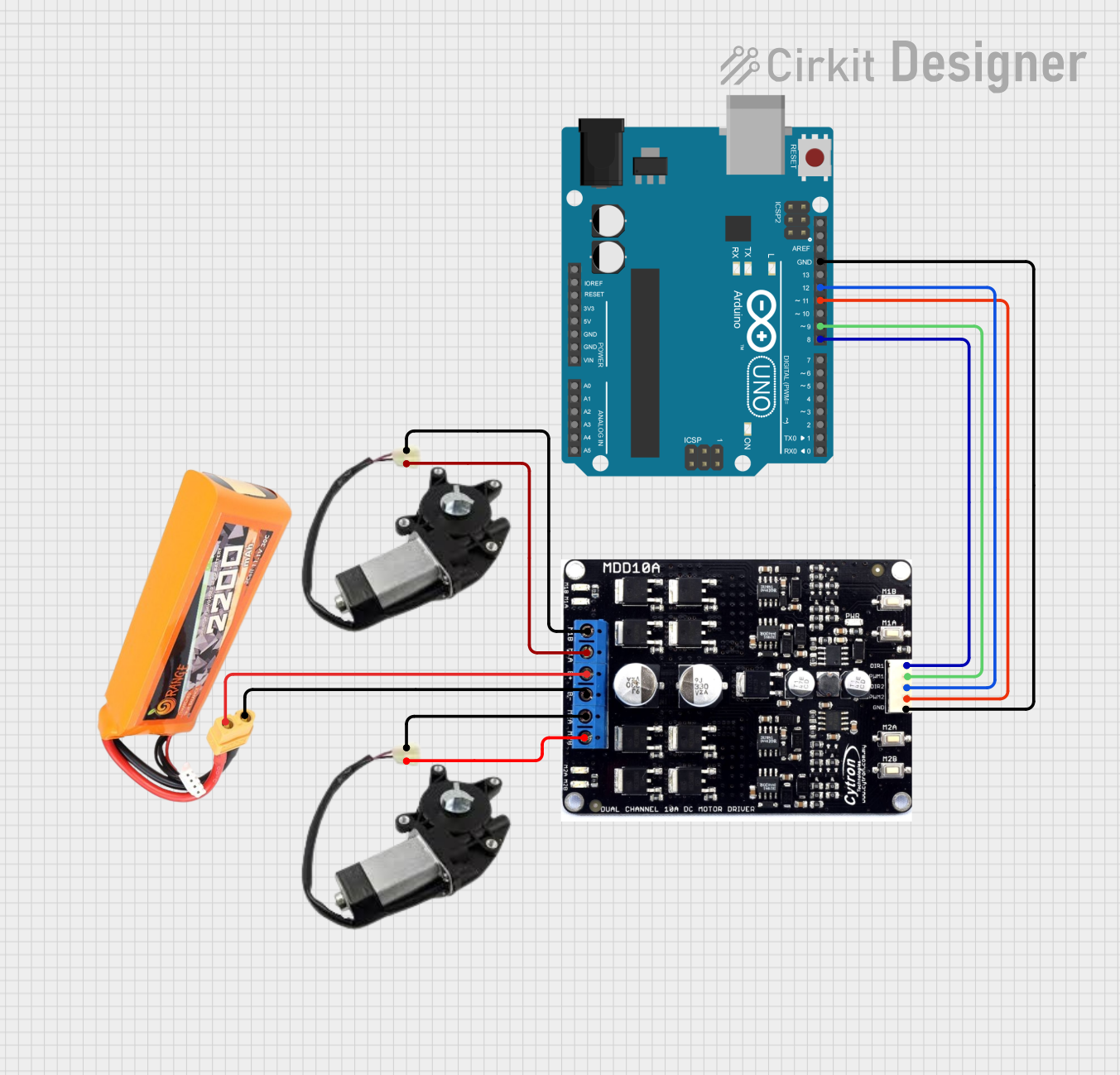

Example Connection with Arduino UNO

// Example code to control a Cytron motor driver with an Arduino UNO

const int in1Pin = 2; // IN1 connected to digital pin 2

const int in2Pin = 3; // IN2 connected to digital pin 3

const int pwmPin = 5; // PWM connected to digital pin 5 (supports PWM)

void setup() {

pinMode(in1Pin, OUTPUT);

pinMode(in2Pin, OUTPUT);

pinMode(pwmPin, OUTPUT);

}

void loop() {

// Set motor direction to clockwise

digitalWrite(in1Pin, HIGH);

digitalWrite(in2Pin, LOW);

// Set motor speed (0 to 255)

analogWrite(pwmPin, 128); // 50% duty cycle for half speed

delay(2000); // Run for 2 seconds

// Change motor direction to counter-clockwise

digitalWrite(in1Pin, LOW);

digitalWrite(in2Pin, HIGH);

delay(2000); // Run for 2 seconds

// Stop the motor

digitalWrite(in1Pin, LOW);

digitalWrite(in2Pin, LOW);

delay(2000); // Stop for 2 seconds

}

Note: The above code is a simple demonstration. Adjust the pin numbers and logic according to your specific application and motor driver model.

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor not running: Check power supply, connections, and signals to IN1, IN2, and PWM.

- Motor running hot: Ensure the current does not exceed the driver's rating and improve cooling.

- Inconsistent motor speed: Verify PWM signal and power supply stability.

Solutions and Tips for Troubleshooting

- Double-check wiring and solder joints for any loose connections.

- Use a multimeter to verify the voltage levels at VCC and the PWM signal.

- Implement a gradual start/stop in your code to avoid sudden current spikes.

FAQs

Q: Can I control two motors with one Cytron driver? A: Some Cytron drivers support dual channels for controlling two motors. Check the specific model's datasheet.

Q: What is the maximum frequency for the PWM signal? A: This depends on the specific motor driver model. Refer to the datasheet for the maximum PWM frequency.

Q: How do I reverse the motor direction? A: Swap the logic levels on IN1 and IN2 pins to reverse the motor's direction.

Note: Always consult the datasheet of the specific Cytron motor driver model you are using for accurate information and instructions.