How to Use Pressure Sensor: Examples, Pinouts, and Specs

Design with Pressure Sensor in Cirkit Designer

Design with Pressure Sensor in Cirkit DesignerIntroduction

The MS4525DO is a high-precision pressure sensor manufactured by TE Connectivity. This device is designed to measure the pressure of gases or liquids and convert the measurement into an electrical signal for monitoring or control purposes. It features a digital output and is ideal for applications requiring accurate and reliable pressure measurements.

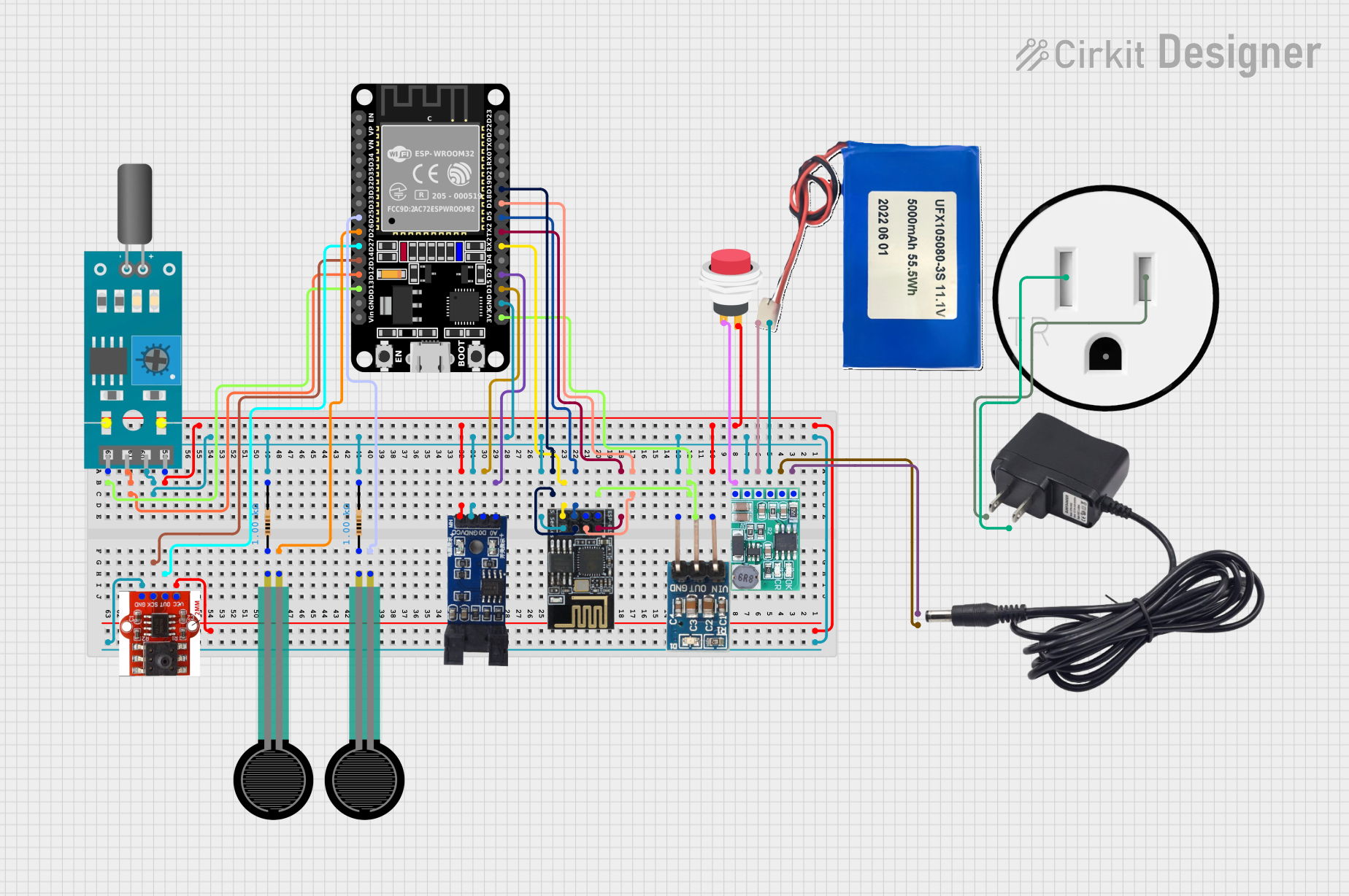

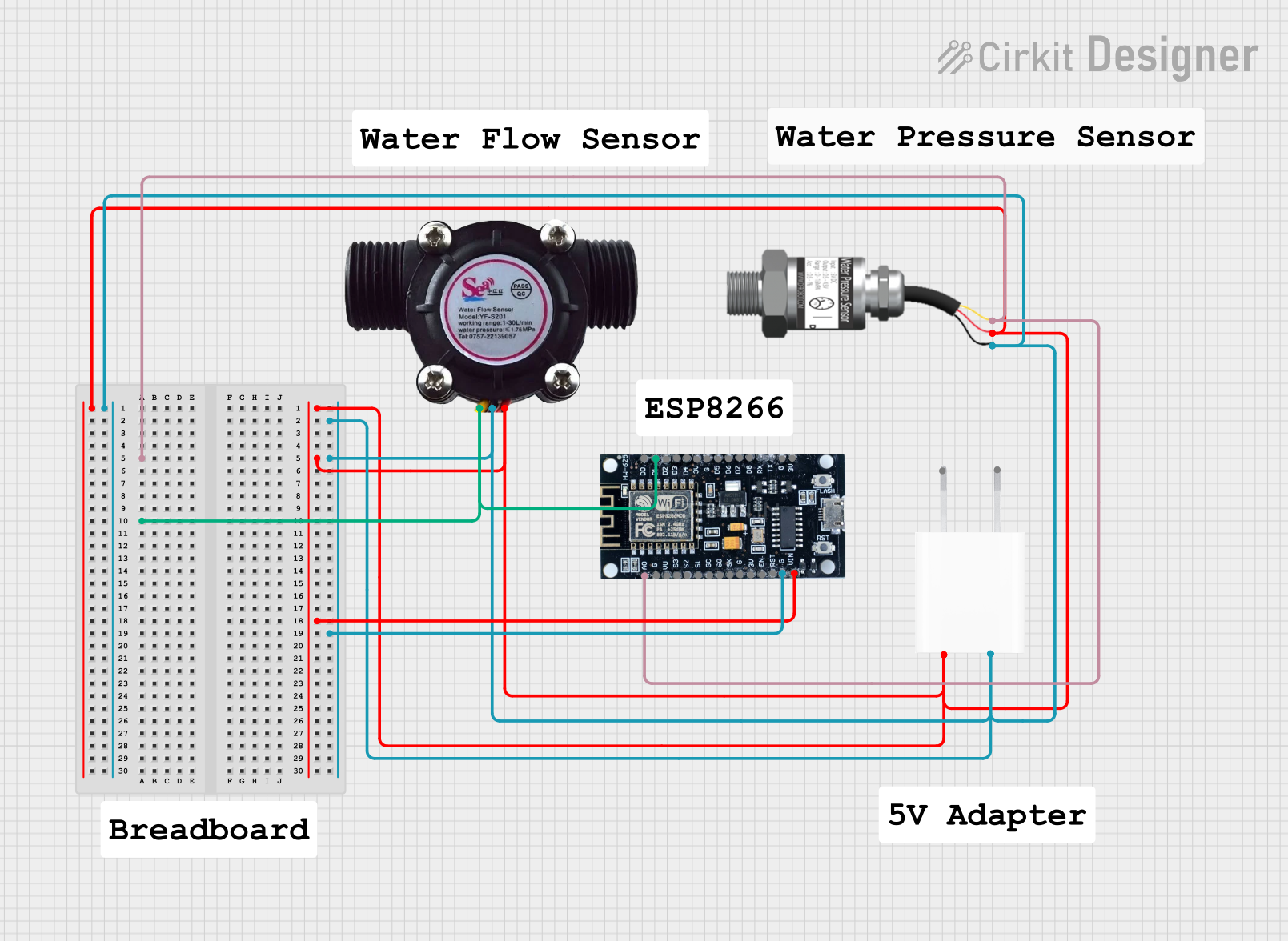

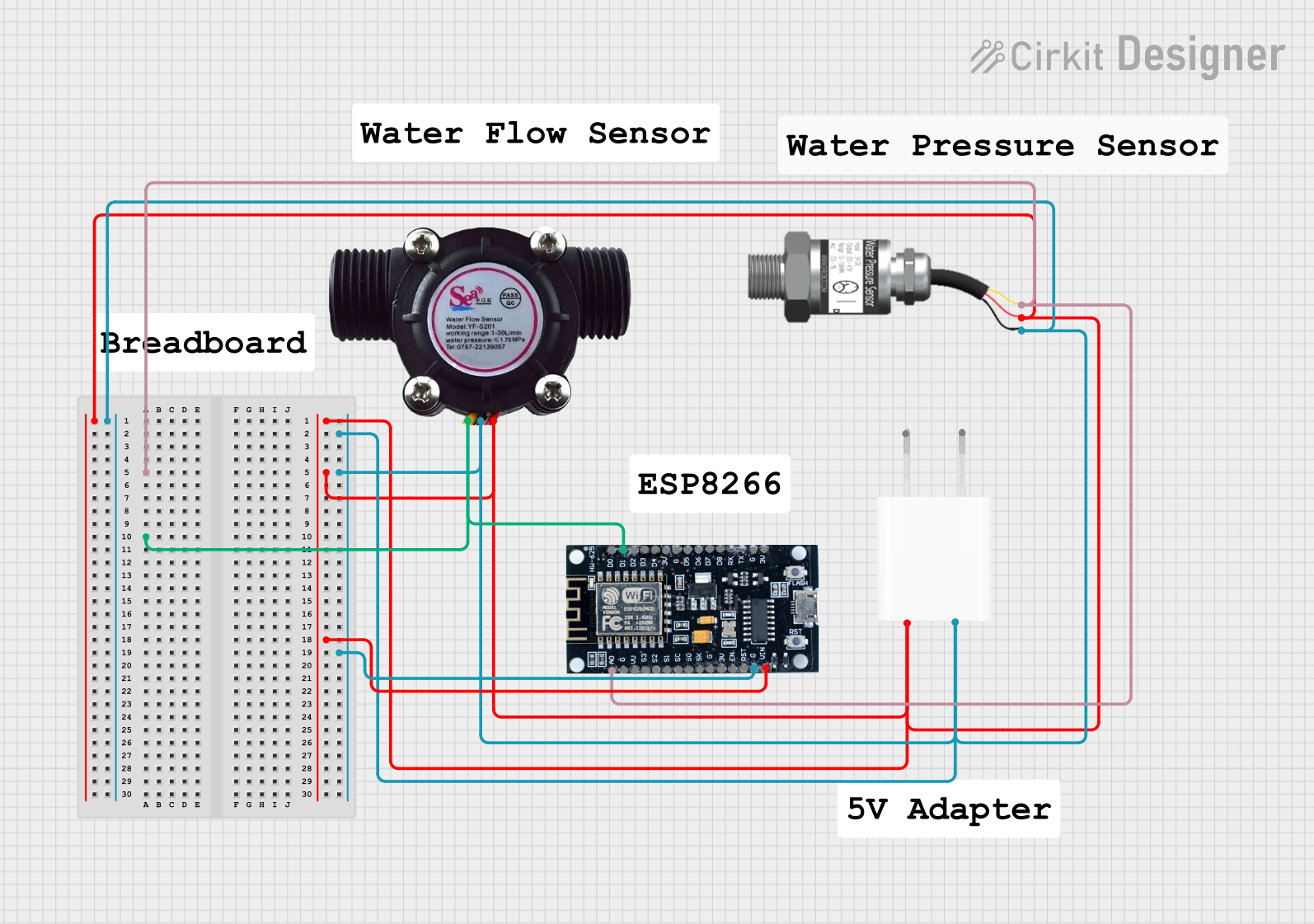

Explore Projects Built with Pressure Sensor

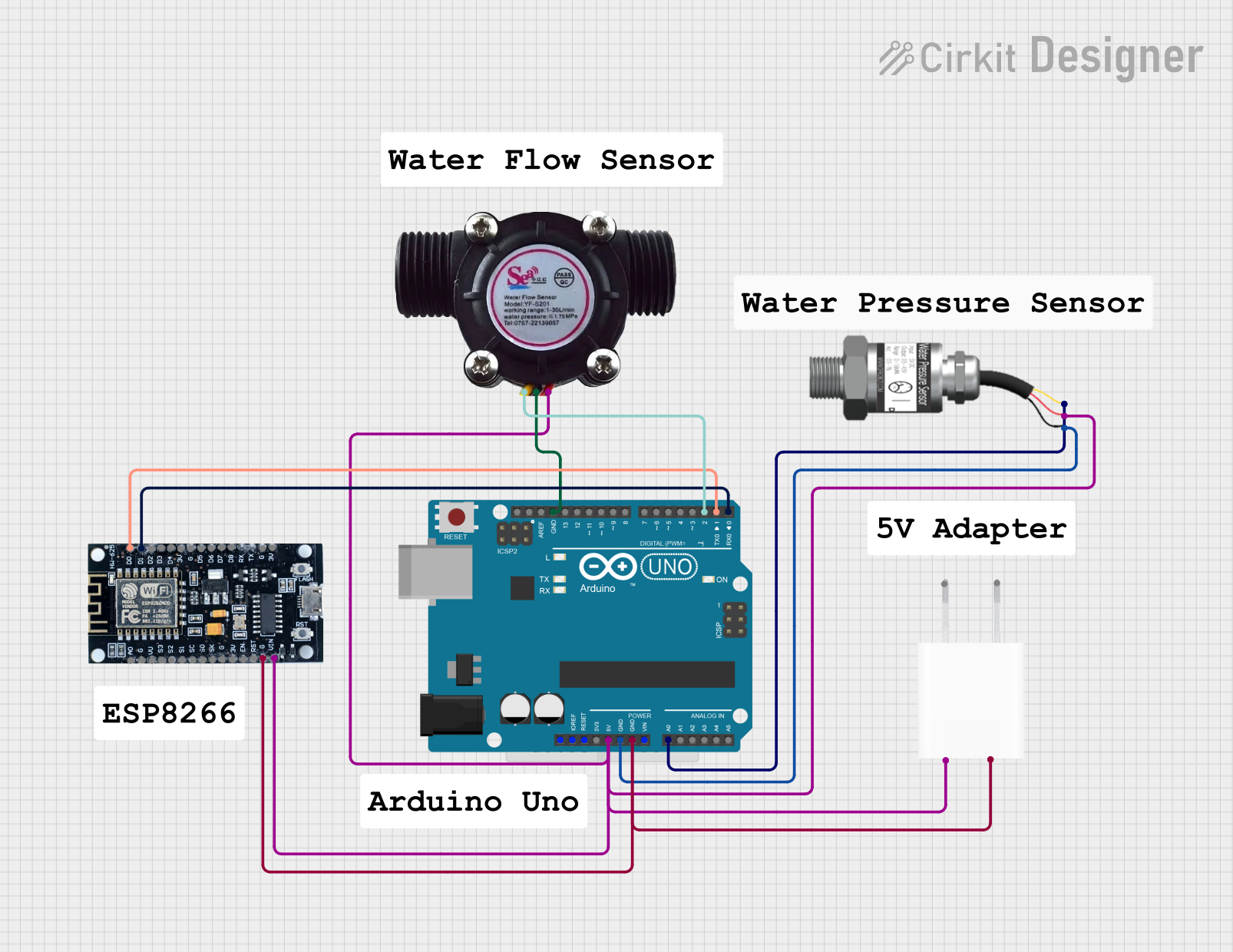

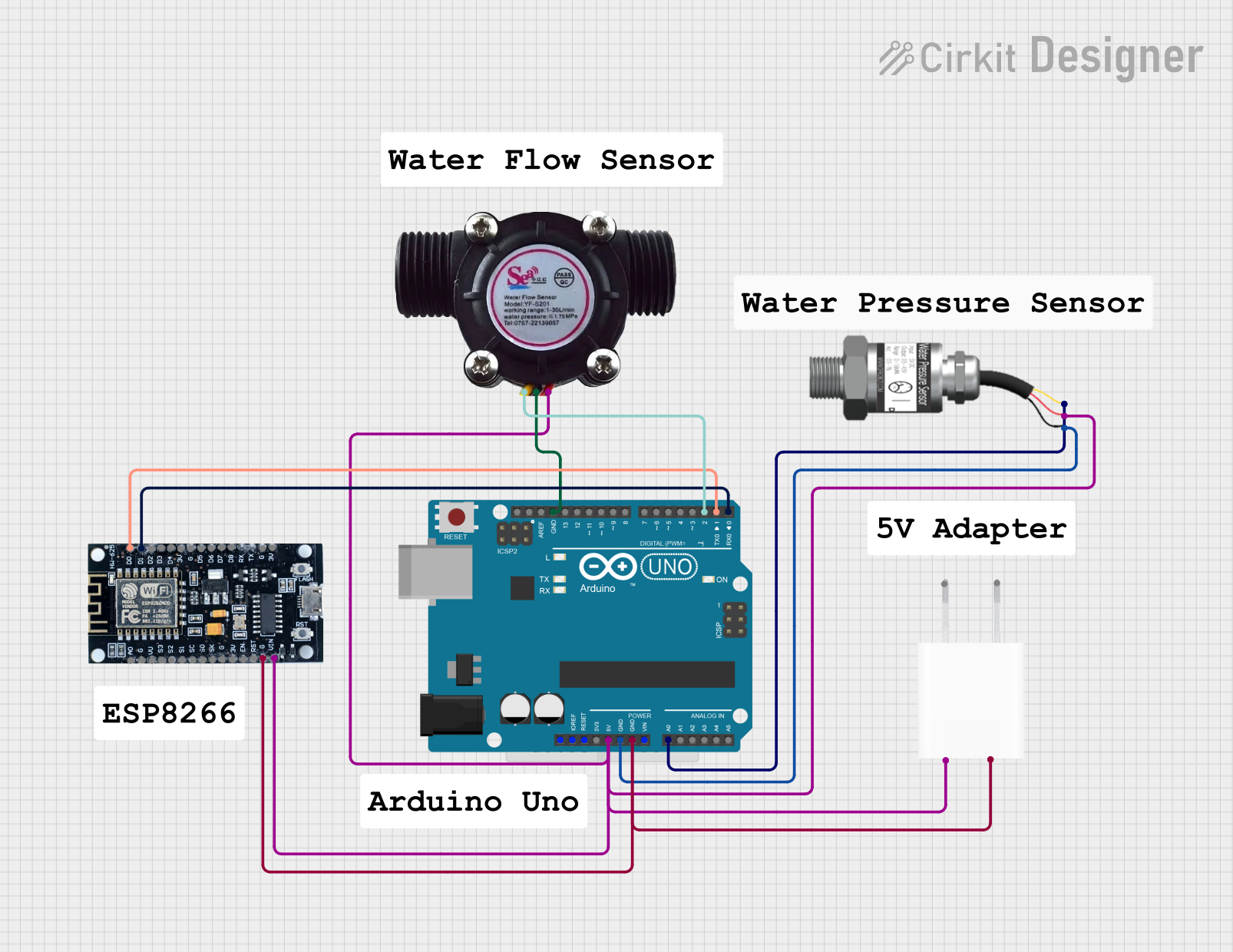

Open Project in Cirkit Designer

Open Project in Cirkit Designer

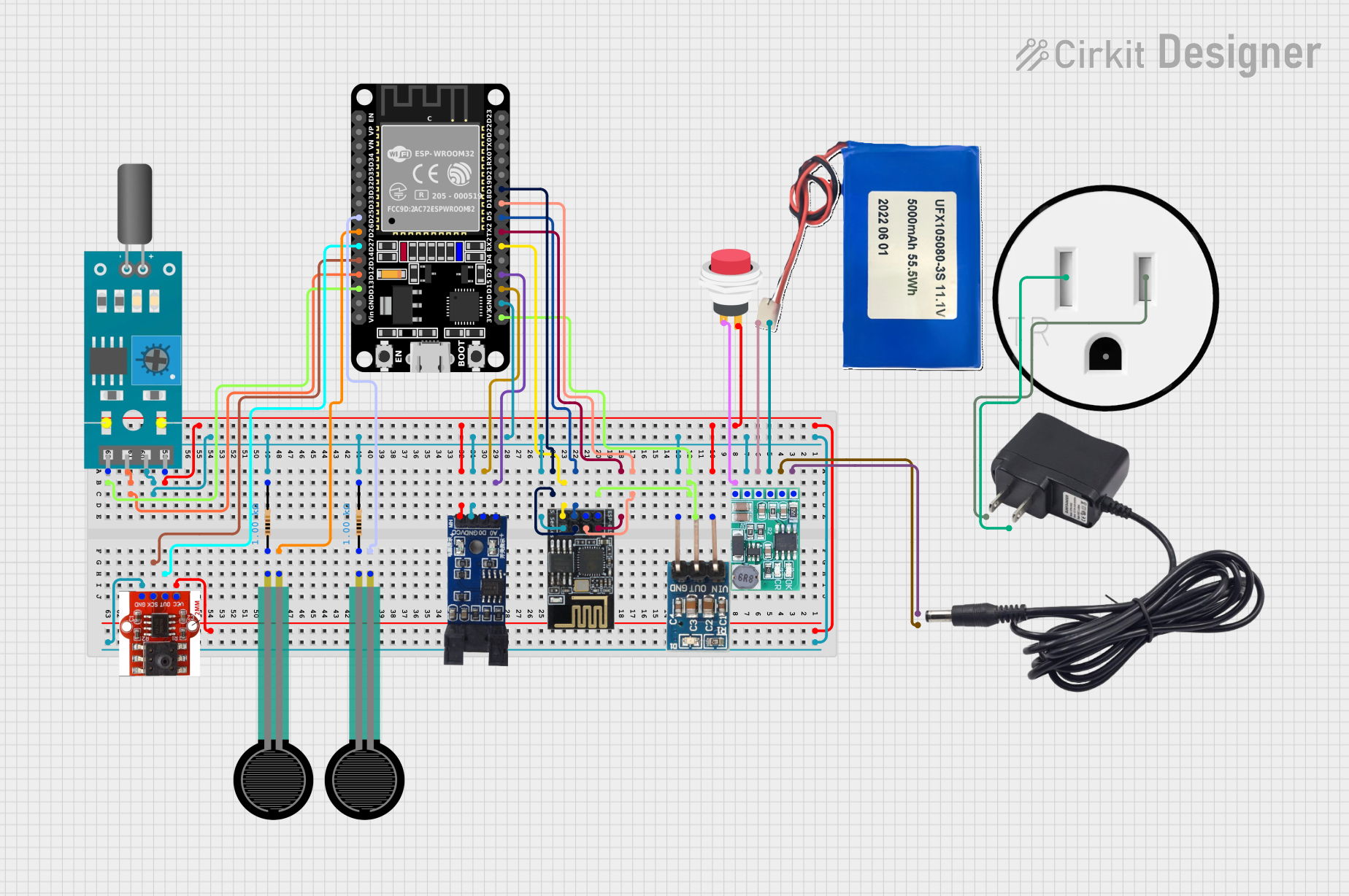

Open Project in Cirkit Designer

Open Project in Cirkit Designer

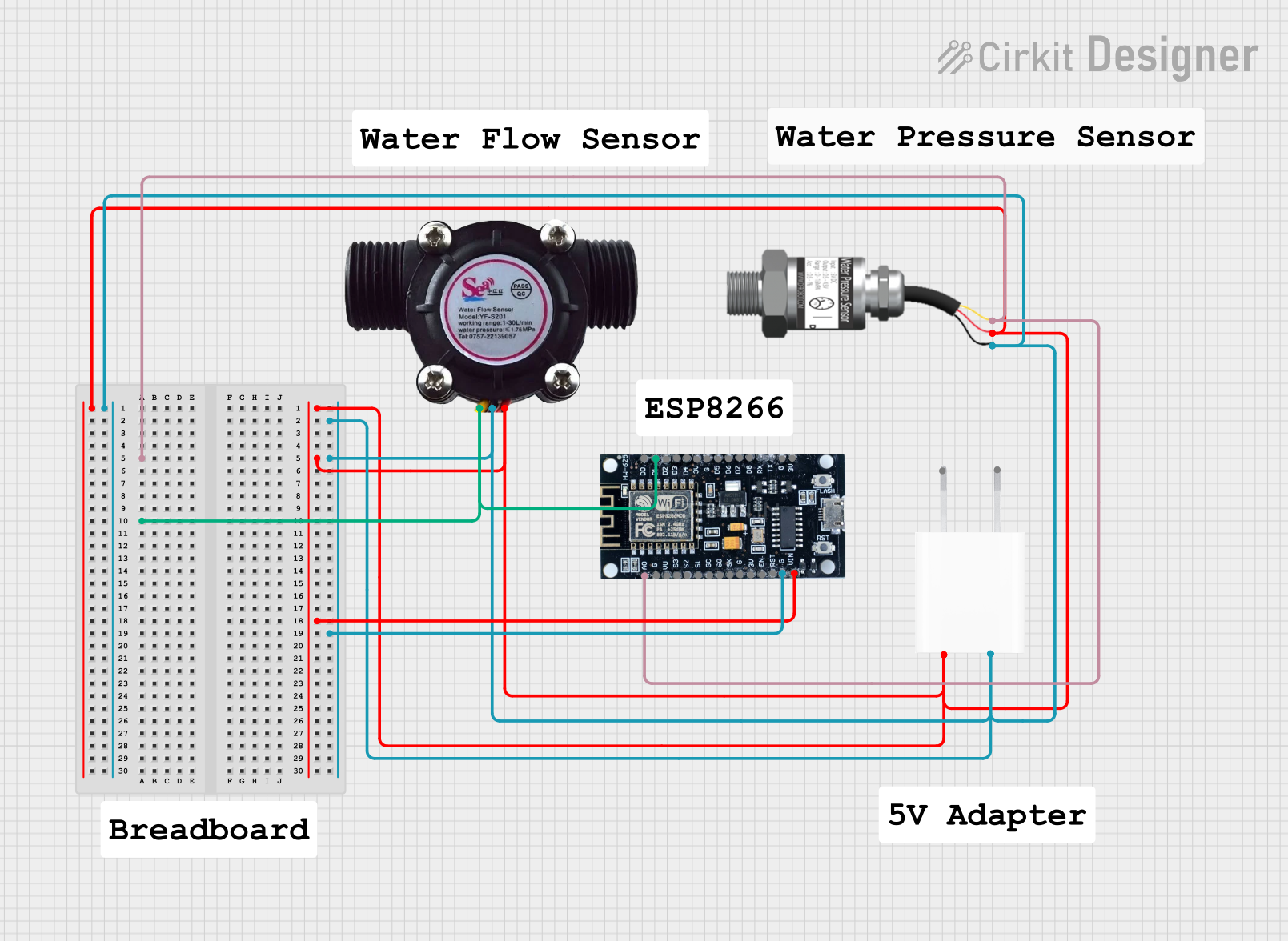

Open Project in Cirkit Designer

Open Project in Cirkit Designer

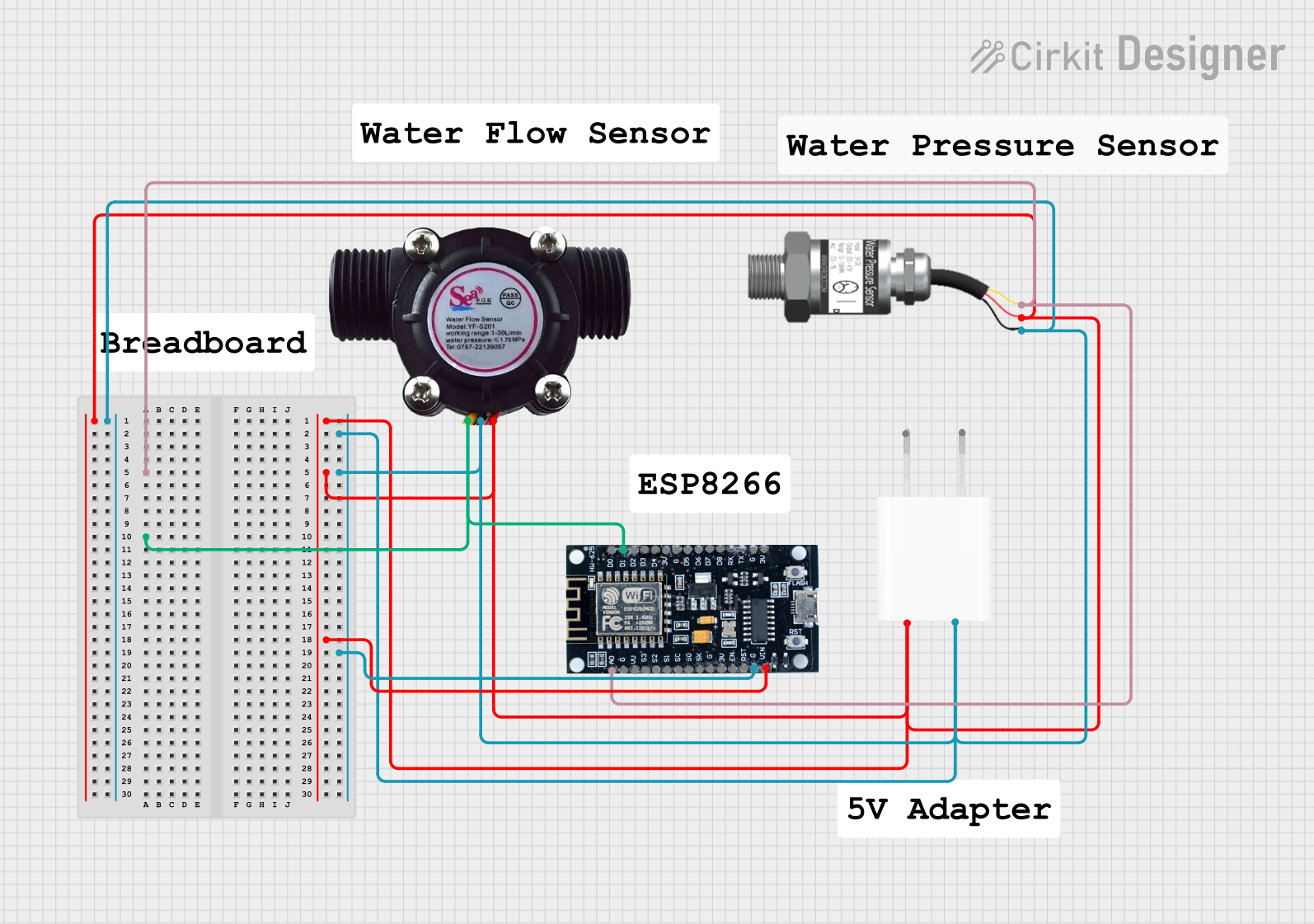

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Pressure Sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial process control systems

- HVAC (Heating, Ventilation, and Air Conditioning) systems

- Medical devices (e.g., ventilators)

- Altitude measurement in drones and aircraft

- Hydraulic and pneumatic systems

- Weather monitoring equipment

Technical Specifications

The MS4525DO pressure sensor is a compact, high-performance device with the following key specifications:

| Parameter | Value |

|---|---|

| Pressure Range | 0 to 1 psi, 0 to 30 psi (varies by model) |

| Pressure Type | Differential or gauge |

| Supply Voltage | 3.3V to 5.0V |

| Output Type | Digital (I²C or SPI interface) |

| Accuracy | ±1.0% of full-scale reading |

| Operating Temperature | -40°C to +125°C |

| Response Time | 1 ms |

| Resolution | 14-bit |

| Media Compatibility | Non-corrosive gases and liquids |

| Package Type | Surface-mount or through-hole |

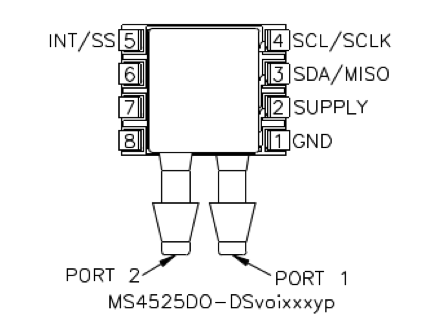

Pin Configuration and Descriptions

The MS4525DO has a 6-pin configuration. The table below describes each pin:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VDD | Power supply input (3.3V to 5.0V) |

| 2 | GND | Ground connection |

| 3 | SDA | Serial Data Line for I²C communication |

| 4 | SCL | Serial Clock Line for I²C communication |

| 5 | NC | No connection (leave unconnected or follow datasheet recommendations) |

| 6 | ADDR | I²C address selection (connect to GND or VDD to set the address) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the VDD pin to a regulated 3.3V or 5.0V power source and the GND pin to the ground of your circuit.

- I²C Communication: Connect the SDA and SCL pins to the corresponding I²C pins on your microcontroller (e.g., Arduino UNO).

- Pull-Up Resistors: Use 4.7kΩ pull-up resistors on the SDA and SCL lines if they are not already present on your microcontroller.

- I²C Address: Set the I²C address by connecting the ADDR pin to either GND or VDD. Refer to the datasheet for the specific address mapping.

- Pressure Ports: Connect the pressure ports to the medium you want to measure. Ensure compatibility with the sensor's media specifications.

Important Considerations and Best Practices

- Media Compatibility: Use the sensor only with non-corrosive gases or liquids to avoid damage.

- Power Supply Stability: Ensure a stable power supply to maintain accurate readings.

- I²C Address Conflicts: If using multiple I²C devices, ensure that each device has a unique address.

- Mounting: Avoid mechanical stress on the sensor during installation to prevent calibration errors.

Example Code for Arduino UNO

Below is an example of how to interface the MS4525DO with an Arduino UNO using the I²C protocol:

#include <Wire.h>

// Define the I²C address of the MS4525DO sensor

#define MS4525DO_ADDRESS 0x28

void setup() {

Wire.begin(); // Initialize I²C communication

Serial.begin(9600); // Start serial communication for debugging

Serial.println("MS4525DO Pressure Sensor Example");

}

void loop() {

Wire.beginTransmission(MS4525DO_ADDRESS); // Start communication with the sensor

Wire.write(0x00); // Request data from the sensor

Wire.endTransmission(false); // End transmission but keep the connection active

Wire.requestFrom(MS4525DO_ADDRESS, 4); // Request 4 bytes of data from the sensor

if (Wire.available() == 4) { // Check if 4 bytes are received

uint8_t byte1 = Wire.read(); // Read the first byte

uint8_t byte2 = Wire.read(); // Read the second byte

uint8_t byte3 = Wire.read(); // Read the third byte

uint8_t byte4 = Wire.read(); // Read the fourth byte

// Combine the bytes to calculate pressure and temperature

int16_t pressure = ((byte1 & 0x3F) << 8) | byte2; // Extract pressure data

int16_t temperature = ((byte3 << 8) | byte4) >> 5; // Extract temperature data

// Convert raw data to human-readable values

float pressureValue = (pressure - 8192) / 16384.0 * 30.0; // Example for 0-30 psi range

float temperatureValue = (temperature / 2047.0) * 200.0 - 50.0;

// Print the results

Serial.print("Pressure: ");

Serial.print(pressureValue);

Serial.println(" psi");

Serial.print("Temperature: ");

Serial.print(temperatureValue);

Serial.println(" °C");

}

delay(1000); // Wait for 1 second before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Data from the Sensor

- Cause: Incorrect I²C address or wiring.

- Solution: Verify the I²C address and ensure proper connections for SDA and SCL.

Inaccurate Readings

- Cause: Unstable power supply or incompatible media.

- Solution: Use a stable power source and ensure the media is non-corrosive.

Communication Errors

- Cause: Missing pull-up resistors on the I²C lines.

- Solution: Add 4.7kΩ pull-up resistors to the SDA and SCL lines.

FAQs

Can the MS4525DO measure liquid pressure?

- Yes, but only for non-corrosive liquids. Avoid using it with corrosive or conductive fluids.

What is the maximum pressure the sensor can handle?

- The maximum pressure depends on the specific model. Refer to the datasheet for details.

Can I use this sensor with a 3.3V microcontroller?

- Yes, the sensor is compatible with both 3.3V and 5.0V systems.

How do I calibrate the sensor?

- The sensor is factory-calibrated. No additional calibration is required under normal conditions.

By following this documentation, you can effectively integrate the MS4525DO pressure sensor into your projects and ensure reliable performance.