How to Use PZEM-016: Examples, Pinouts, and Specs

Design with PZEM-016 in Cirkit Designer

Design with PZEM-016 in Cirkit DesignerIntroduction

The PZEM-016 is a multifunctional energy meter designed for monitoring and measuring key electrical parameters in AC circuits. Manufactured by PZEM, this device provides accurate readings of voltage, current, power, energy, and frequency. It is equipped with a digital display for real-time monitoring and supports UART communication for data logging and remote monitoring applications.

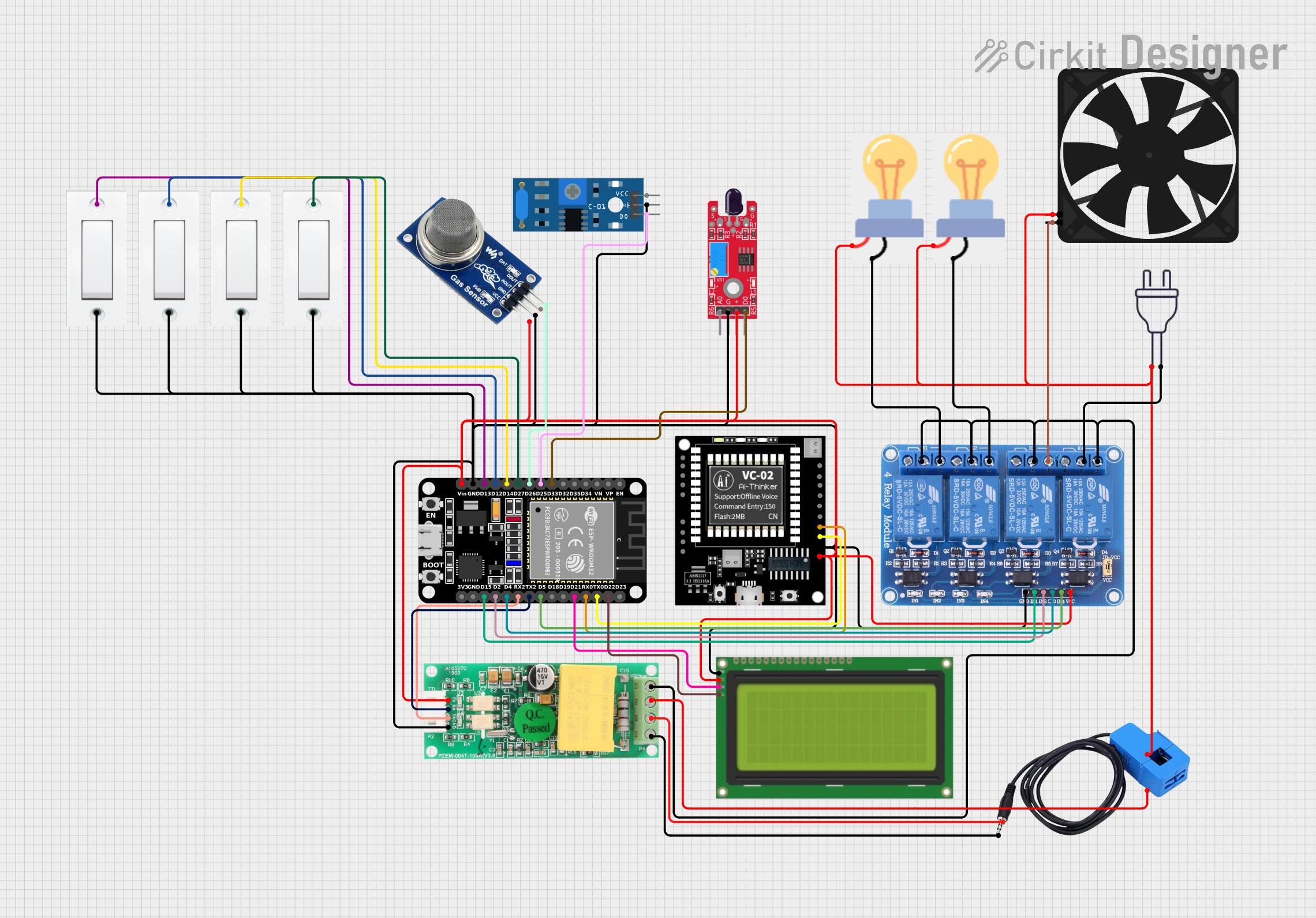

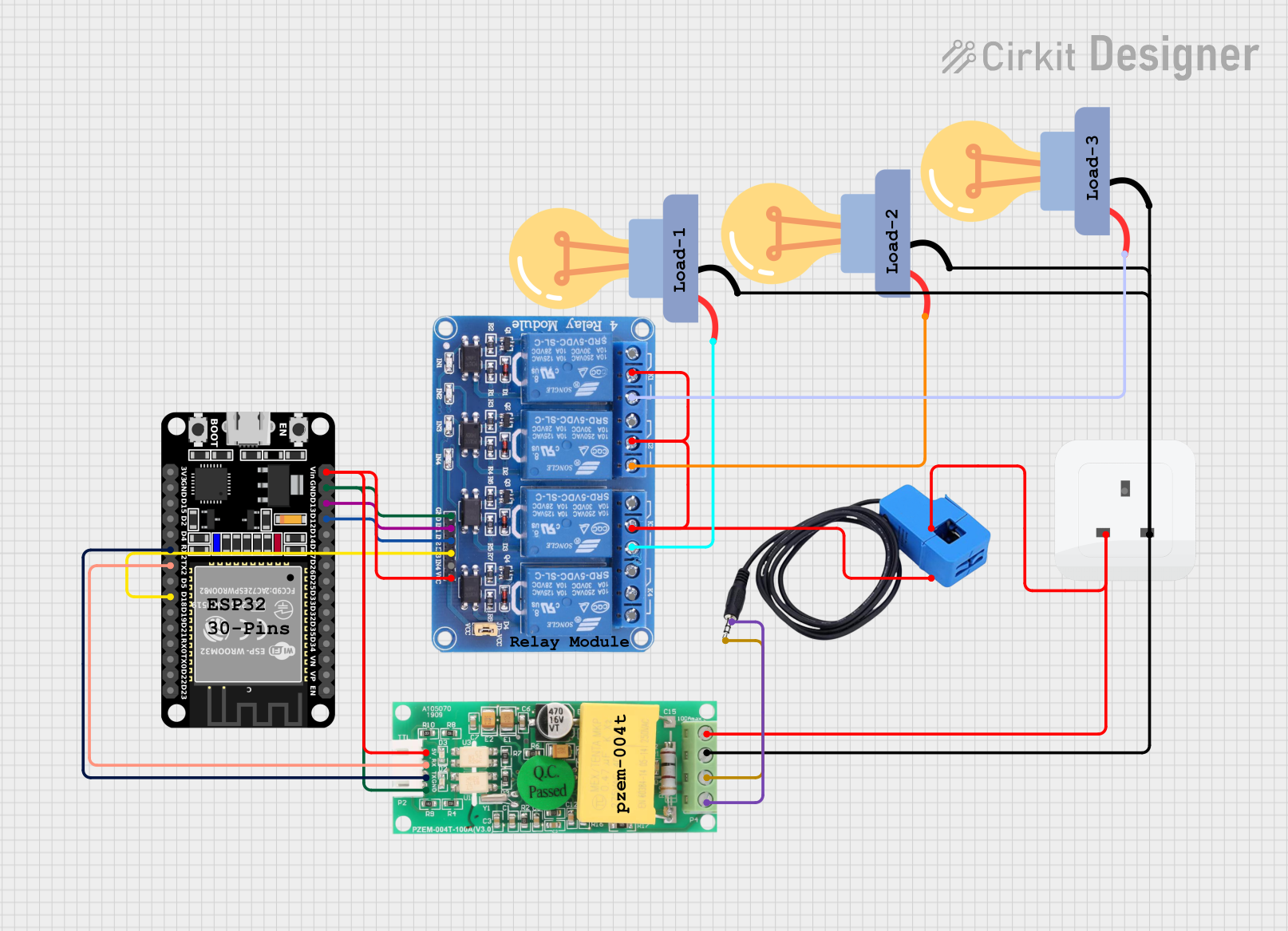

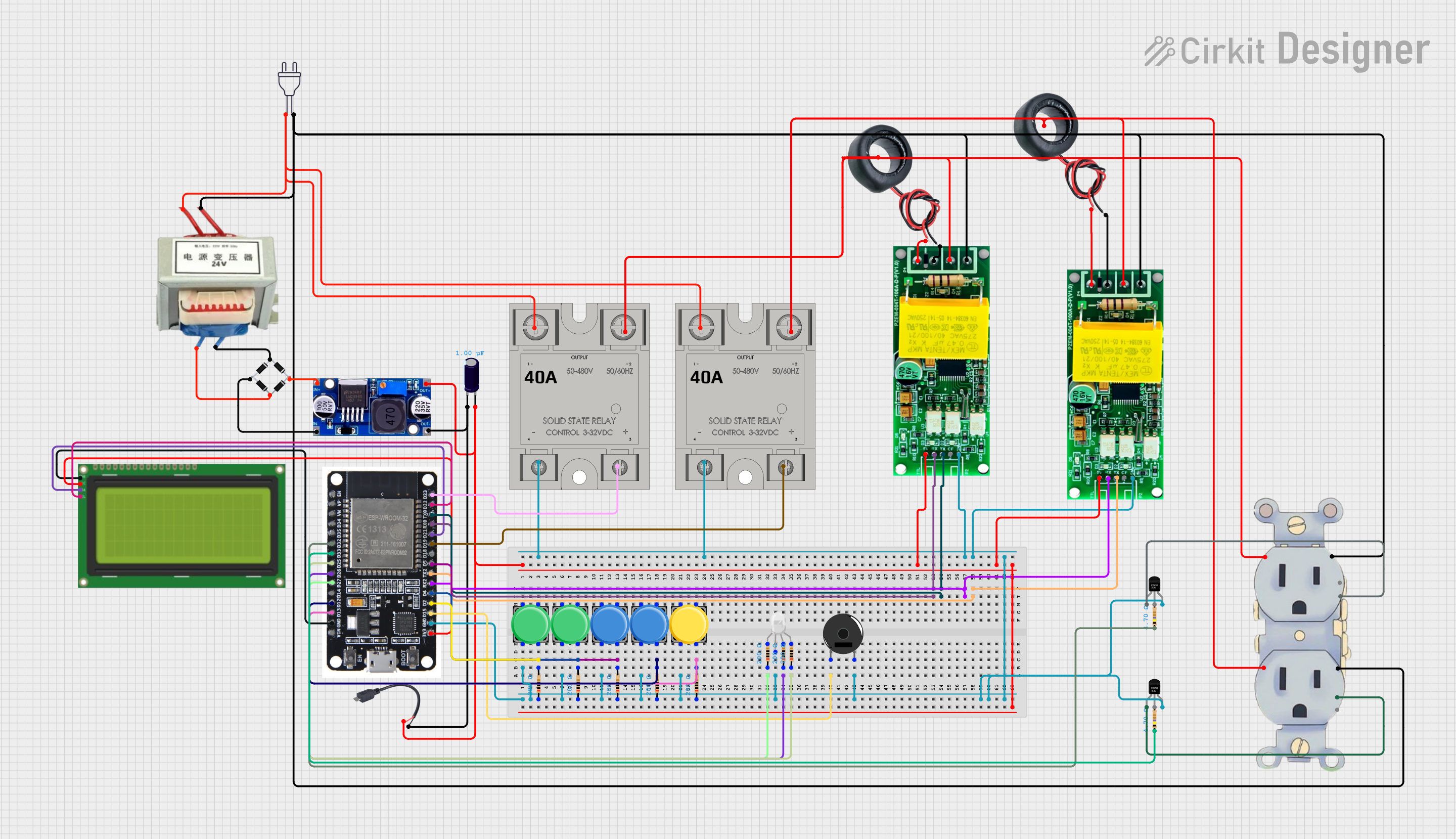

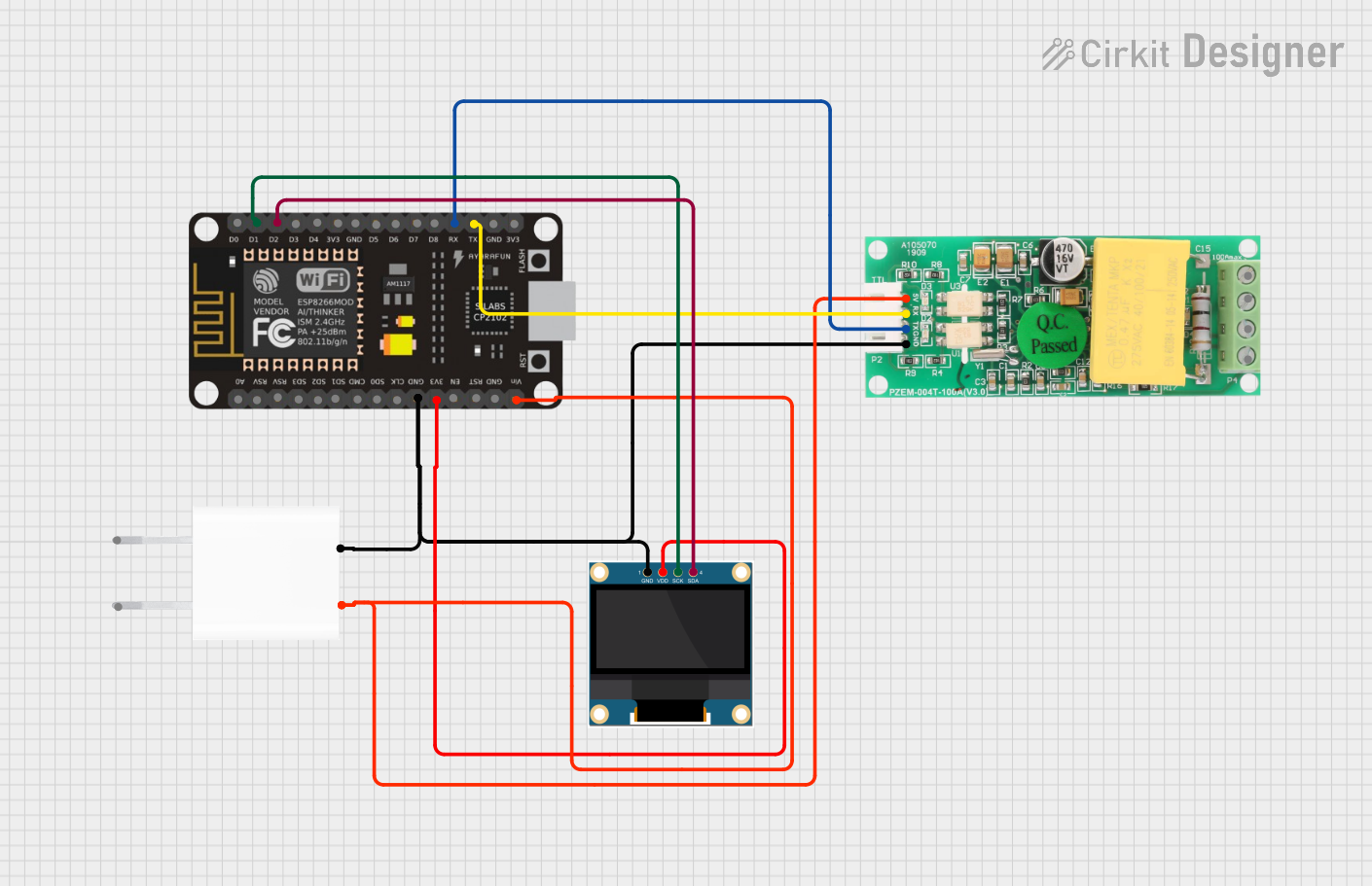

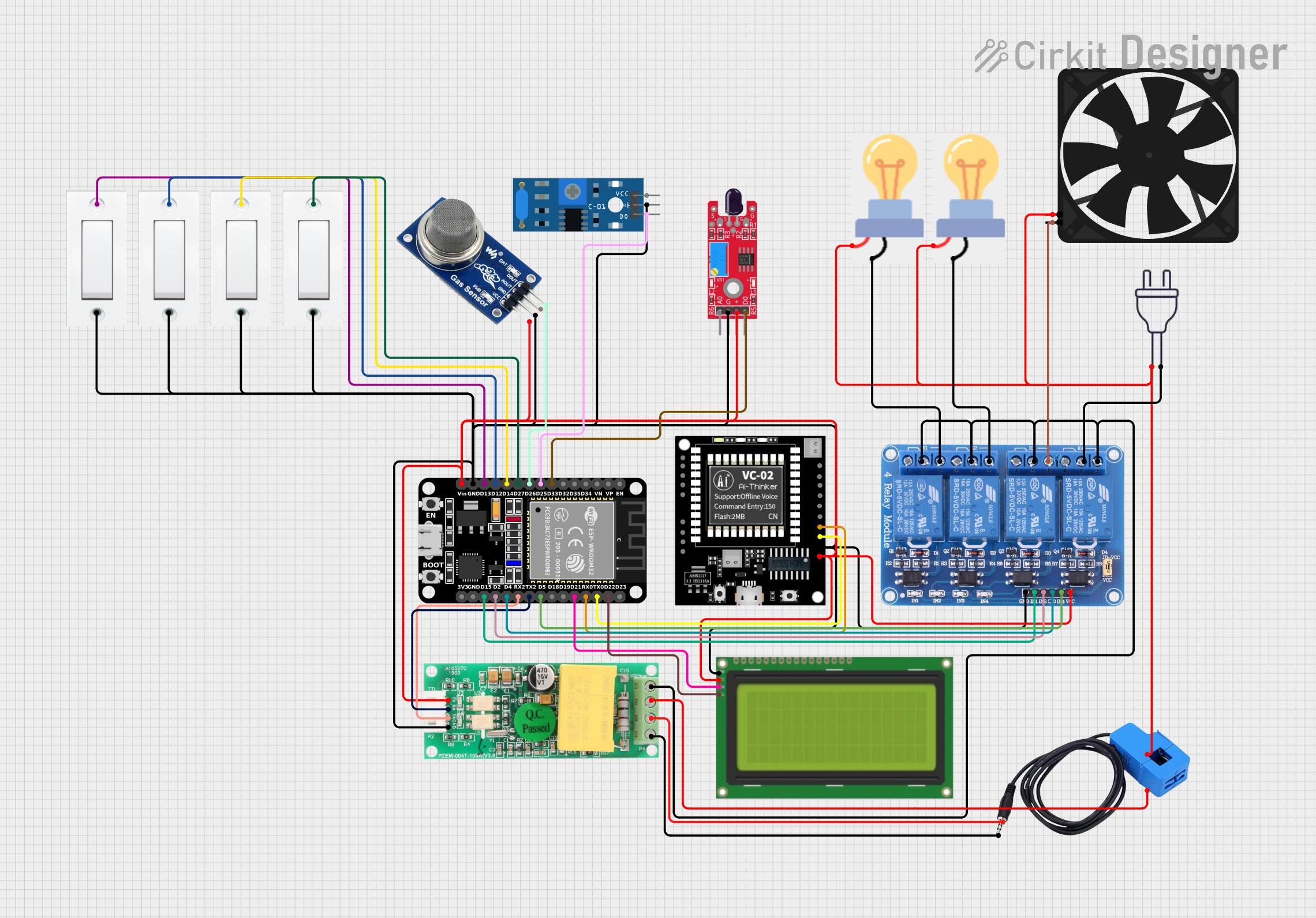

Explore Projects Built with PZEM-016

Open Project in Cirkit Designer

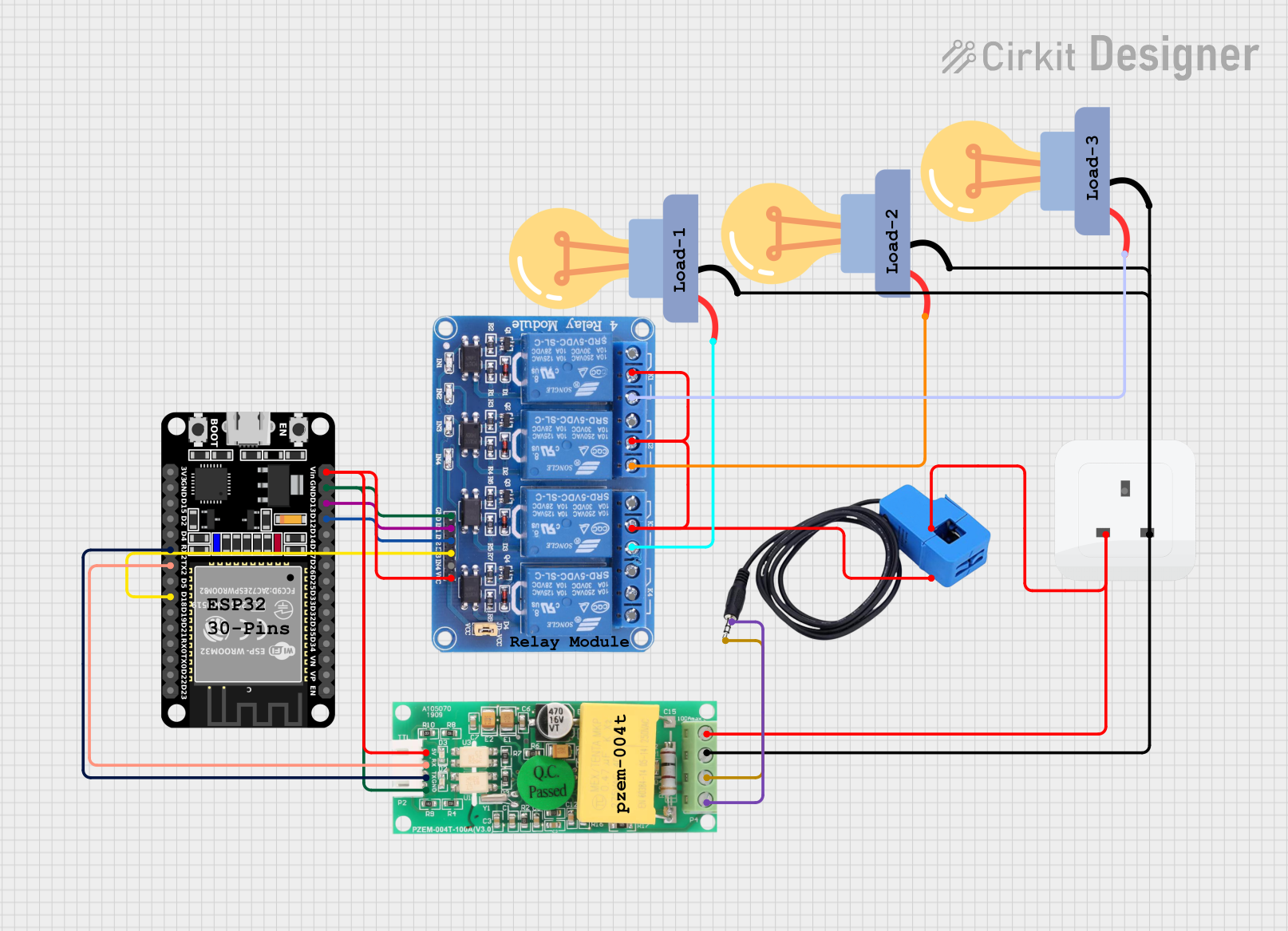

Open Project in Cirkit Designer

Open Project in Cirkit Designer

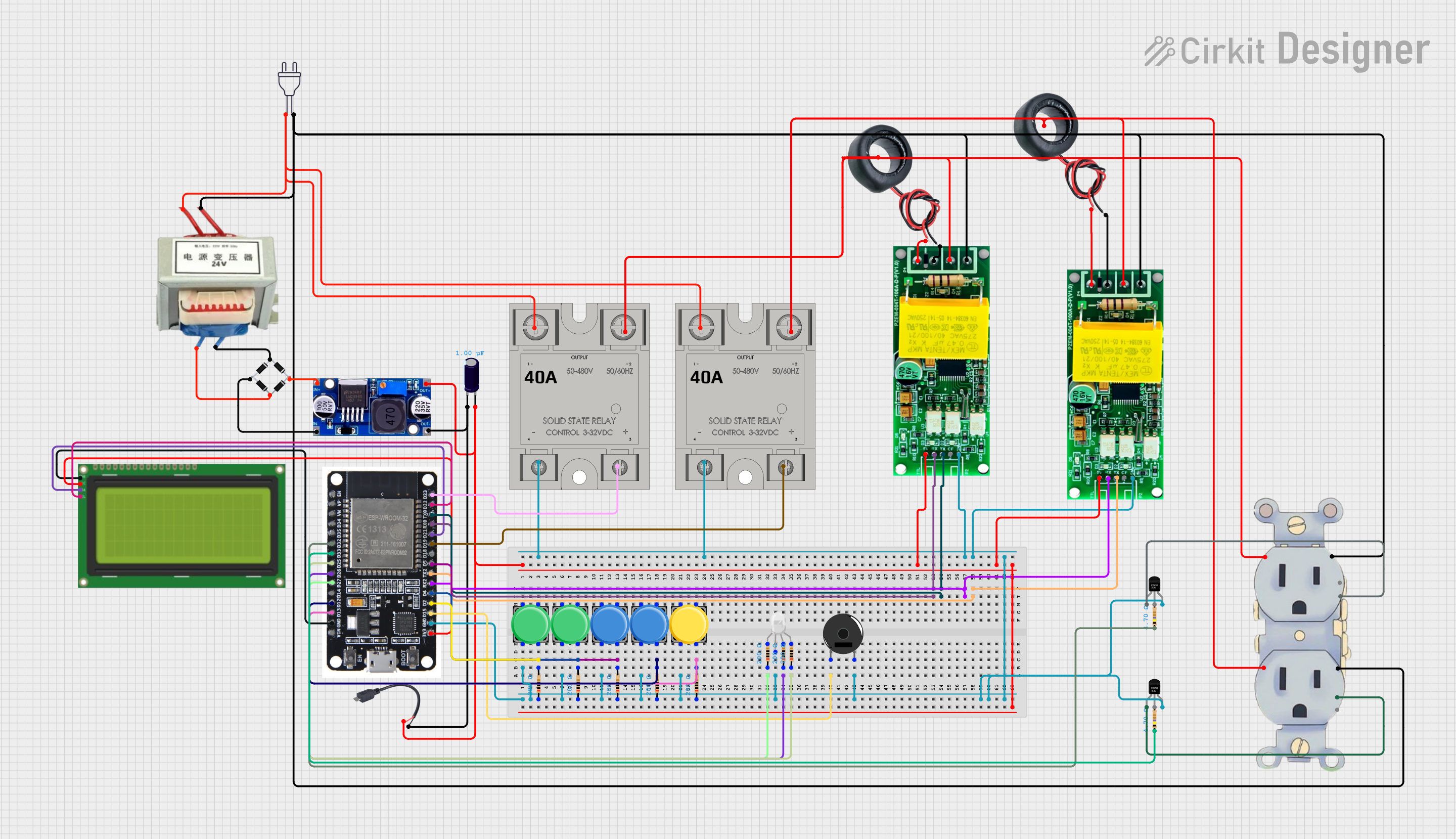

Open Project in Cirkit Designer

Open Project in Cirkit Designer

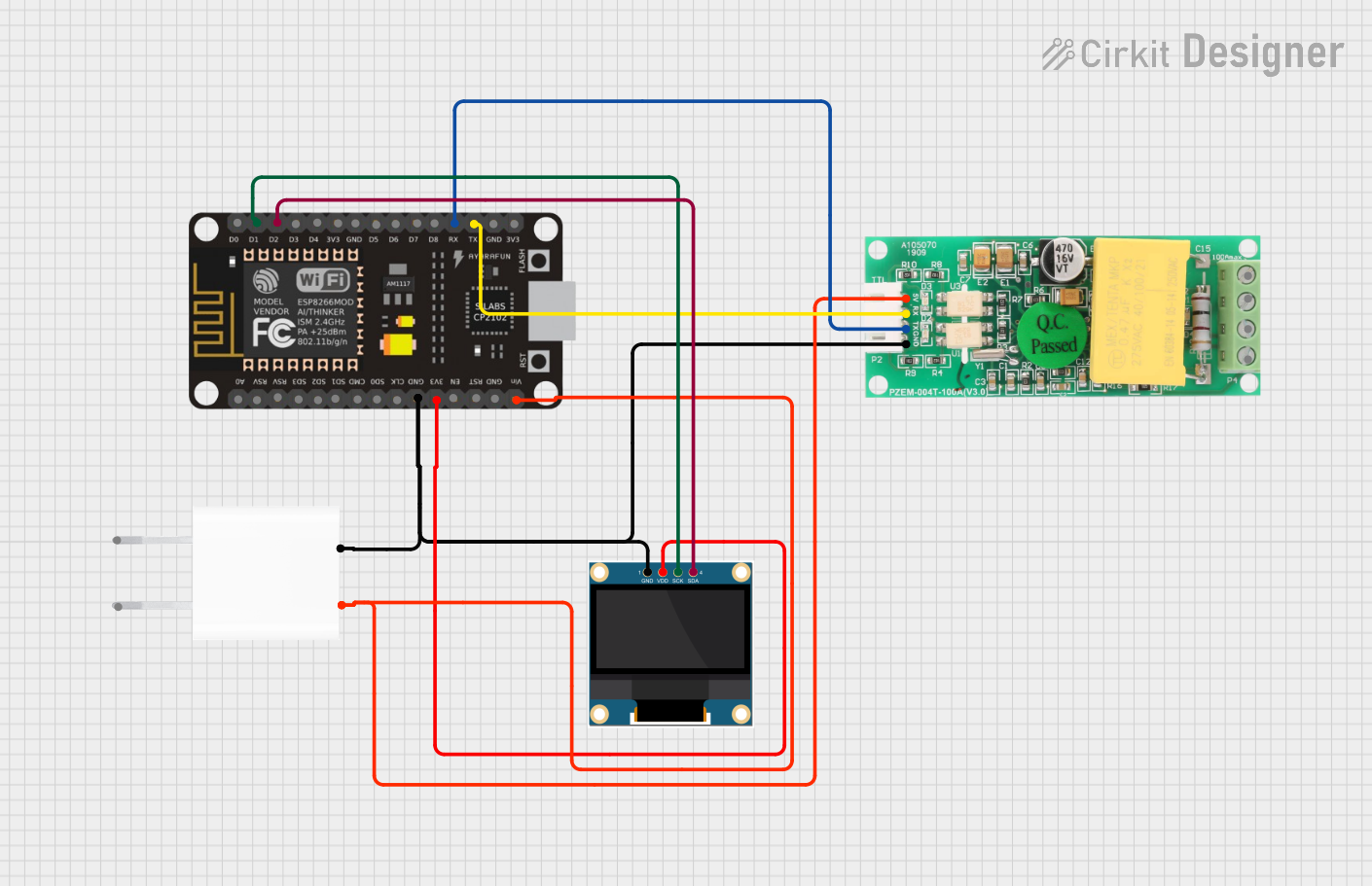

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with PZEM-016

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial Automation: Monitoring power consumption in industrial equipment.

- Home Energy Management: Tracking household energy usage for efficiency.

- Renewable Energy Systems: Measuring output from solar inverters or wind turbines.

- Data Logging: Collecting electrical data for analysis and reporting.

- Remote Monitoring: Integrating with microcontrollers or IoT systems for remote energy monitoring.

Technical Specifications

The following table outlines the key technical specifications of the PZEM-016:

| Parameter | Specification |

|---|---|

| Voltage Range | 80V - 260V AC |

| Current Range | 0A - 100A (requires external current transformer) |

| Power Range | 0W - 22kW |

| Energy Range | 0kWh - 9999kWh |

| Frequency Range | 45Hz - 65Hz |

| Communication Interface | UART (9600 baud rate) |

| Power Supply | 5V DC (via UART interface) |

| Accuracy | ±0.5% |

| Operating Temperature | -10°C to 60°C |

| Dimensions | 96mm x 58mm x 24mm |

Pin Configuration and Descriptions

The PZEM-016 has a simple pinout for both power and communication. The table below describes the pin configuration:

| Pin Name | Description |

|---|---|

| V+ | AC voltage input (live wire) |

| V- | AC voltage input (neutral wire) |

| I+ | Current transformer input (live wire) |

| I- | Current transformer input (neutral wire) |

| TX | UART transmit pin (connect to RX of microcontroller) |

| RX | UART receive pin (connect to TX of microcontroller) |

| GND | Ground (common ground for UART and power supply) |

| 5V | 5V DC power input for the module |

Usage Instructions

How to Use the PZEM-016 in a Circuit

- Connect the Voltage Input:

- Connect the V+ pin to the live wire of the AC circuit.

- Connect the V- pin to the neutral wire of the AC circuit.

- Connect the Current Transformer (CT):

- Attach the CT to the live wire of the AC circuit.

- Connect the CT's output wires to the I+ and I- pins of the PZEM-016.

- Power the Module:

- Provide a 5V DC power supply to the 5V and GND pins.

- Connect to a Microcontroller (Optional):

- Use the TX and RX pins to connect the PZEM-016 to a microcontroller (e.g., Arduino UNO) for UART communication.

Important Considerations and Best Practices

- Safety First: Always ensure the circuit is powered off before making connections to avoid electric shock.

- Current Transformer Placement: Ensure the CT is clamped around the live wire only, not both live and neutral wires.

- UART Communication: Use a logic level converter if your microcontroller operates at 3.3V logic levels.

- Power Supply: Use a stable 5V DC power source to avoid communication errors or inaccurate readings.

- Calibration: The PZEM-016 is pre-calibrated, but you can recalibrate it if necessary using the manufacturer's instructions.

Example Code for Arduino UNO

Below is an example Arduino sketch to read data from the PZEM-016 using UART communication:

#include <SoftwareSerial.h>

// Define RX and TX pins for SoftwareSerial

SoftwareSerial pzemSerial(10, 11); // RX = pin 10, TX = pin 11

void setup() {

Serial.begin(9600); // Initialize Serial Monitor

pzemSerial.begin(9600); // Initialize UART communication with PZEM-016

Serial.println("PZEM-016 Energy Meter Example");

}

void loop() {

// Request data from PZEM-016

byte request[] = {0x01, 0x04, 0x00, 0x00, 0x00, 0x0A, 0x70, 0x0D};

pzemSerial.write(request, sizeof(request));

delay(100); // Wait for response

// Read response from PZEM-016

if (pzemSerial.available()) {

Serial.print("Data received: ");

while (pzemSerial.available()) {

byte data = pzemSerial.read();

Serial.print(data, HEX);

Serial.print(" ");

}

Serial.println();

}

delay(1000); // Wait 1 second before next request

}

Note: The above code sends a Modbus RTU request to the PZEM-016 and prints the raw response. You will need to parse the response to extract voltage, current, power, etc., based on the Modbus protocol.

Troubleshooting and FAQs

Common Issues and Solutions

No Data Received via UART:

- Ensure the TX and RX pins are correctly connected (crossed: TX to RX, RX to TX).

- Verify the baud rate is set to 9600 in your code.

- Check the power supply to the PZEM-016.

Inaccurate Readings:

- Ensure the current transformer is properly clamped around the live wire.

- Verify that the voltage input connections (V+ and V-) are secure.

Communication Errors:

- Use shorter UART cables to reduce noise.

- Ensure a common ground between the PZEM-016 and the microcontroller.

Module Not Powering On:

- Check the 5V power supply for proper voltage and current output.

- Inspect the wiring for loose or incorrect connections.

FAQs

Q: Can the PZEM-016 measure DC circuits?

A: No, the PZEM-016 is designed specifically for AC circuits and cannot measure DC parameters.

Q: Can I use the PZEM-016 with a Raspberry Pi?

A: Yes, but you will need a USB-to-UART adapter or GPIO UART pins and a logic level converter if the Raspberry Pi operates at 3.3V logic.

Q: How do I reset the energy counter?

A: The energy counter can be reset via a specific Modbus command. Refer to the manufacturer's Modbus protocol documentation for details.

Q: Is the PZEM-016 waterproof?

A: No, the PZEM-016 is not waterproof and should be used in a dry environment.