How to Use CAN BUS: Examples, Pinouts, and Specs

Design with CAN BUS in Cirkit Designer

Design with CAN BUS in Cirkit DesignerIntroduction

The CAN (Controller Area Network) BUS module is an electronic communication interface used for connecting multiple microcontrollers in applications without a host computer. It is commonly used in automotive and industrial systems for allowing microcontrollers and devices to communicate with each other within a vehicle or machinery without a central computer.

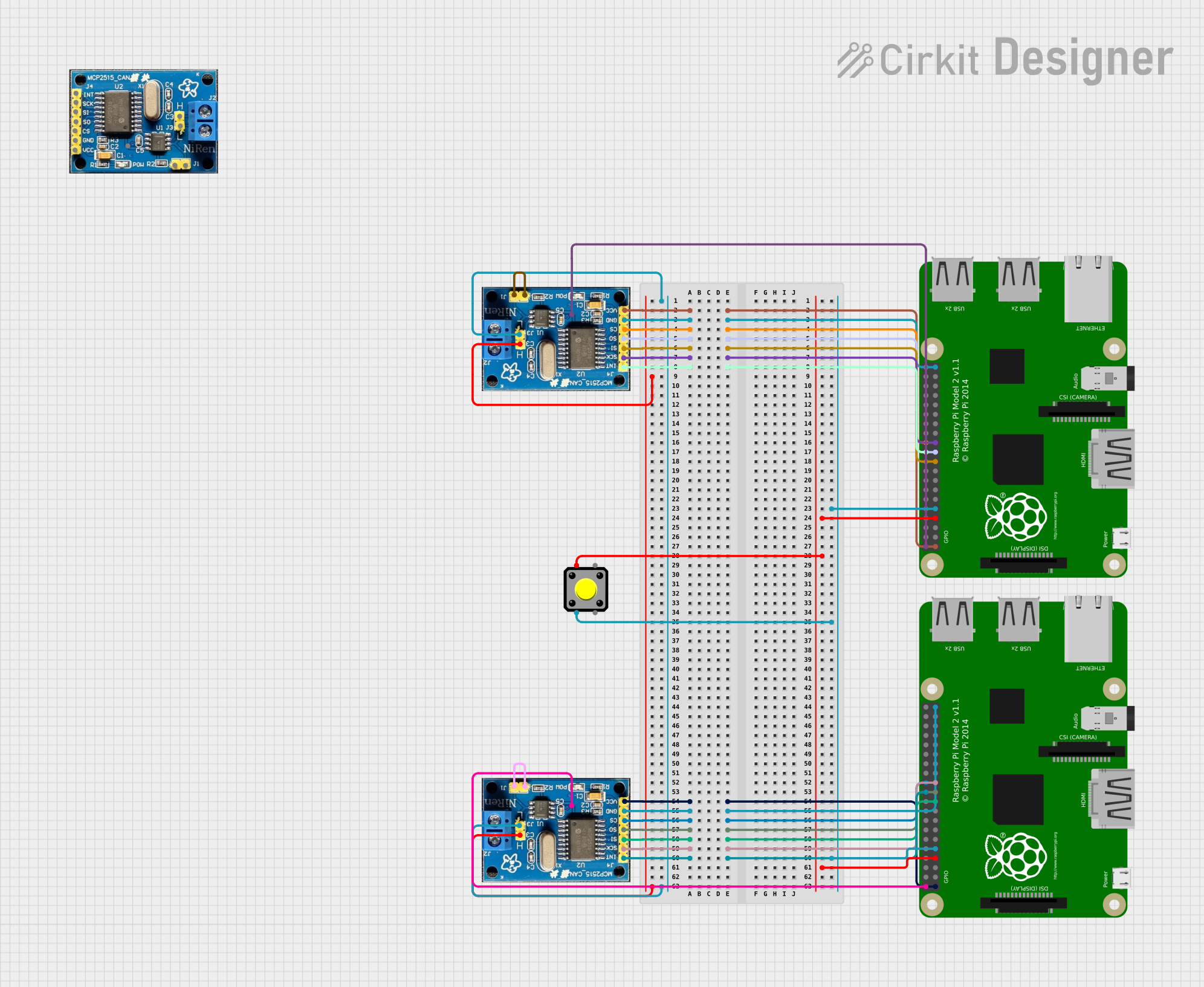

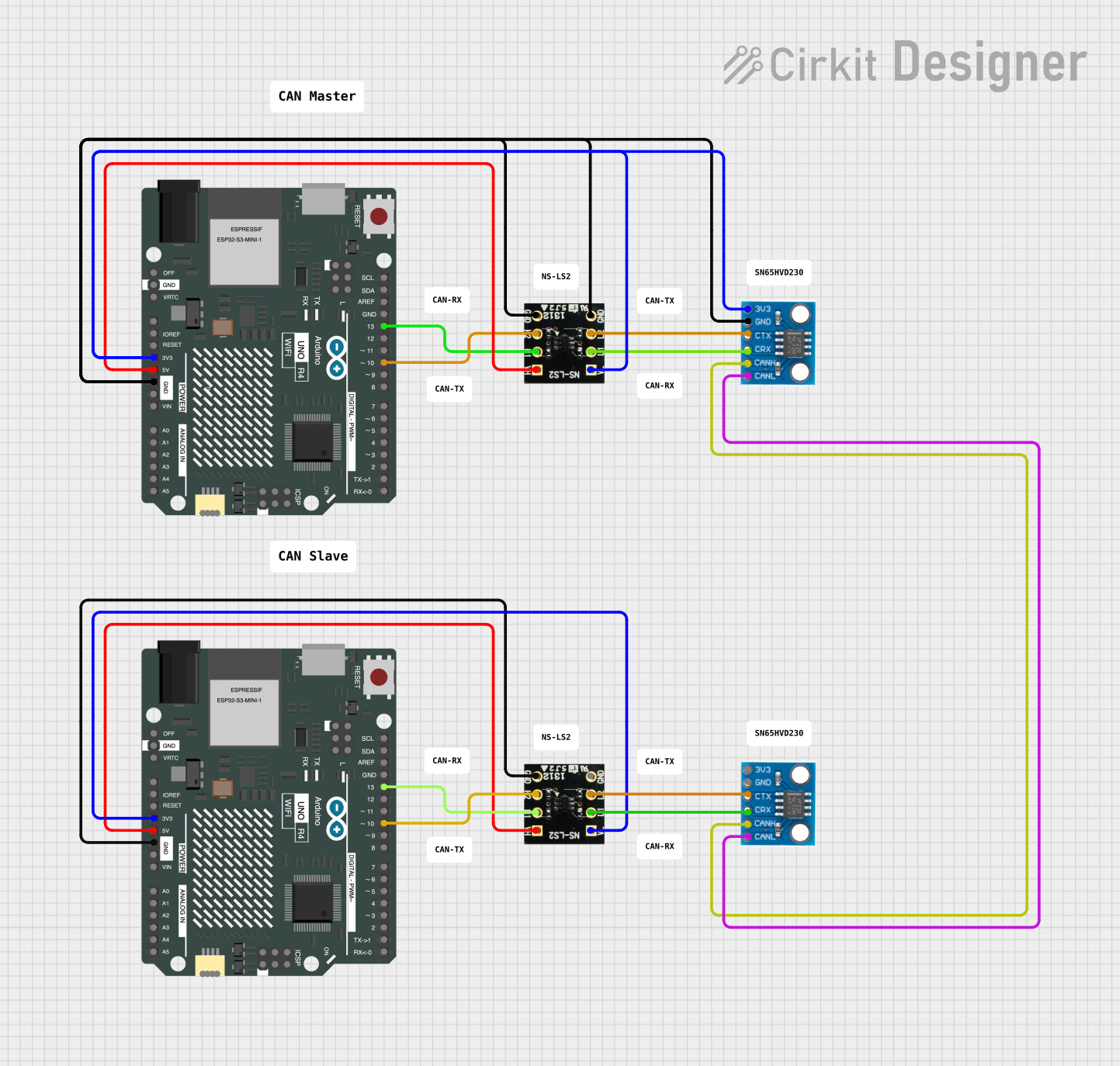

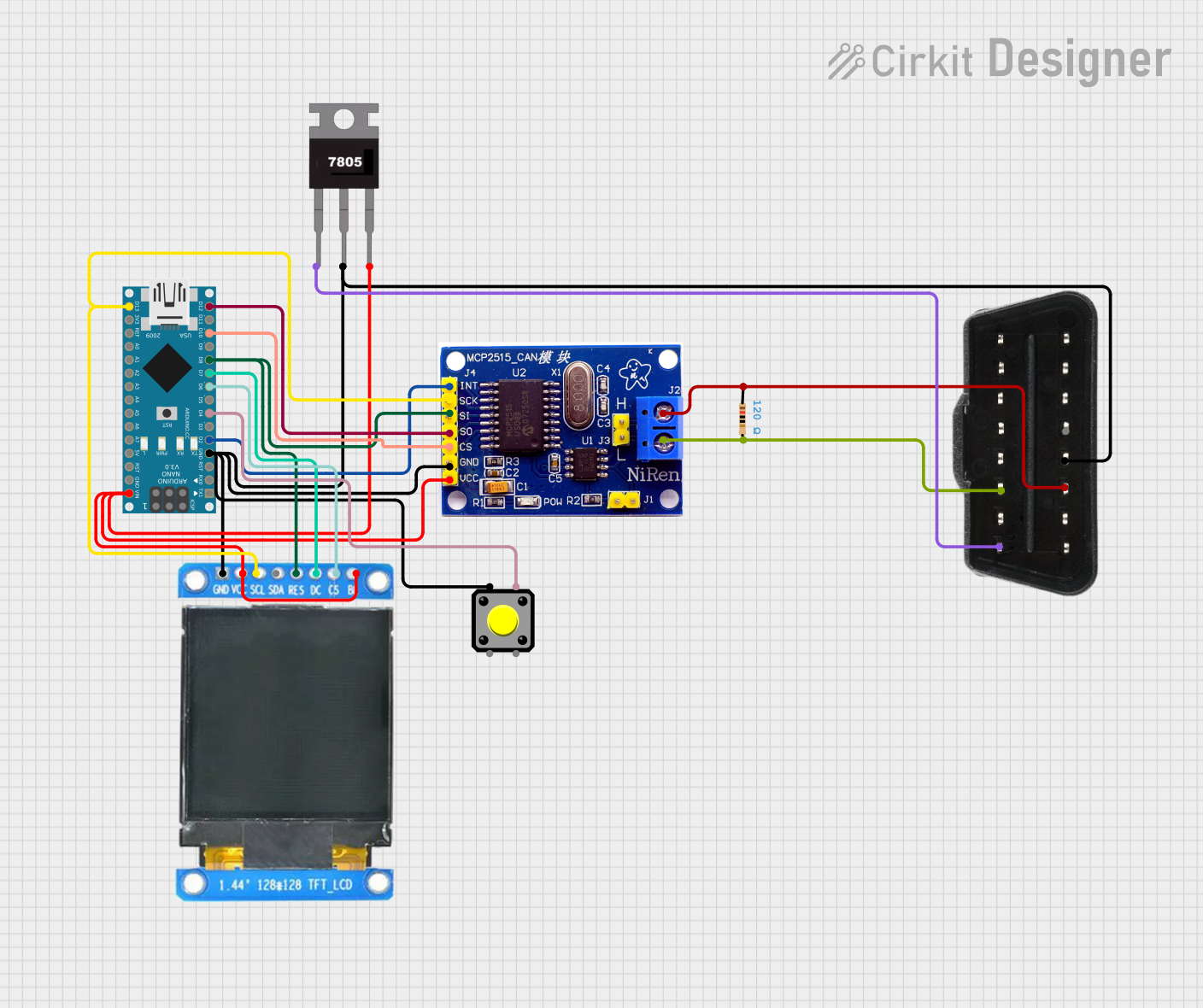

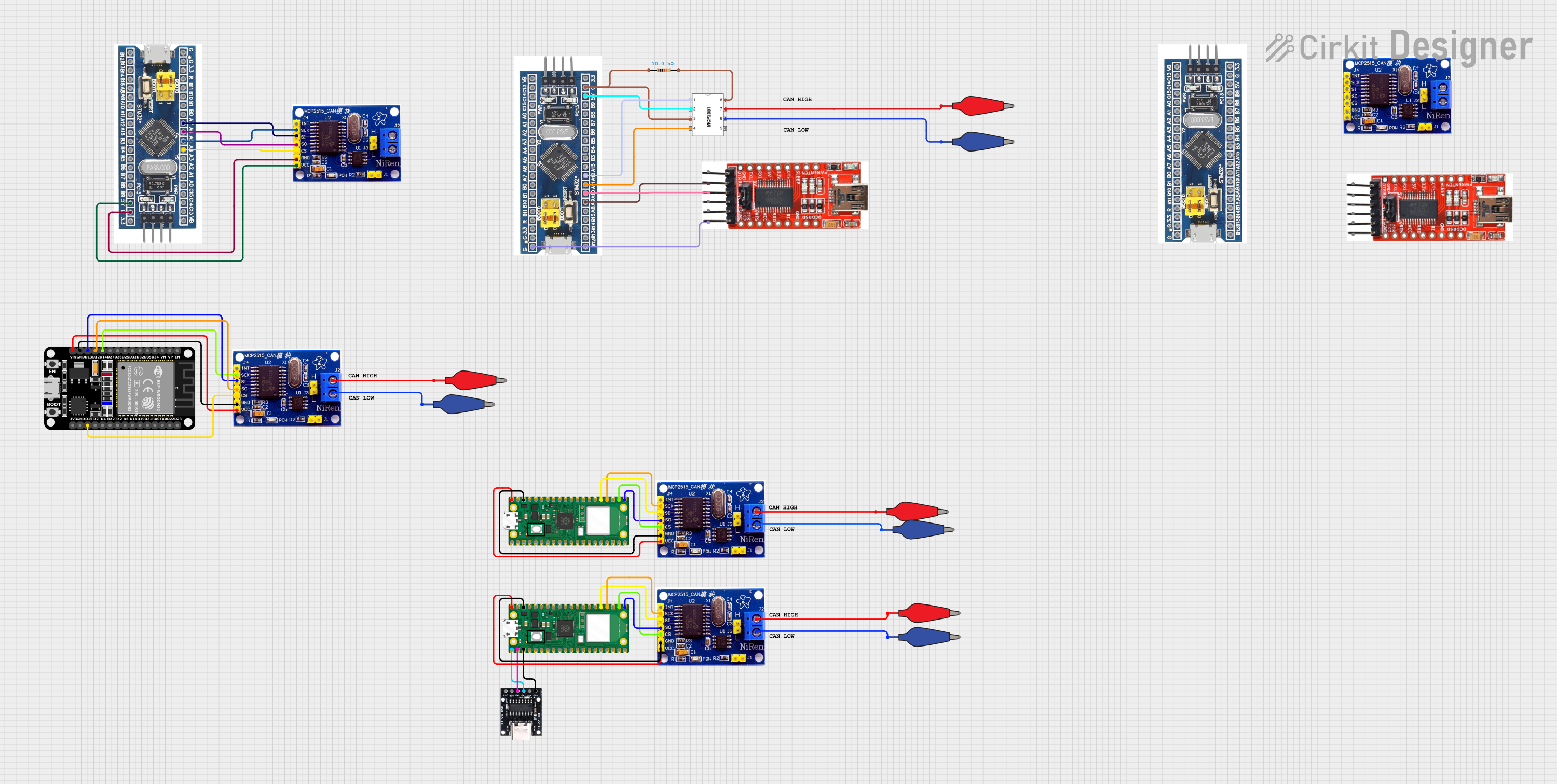

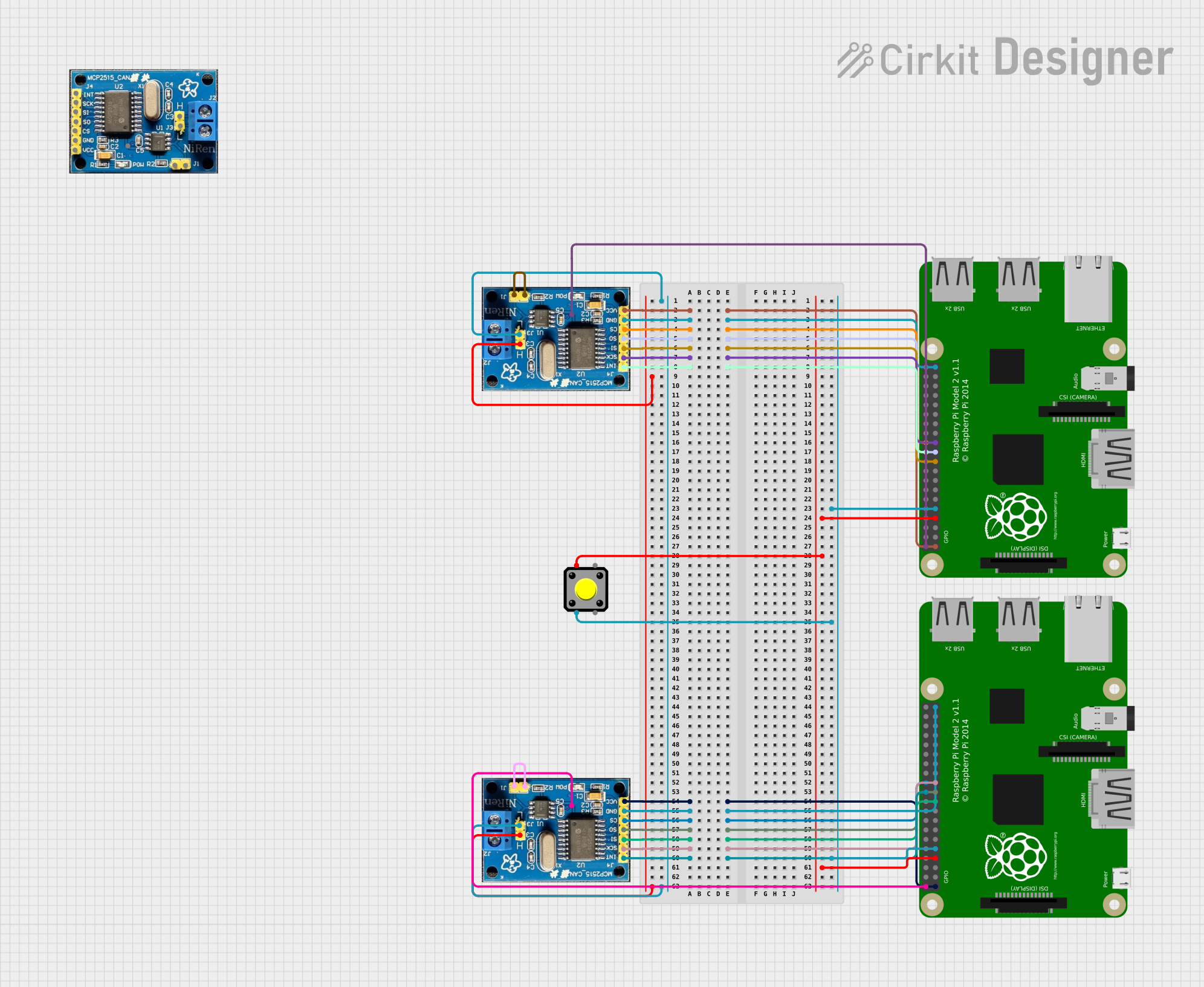

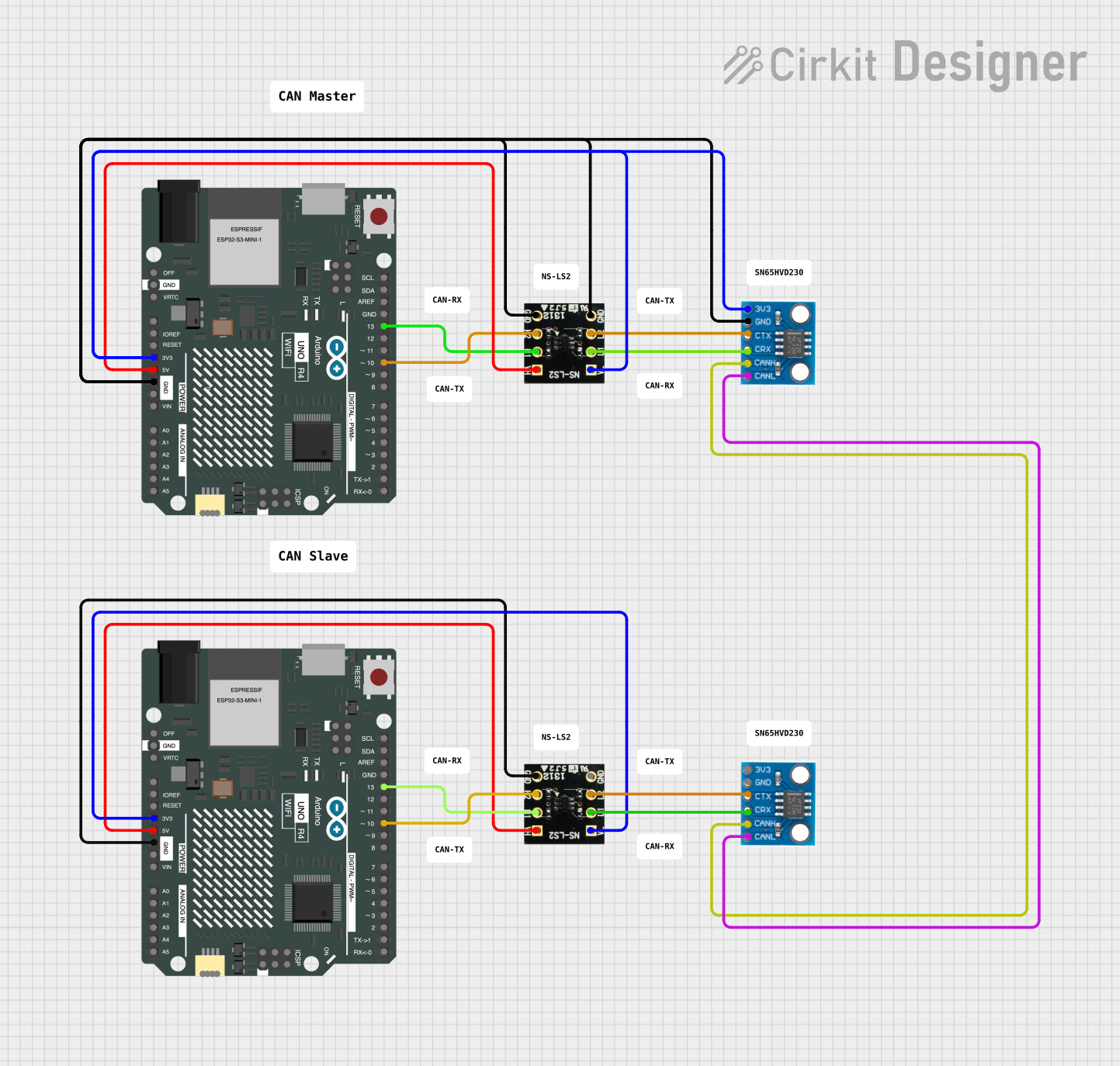

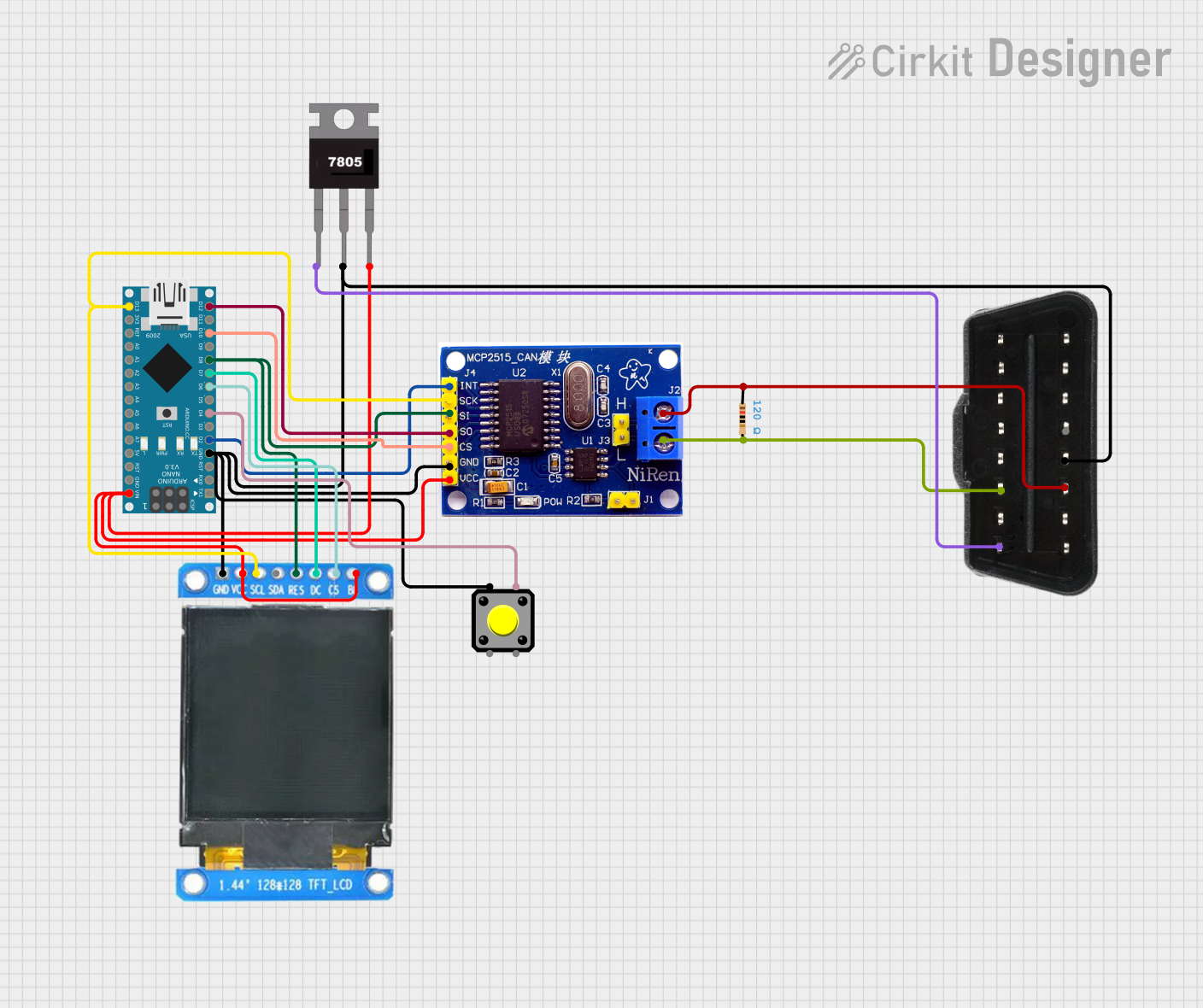

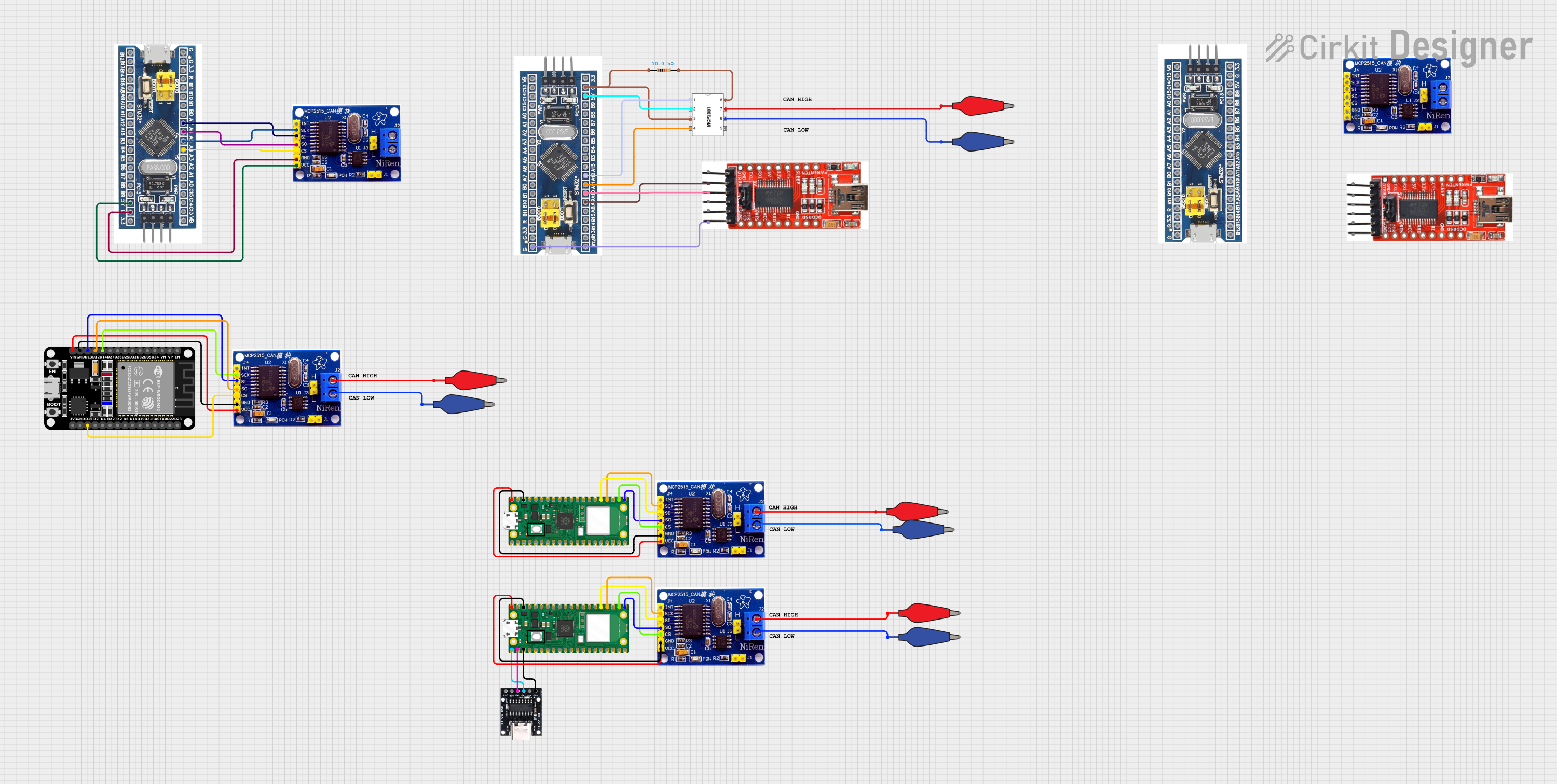

Explore Projects Built with CAN BUS

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with CAN BUS

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Automotive systems (e.g., engine management, infotainment, sensors)

- Industrial automation and control systems

- Robotics

- Aerospace and defense systems

Technical Specifications

Key Technical Details

- Operating Voltage: Typically 5V

- Current Consumption: Varies with the module, often < 100 mA

- Differential Voltage Range: ±12V (max)

- Logic Level: 2.5V (recessive) to 3.5V (dominant)

- Maximum Speed: Up to 1 Mbps

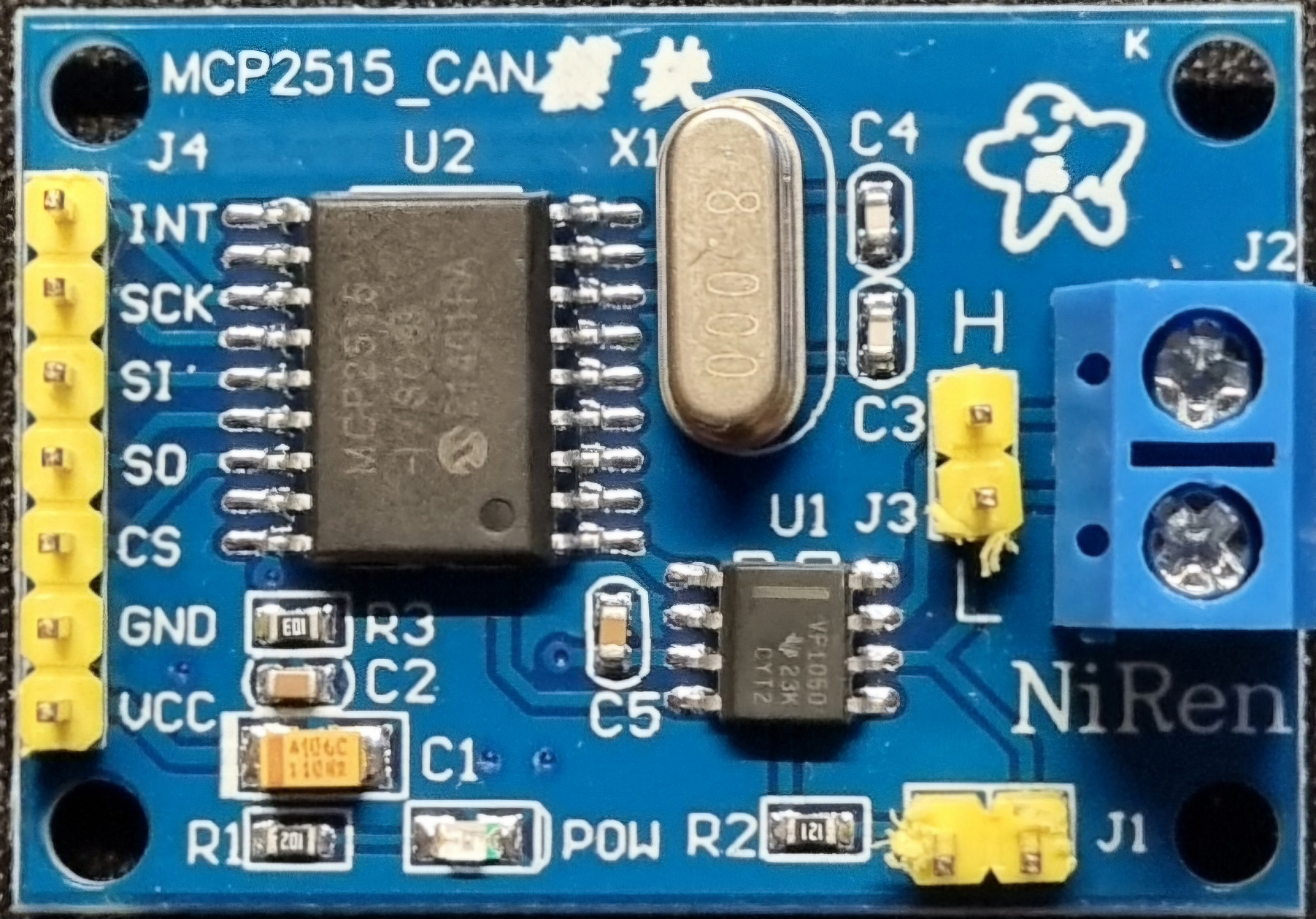

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | VCC | Power supply (5V) |

| 2 | GND | Ground connection |

| 3 | CANH | CAN High |

| 4 | CANL | CAN Low |

| 5 | RX | Receive data (optional, for some modules) |

| 6 | TX | Transmit data (optional, for some modules) |

Usage Instructions

How to Use the Component in a Circuit

- Power Connections: Connect the VCC pin to a 5V power supply and the GND pin to the ground.

- CAN Bus Connections: Connect the CANH and CANL pins to the corresponding CANH and CANL lines of the CAN network.

- Microcontroller Interface: If the module has RX and TX pins, connect them to the respective TX and RX pins of the microcontroller.

Important Considerations and Best Practices

- Ensure that the power supply is stable and within the specified voltage range.

- Terminate the CAN bus properly with 120-ohm resistors at both ends of the bus.

- Keep the CANH and CANL lines as twisted pairs to reduce interference.

- Avoid stubs in the CAN bus wiring to prevent signal reflections.

- Use shielded cables in noisy environments.

Example Code for Arduino UNO

#include <SPI.h>

#include <mcp_can.h>

// Initialize CAN BUS module with CS pin

MCP_CAN CAN(10);

void setup() {

Serial.begin(115200);

// Initialize CAN BUS module at 500kbps speed

if (CAN_OK == CAN.begin(CAN_500KBPS)) {

Serial.println("CAN BUS Shield init ok!");

}

else {

Serial.println("CAN BUS Shield init fail");

Serial.println("Init CAN BUS Shield again");

delay(100);

}

}

void loop() {

// Check if data is available to read

unsigned char len = 0;

unsigned char buf[8];

if (CAN_MSGAVAIL == CAN.checkReceive()) {

CAN.readMsgBuf(&len, buf); // Read data, len: data length, buf: data buffer

unsigned long canId = CAN.getCanId();

Serial.println("-----------------------------");

Serial.print("Get data from ID: 0x");

Serial.println(canId, HEX);

for (int i = 0; i < len; i++) { // Print each byte of the data

Serial.print(buf[i], HEX);

Serial.print("\t");

}

Serial.println();

}

}

Troubleshooting and FAQs

Common Issues Users Might Face

- No Communication: Check power supply, wiring, and termination resistors.

- Error Frames: Ensure there are no physical layer issues, such as damaged cables or connectors.

- Bus Off: The module may go into a bus-off state if errors exceed a certain threshold. Check for noise, incorrect baud rate, or faulty nodes.

Solutions and Tips for Troubleshooting

- Verify that all connections are secure and correct.

- Use an oscilloscope to check the signal quality on the CANH and CANL lines.

- Ensure that all nodes on the network have a unique identifier.

- Check for software issues, such as incorrect initialization of the CAN module.

FAQs

Q: Can I use the CAN BUS module with a 3.3V system? A: Some CAN BUS modules are 3.3V compatible, but you must check the specific module's datasheet.

Q: How many devices can be connected to a CAN BUS? A: The CAN specification allows up to 112 nodes, but practical limits are lower and depend on the total bus length and the transceiver used.

Q: What is the maximum length of a CAN BUS network? A: The maximum length depends on the baud rate; for example, at 1 Mbps, the maximum length is typically around 40 meters.

Q: Do I need to use termination resistors? A: Yes, proper termination is critical for preventing reflections and ensuring signal integrity on the CAN bus.