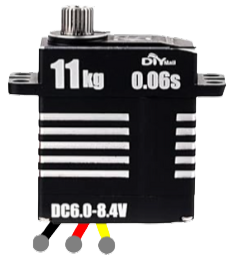

How to Use High Torque 11KG Mini All-Metal Digital Servo High Pressure Coreless Motor: Examples, Pinouts, and Specs

Design with High Torque 11KG Mini All-Metal Digital Servo High Pressure Coreless Motor in Cirkit Designer

Design with High Torque 11KG Mini All-Metal Digital Servo High Pressure Coreless Motor in Cirkit DesignerIntroduction

The High Torque 11KG Mini All-Metal Digital Servo, manufactured by DIYmall, is a robust and versatile servo motor designed for applications requiring high torque and precision. With its all-metal gear construction and coreless motor, this servo offers durability, reliability, and smooth operation. It is ideal for robotics, RC vehicles, drones, and other projects where precise control and high torque are essential.

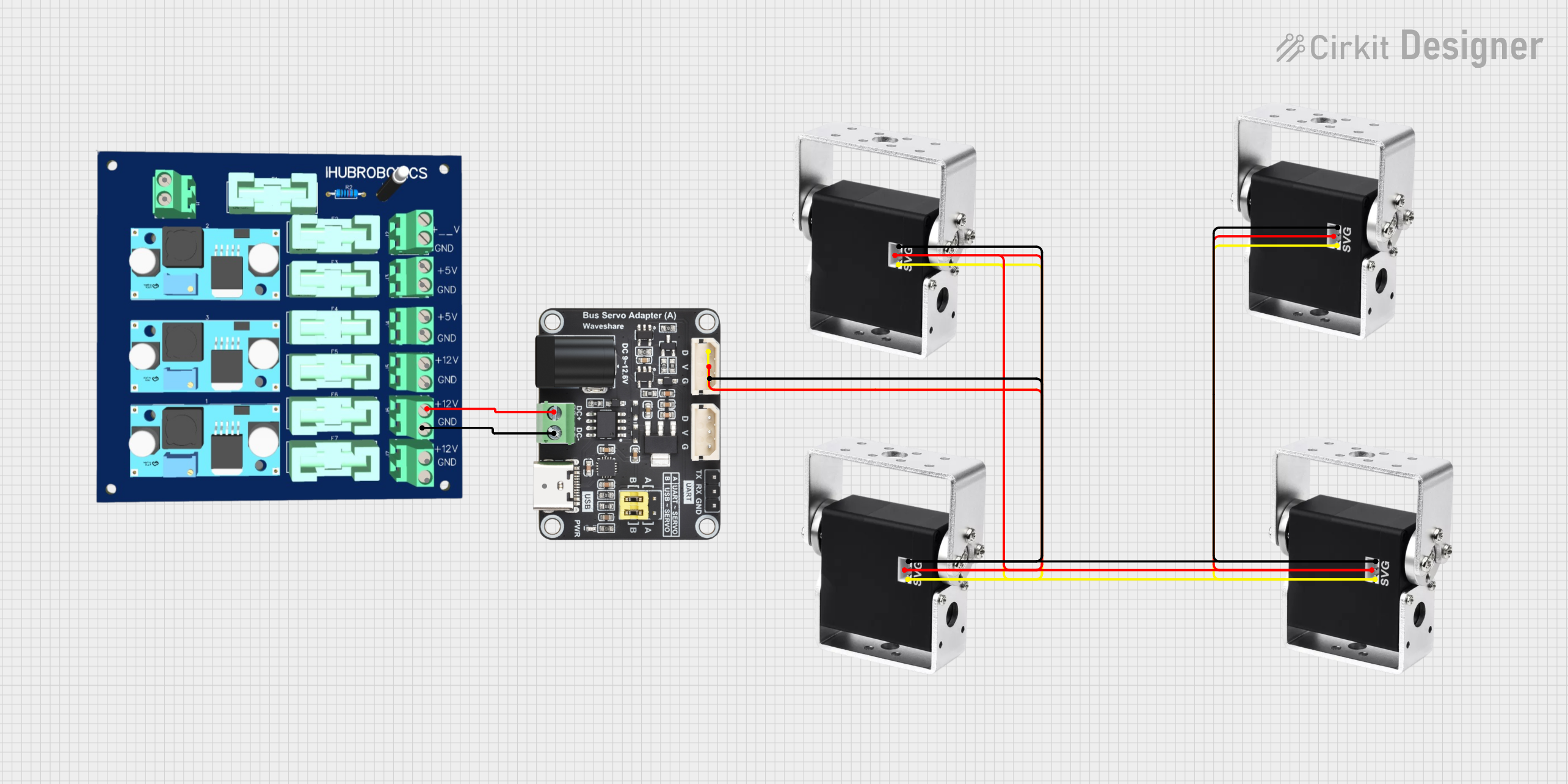

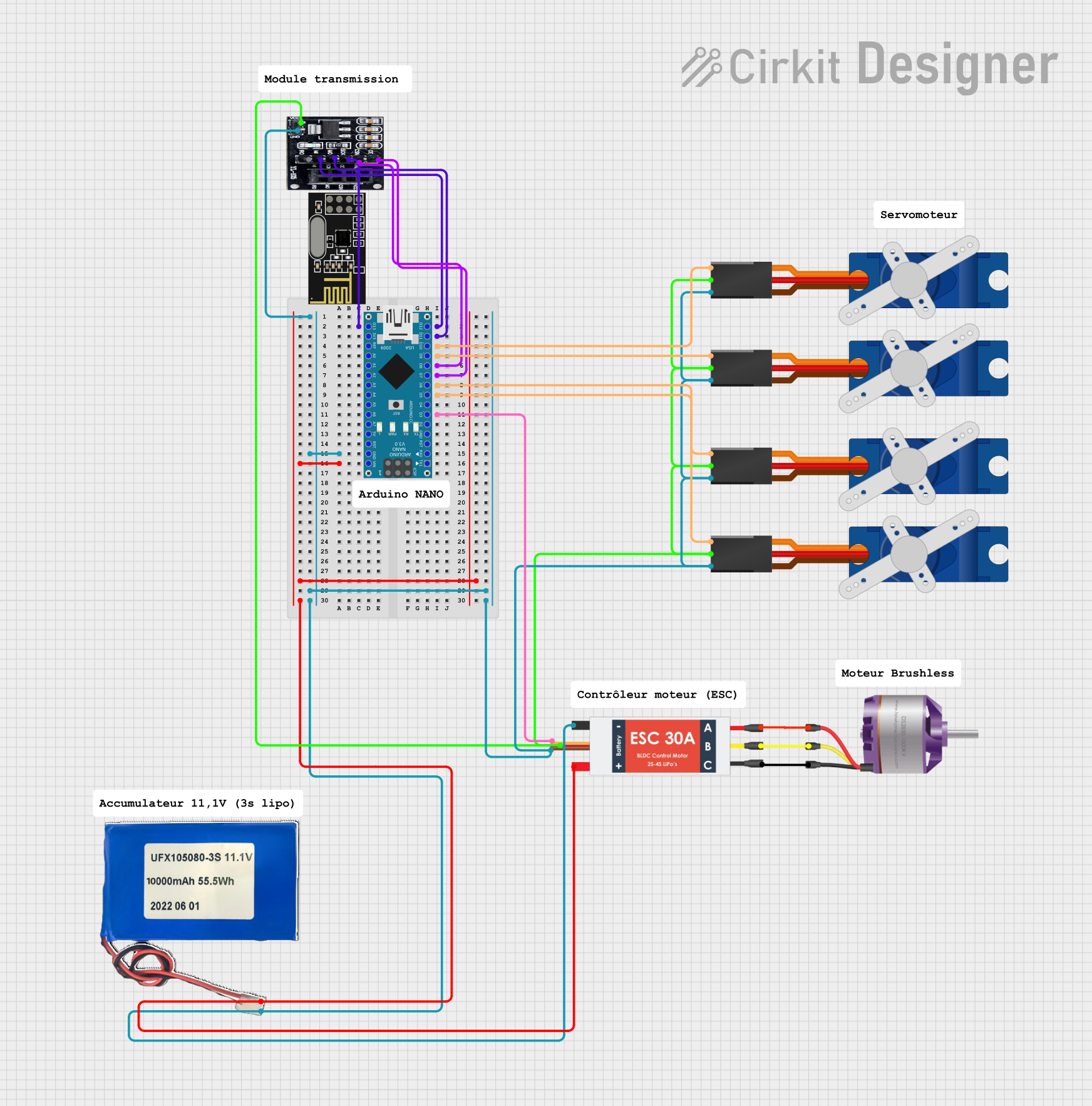

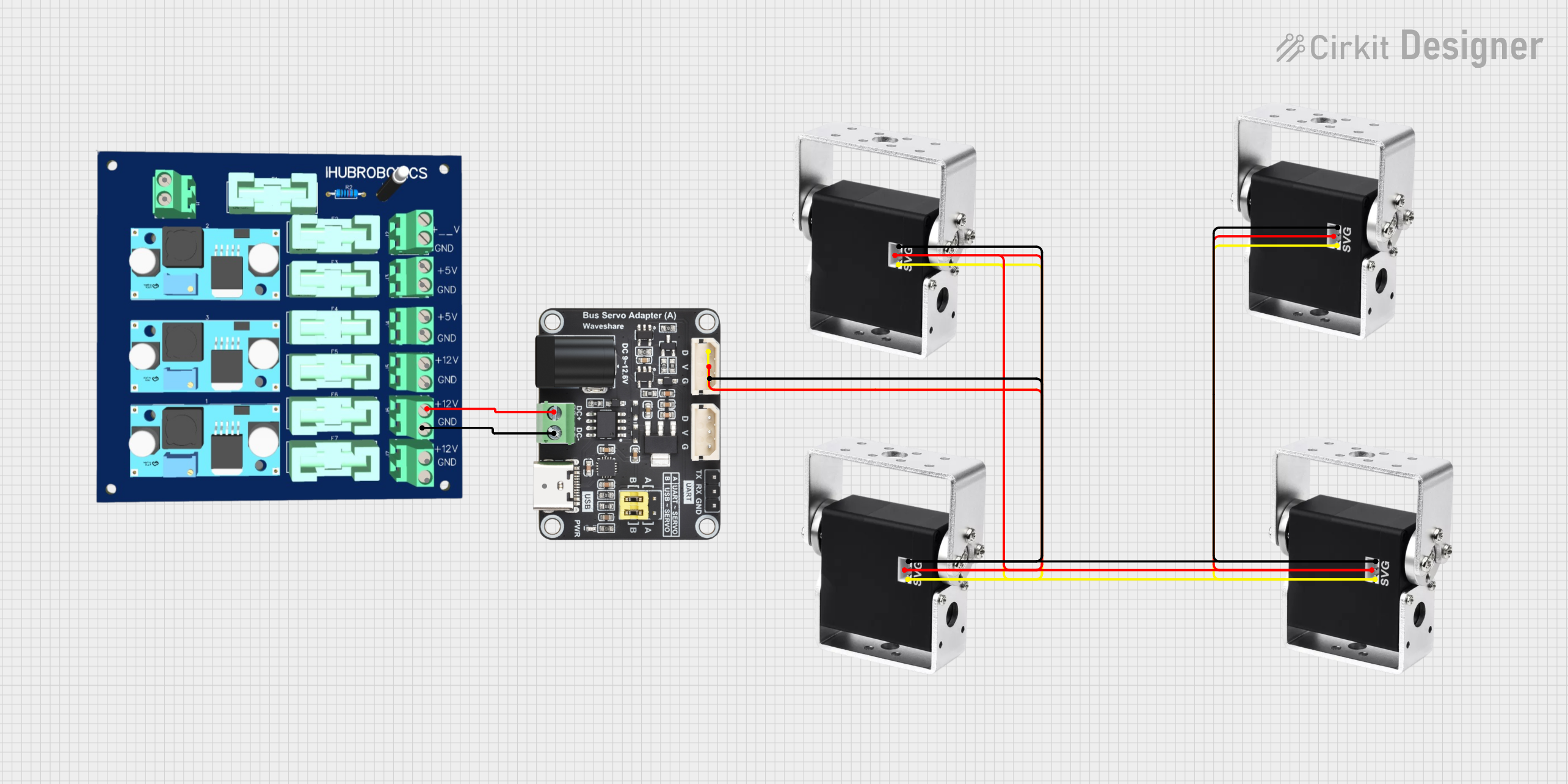

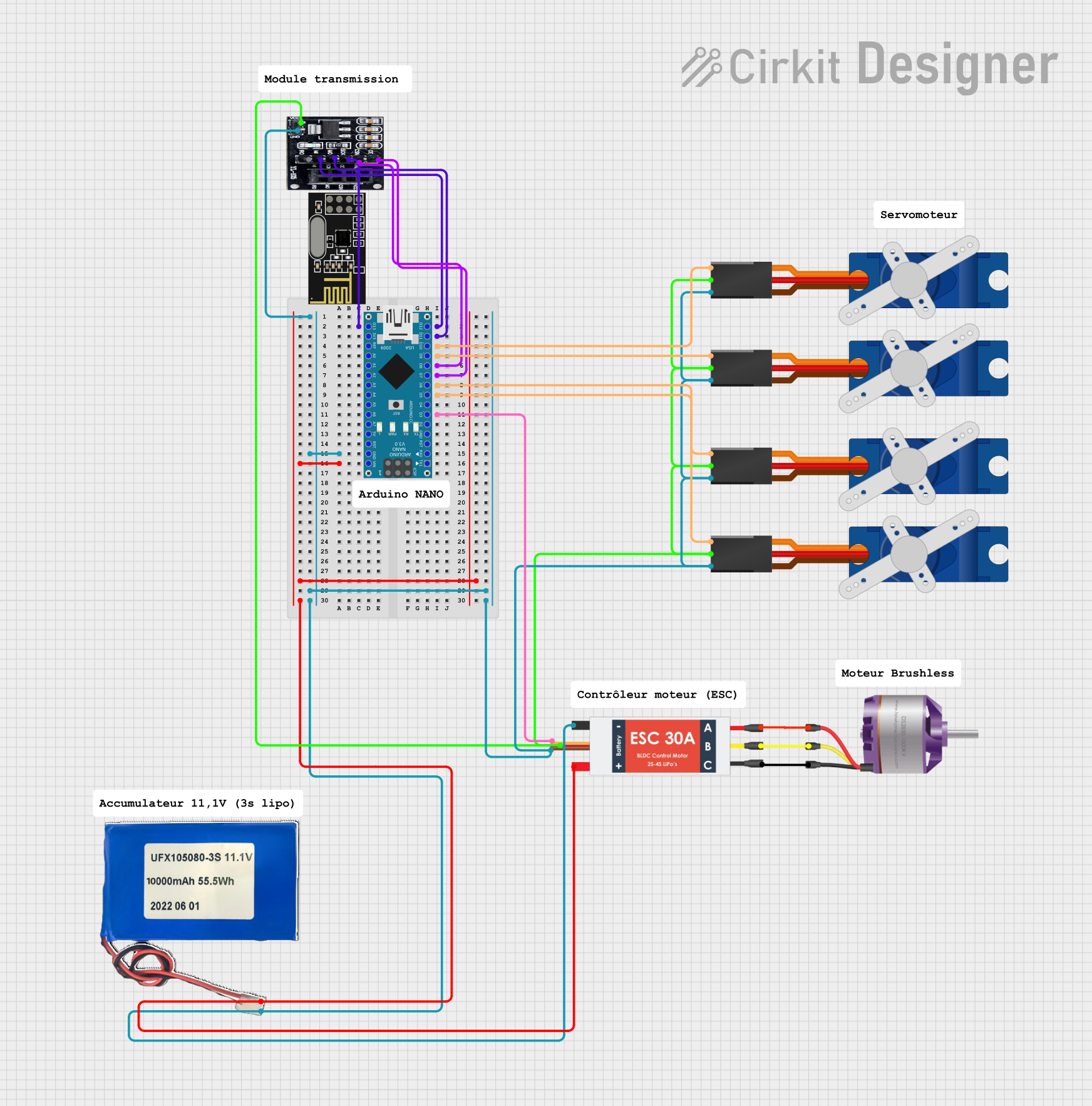

Explore Projects Built with High Torque 11KG Mini All-Metal Digital Servo High Pressure Coreless Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with High Torque 11KG Mini All-Metal Digital Servo High Pressure Coreless Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Arm joints, grippers, and movement mechanisms

- RC vehicles: Steering and throttle control

- Drones: Gimbal stabilization and control surfaces

- Industrial automation: Actuation and positioning systems

- DIY projects: Custom mechanisms requiring precise motion

Technical Specifications

The following table outlines the key technical specifications of the High Torque 11KG Mini All-Metal Digital Servo:

| Specification | Value |

|---|---|

| Operating Voltage | 4.8V - 6.6V |

| Stall Torque | 11 kg·cm (at 6.6V) |

| Operating Speed | 0.09 sec/60° (at 6.6V) |

| Motor Type | Coreless |

| Gear Material | All-metal |

| Control Signal | PWM (Pulse Width Modulation) |

| PWM Pulse Range | 500 µs - 2500 µs |

| Weight | 55 g |

| Dimensions | 40.5 mm x 20.2 mm x 38 mm |

| Connector Type | 3-pin female header (Futaba/JR) |

Pin Configuration and Descriptions

The servo motor has a standard 3-pin connector. The pinout is as follows:

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Brown | Ground (GND) |

| 2 | Red | Power Supply (VCC) |

| 3 | Orange | Signal (PWM control input) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the red wire to a stable power source (4.8V to 6.6V). Ensure the power supply can provide sufficient current (at least 2A) to handle the servo's peak load.

- Ground Connection: Connect the brown wire to the ground (GND) of your circuit.

- Signal Input: Connect the orange wire to a PWM-capable pin on your microcontroller (e.g., Arduino UNO).

- PWM Signal: Generate a PWM signal with a pulse width between 500 µs and 2500 µs to control the servo's position. A 1500 µs pulse typically corresponds to the neutral (center) position.

Important Considerations and Best Practices

- Power Supply: Use a dedicated power source for the servo to avoid voltage drops that could affect other components in your circuit.

- PWM Frequency: The servo operates best with a PWM frequency of 50 Hz.

- Avoid Overloading: Do not exceed the torque rating of 11 kg·cm to prevent damage to the motor or gears.

- Mounting: Secure the servo firmly to prevent vibrations or misalignment during operation.

- Calibration: Test and calibrate the servo's range of motion to ensure it operates within safe limits.

Example Code for Arduino UNO

Below is an example of how to control the servo using an Arduino UNO:

#include <Servo.h> // Include the Servo library

Servo myServo; // Create a Servo object

void setup() {

myServo.attach(9); // Attach the servo to pin 9

// Set the initial position of the servo to 90 degrees

myServo.write(90);

}

void loop() {

// Sweep the servo from 0 to 180 degrees

for (int pos = 0; pos <= 180; pos += 1) {

myServo.write(pos); // Move the servo to the current position

delay(15); // Wait 15ms for the servo to reach the position

}

// Sweep the servo back from 180 to 0 degrees

for (int pos = 180; pos >= 0; pos -= 1) {

myServo.write(pos); // Move the servo to the current position

delay(15); // Wait 15ms for the servo to reach the position

}

}

Troubleshooting and FAQs

Common Issues and Solutions

Servo Not Moving:

- Cause: Insufficient power supply.

- Solution: Ensure the power source provides at least 2A and is within the voltage range (4.8V - 6.6V).

Jittery or Erratic Movement:

- Cause: Electrical noise or unstable PWM signal.

- Solution: Use decoupling capacitors near the servo's power pins and ensure the PWM signal is clean and stable.

Overheating:

- Cause: Prolonged operation under high torque or stalled conditions.

- Solution: Avoid stalling the servo and ensure it operates within its torque limits.

Limited Range of Motion:

- Cause: Incorrect PWM pulse width or mechanical obstruction.

- Solution: Verify the PWM pulse width is within the 500 µs - 2500 µs range and check for physical obstructions.

FAQs

Q: Can I power the servo directly from the Arduino UNO?

A: No, the Arduino UNO cannot supply sufficient current for the servo. Use an external power source.Q: What is the maximum angle of rotation for this servo?

A: The servo typically rotates 180°, but this may vary slightly depending on the PWM signal.Q: Can I use this servo with a 3.3V microcontroller?

A: Yes, but ensure the signal voltage is compatible with the servo's input. A level shifter may be required.Q: How do I prevent the servo from drawing too much current?

A: Use a current-limiting power supply or a fuse to protect your circuit.

This concludes the documentation for the High Torque 11KG Mini All-Metal Digital Servo High Pressure Coreless Motor.