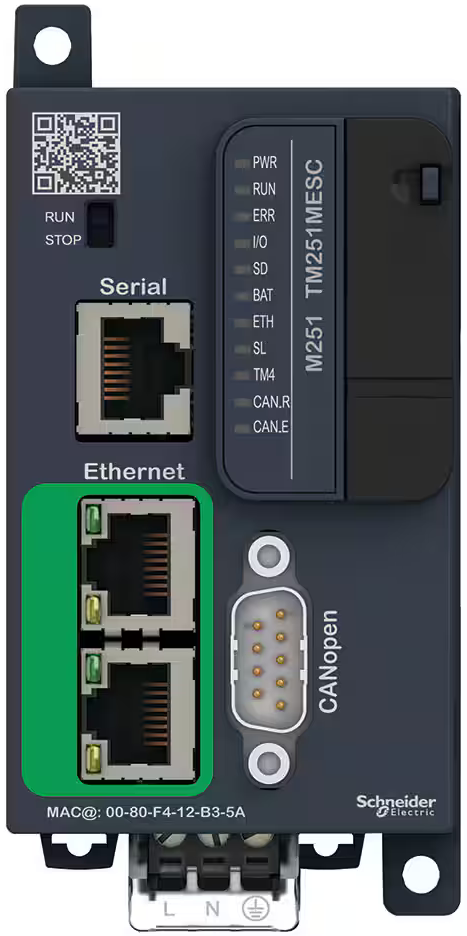

How to Use M251: Examples, Pinouts, and Specs

Design with M251 in Cirkit Designer

Design with M251 in Cirkit DesignerIntroduction

The M251 (TM251MESC) is a compact and versatile programmable logic controller (PLC) manufactured by Schneider Electric. It is designed for industrial automation and control applications, offering high performance, flexibility, and connectivity. The M251 is particularly suited for applications requiring distributed control, remote monitoring, and integration with industrial networks.

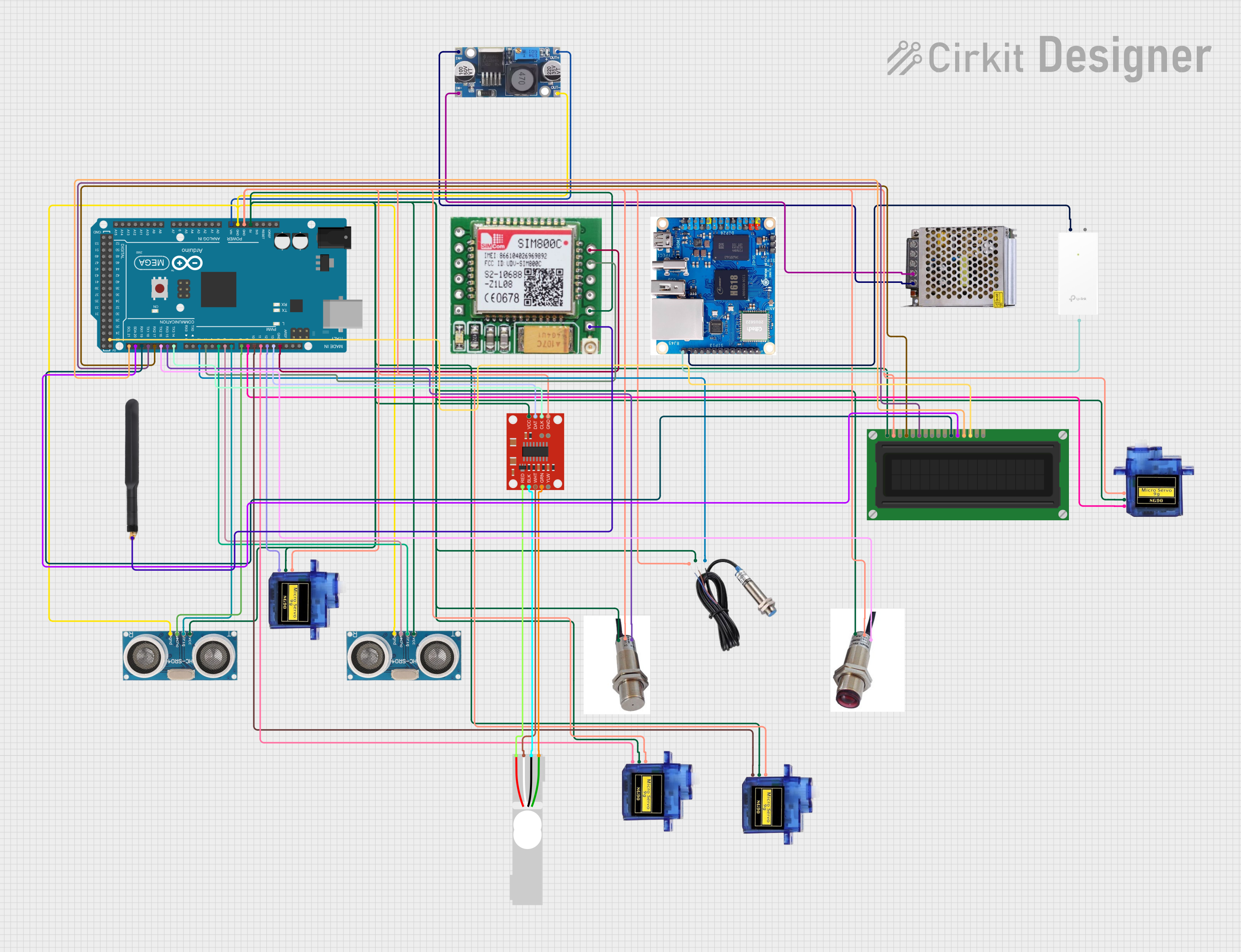

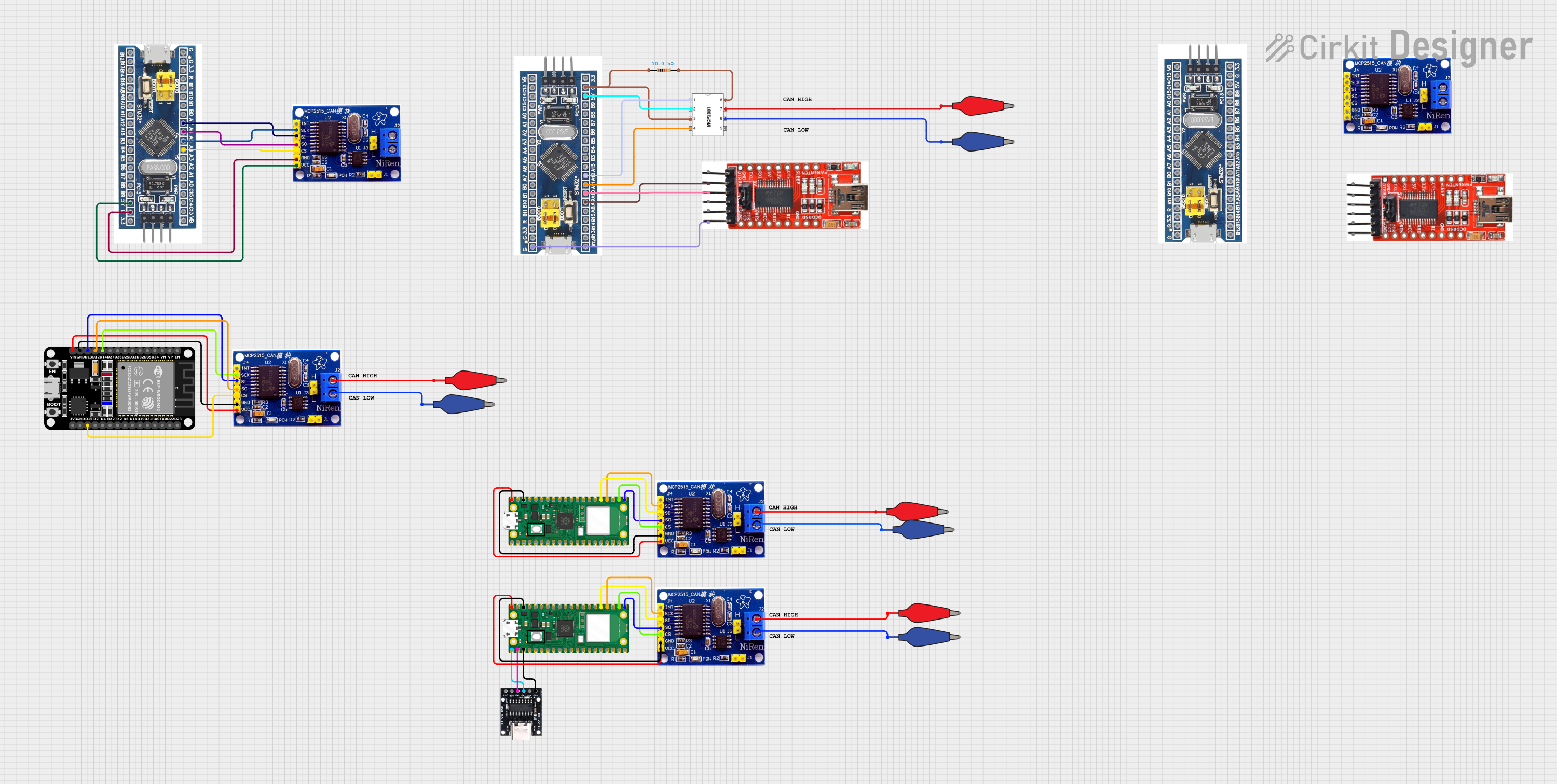

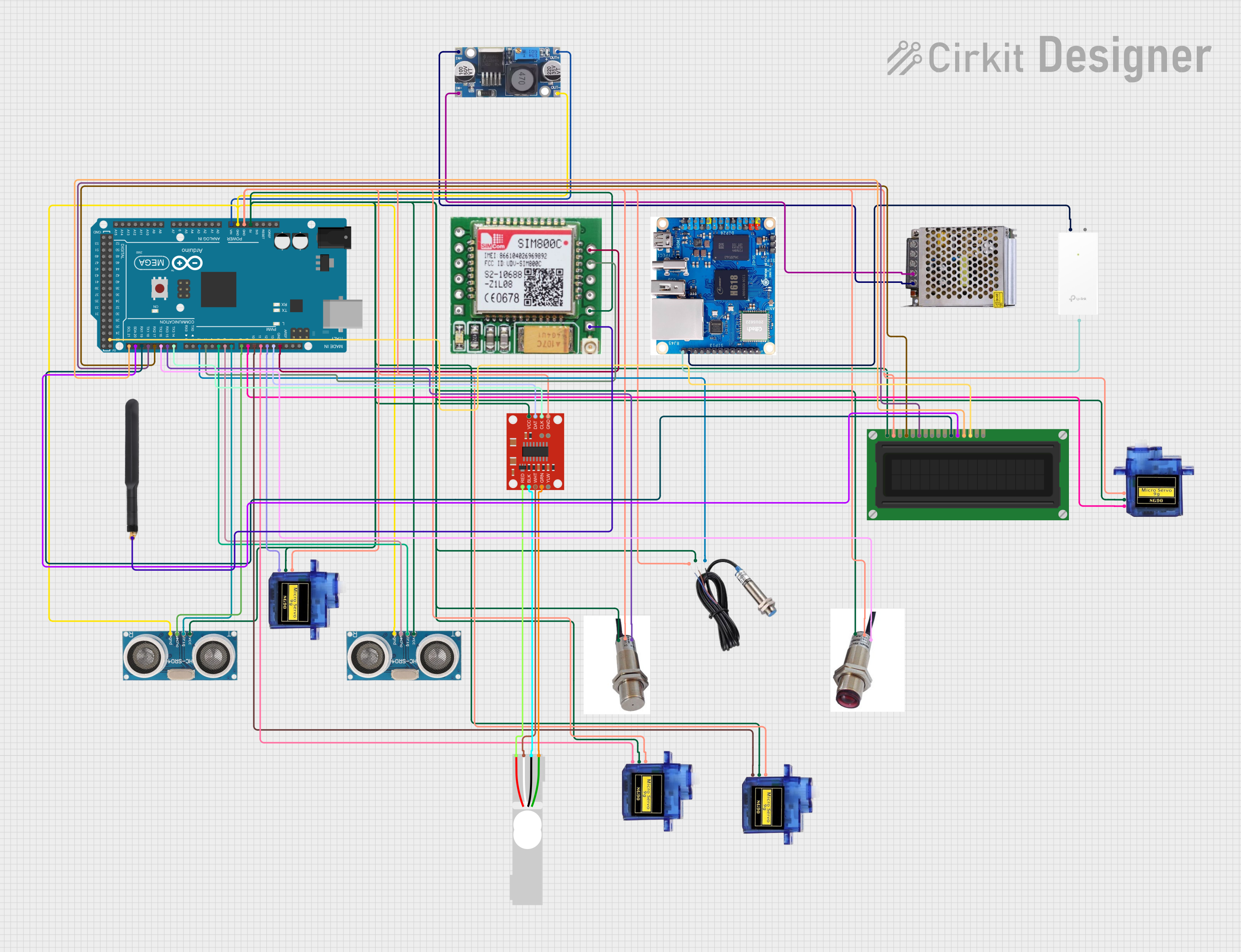

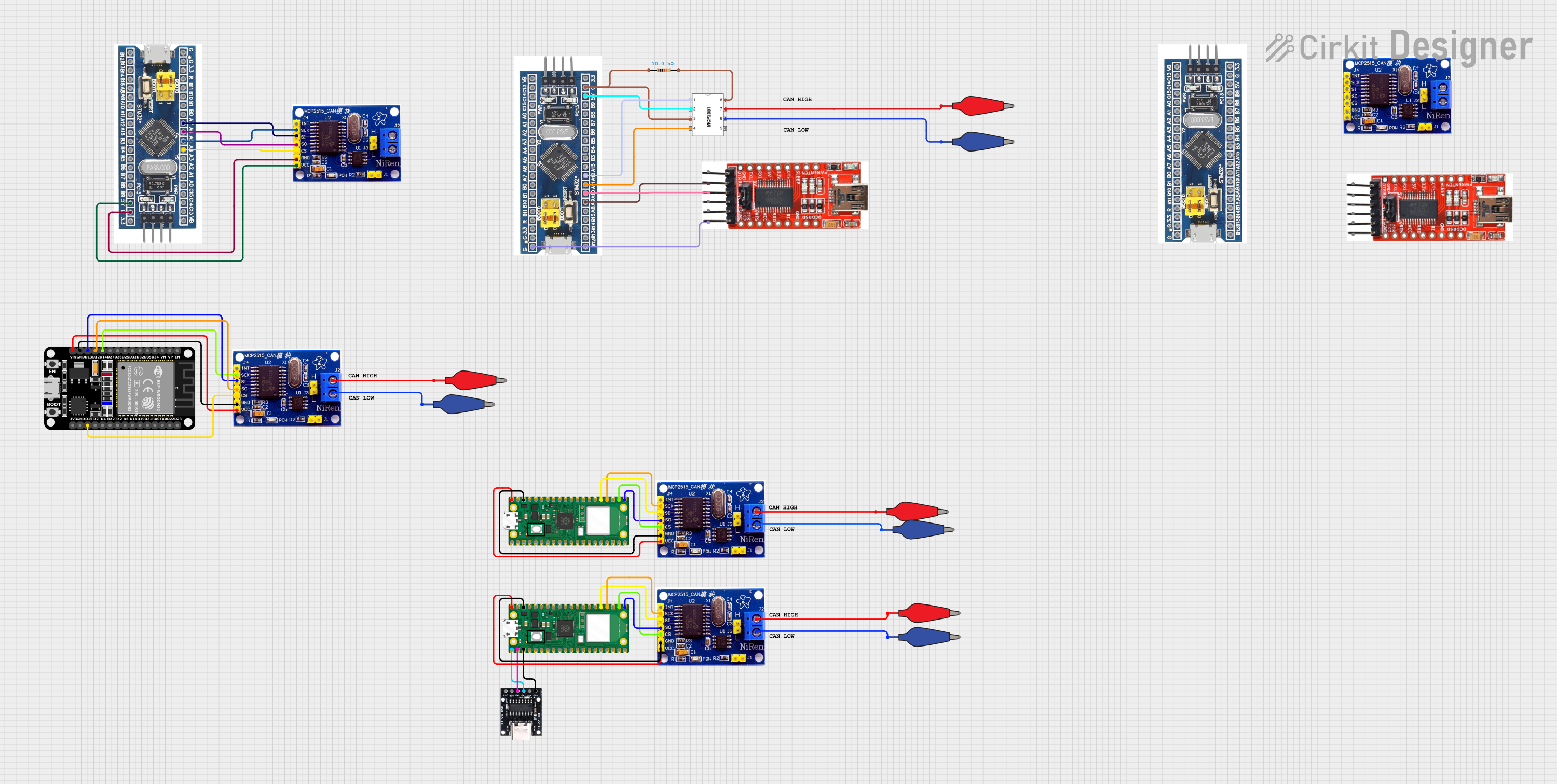

Explore Projects Built with M251

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with M251

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial automation and process control

- Machine control and monitoring

- Distributed I/O systems

- Integration with Modbus, Ethernet/IP, and other industrial communication protocols

- Remote monitoring and data acquisition in smart factories

Technical Specifications

Key Technical Details

- Manufacturer: Schneider Electric

- Part Number: TM251MESC

- Processor: ARM Cortex-A9, 600 MHz

- Memory:

- 64 MB RAM

- 128 MB Flash memory

- Power Supply: 24 V DC (±20%)

- Communication Ports:

- 2x Ethernet ports (10/100 Mbps)

- 1x Serial port (RS-232/RS-485)

- 1x USB port (for programming and diagnostics)

- Supported Protocols: Modbus TCP, Ethernet/IP, OPC UA, and more

- Operating Temperature: -10°C to +55°C

- Dimensions: 90 x 95 x 70 mm (H x W x D)

- Mounting: DIN rail

Pin Configuration and Descriptions

The M251 (TM251MESC) has multiple ports and terminals for power, communication, and I/O connections. Below is a summary of the key pin configurations:

Power Supply Terminals

| Pin Number | Description | Notes |

|---|---|---|

| 1 | +24 V DC Input | Connect to a 24 V DC power source. |

| 2 | 0 V (Ground) | Common ground for the power supply. |

Ethernet Ports

| Port Number | Description | Notes |

|---|---|---|

| ETH1 | Ethernet Port 1 | For network communication. |

| ETH2 | Ethernet Port 2 | Supports daisy-chaining. |

Serial Port (RS-232/RS-485)

| Pin Number | Description | Notes |

|---|---|---|

| TXD | Transmit Data | RS-232 communication. |

| RXD | Receive Data | RS-232 communication. |

| A | Data+ (RS-485) | RS-485 communication. |

| B | Data- (RS-485) | RS-485 communication. |

USB Port

| Port Number | Description | Notes |

|---|---|---|

| USB | USB Programming Port | For programming and diagnostics. |

Usage Instructions

How to Use the M251 in a Circuit

Power Connection:

- Connect the +24 V DC power supply to the power input terminals (Pin 1 and Pin 2).

- Ensure the power supply is stable and within the specified voltage range (24 V ±20%).

Communication Setup:

- Use the Ethernet ports (ETH1 and ETH2) to connect the M251 to your industrial network.

- Configure the IP address and communication settings using Schneider Electric's EcoStruxure Machine Expert software.

Programming:

- Connect the M251 to your PC using the USB programming port.

- Use EcoStruxure Machine Expert to write and upload your control logic.

I/O Configuration:

- Connect external sensors, actuators, or other devices to the M251's I/O modules (if applicable).

- Configure the I/O settings in the software to match your application requirements.

Testing and Deployment:

- Test the system functionality in a controlled environment.

- Deploy the M251 in your industrial setup and monitor its performance.

Important Considerations and Best Practices

- Always use a regulated 24 V DC power supply to avoid damage to the device.

- Ensure proper grounding to minimize electrical noise and interference.

- Use shielded cables for communication ports to improve signal integrity.

- Regularly update the firmware to benefit from the latest features and security patches.

- Follow all safety guidelines and standards for industrial automation systems.

Example Code for Modbus Communication with Arduino UNO

Below is an example of how to communicate with the M251 using Modbus RTU protocol and an Arduino UNO:

#include <ModbusMaster.h>

// Instantiate ModbusMaster object

ModbusMaster node;

void setup() {

// Initialize serial communication for debugging

Serial.begin(9600);

// Initialize Modbus communication (RS-485)

node.begin(1, Serial); // Slave ID = 1

// Configure RS-485 communication settings

Serial.begin(19200, SERIAL_8N1); // 19200 baud, 8 data bits, no parity, 1 stop bit

}

void loop() {

uint8_t result;

uint16_t data;

// Read a holding register (e.g., register 40001)

result = node.readHoldingRegisters(0x0000, 1);

if (result == node.ku8MBSuccess) {

data = node.getResponseBuffer(0);

Serial.print("Register Value: ");

Serial.println(data);

} else {

Serial.print("Error Code: ");

Serial.println(result);

}

delay(1000); // Wait 1 second before the next request

}

Troubleshooting and FAQs

Common Issues and Solutions

Device Not Powering On:

- Cause: Incorrect power supply voltage or loose connections.

- Solution: Verify the power supply voltage (24 V ±20%) and check all connections.

Communication Failure:

- Cause: Incorrect IP address or communication settings.

- Solution: Double-check the network configuration in EcoStruxure Machine Expert.

Program Upload Fails:

- Cause: USB cable not connected properly or driver issues.

- Solution: Ensure the USB cable is securely connected and update the USB driver if necessary.

I/O Modules Not Responding:

- Cause: Incorrect wiring or configuration.

- Solution: Verify the wiring and ensure the I/O modules are properly configured in the software.

FAQs

Q: Can the M251 be used in harsh environments?

A: Yes, the M251 is designed to operate in temperatures ranging from -10°C to +55°C. However, ensure it is installed in a suitable enclosure for protection against dust and moisture.Q: Does the M251 support remote monitoring?

A: Yes, the M251 supports remote monitoring via Ethernet and protocols like Modbus TCP and OPC UA.Q: Can I expand the I/O capabilities of the M251?

A: Yes, the M251 supports expansion modules for additional I/O channels.Q: What software is required to program the M251?

A: Schneider Electric's EcoStruxure Machine Expert software is used for programming and configuration.

This concludes the documentation for the M251 (TM251MESC). For further assistance, refer to the official Schneider Electric user manual or contact their technical support.