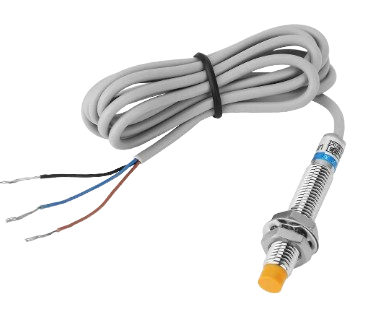

How to Use inductive sensor: Examples, Pinouts, and Specs

Design with inductive sensor in Cirkit Designer

Design with inductive sensor in Cirkit DesignerIntroduction

An inductive sensor is a non-contact electronic proximity sensor that is used to detect the presence of metal objects without requiring physical contact. It operates on the principle of inductance, which is the property of an electrical conductor to induce a voltage in itself or in any nearby conductors due to a change in the magnetic field.

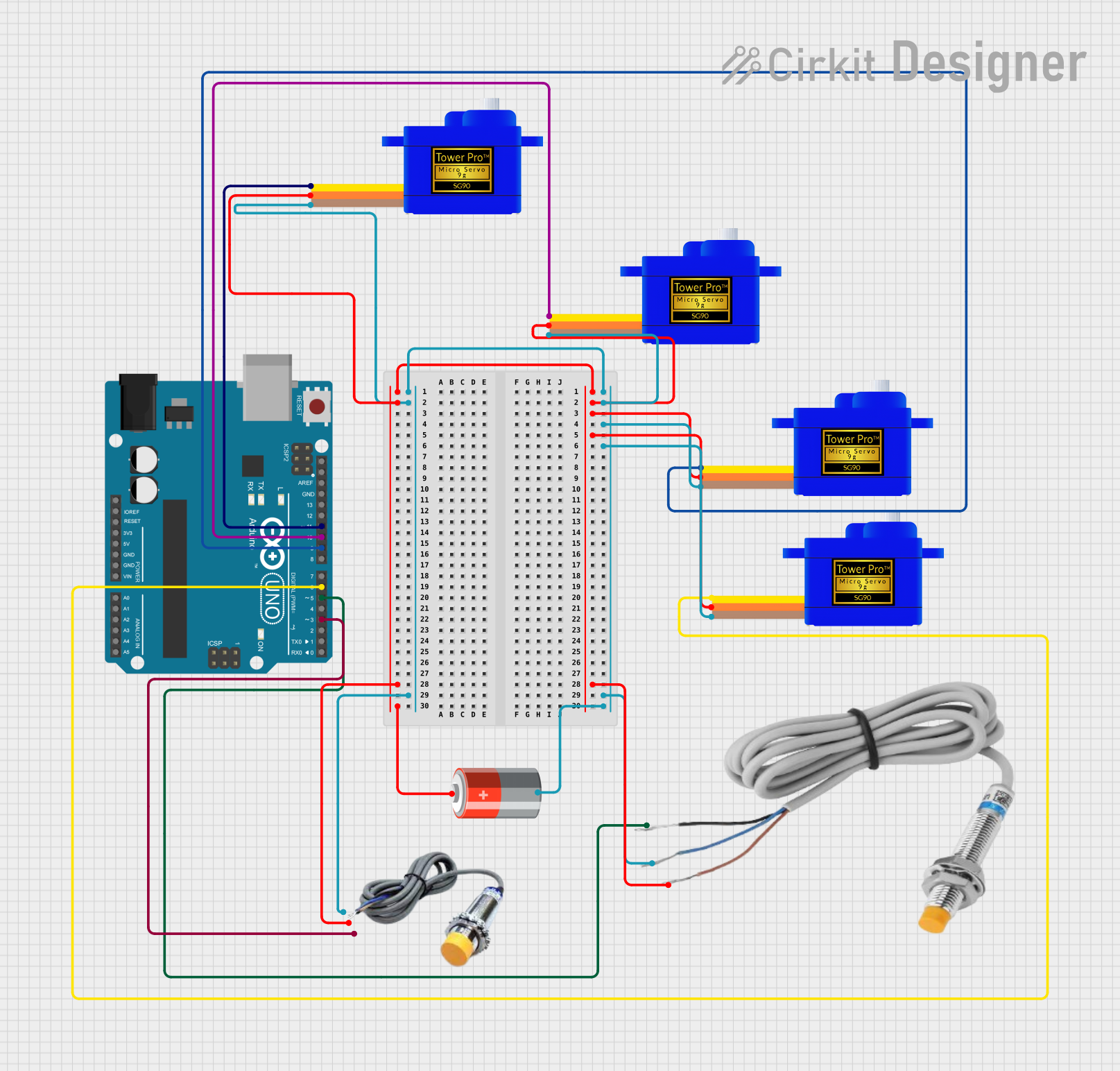

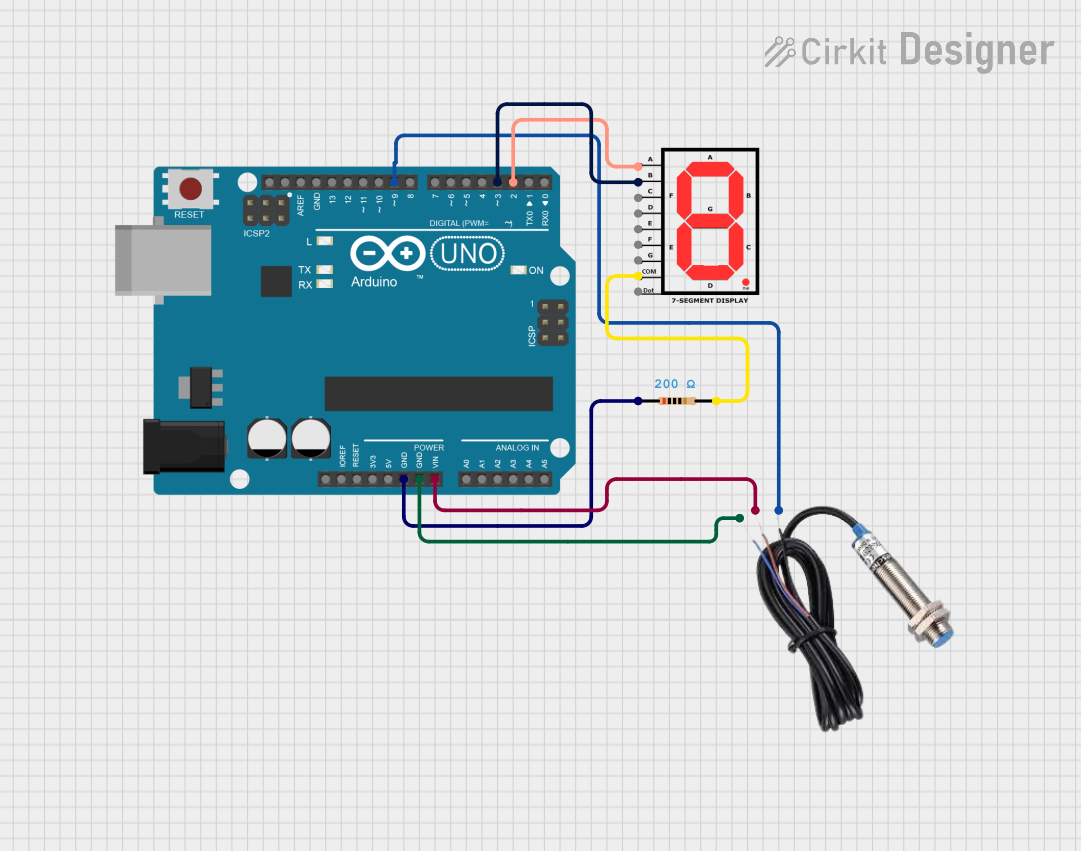

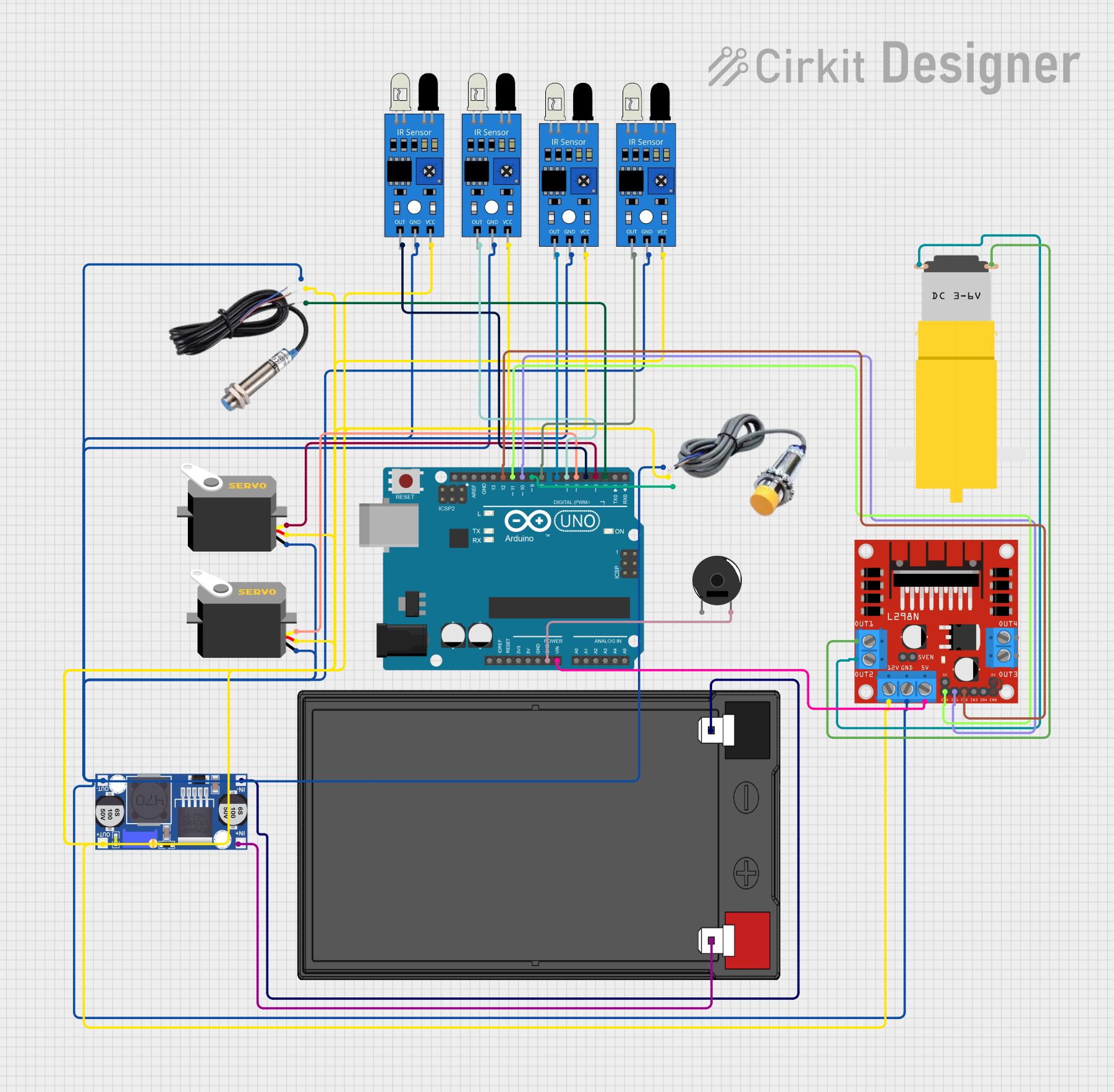

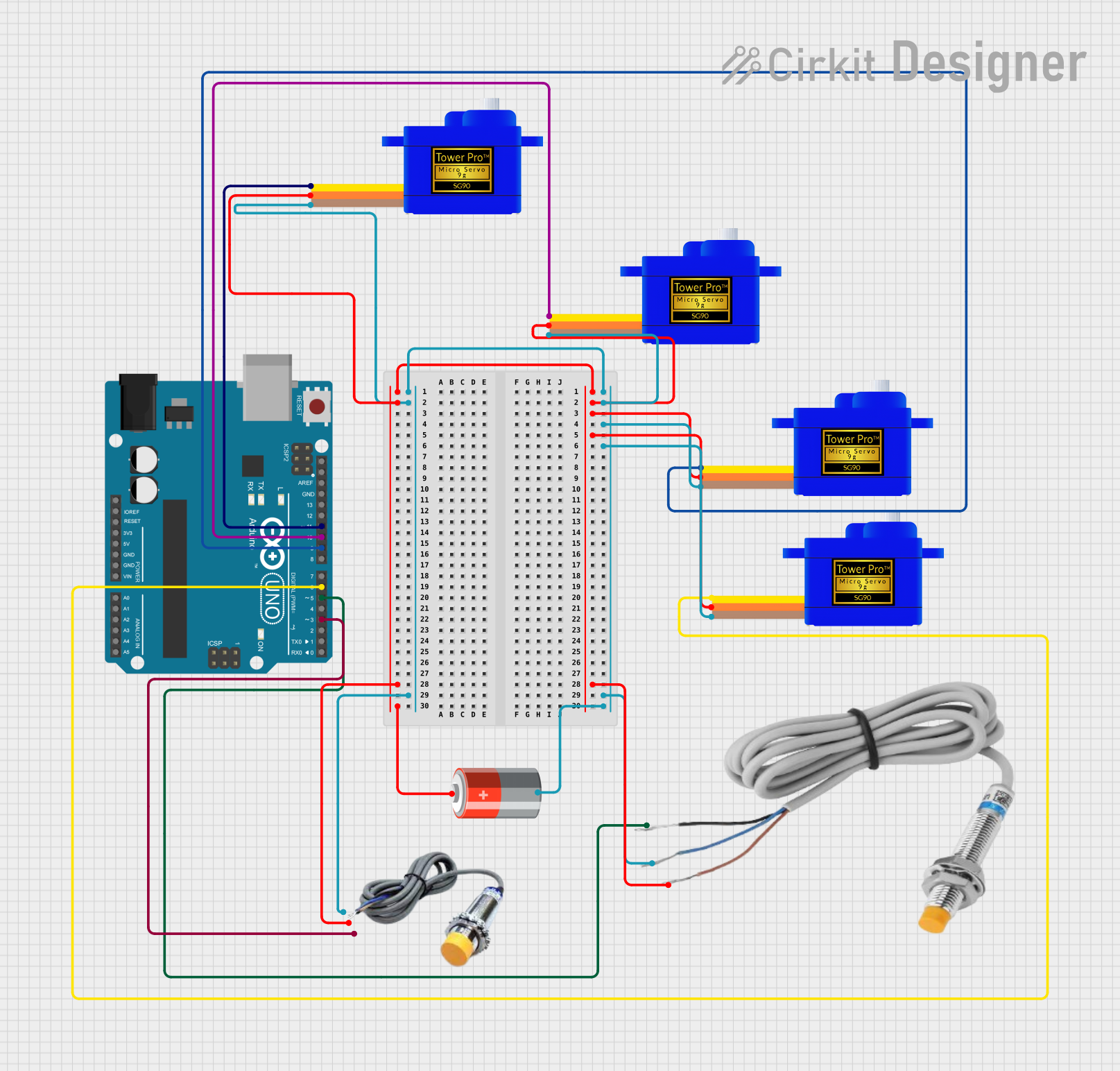

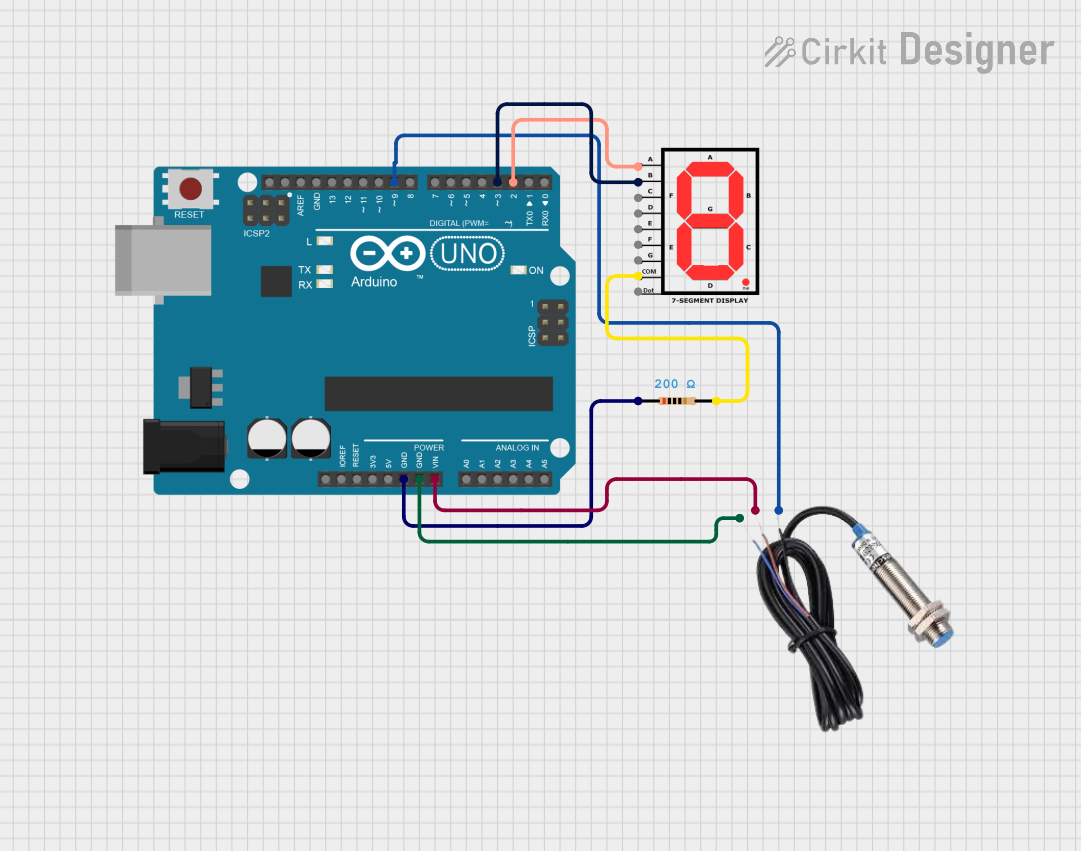

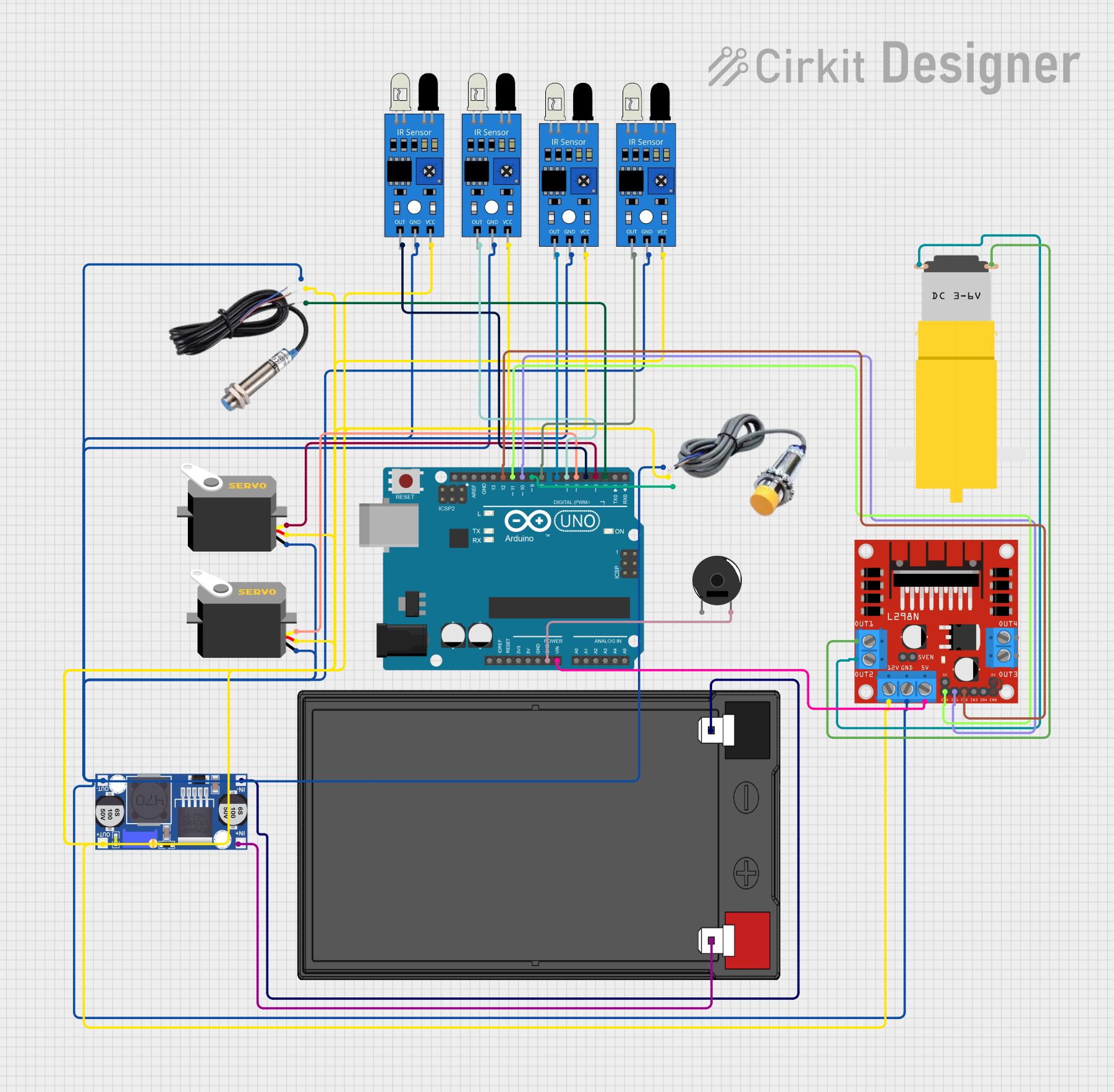

Explore Projects Built with inductive sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with inductive sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial automation and robotics

- Position sensing

- Metal object detection

- Revolution counting

- Speed monitoring

Technical Specifications

Key Technical Details

- Supply Voltage (Vcc): Typically 6-36V DC

- Output Current: Usually up to 200 mA

- Sensing Distance: Varies, typically 1-20 mm depending on the sensor size and the target material

- Frequency: Can range from a few Hz to several kHz

- Operating Temperature: -25°C to +70°C (may vary by model)

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Vcc (Power Supply) | Connect to positive power supply |

| 2 | Output | Switching signal (NPN/PNP) |

| 3 | Ground (GND) | Connect to system ground |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the Vcc pin to a DC power supply within the sensor's specified voltage range.

- Grounding: Connect the GND pin to the ground of the power supply and your control system.

- Output Signal: Connect the output pin to the input of your control system (e.g., PLC, microcontroller).

Important Considerations and Best Practices

- Ensure that the metal target is within the specified sensing range.

- Avoid placing the sensor near large metal surfaces that may interfere with the magnetic field.

- Use shielded cables to minimize electromagnetic interference (EMI).

- Do not exceed the voltage and current ratings to prevent damage to the sensor.

Example Connection with Arduino UNO

// Define the sensor output pin connected to the Arduino

const int inductiveSensorPin = 2; // Digital pin 2

void setup() {

// Set the sensor pin as an input

pinMode(inductiveSensorPin, INPUT);

// Begin serial communication at 9600 baud rate

Serial.begin(9600);

}

void loop() {

// Read the sensor state (HIGH when metal is detected)

int sensorState = digitalRead(inductiveSensorPin);

// Print the sensor state to the Serial Monitor

Serial.println(sensorState);

delay(100); // Delay for stability

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Sensor not detecting metal: Check if the metal object is within the sensing range and the sensor is properly powered.

- False triggering: Ensure there are no unintended metal objects within the sensing range and check for EMI sources.

- No output signal: Verify connections, ensure the power supply is within the specified range, and check the sensor's LED indicator if available.

Solutions and Tips for Troubleshooting

- Use a multimeter to check for proper voltage levels at the sensor's power supply and output pins.

- Reorient or relocate the sensor to minimize interference from other metal objects or EMI sources.

- Check the manufacturer's datasheet for specific troubleshooting steps related to your sensor model.

FAQs

Q: Can inductive sensors detect non-metal objects? A: No, inductive sensors are designed to detect metal objects only.

Q: What is the difference between NPN and PNP output? A: NPN (sinking) outputs connect to ground when activated, while PNP (sourcing) outputs connect to the power supply when activated. Choose based on your control system requirements.

Q: How can I extend the sensing range of my inductive sensor? A: The sensing range is fixed based on the sensor design. Using a larger sensor or one specifically designed for a greater range is necessary to detect objects from further away.

Q: Are inductive sensors affected by water or dust? A: Inductive sensors are typically enclosed in a robust housing making them suitable for harsh environments, but always check the IP rating for specifics on water and dust resistance.