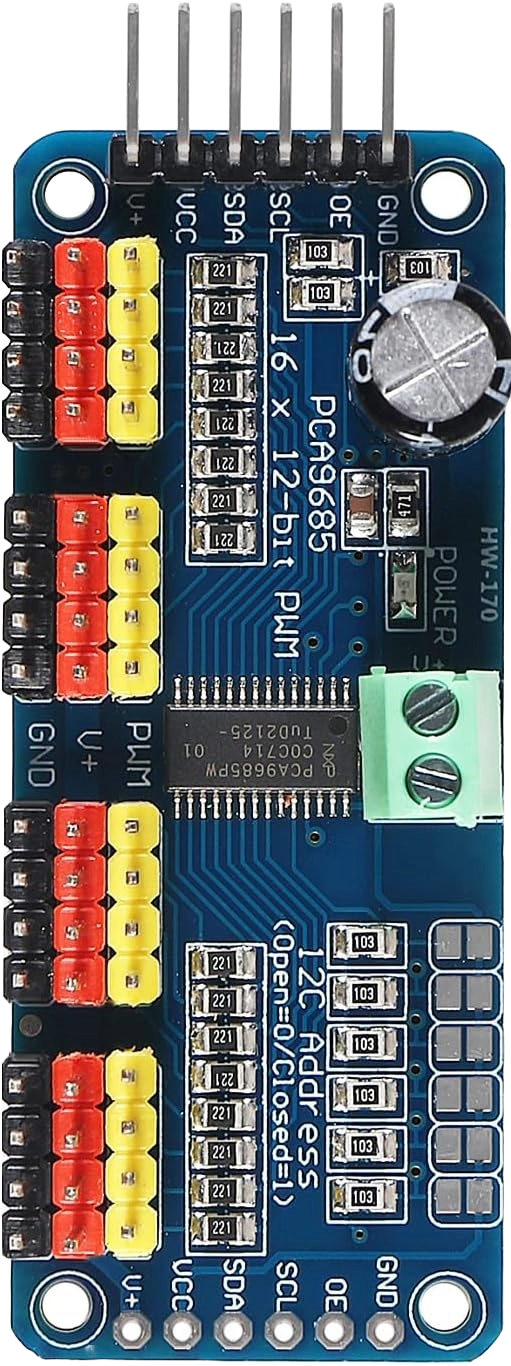

How to Use 16-Channel PWM Servo Driver: Examples, Pinouts, and Specs

Design with 16-Channel PWM Servo Driver in Cirkit Designer

Design with 16-Channel PWM Servo Driver in Cirkit DesignerIntroduction

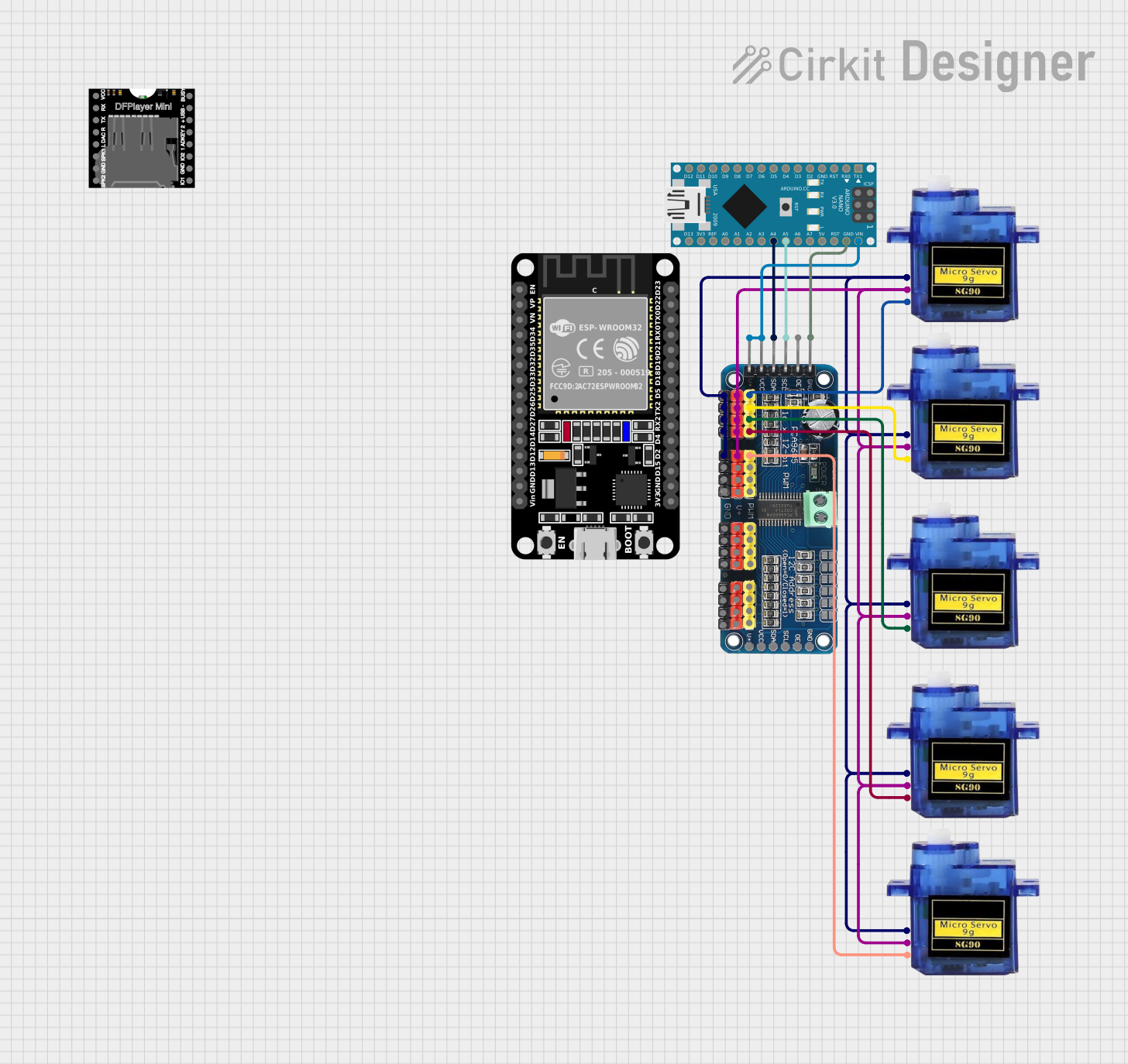

The 16-Channel PWM Servo Driver is an electronic device designed to control up to 16 servo motors simultaneously using Pulse Width Modulation (PWM). It is ideal for robotics, animatronics, custom control systems, and any application requiring precise multi-servo control. By offloading the PWM generation from the main microcontroller, such as an Arduino, it allows for smoother and more efficient operation of multiple servos.

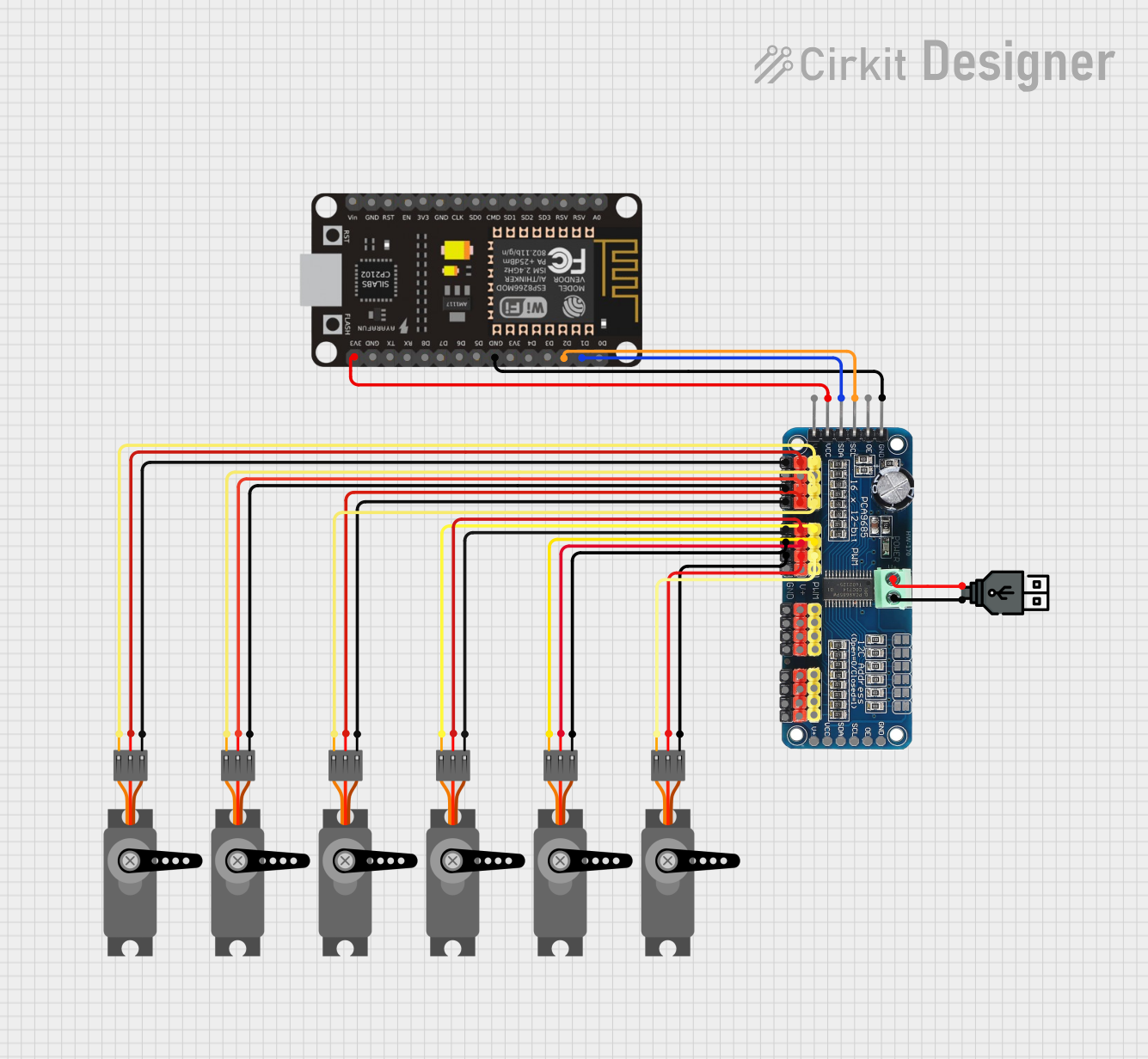

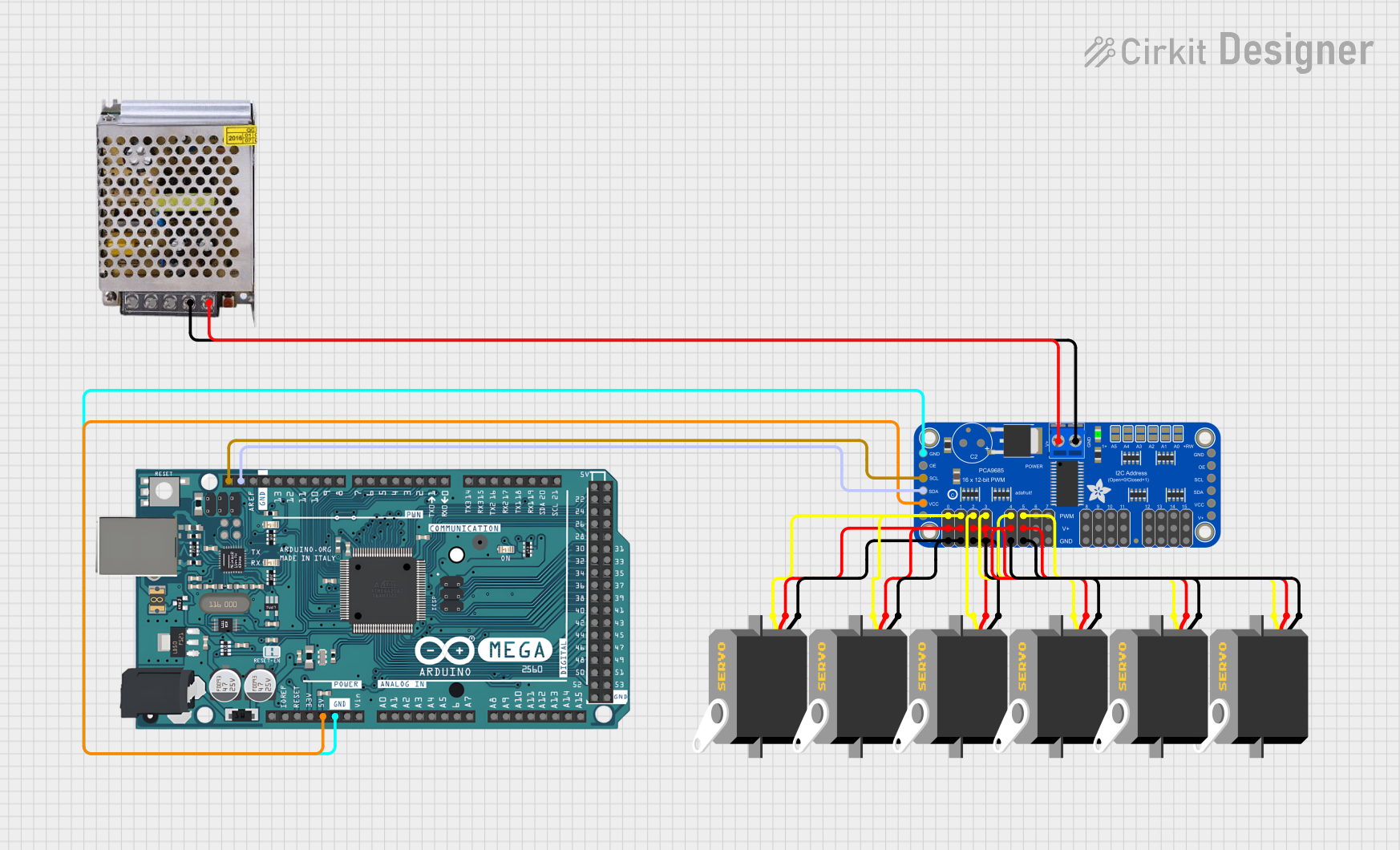

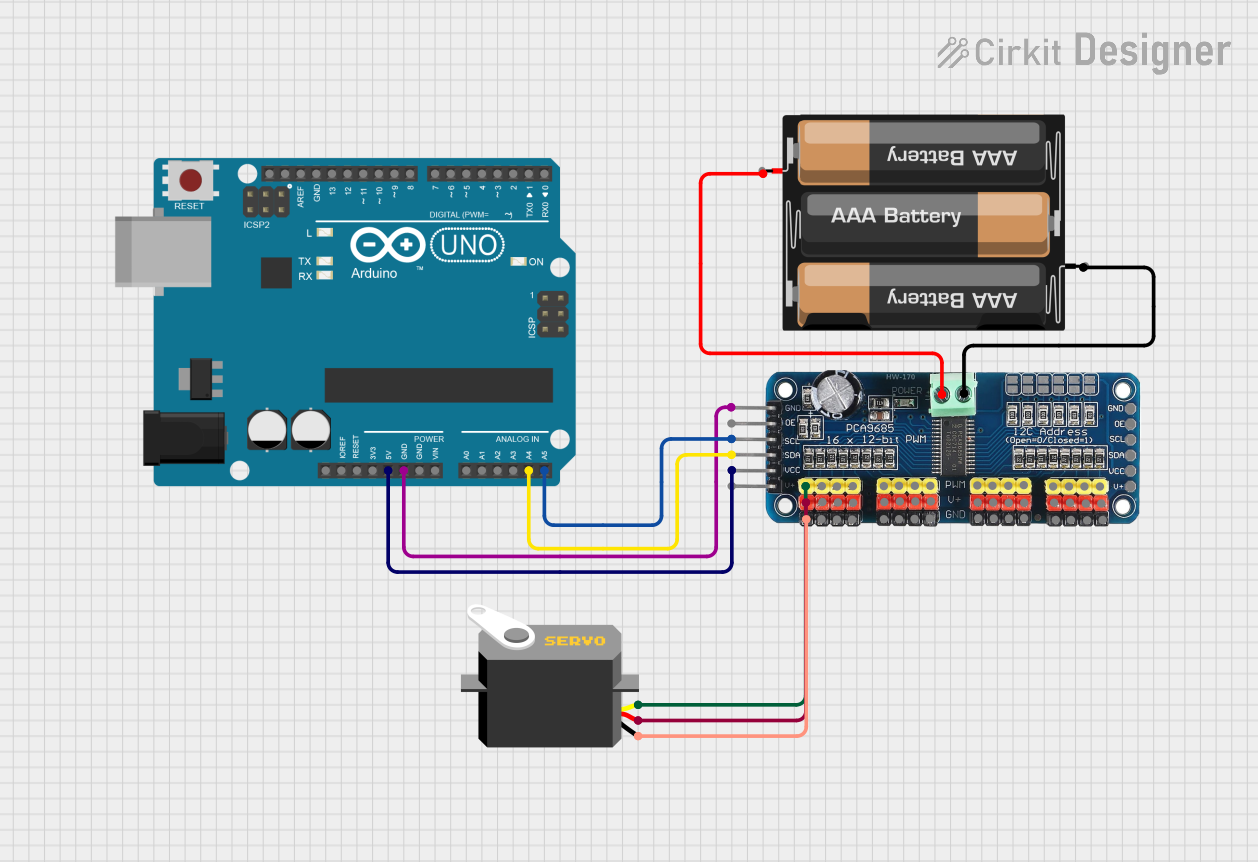

Explore Projects Built with 16-Channel PWM Servo Driver

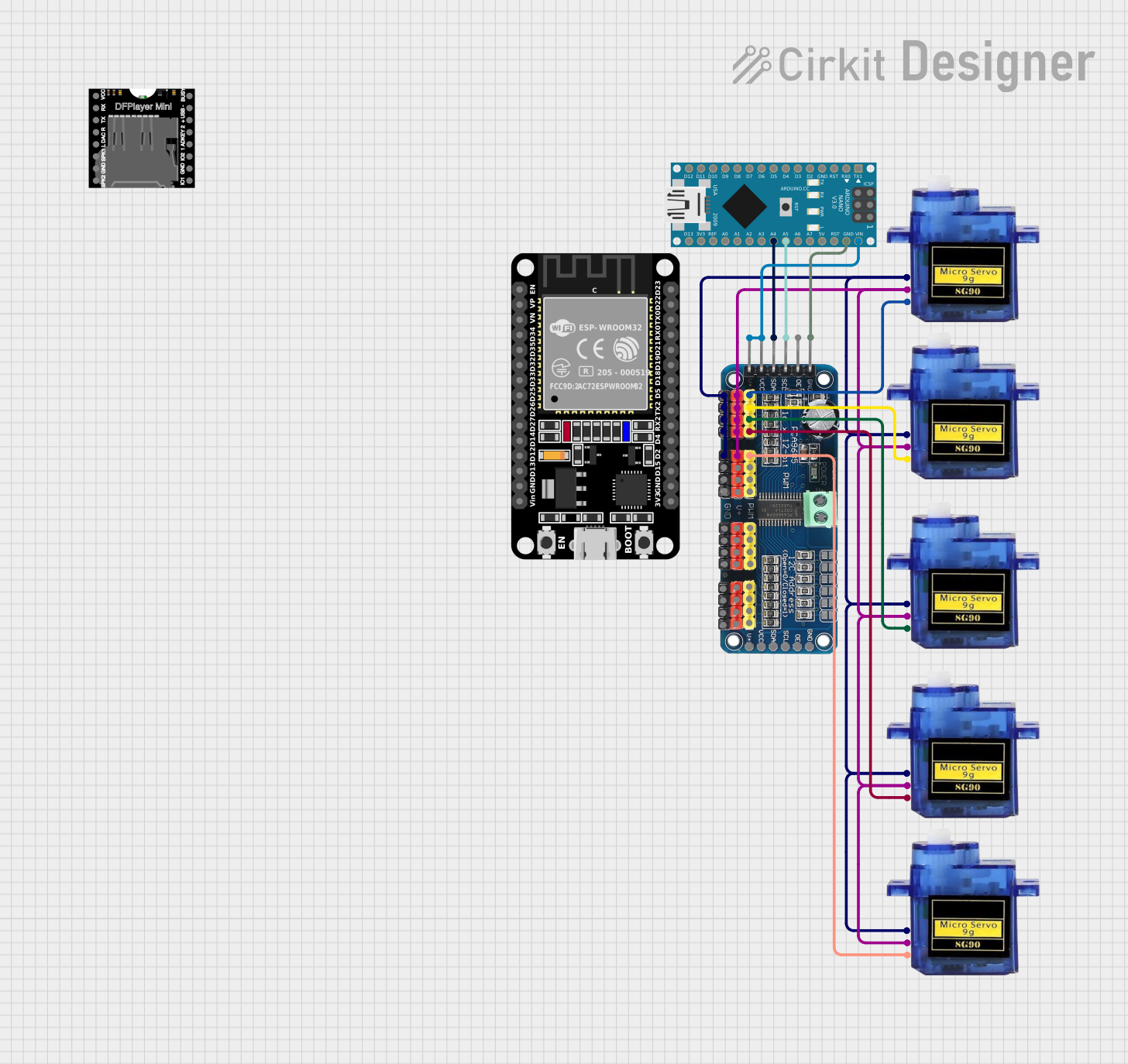

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

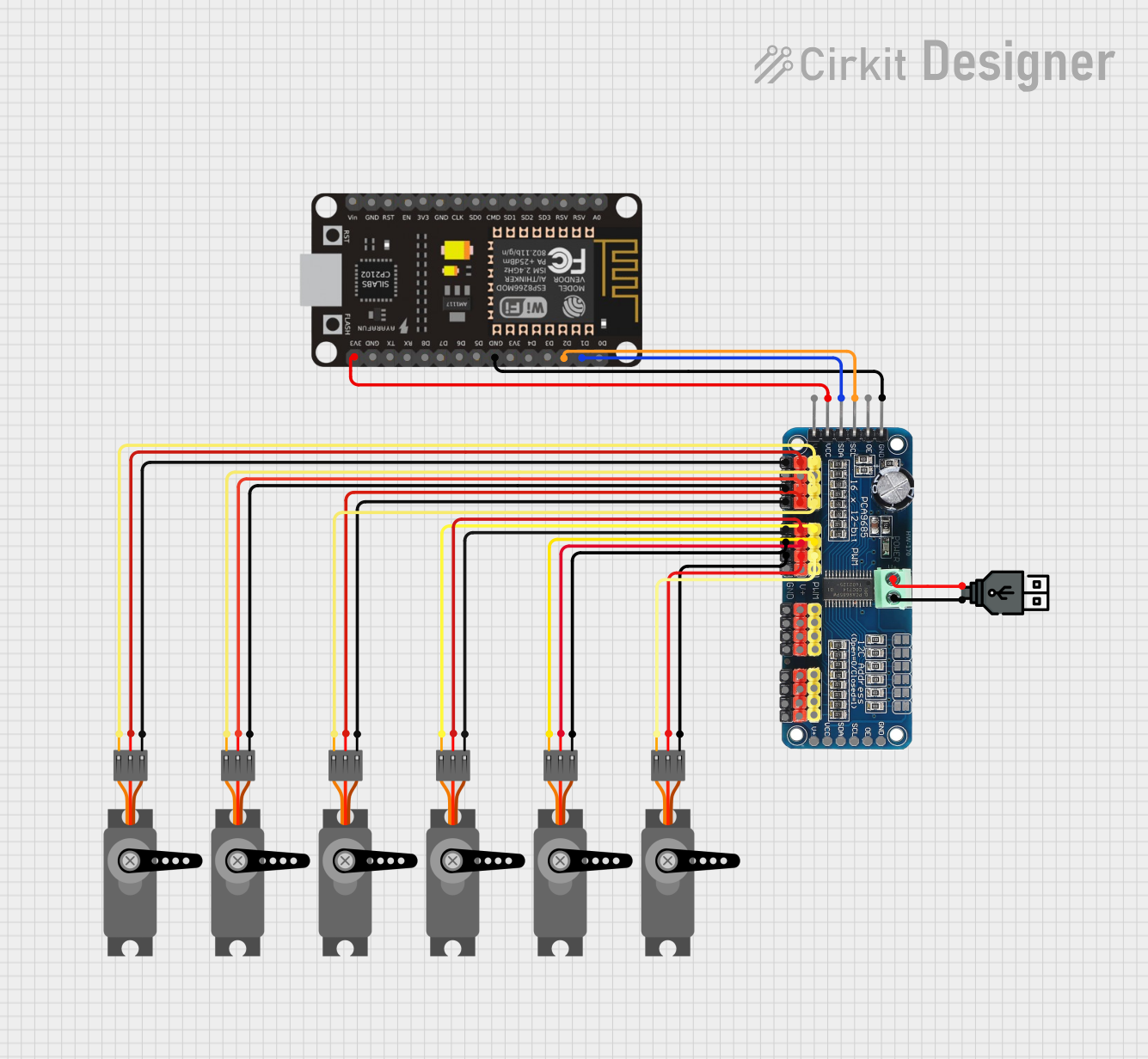

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 16-Channel PWM Servo Driver

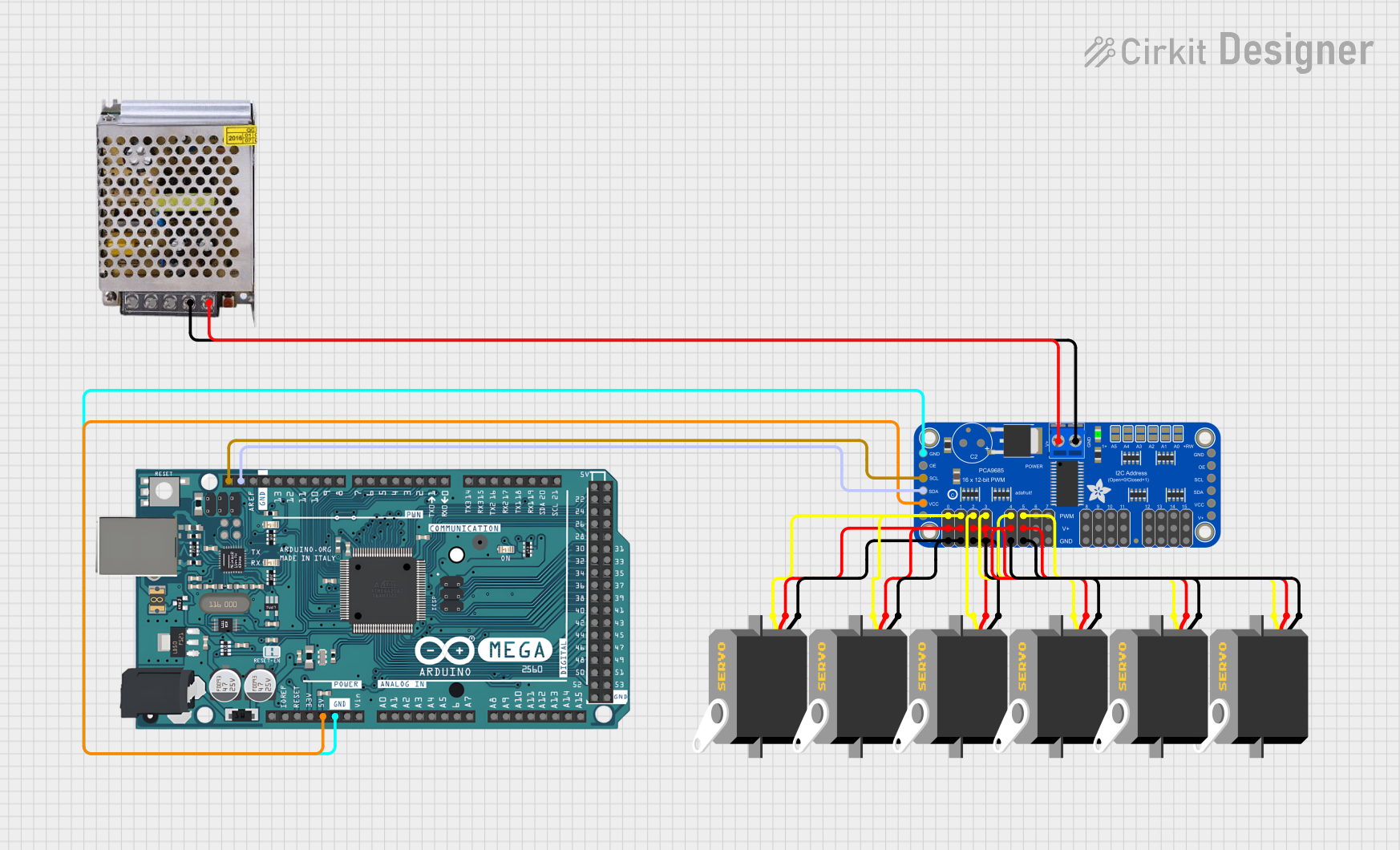

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

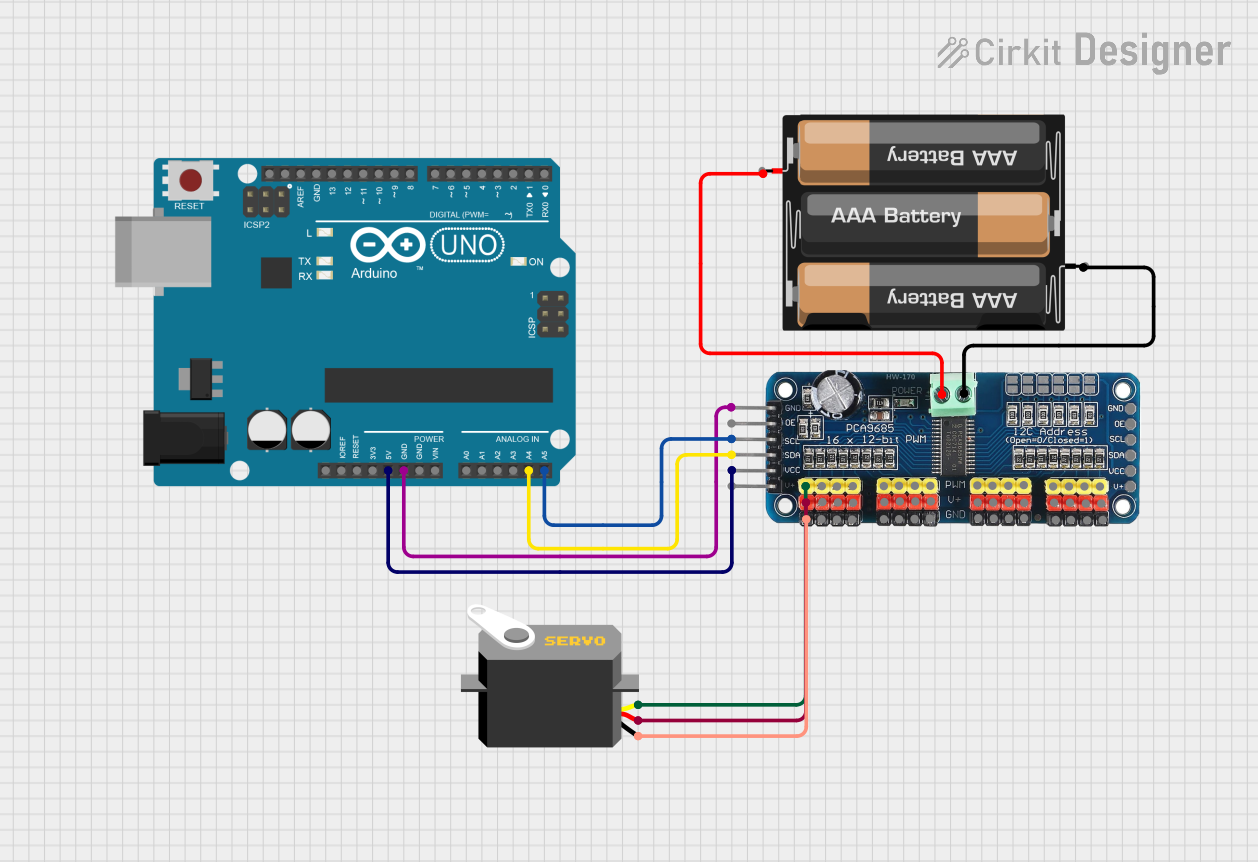

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics arms and legs

- Animatronic figures

- Automated machinery

- Multi-servo projects like hexapods

- Remote-controlled vehicles with multiple control surfaces

Technical Specifications

Key Technical Details

- Voltage: 5-6V (logic), 5-6V (servo power)

- Current: 990mA max (without servos)

- Power Ratings: 6A max (with servos, depends on the servo specifications)

- Resolution: 12-bit, 4096 steps

- Frequency: 40-1000Hz adjustable PWM frequency

- Communication: I2C interface

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | GND | Ground |

| 2 | VCC | Logic power supply (5-6V) |

| 3 | SDA | I2C data line |

| 4 | SCL | I2C clock line |

| 5-20 | Servo Channels (1-16) | PWM output to servos |

| 21 | OE | Output enable (active low) |

| 22 | OUTNE | Output not enable (active high) |

| 23 | SERVO V+ | Servo power supply (5-6V) |

| 24 | I2C ADDR Pins (A0, A1, A2, A3, A4) | I2C address selection pins |

Usage Instructions

How to Use the Component in a Circuit

Power Connections:

- Connect the logic power supply (5-6V) to the VCC and GND pins.

- Connect the servo power supply (5-6V) to the SERVO V+ and GND pins.

I2C Connections:

- Connect the SDA and SCL pins to the corresponding I2C data and clock lines on your microcontroller.

Servo Connections:

- Connect your servo motors to the Servo Channels (1-16) with the correct polarity.

Address Selection:

- Set the I2C address using the ADDR pins if you need to use multiple drivers on the same I2C bus.

Important Considerations and Best Practices

- Ensure that the power supply can handle the current draw of all connected servos.

- Use a separate power supply for the servos if the current draw is high to prevent voltage drops.

- Always connect the grounds of the logic and servo power supplies.

- Avoid long wires to reduce I2C communication errors.

- Use pull-up resistors on the I2C lines if necessary.

Troubleshooting and FAQs

Common Issues Users Might Face

- Servos not responding: Check power supplies, I2C connections, and ensure the correct I2C address is used.

- Jittery servo movement: Ensure a stable power supply and check for signal interference.

- Overheating: Check if the current draw exceeds the power supply capacity.

Solutions and Tips for Troubleshooting

- Verify all connections and ensure proper polarity.

- Use a multimeter to check for correct voltages.

- If using an Arduino, use the

Wirelibrary to scan for the correct I2C address. - Reduce the PWM frequency if servos are not rated for high frequencies.

Example Code for Arduino UNO

#include <Wire.h>

#include <Adafruit_PWMServoDriver.h>

// Initialize the PWM driver

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

void setup() {

Serial.begin(9600);

Serial.println("16-channel PWM Servo Driver test!");

pwm.begin();

pwm.setPWMFreq(60); // Set frequency to 60 Hz

}

void loop() {

// Sweep servo on channel 0 from min to max position

for (uint16_t pulselen = SERVOMIN; pulselen < SERVOMAX; pulselen++) {

pwm.setPWM(0, 0, pulselen);

}

delay(500);

for (uint16_t pulselen = SERVOMAX; pulselen > SERVOMIN; pulselen--) {

pwm.setPWM(0, 0, pulselen);

}

delay(500);

}

Note: The Adafruit_PWMServoDriver library must be installed in the Arduino IDE. The SERVOMIN and SERVOMAX constants should be defined according to your servo's specifications.

This documentation provides a comprehensive guide to using the 16-Channel PWM Servo Driver. For further assistance, consult the manufacturer's datasheet or contact technical support.