How to Use peristaltic pumpe: Examples, Pinouts, and Specs

Design with peristaltic pumpe in Cirkit Designer

Design with peristaltic pumpe in Cirkit DesignerIntroduction

A peristaltic pump is a type of positive displacement pump used for pumping a variety of fluids. The fluid is contained within a flexible tube fitted inside a circular pump casing. A rotor with a number of "rollers" or "wipers" compresses the flexible tube. As the rotor turns, the part of the tube under compression closes (or "occludes"), thus forcing the fluid to be pumped to move through the tube. Additionally, as the tube opens to its natural state after the passing of the cam ("restitution" or "resilience"), fluid flow is induced to the pump. This process is called peristalsis and is used in many biological systems such as the gastrointestinal tract.

Explore Projects Built with peristaltic pumpe

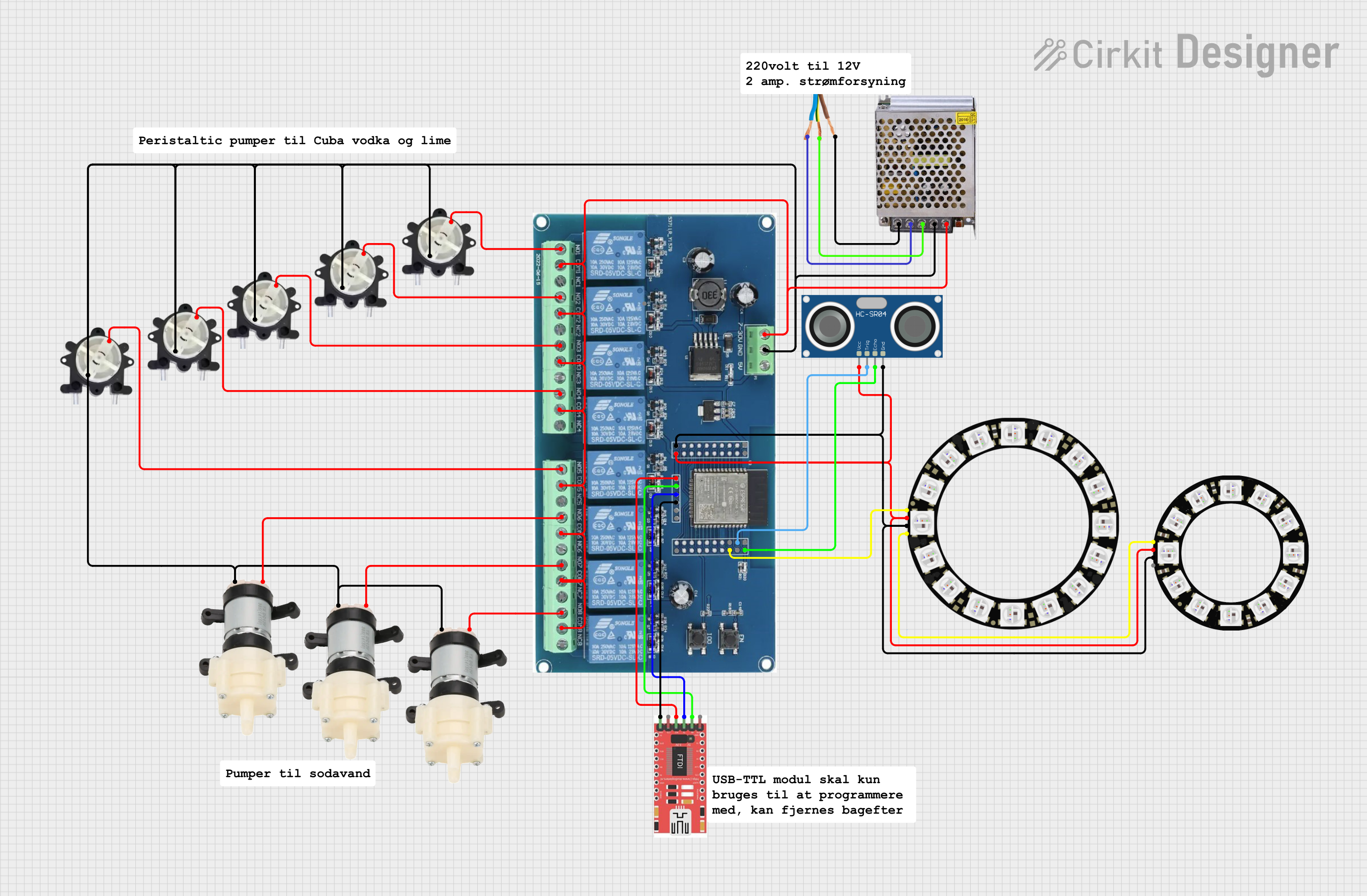

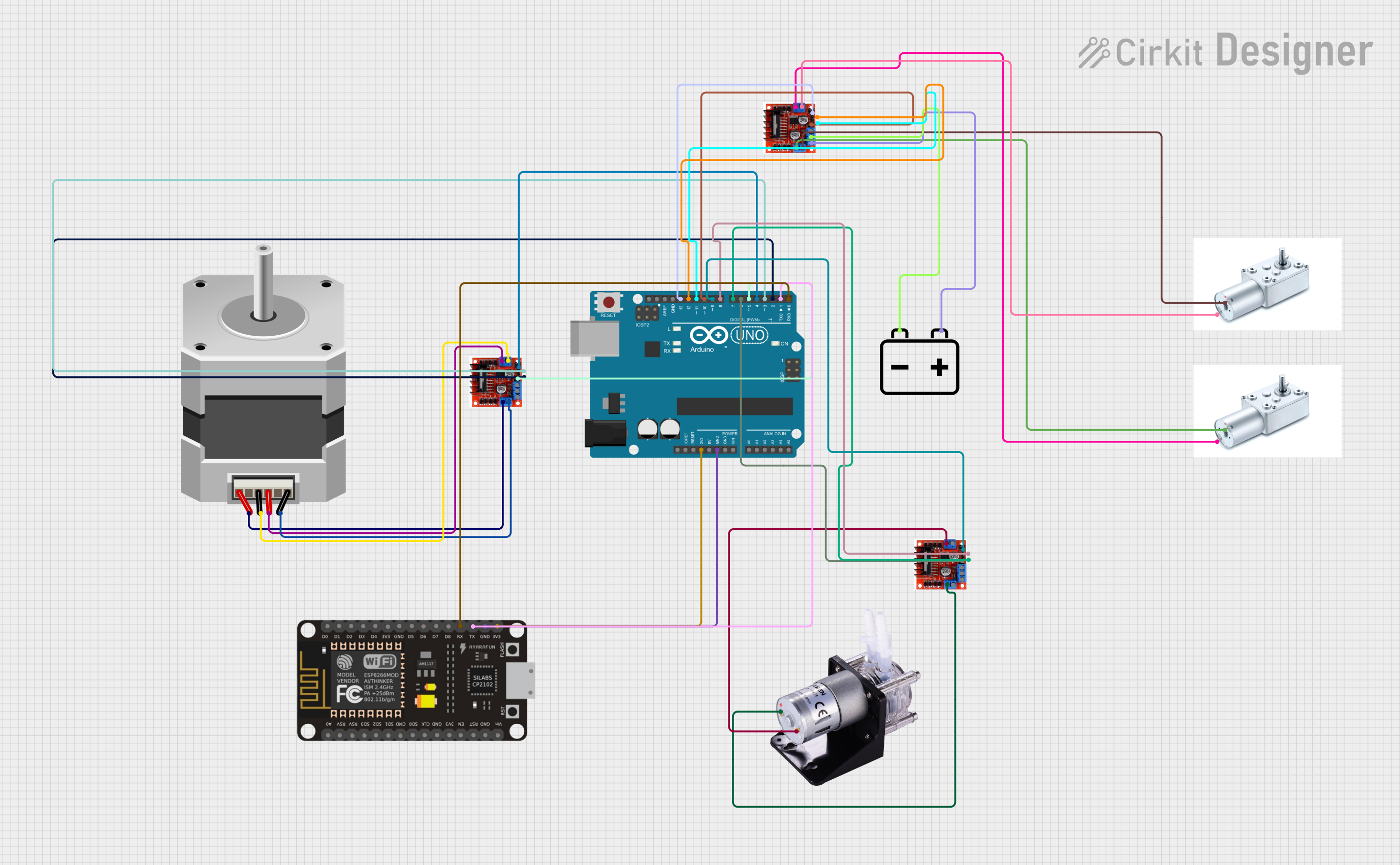

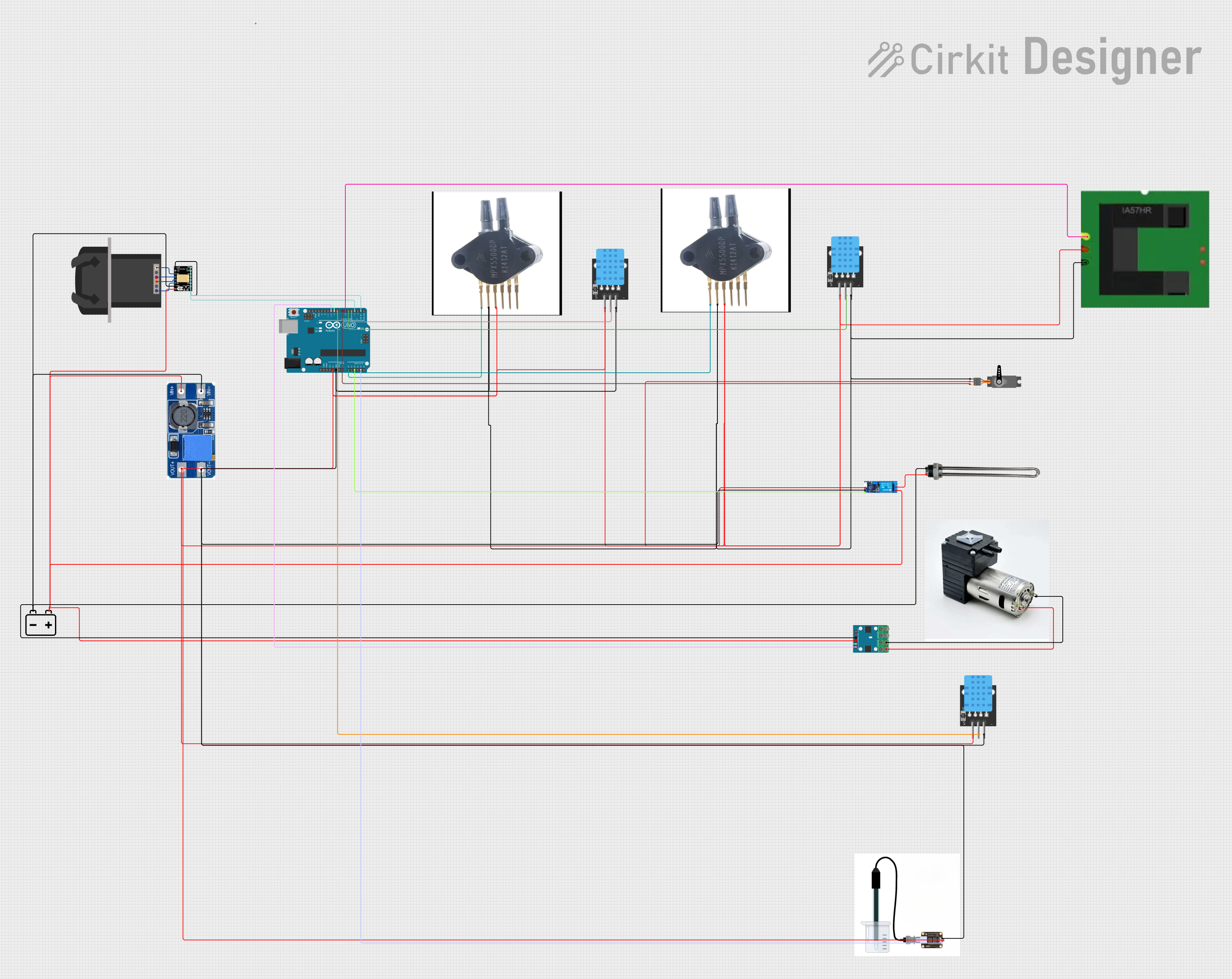

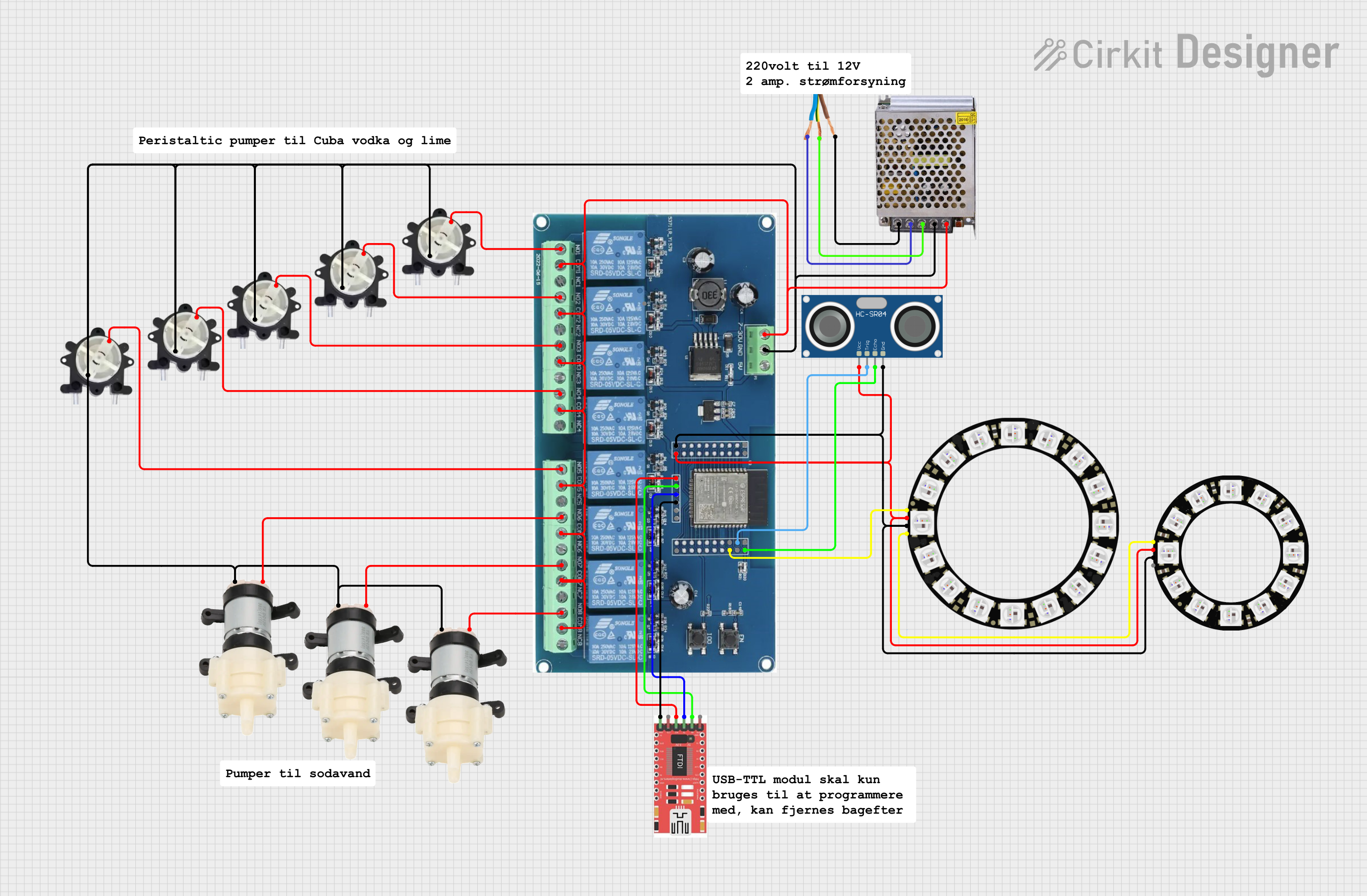

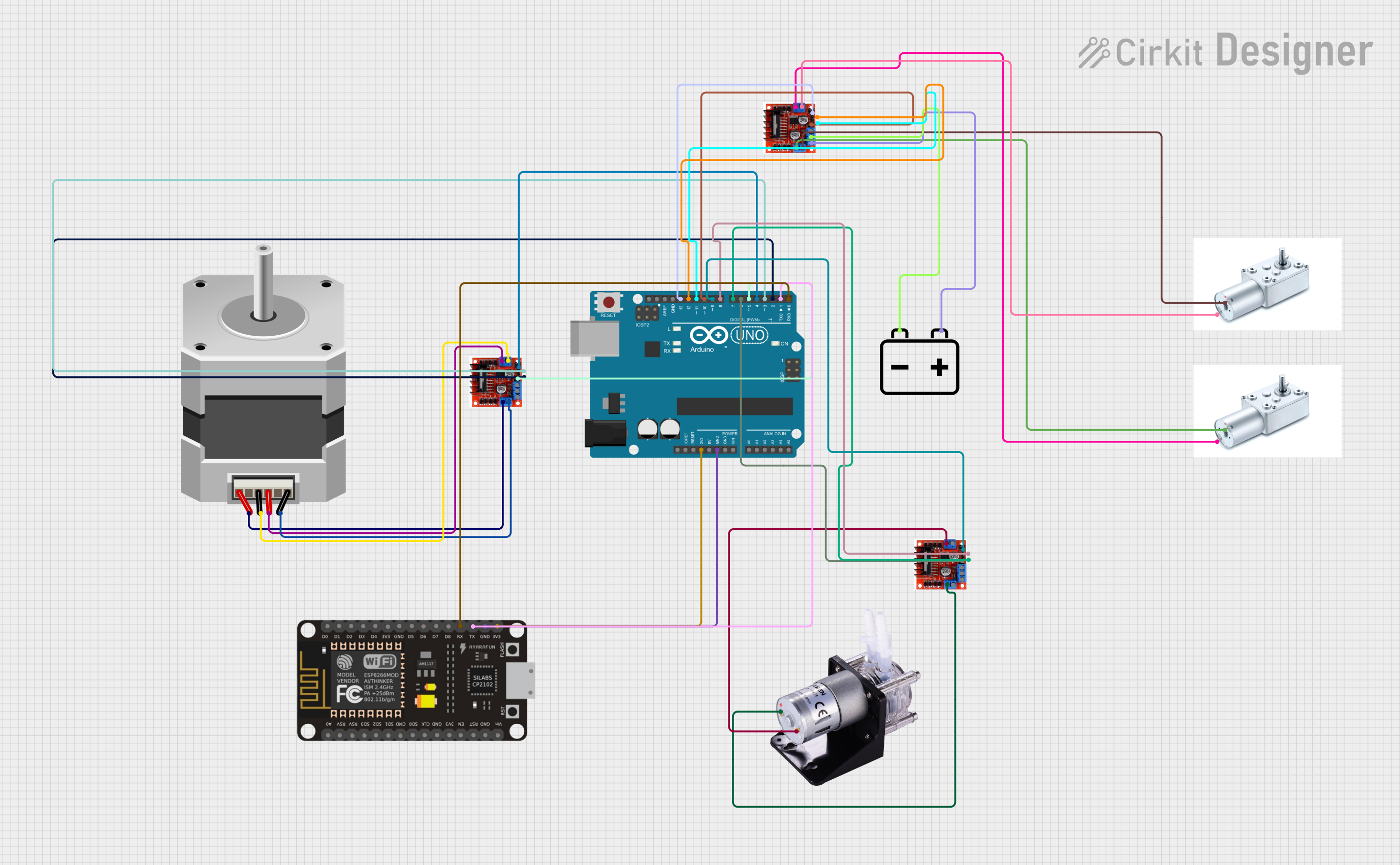

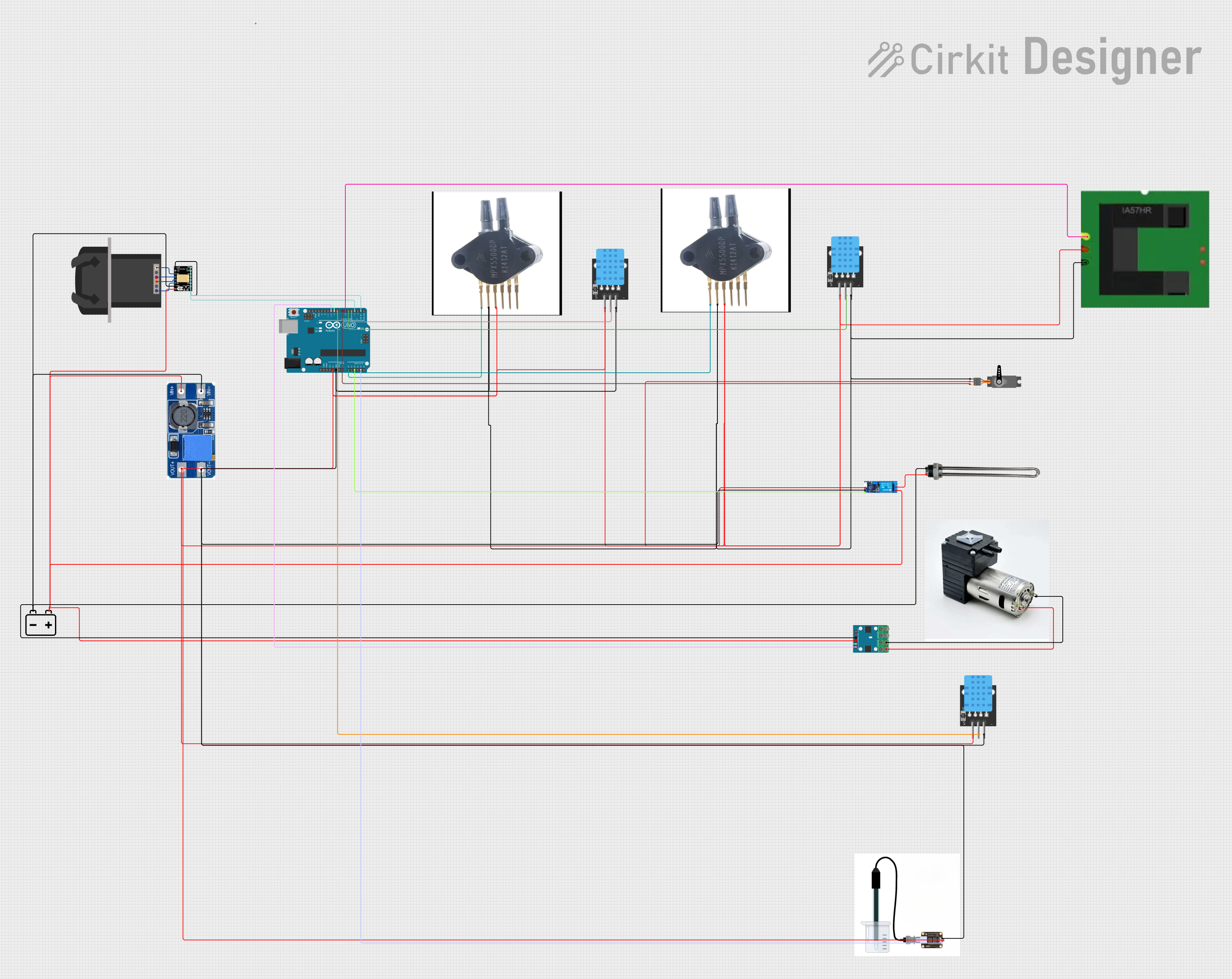

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with peristaltic pumpe

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Medical Devices: Used for precise fluid delivery in medical applications.

- Laboratory Equipment: Ideal for transferring chemicals and biological fluids.

- Food and Beverage Industry: Used for handling food-grade liquids.

- Aquariums: Commonly used for dosing chemicals and nutrients.

- Industrial Applications: Suitable for pumping abrasive, corrosive, or viscous fluids.

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Voltage | 12V DC |

| Current | 0.5A |

| Flow Rate | 100 mL/min |

| Tube Material | Silicone |

| Tube Inner Diameter | 2 mm |

| Tube Outer Diameter | 4 mm |

| Maximum Pressure | 2 bar |

| Operating Temperature Range | 0°C to 40°C |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply (12V DC) |

| 2 | GND | Ground |

| 3 | IN1 | Control signal input 1 |

| 4 | IN2 | Control signal input 2 |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the VCC pin to a 12V DC power supply and the GND pin to the ground.

- Control Signals: Use IN1 and IN2 to control the direction of the pump. These pins can be connected to a microcontroller like an Arduino UNO.

Example Circuit Diagram

Arduino UNO Peristaltic Pump

5V ----------------> VCC

GND ----------------> GND

D2 ----------------> IN1

D3 ----------------> IN2

Example Arduino Code

// Define the control pins for the peristaltic pump

const int IN1 = 2;

const int IN2 = 3;

void setup() {

// Initialize the control pins as outputs

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

}

void loop() {

// Rotate the pump in one direction

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

delay(5000); // Run for 5 seconds

// Stop the pump

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

delay(2000); // Pause for 2 seconds

// Rotate the pump in the opposite direction

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

delay(5000); // Run for 5 seconds

// Stop the pump

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

delay(2000); // Pause for 2 seconds

}

Important Considerations and Best Practices

- Power Supply: Ensure that the power supply voltage matches the pump's rated voltage (12V DC).

- Tube Material: Use the recommended tube material (silicone) to avoid chemical reactions and ensure longevity.

- Flow Rate: Adjust the control signals to manage the flow rate as needed.

- Maintenance: Regularly check and replace the tubing to prevent wear and tear.

Troubleshooting and FAQs

Common Issues Users Might Face

Pump Not Running:

- Solution: Check the power supply and ensure it is providing 12V DC. Verify the connections to the control pins.

Low Flow Rate:

- Solution: Ensure the tubing is not kinked or blocked. Check for any obstructions in the fluid path.

Pump Running in Wrong Direction:

- Solution: Verify the control signals (IN1 and IN2) are correctly set for the desired direction.

Excessive Noise:

- Solution: Ensure the pump is securely mounted and the tubing is properly installed. Check for any loose components.

FAQs

Q: Can I use a different tube material? A: It is recommended to use silicone tubing as specified. Other materials may not be compatible and could degrade quickly.

Q: How do I adjust the flow rate? A: The flow rate can be adjusted by changing the speed of the control signals. Use PWM (Pulse Width Modulation) to fine-tune the speed.

Q: Is the pump suitable for high-viscosity fluids? A: Yes, peristaltic pumps are suitable for high-viscosity fluids, but the flow rate may be lower.

Q: Can I run the pump continuously? A: While the pump can run continuously, it is advisable to allow periodic rest to prevent overheating and extend the pump's lifespan.

This documentation provides a comprehensive guide to understanding, using, and troubleshooting a peristaltic pump. Whether you are a beginner or an experienced user, following these guidelines will help you achieve optimal performance and longevity from your peristaltic pump.