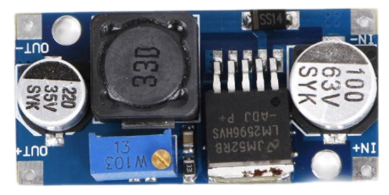

How to Use STEP DOWN : Examples, Pinouts, and Specs

Design with STEP DOWN in Cirkit Designer

Design with STEP DOWN in Cirkit DesignerIntroduction

The STEP DOWN converter, manufactured by DEWA with part ID audi variasi, is a DC-DC buck converter designed to reduce voltage from a higher level to a lower level while increasing current. This component is widely used in power management systems to efficiently step down voltage for various electronic devices and circuits.

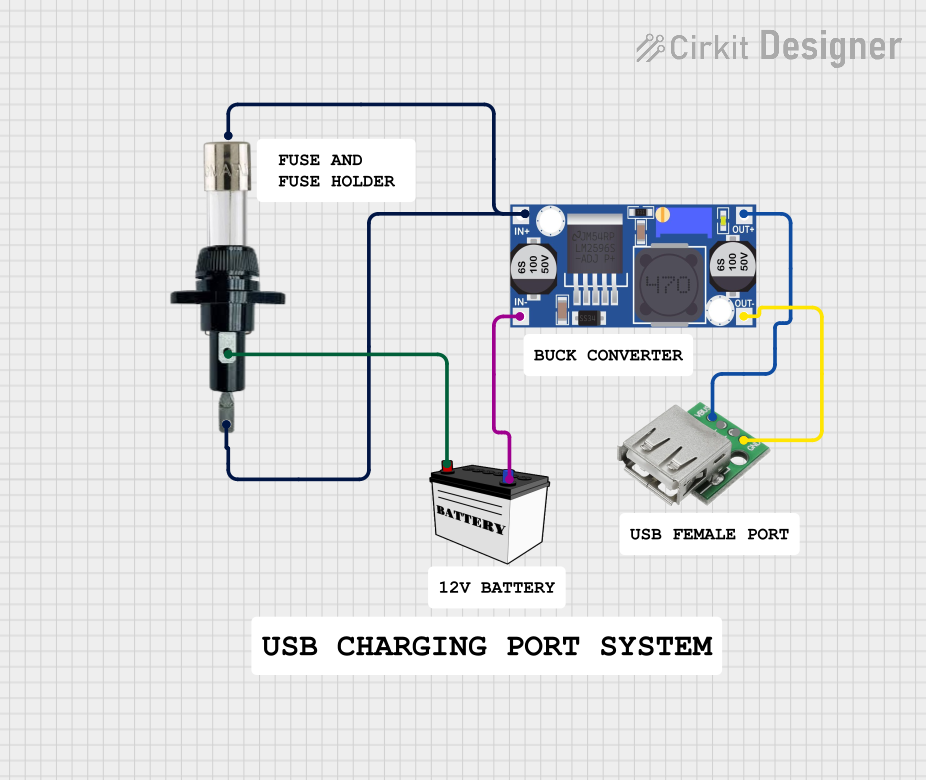

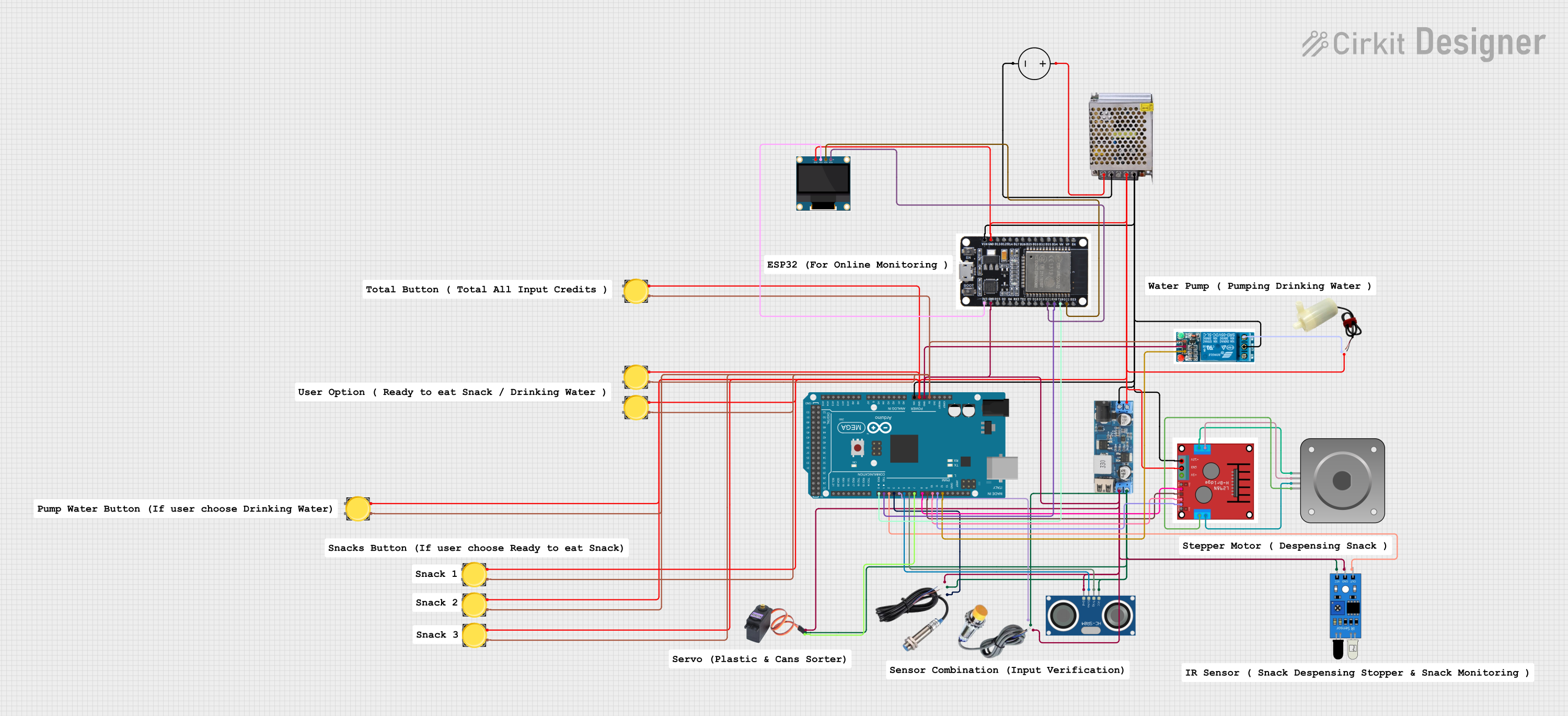

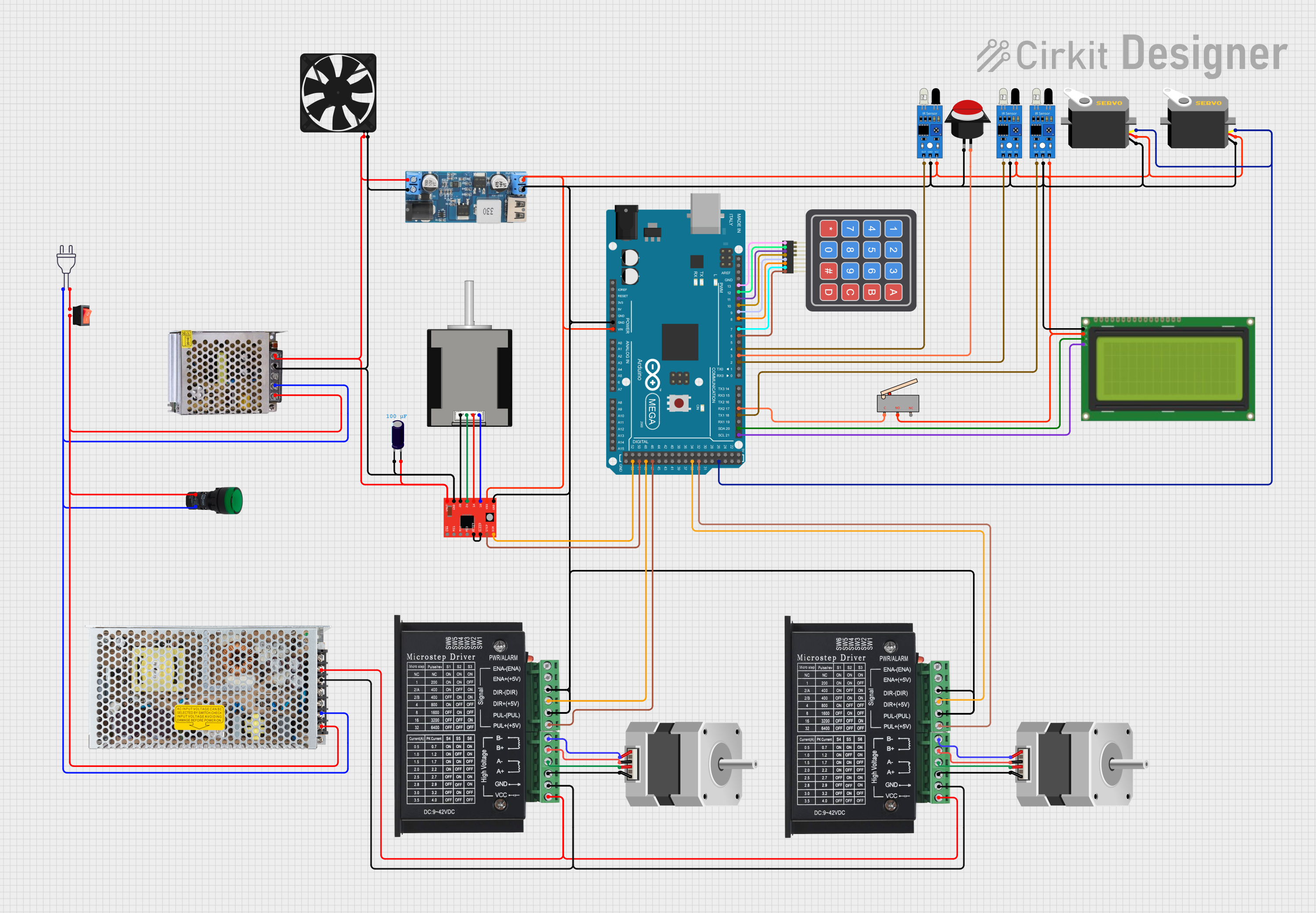

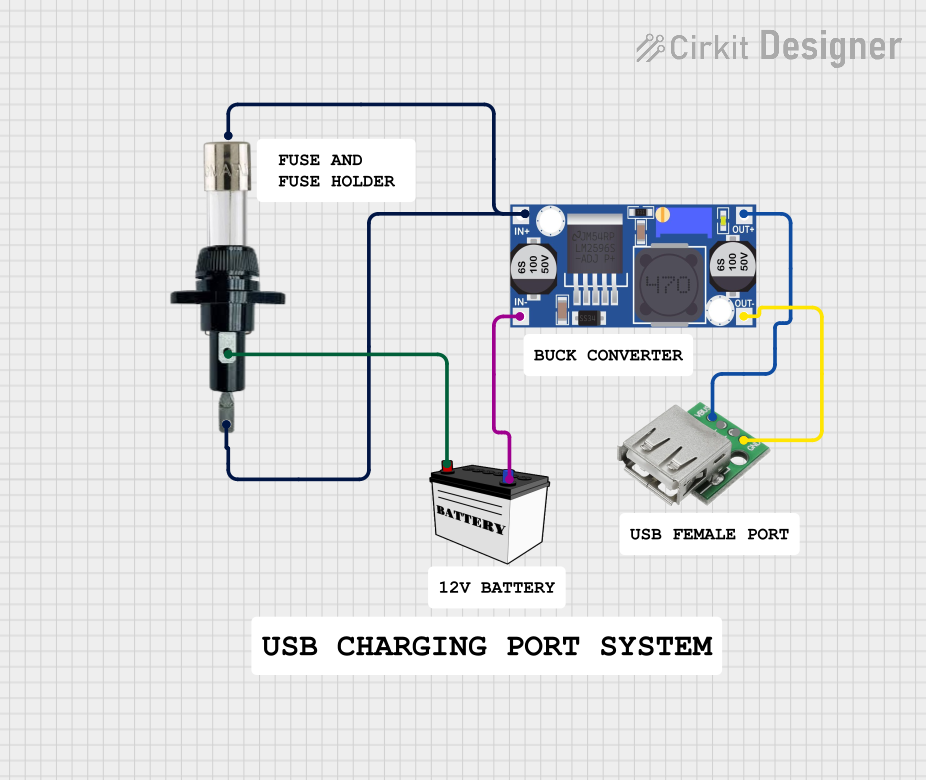

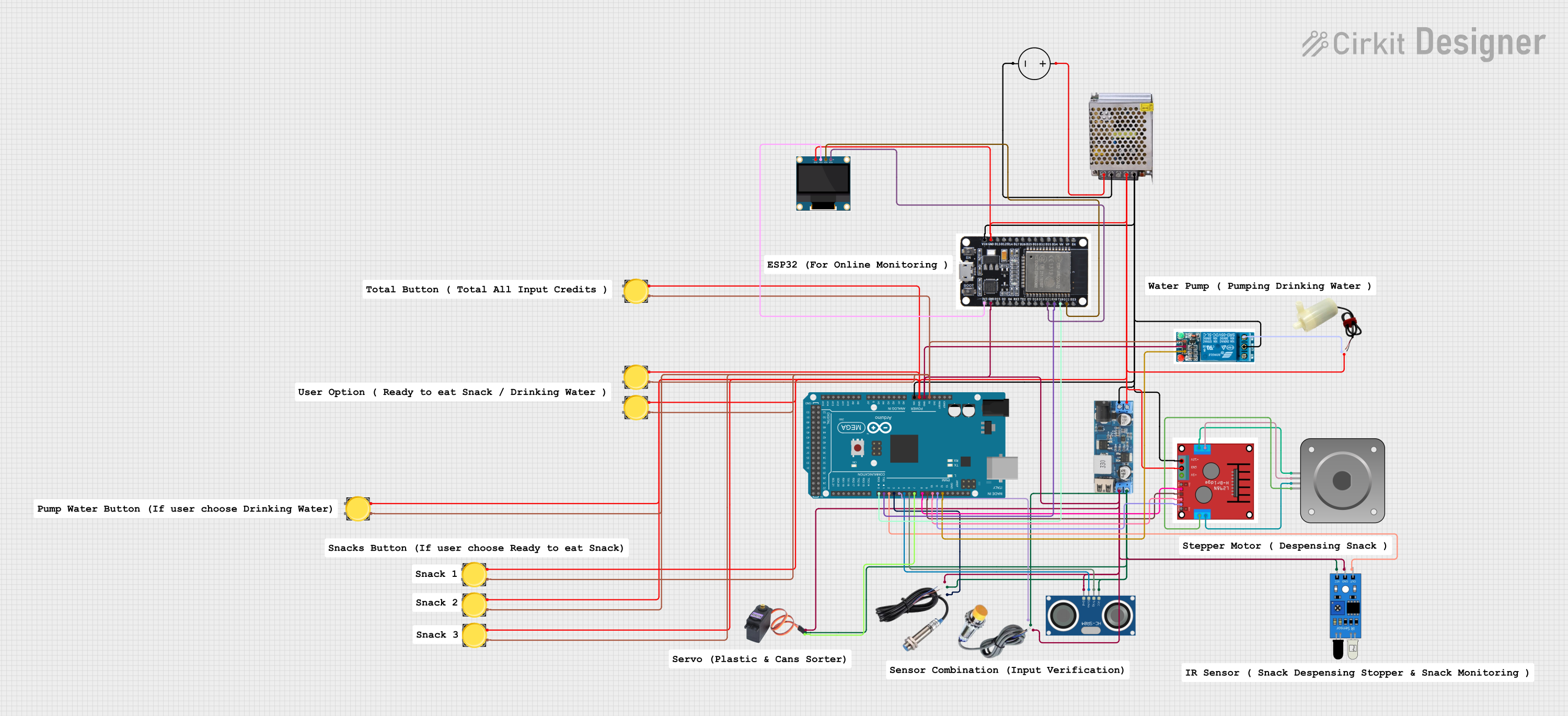

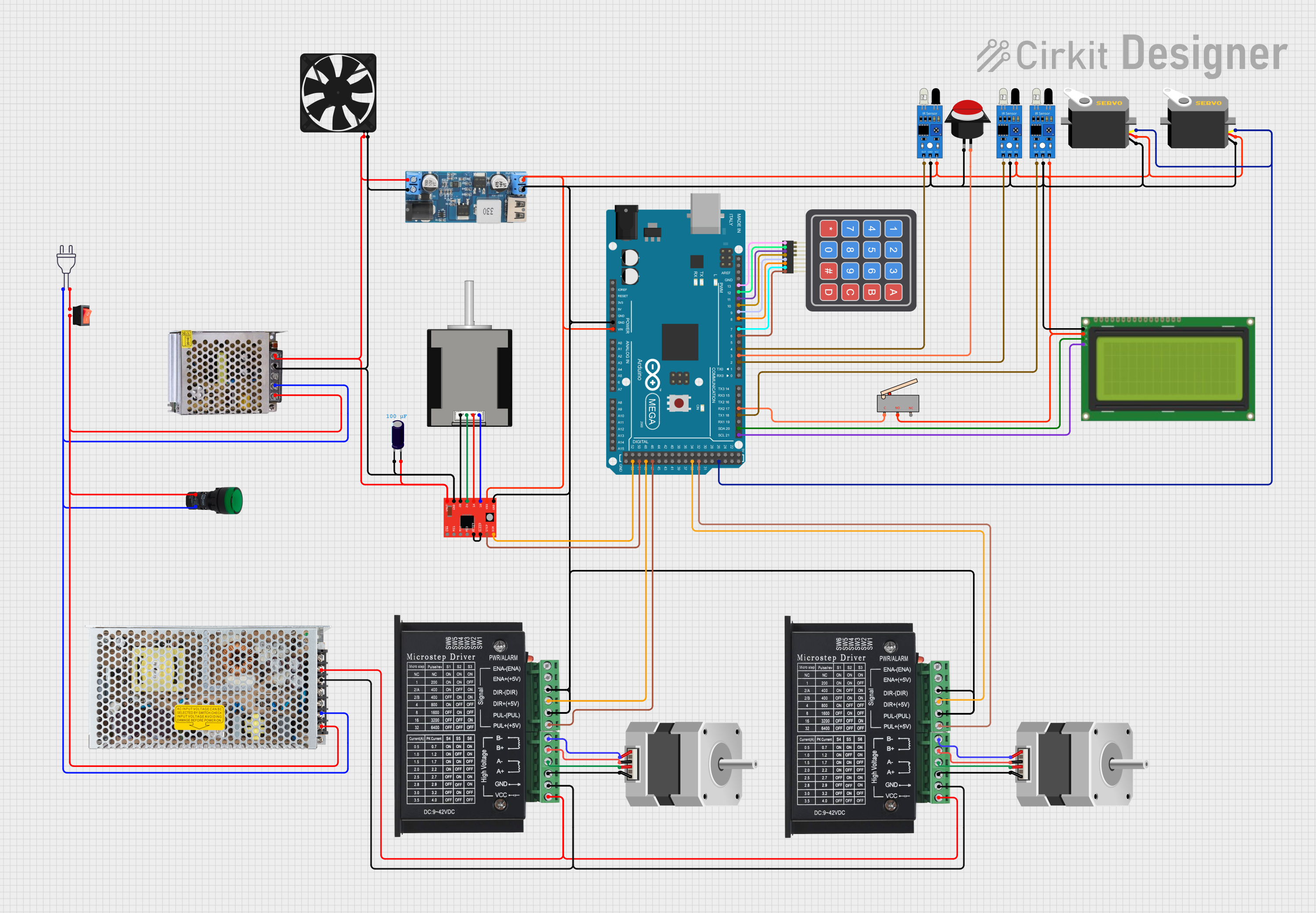

Explore Projects Built with STEP DOWN

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with STEP DOWN

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Powering low-voltage devices from a higher-voltage source (e.g., 12V to 5V conversion)

- Battery-powered systems to regulate voltage levels

- Embedded systems and microcontroller-based projects

- LED drivers and portable electronics

- Renewable energy systems, such as solar power setups

Technical Specifications

The following table outlines the key technical details of the STEP DOWN converter:

| Parameter | Value |

|---|---|

| Input Voltage Range | 6V to 40V |

| Output Voltage Range | 1.25V to 35V |

| Maximum Output Current | 3A (with proper heat dissipation) |

| Efficiency | Up to 92% |

| Switching Frequency | 150 kHz |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 43mm x 21mm x 14mm |

Pin Configuration and Descriptions

The STEP DOWN converter typically has the following pin configuration:

| Pin Name | Description |

|---|---|

| VIN | Input voltage pin. Connect the higher voltage source here (e.g., 12V or 24V). |

| GND | Ground pin. Connect to the ground of the power source and the load. |

| VOUT | Output voltage pin. Provides the stepped-down voltage to the load. |

| ADJ (optional) | Adjustment pin. Used to set the output voltage using an external potentiometer. |

Usage Instructions

How to Use the Component in a Circuit

Connect the Input Voltage (VIN):

Attach the higher voltage source (e.g., a 12V battery) to the VIN pin. Ensure the input voltage is within the specified range (6V to 40V).Connect the Ground (GND):

Connect the GND pin to the ground of both the input power source and the load.Set the Output Voltage (VOUT):

- If the module has an adjustable output, use the onboard potentiometer or external resistor to set the desired output voltage.

- Measure the output voltage using a multimeter to ensure it matches the required level.

Connect the Load:

Attach the load (e.g., a microcontroller, LED, or motor) to the VOUT pin. Ensure the load does not exceed the maximum current rating of 3A.Test the Circuit:

Power on the input source and verify the output voltage and current using a multimeter.

Important Considerations and Best Practices

Heat Dissipation:

For high-current applications, ensure proper heat dissipation by attaching a heatsink or using active cooling (e.g., a fan).Input Voltage Range:

Always ensure the input voltage is within the specified range (6V to 40V). Exceeding this range may damage the component.Output Voltage Adjustment:

When adjusting the output voltage, turn the potentiometer slowly and measure the voltage frequently to avoid overshooting the desired value.Capacitor Placement:

Place input and output capacitors close to the module to reduce voltage ripple and improve stability.

Example: Using the STEP DOWN with an Arduino UNO

The STEP DOWN converter can be used to power an Arduino UNO from a 12V source by stepping down the voltage to 5V. Below is an example circuit and Arduino code:

Circuit Connections

- Connect the 12V source to the VIN pin of the STEP DOWN converter.

- Connect the GND pin of the STEP DOWN to the ground of the 12V source and the Arduino UNO.

- Set the output voltage of the STEP DOWN to 5V using the potentiometer.

- Connect the VOUT pin of the STEP DOWN to the 5V pin of the Arduino UNO.

Arduino Code Example

// Example code to blink an LED using Arduino UNO powered by the STEP DOWN converter

const int ledPin = 13; // Pin connected to the onboard LED

void setup() {

pinMode(ledPin, OUTPUT); // Set the LED pin as an output

}

void loop() {

digitalWrite(ledPin, HIGH); // Turn the LED on

delay(1000); // Wait for 1 second

digitalWrite(ledPin, LOW); // Turn the LED off

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Cause: Input voltage is not connected or is below the minimum required level.

- Solution: Verify the input voltage is within the range of 6V to 40V.

Output Voltage is Incorrect:

- Cause: The potentiometer is not adjusted correctly.

- Solution: Slowly adjust the potentiometer while monitoring the output voltage with a multimeter.

Overheating:

- Cause: Excessive current draw or insufficient heat dissipation.

- Solution: Reduce the load current or attach a heatsink to the module.

Voltage Ripple or Noise:

- Cause: Insufficient input/output capacitors.

- Solution: Add low-ESR capacitors close to the input and output pins.

FAQs

Q: Can the STEP DOWN converter handle AC input?

A: No, the STEP DOWN converter is designed for DC input only. Use a rectifier circuit to convert AC to DC before connecting.Q: What happens if the input voltage exceeds 40V?

A: Exceeding the maximum input voltage may permanently damage the module. Always stay within the specified range.Q: Can I use the STEP DOWN converter to charge a battery?

A: Yes, but ensure the output voltage and current are set according to the battery's charging specifications.Q: How do I calculate the efficiency of the converter?

A: Efficiency (%) = (Output Power / Input Power) × 100. Measure the input and output voltage and current to calculate power.

This concludes the documentation for the STEP DOWN converter by DEWA.