How to Use Emergency STOP: Examples, Pinouts, and Specs

Design with Emergency STOP in Cirkit Designer

Design with Emergency STOP in Cirkit DesignerIntroduction

The Emergency STOP (E-STOP) is a safety device designed to immediately halt the operation of machinery or equipment in case of an emergency. It ensures a quick response to prevent accidents, protect personnel, and safeguard equipment. E-STOPs are commonly used in industrial environments, manufacturing plants, and any application where machinery poses a potential safety risk.

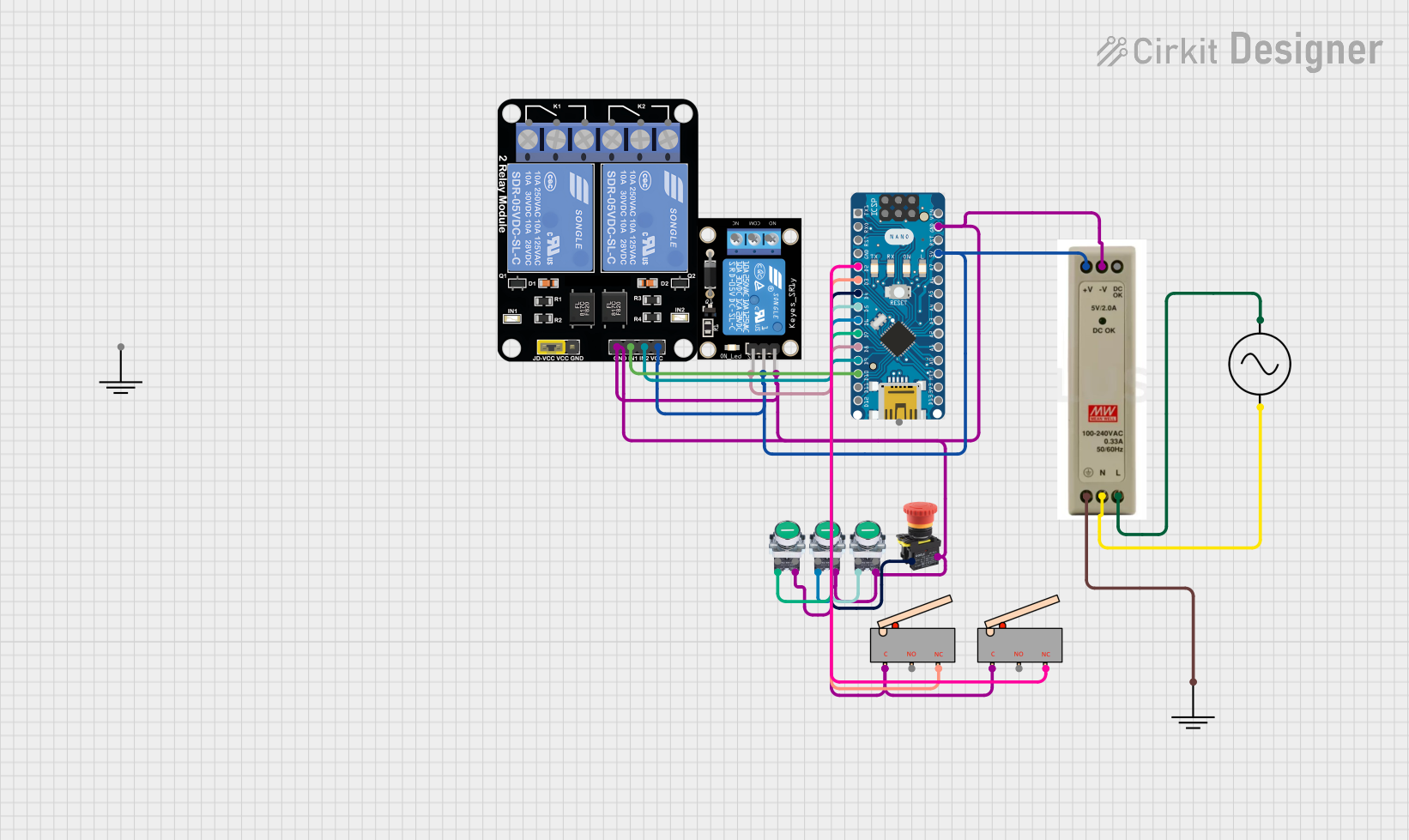

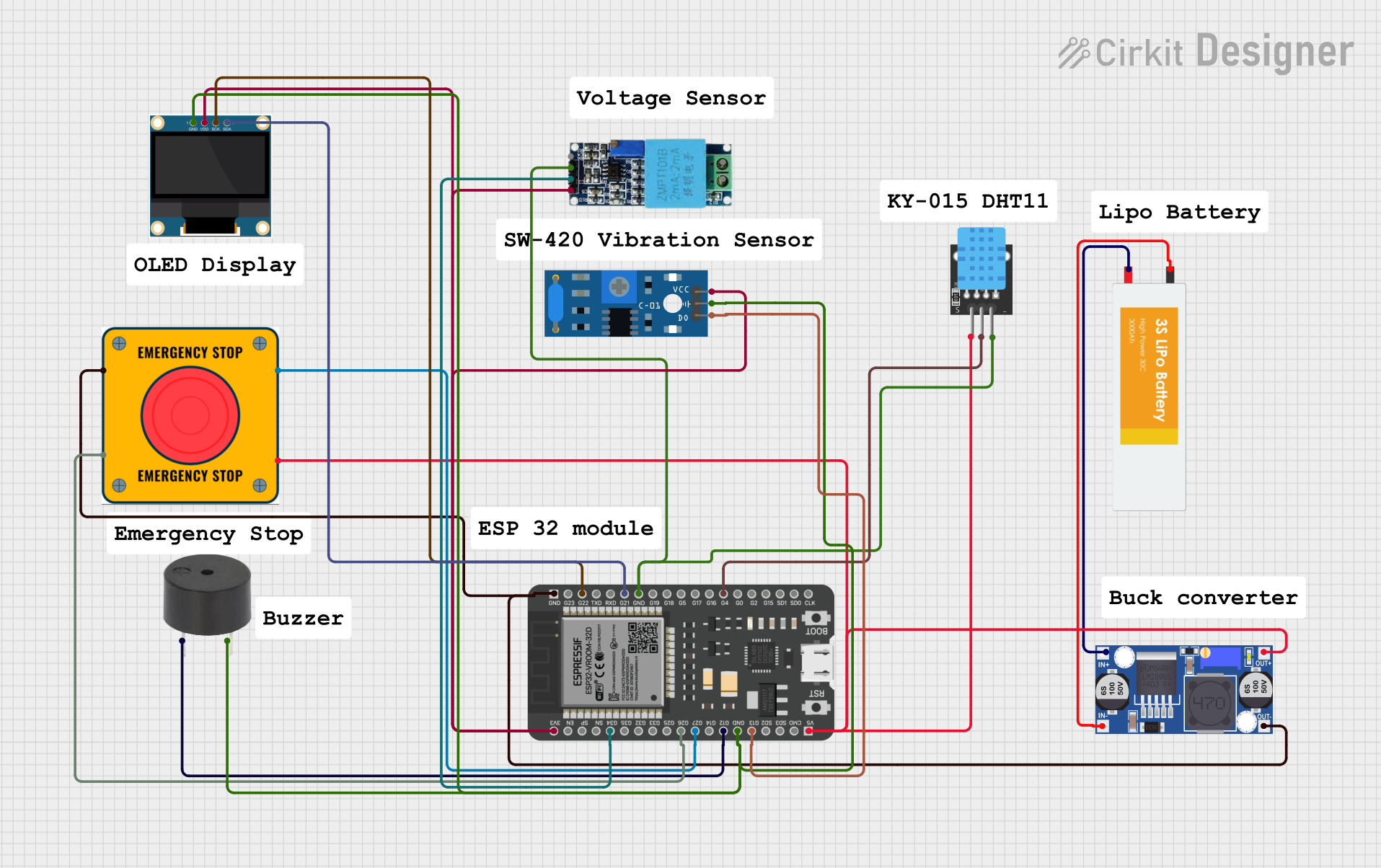

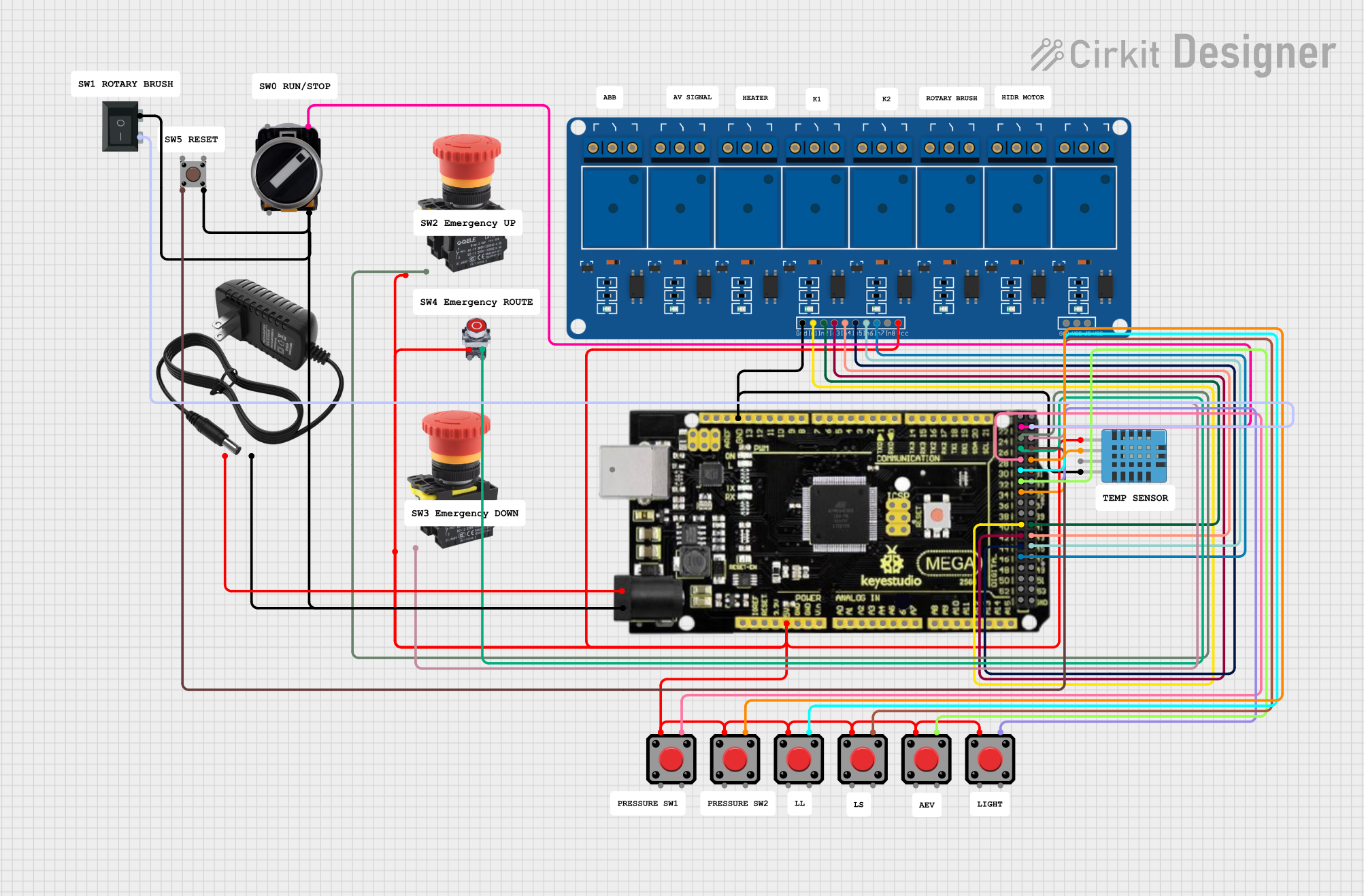

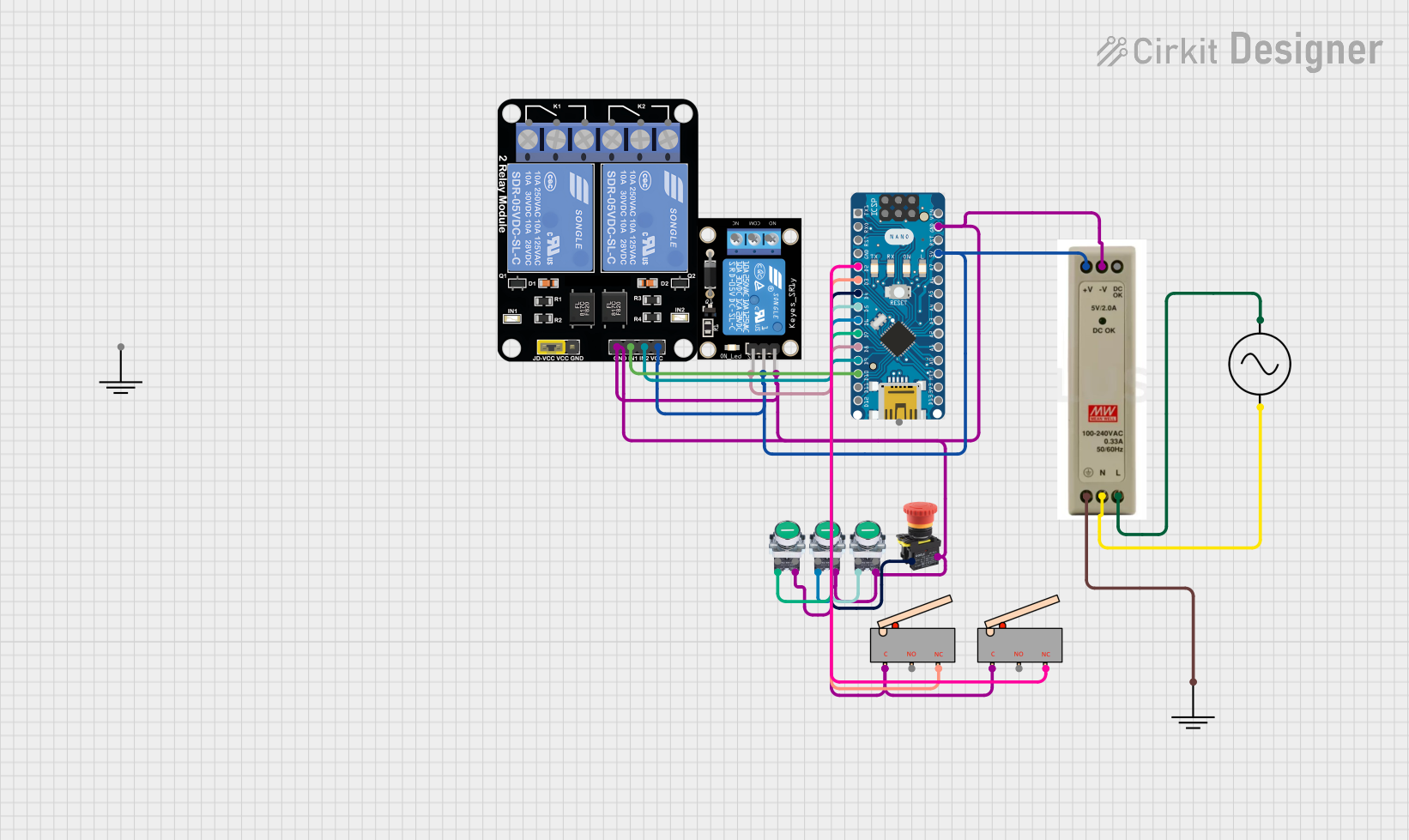

Explore Projects Built with Emergency STOP

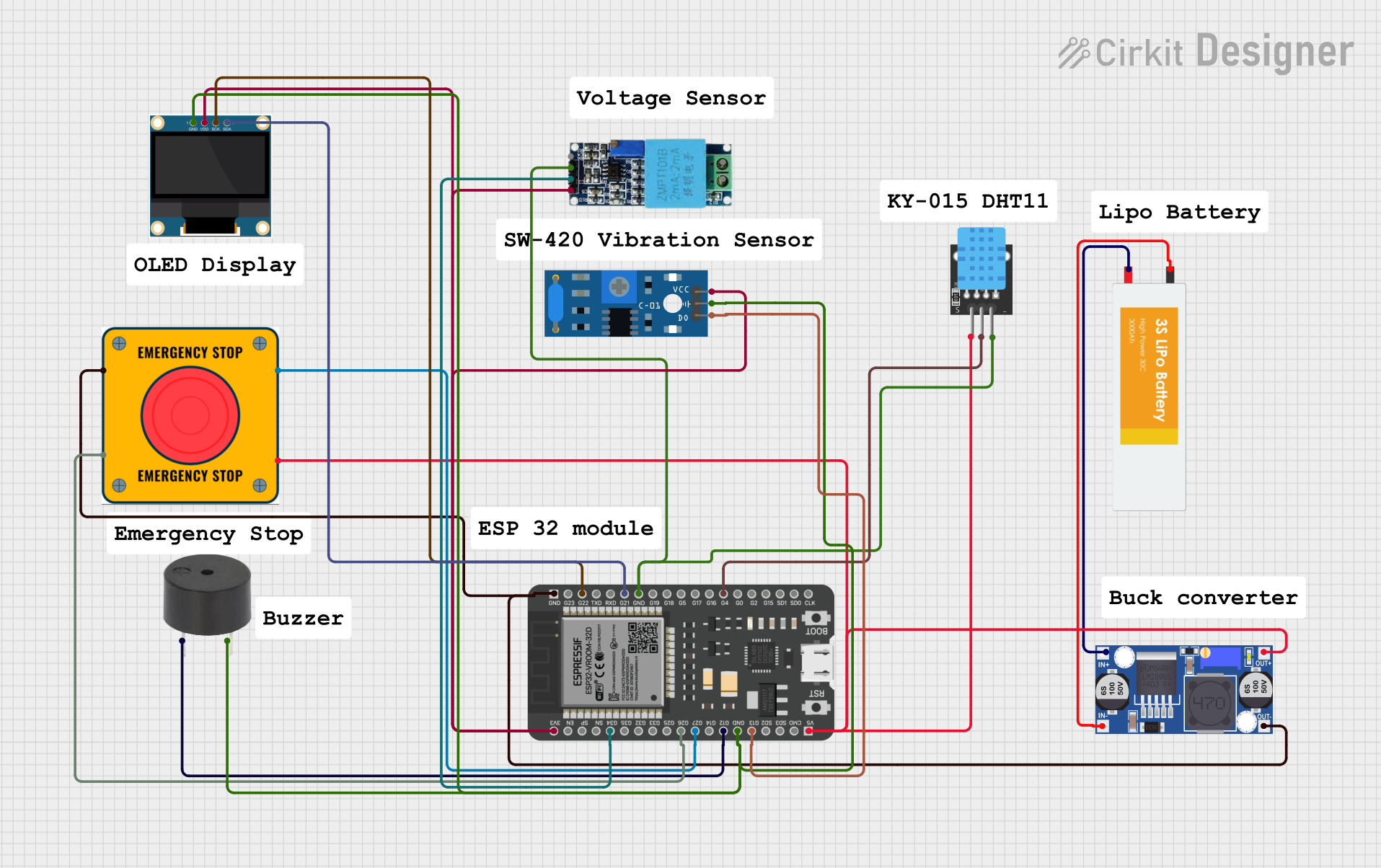

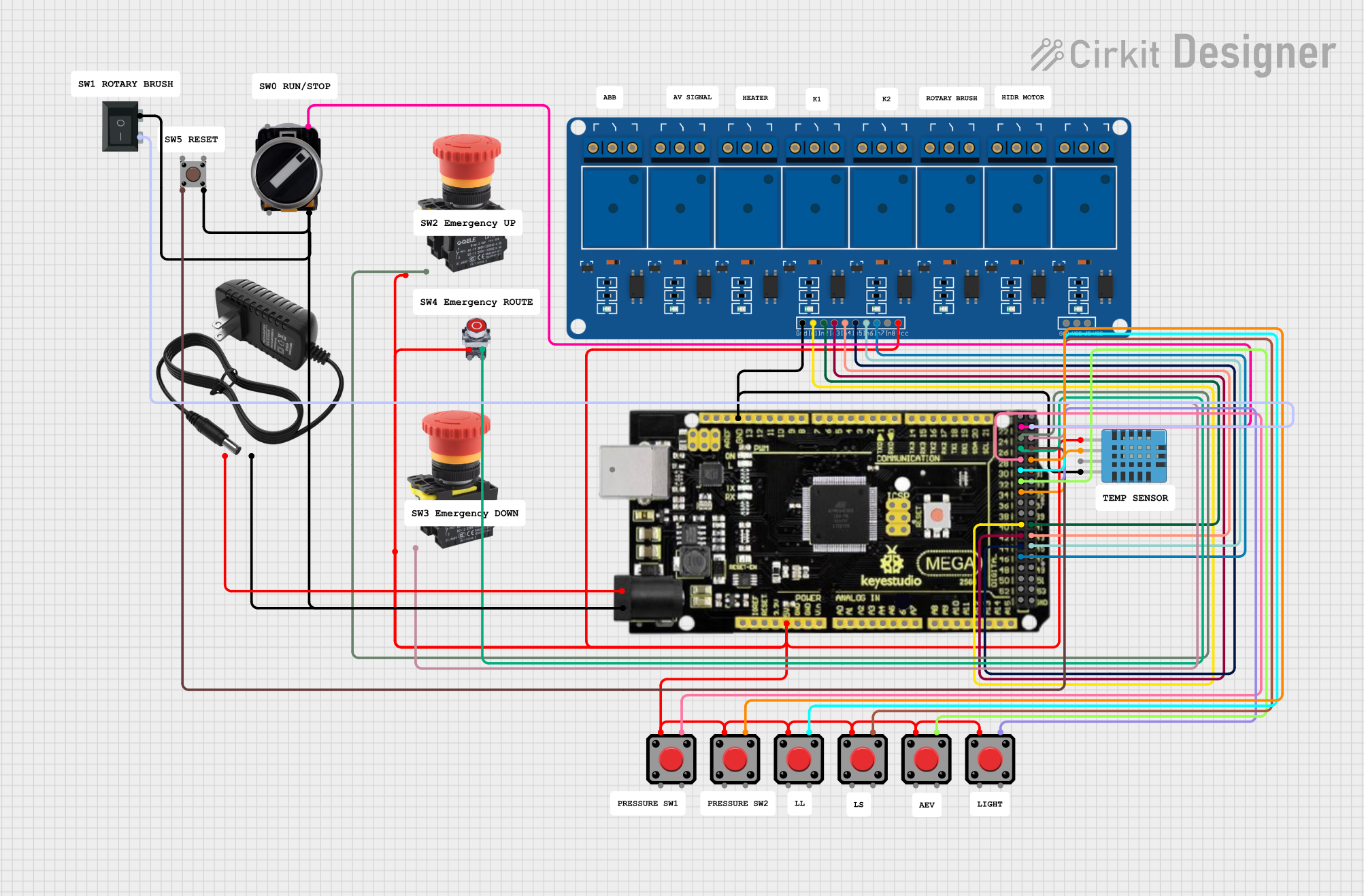

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Emergency STOP

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial machinery and conveyor systems

- Robotics and automated systems

- CNC machines and heavy equipment

- Elevators and escalators

- Laboratory and testing equipment

- Any environment requiring immediate shutdown for safety

Technical Specifications

The Emergency STOP button is typically a momentary, normally closed (NC) switch with a latching mechanism. Below are the general technical specifications:

| Parameter | Value |

|---|---|

| Operating Voltage | 12V to 240V AC/DC (varies by model) |

| Current Rating | 1A to 10A (varies by model) |

| Contact Configuration | Normally Closed (NC) or NC + NO |

| Actuation Force | 10-50N (varies by model) |

| Reset Mechanism | Twist or pull-to-release |

| Mounting Hole Diameter | 16mm, 22mm, or 30mm |

| Operating Temperature | -25°C to +70°C |

| IP Rating | IP65 or higher (dust and water resistance) |

Pin Configuration and Descriptions

The Emergency STOP button typically has two or more terminals for wiring. Below is a table describing the pin configuration:

| Pin Name | Description |

|---|---|

| NC (Normally Closed) | Connects to the circuit; opens when the button is pressed, breaking the circuit. |

| NO (Normally Open) | Optional; closes when the button is pressed, used for signaling or alarms. |

| COM (Common) | Common terminal for NC and NO connections. |

Usage Instructions

How to Use the Emergency STOP in a Circuit

Wiring the E-STOP Button:

- Connect the NC terminal in series with the power supply line of the machinery or equipment.

- Optionally, connect the NO terminal to an alarm or indicator circuit to signal when the E-STOP is activated.

- Ensure proper insulation and secure connections to avoid accidental disconnections.

Mounting the E-STOP:

- Drill a hole in the control panel or mounting surface matching the button's diameter (e.g., 22mm).

- Insert the E-STOP button and secure it using the provided locking nut.

Resetting the E-STOP:

- After activation, twist or pull the button (depending on the model) to reset it and restore the circuit.

Important Considerations and Best Practices

- Always verify the voltage and current ratings of the E-STOP button to ensure compatibility with your system.

- Test the E-STOP functionality regularly to ensure it operates correctly.

- Use an E-STOP button with an appropriate IP rating for environments exposed to dust, water, or other contaminants.

- Label the E-STOP button clearly to ensure it is easily identifiable in an emergency.

- For systems controlled by microcontrollers (e.g., Arduino), use the E-STOP to cut power to the entire system rather than relying solely on software-based safety mechanisms.

Example: Connecting an E-STOP to an Arduino UNO

Below is an example of how to use an E-STOP button with an Arduino UNO to monitor its state and trigger an emergency response:

// Define the pin connected to the NC terminal of the E-STOP button

const int eStopPin = 2; // Digital pin 2

// Define the pin for an LED to indicate emergency state

const int ledPin = 13; // Built-in LED on most Arduino boards

void setup() {

pinMode(eStopPin, INPUT_PULLUP); // Use internal pull-up resistor

pinMode(ledPin, OUTPUT); // Set LED pin as output

digitalWrite(ledPin, LOW); // Ensure LED is off initially

Serial.begin(9600); // Initialize serial communication

}

void loop() {

// Read the state of the E-STOP button

int eStopState = digitalRead(eStopPin);

if (eStopState == HIGH) {

// E-STOP is not pressed (circuit closed)

digitalWrite(ledPin, LOW); // Turn off LED

Serial.println("System running normally.");

} else {

// E-STOP is pressed (circuit open)

digitalWrite(ledPin, HIGH); // Turn on LED

Serial.println("EMERGENCY STOP ACTIVATED!");

// Add additional emergency handling code here

}

delay(100); // Small delay for stability

}

Note: The NC terminal is connected to the Arduino pin with a pull-up resistor. When the E-STOP is pressed, the circuit opens, and the Arduino detects a LOW signal.

Troubleshooting and FAQs

Common Issues and Solutions

E-STOP Button Does Not Stop the Machinery:

- Cause: Incorrect wiring or loose connections.

- Solution: Verify the wiring, ensuring the NC terminal is properly connected in series with the power supply line.

E-STOP Button Does Not Reset:

- Cause: Faulty reset mechanism or debris in the button.

- Solution: Inspect the button for physical damage or obstructions. Replace if necessary.

False Triggers or Unintended Activation:

- Cause: Electrical noise or vibration.

- Solution: Use shielded cables and secure the button to minimize vibration.

Arduino Does Not Detect E-STOP Activation:

- Cause: Incorrect pin configuration or missing pull-up resistor.

- Solution: Ensure the pin is configured as

INPUT_PULLUPin the Arduino code.

FAQs

Q1: Can I use an E-STOP button with high-power equipment?

A1: Yes, but ensure the button's voltage and current ratings match or exceed the equipment's requirements. For very high-power systems, use the E-STOP to control a relay or contactor.

Q2: How often should I test the E-STOP button?

A2: Regular testing is recommended, typically during routine maintenance or at least once a month.

Q3: Can I use an E-STOP button outdoors?

A3: Yes, but ensure the button has an appropriate IP rating (e.g., IP65 or higher) for outdoor use.

Q4: What happens if the E-STOP button fails?

A4: Most E-STOP buttons are designed to fail-safe, meaning they will open the circuit in case of a failure. However, regular testing is essential to ensure reliability.