How to Use pwm to voltage : Examples, Pinouts, and Specs

Design with pwm to voltage in Cirkit Designer

Design with pwm to voltage in Cirkit DesignerIntroduction

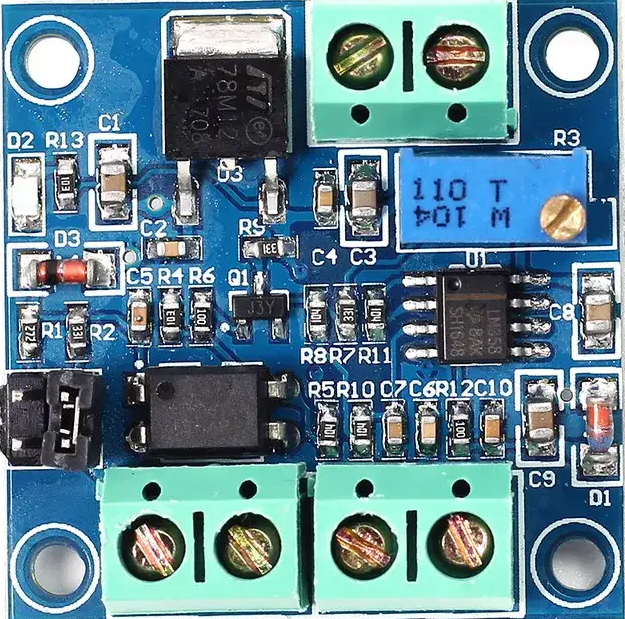

A PWM to Voltage Converter is an electronic component that transforms pulse-width modulation (PWM) signals into a corresponding analog voltage level. This conversion is essential in applications where analog control is required but the controlling device (e.g., a microcontroller) outputs only PWM signals. By interpreting the duty cycle of the PWM signal, the converter generates a proportional DC voltage.

Explore Projects Built with pwm to voltage

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with pwm to voltage

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Motor speed control in industrial and hobbyist projects

- LED brightness adjustment

- Analog signal generation for audio or control systems

- Interfacing PWM-based microcontrollers (e.g., Arduino, Raspberry Pi) with analog devices

- Voltage-controlled devices such as amplifiers or actuators

Technical Specifications

Below are the typical specifications for a PWM to Voltage Converter. Note that actual values may vary depending on the specific model or manufacturer.

| Parameter | Specification |

|---|---|

| Input Voltage Range | 3.3V to 24V |

| Output Voltage Range | 0V to 10V (proportional to PWM duty cycle) |

| PWM Input Frequency | 1 kHz to 10 kHz |

| Input PWM Duty Cycle | 0% to 100% |

| Output Current Capability | Up to 10 mA |

| Conversion Accuracy | ±1% |

| Operating Temperature | -40°C to 85°C |

Pin Configuration and Descriptions

| Pin Name | Description |

|---|---|

| VCC | Power supply input (3.3V to 24V) |

| GND | Ground connection |

| PWM_IN | PWM signal input (from microcontroller or other source) |

| V_OUT | Analog voltage output (proportional to PWM duty cycle) |

Usage Instructions

How to Use the Component in a Circuit

- Power the Converter: Connect the VCC pin to a suitable power source (e.g., 5V or 12V) and the GND pin to the ground of your circuit.

- Input PWM Signal: Connect the PWM_IN pin to the PWM output of your microcontroller or other signal source. Ensure the PWM signal frequency is within the supported range (e.g., 1 kHz to 10 kHz).

- Output Voltage: The V_OUT pin will provide an analog voltage proportional to the duty cycle of the PWM signal. For example:

- A 50% duty cycle PWM signal will produce approximately half of the maximum output voltage.

- A 100% duty cycle will produce the maximum output voltage.

Important Considerations and Best Practices

- Filter Capacitor: Many PWM to Voltage Converters include an onboard low-pass filter to smooth the PWM signal into a stable DC voltage. If your converter does not include this, you may need to add an external RC filter.

- PWM Frequency: Ensure the PWM signal frequency is within the specified range. Frequencies too low may result in unstable or inaccurate output voltages.

- Load Impedance: Avoid connecting loads with very low impedance directly to the V_OUT pin, as this may exceed the current capability of the converter.

- Calibration: Some converters include a potentiometer for fine-tuning the output voltage. Adjust this as needed for precise control.

Example: Using with an Arduino UNO

Below is an example of how to use a PWM to Voltage Converter with an Arduino UNO to control the output voltage.

Circuit Connections

- Connect the VCC pin of the converter to the 5V pin of the Arduino.

- Connect the GND pin of the converter to the GND pin of the Arduino.

- Connect the PWM_IN pin of the converter to pin 9 of the Arduino (a PWM-capable pin).

- Measure the output voltage at the V_OUT pin using a multimeter or connect it to an analog device.

Arduino Code

// Example code to generate a PWM signal on pin 9 of Arduino UNO

// This will vary the duty cycle from 0% to 100% in steps of 10%.

void setup() {

pinMode(9, OUTPUT); // Set pin 9 as an output for PWM signal

}

void loop() {

for (int dutyCycle = 0; dutyCycle <= 255; dutyCycle += 25) {

analogWrite(9, dutyCycle); // Write PWM signal with varying duty cycle

delay(500); // Wait for 500ms to observe the change in output voltage

}

}

Notes on the Code

- The

analogWrite()function generates a PWM signal on pin 9. The duty cycle is controlled by the value passed to the function (0 for 0% duty cycle, 255 for 100% duty cycle). - The output voltage at the V_OUT pin will change proportionally to the duty cycle.

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage

- Cause: Incorrect wiring or no PWM signal input.

- Solution: Verify all connections and ensure the PWM_IN pin is receiving a valid PWM signal.

Unstable Output Voltage

- Cause: PWM frequency is too low or insufficient filtering.

- Solution: Increase the PWM frequency or add an external low-pass filter.

Output Voltage Does Not Match Expected Value

- Cause: Calibration issue or incorrect duty cycle.

- Solution: Adjust the onboard potentiometer (if available) or verify the PWM duty cycle.

Overheating

- Cause: Excessive current draw from the V_OUT pin.

- Solution: Ensure the load connected to the V_OUT pin does not exceed the current rating of the converter.

FAQs

Q: Can I use this converter with a 3.3V microcontroller?

A: Yes, as long as the PWM signal voltage level is compatible with the converter's input specifications.

Q: What happens if the PWM frequency is too high?

A: If the frequency exceeds the supported range, the converter may not accurately generate the corresponding analog voltage.

Q: Can I use this converter to control a motor directly?

A: No, the output current capability is typically too low to drive a motor directly. Use the output voltage to control a motor driver or amplifier instead.