How to Use Torque Sensor: Examples, Pinouts, and Specs

Design with Torque Sensor in Cirkit Designer

Design with Torque Sensor in Cirkit DesignerIntroduction

A torque sensor is a device that measures and records the torque on a rotating system, such as an engine or a crankshaft. Torque sensors are essential in various applications, including automotive testing, industrial machinery, and robotics. They provide critical data for performance analysis, quality control, and system optimization.

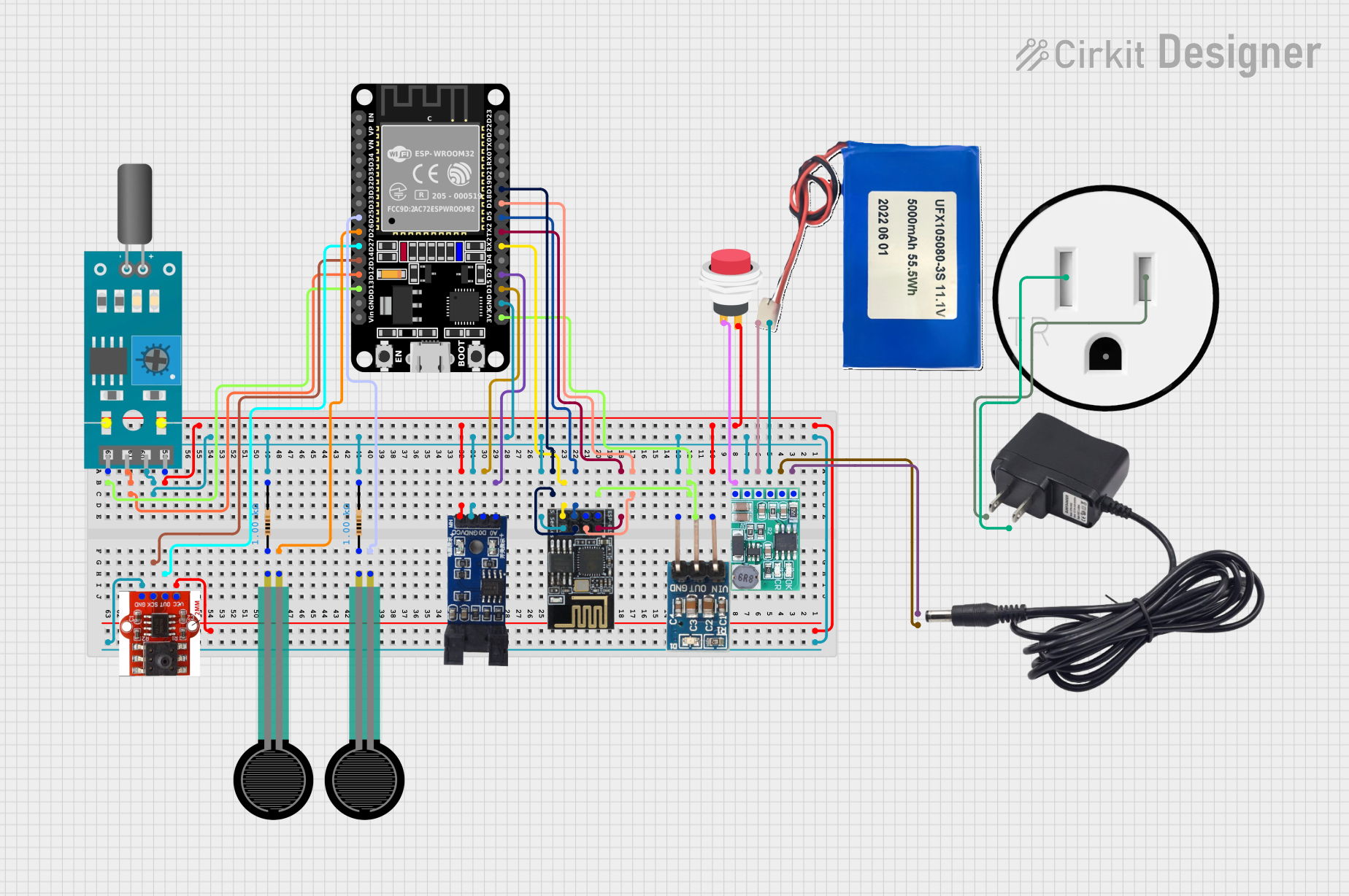

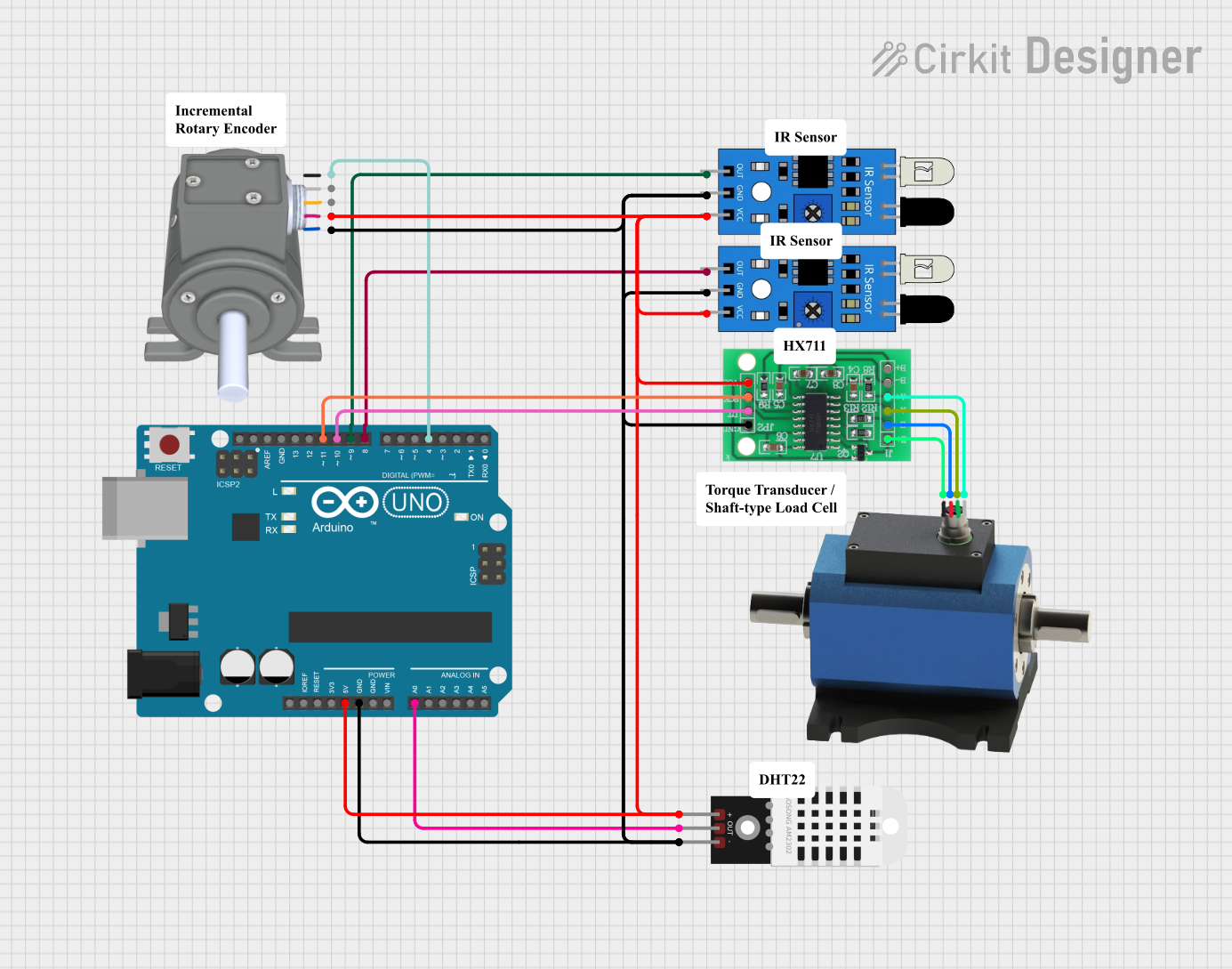

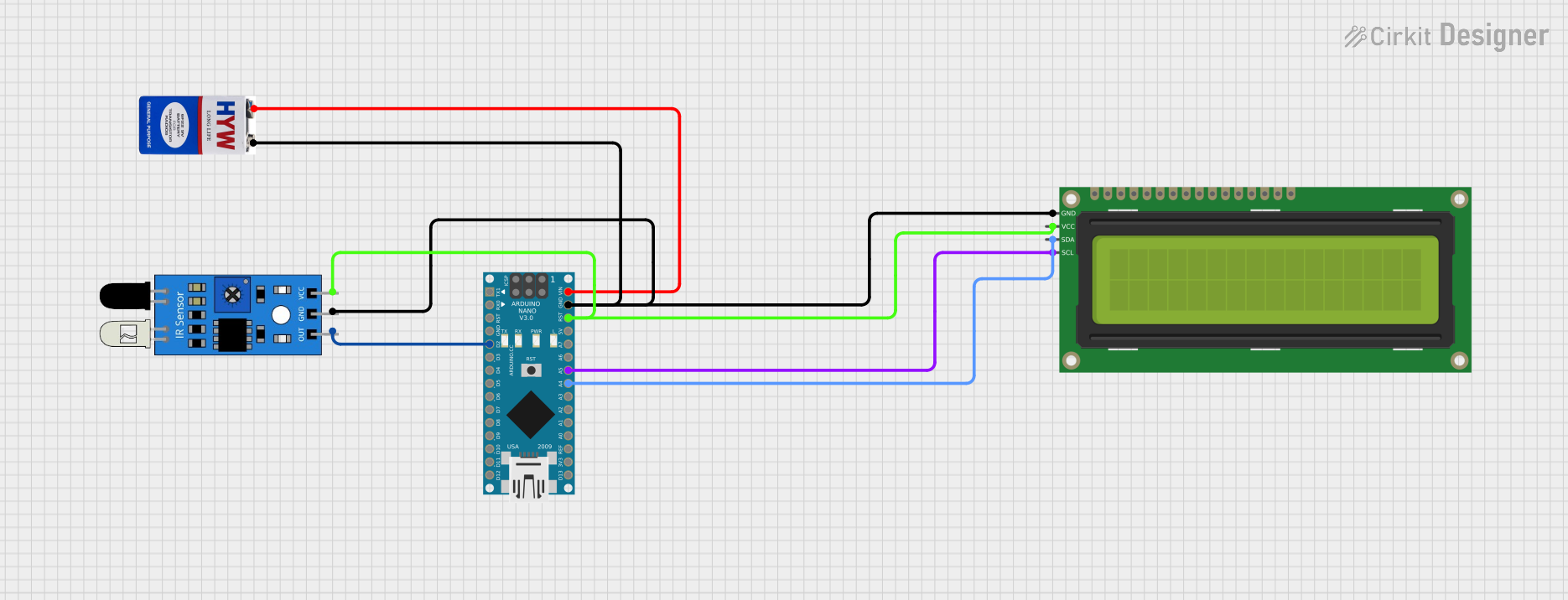

Explore Projects Built with Torque Sensor

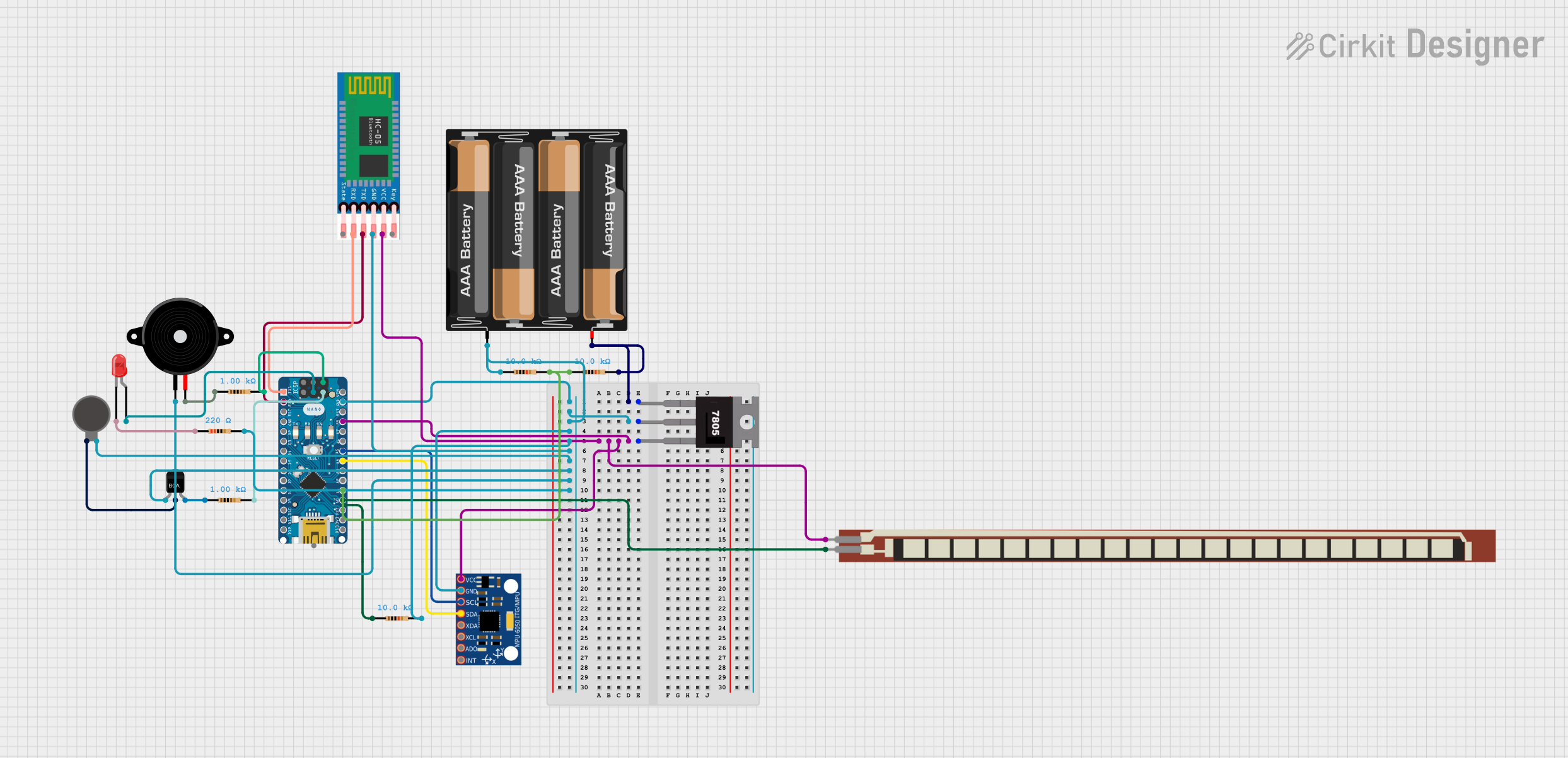

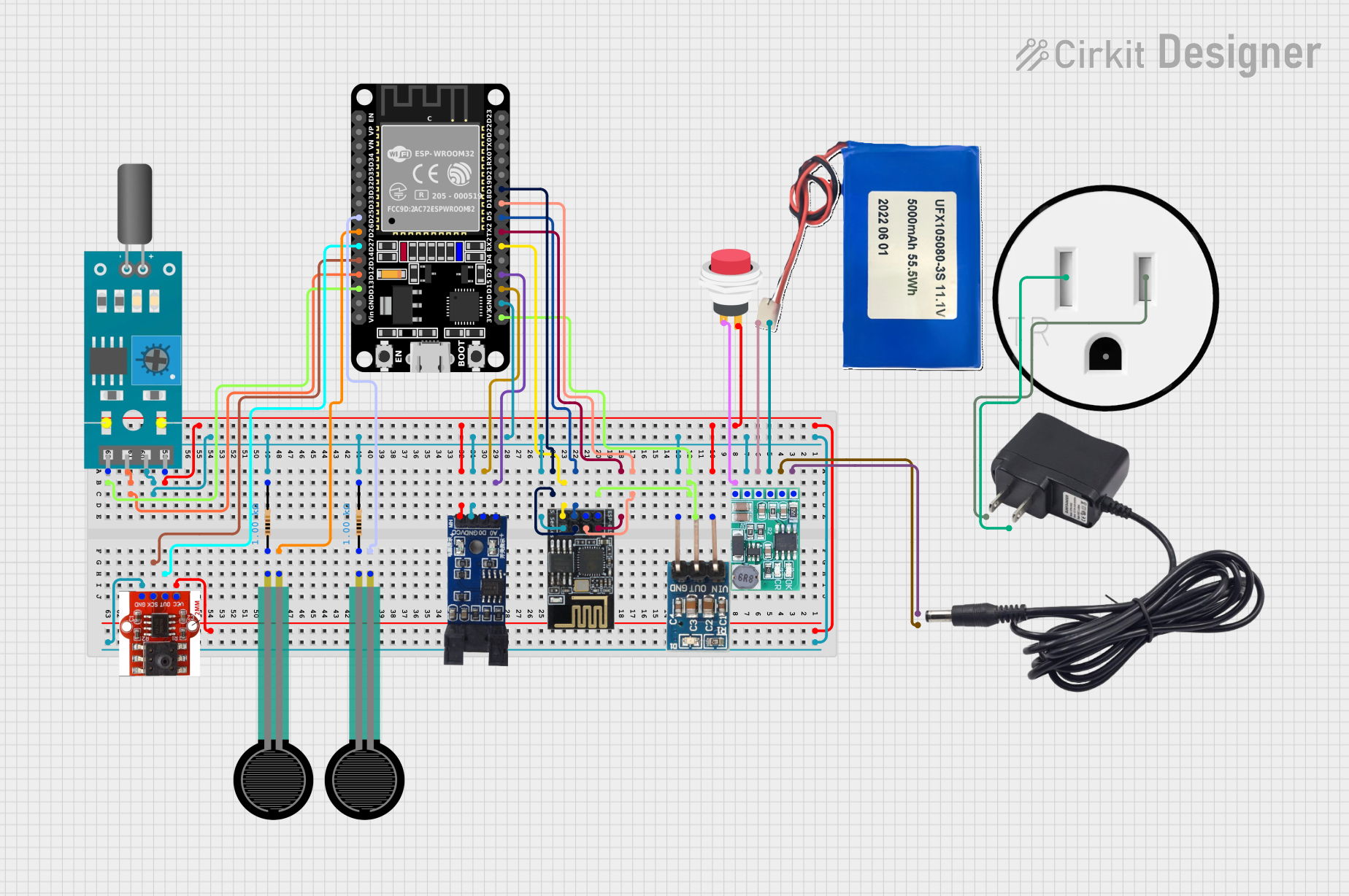

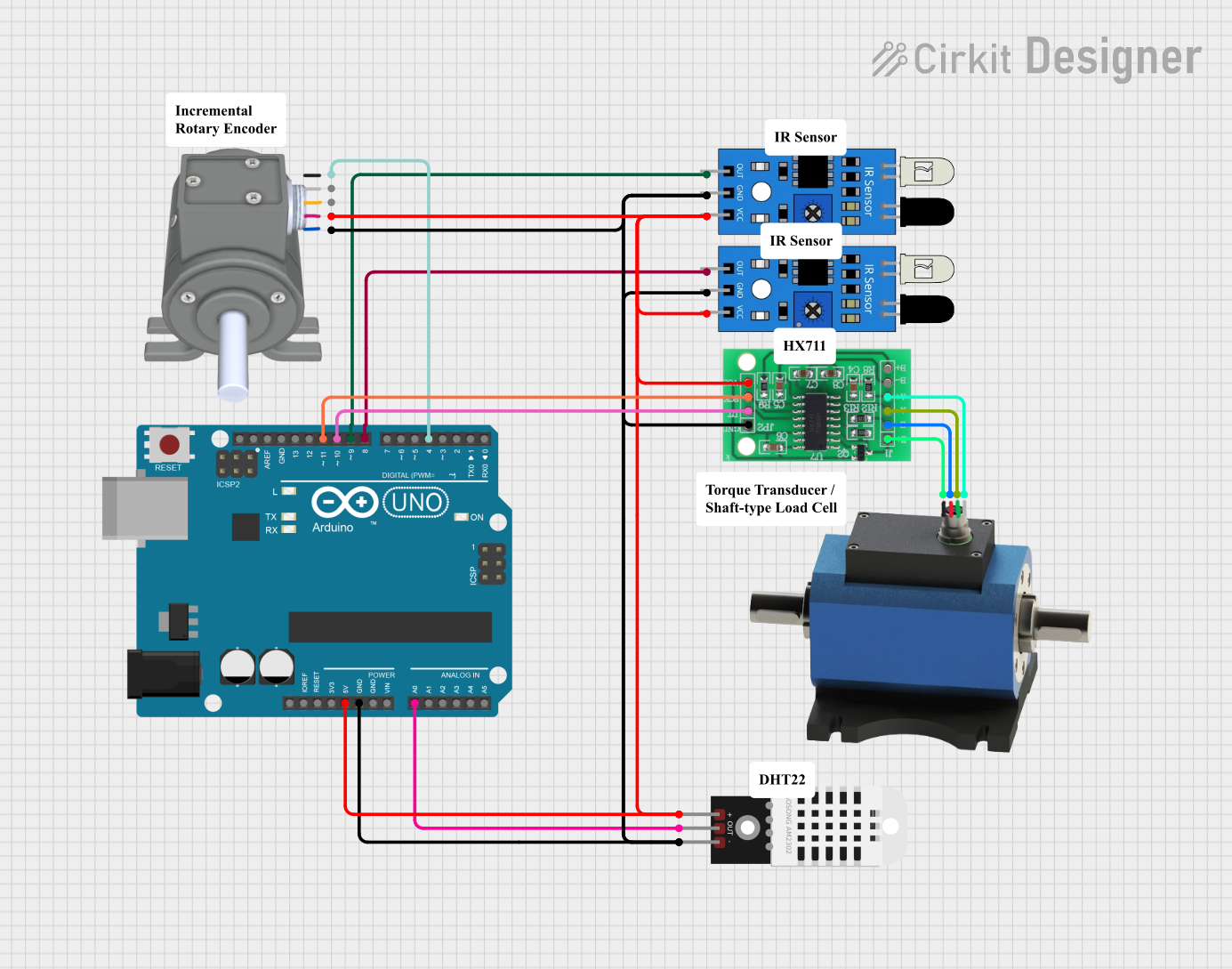

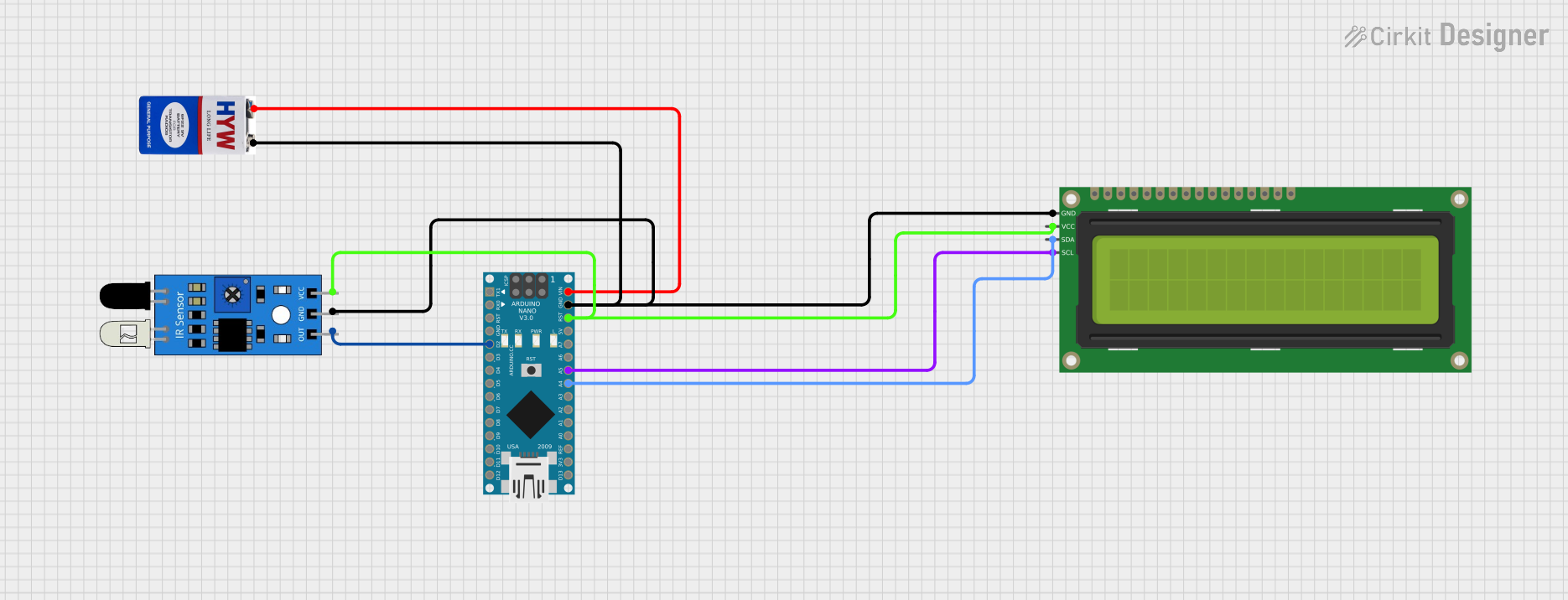

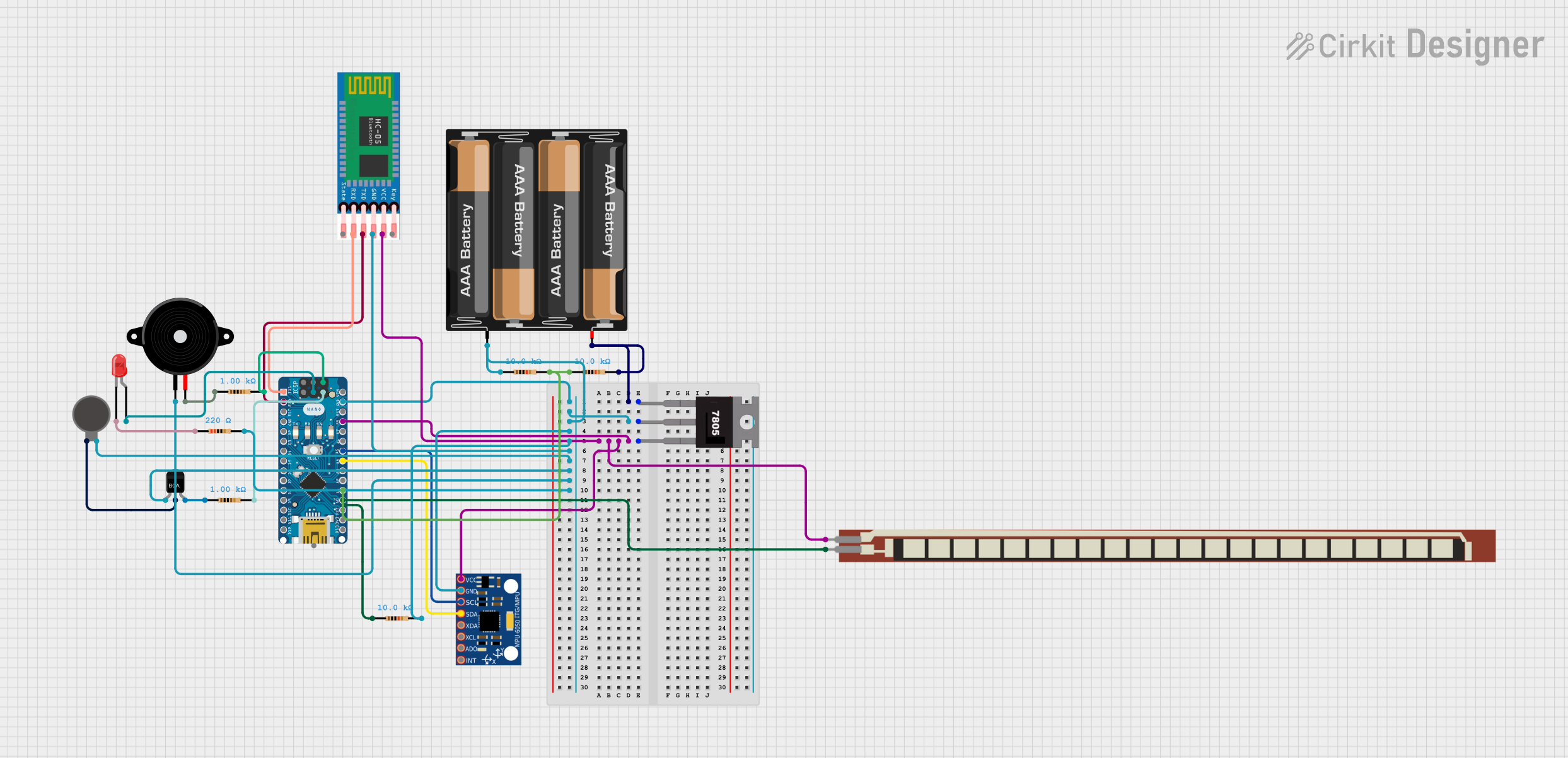

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Torque Sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Supply Voltage | 5V DC |

| Output Signal | Analog (0-5V) |

| Measurement Range | 0-100 Nm |

| Accuracy | ±0.5% of full scale |

| Operating Temperature | -20°C to 85°C |

| Response Time | < 1 ms |

| Interface | 3-wire (Vcc, GND, Signal) |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | Vcc | Power supply (5V DC) |

| 2 | GND | Ground |

| 3 | Signal | Analog output signal (0-5V) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the Vcc pin to a 5V DC power supply.

- Ground: Connect the GND pin to the ground of the power supply.

- Signal Output: Connect the Signal pin to an analog input pin on a microcontroller (e.g., Arduino UNO).

Important Considerations and Best Practices

- Calibration: Ensure the torque sensor is calibrated before use to maintain accuracy.

- Mounting: Securely mount the sensor to avoid vibrations and mechanical stress that could affect readings.

- Temperature: Operate within the specified temperature range to prevent damage and ensure accurate measurements.

- Shielding: Use shielded cables to minimize electrical noise and interference.

Example Circuit Diagram

Arduino UNO Example Code

// Torque Sensor Example Code

// This code reads the analog signal from the torque sensor and prints the

// torque value to the Serial Monitor.

const int torqueSensorPin = A0; // Analog pin connected to the Signal pin

float torqueValue = 0; // Variable to store the torque value

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud rate

}

void loop() {

int sensorValue = analogRead(torqueSensorPin); // Read the analog value

torqueValue = (sensorValue / 1023.0) * 100; // Convert to torque (0-100 Nm)

Serial.print("Torque: ");

Serial.print(torqueValue);

Serial.println(" Nm");

delay(500); // Wait for 500 milliseconds before the next reading

}

Troubleshooting and FAQs

Common Issues Users Might Face

Inaccurate Readings:

- Solution: Ensure the sensor is properly calibrated and securely mounted. Check for any mechanical stress or vibrations that could affect the readings.

No Output Signal:

- Solution: Verify the power supply connections (Vcc and GND). Ensure the Signal pin is correctly connected to the analog input of the microcontroller.

Fluctuating Readings:

- Solution: Use shielded cables to minimize electrical noise. Ensure the sensor is operating within the specified temperature range.

FAQs

Q1: How do I calibrate the torque sensor?

- A1: Follow the manufacturer's calibration procedure, which typically involves applying known torque values and adjusting the sensor output accordingly.

Q2: Can I use the torque sensor with a different microcontroller?

- A2: Yes, the torque sensor can be used with any microcontroller that has an analog input pin and operates at 5V DC.

Q3: What should I do if the sensor gets damaged?

- A3: If the sensor is physically damaged, it is recommended to replace it. For minor issues, consult the manufacturer's troubleshooting guide.

Q4: How often should I recalibrate the sensor?

- A4: Recalibration frequency depends on the application and usage. For critical applications, recalibrate periodically as recommended by the manufacturer.

This documentation provides a comprehensive guide to understanding, using, and troubleshooting a torque sensor. Whether you are a beginner or an experienced user, following these guidelines will help you achieve accurate and reliable torque measurements in your projects.