How to Use Servo: Examples, Pinouts, and Specs

Design with Servo in Cirkit Designer

Design with Servo in Cirkit DesignerIntroduction

A servo is a rotary actuator that allows for precise control of angular position, velocity, and acceleration. It consists of a motor coupled to a sensor for position feedback, along with a control circuit. Servos are widely used in robotics, automation, remote-controlled vehicles, and industrial machinery due to their ability to provide accurate and repeatable motion.

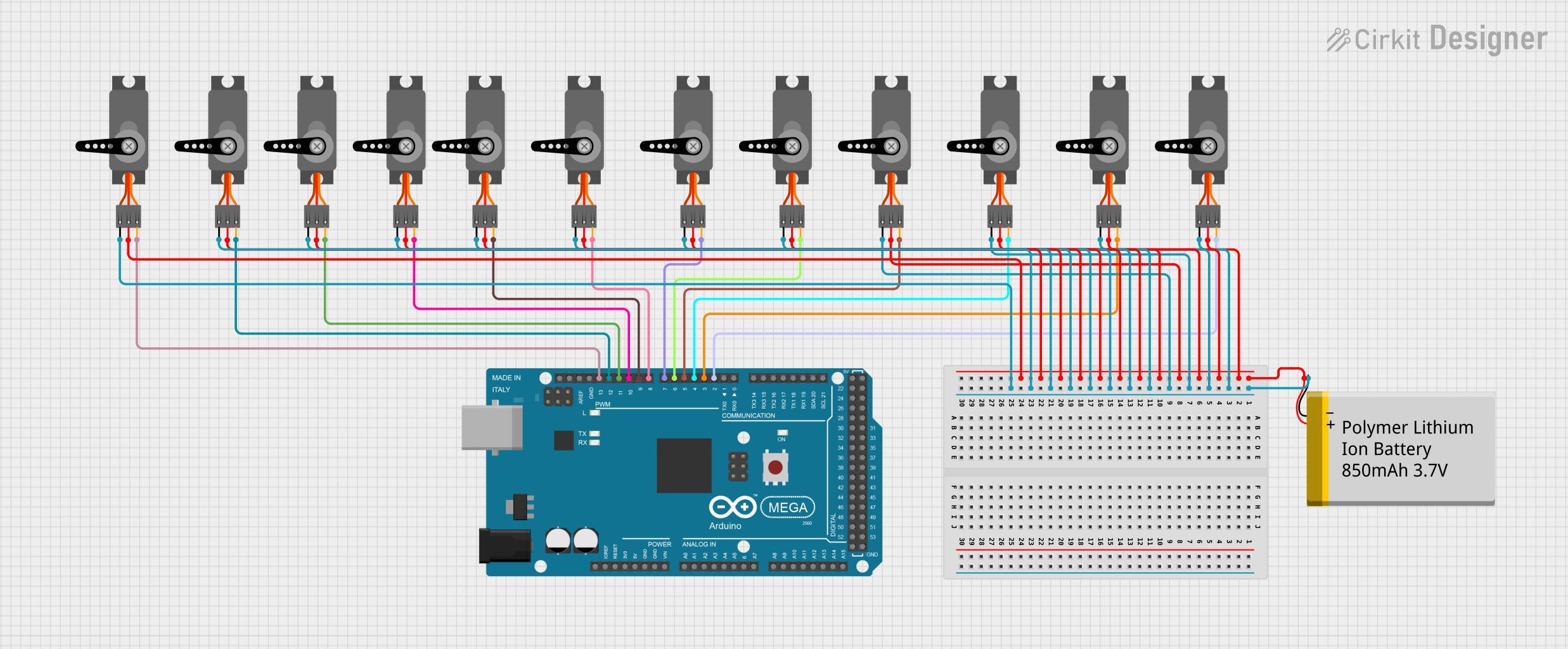

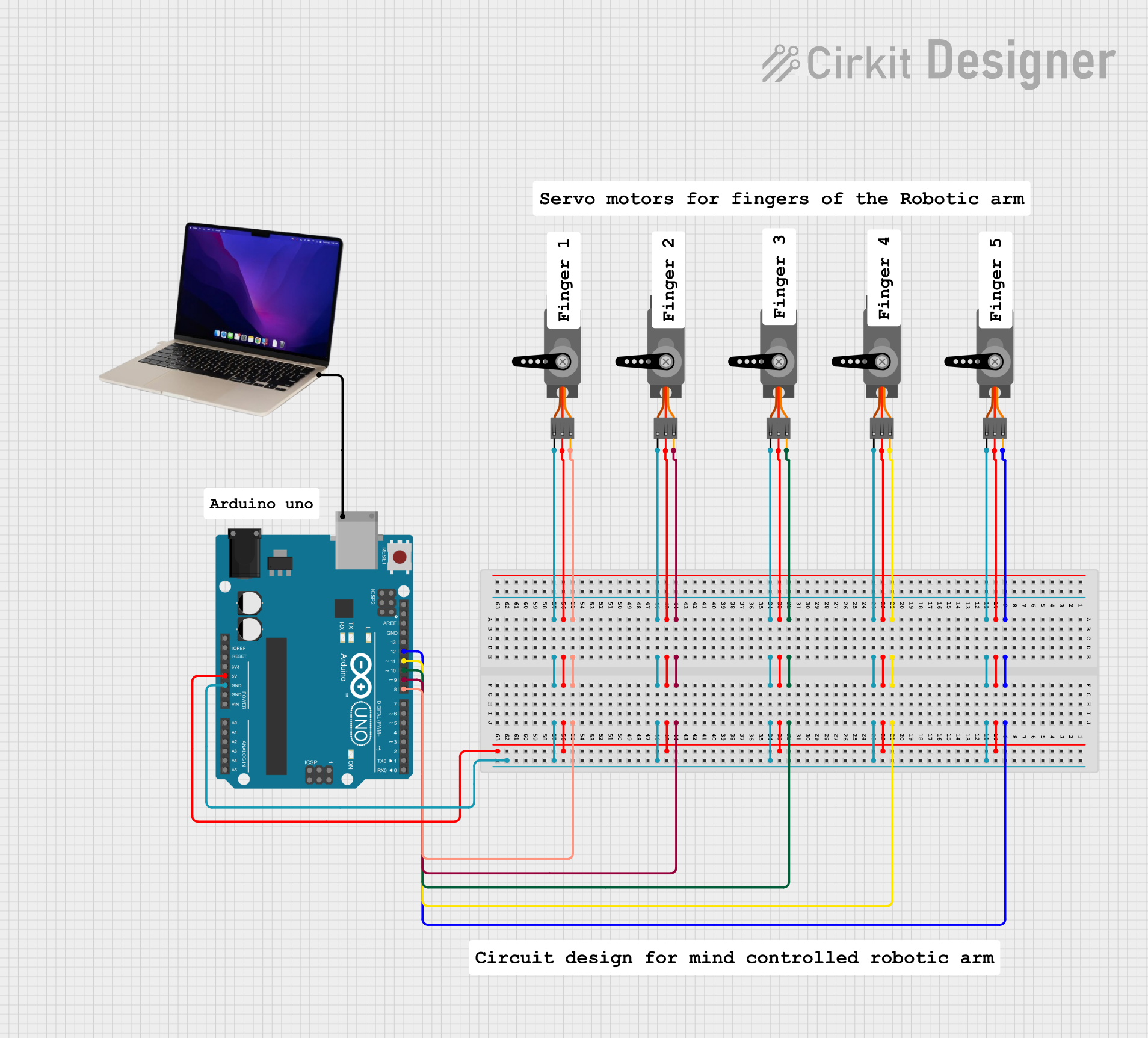

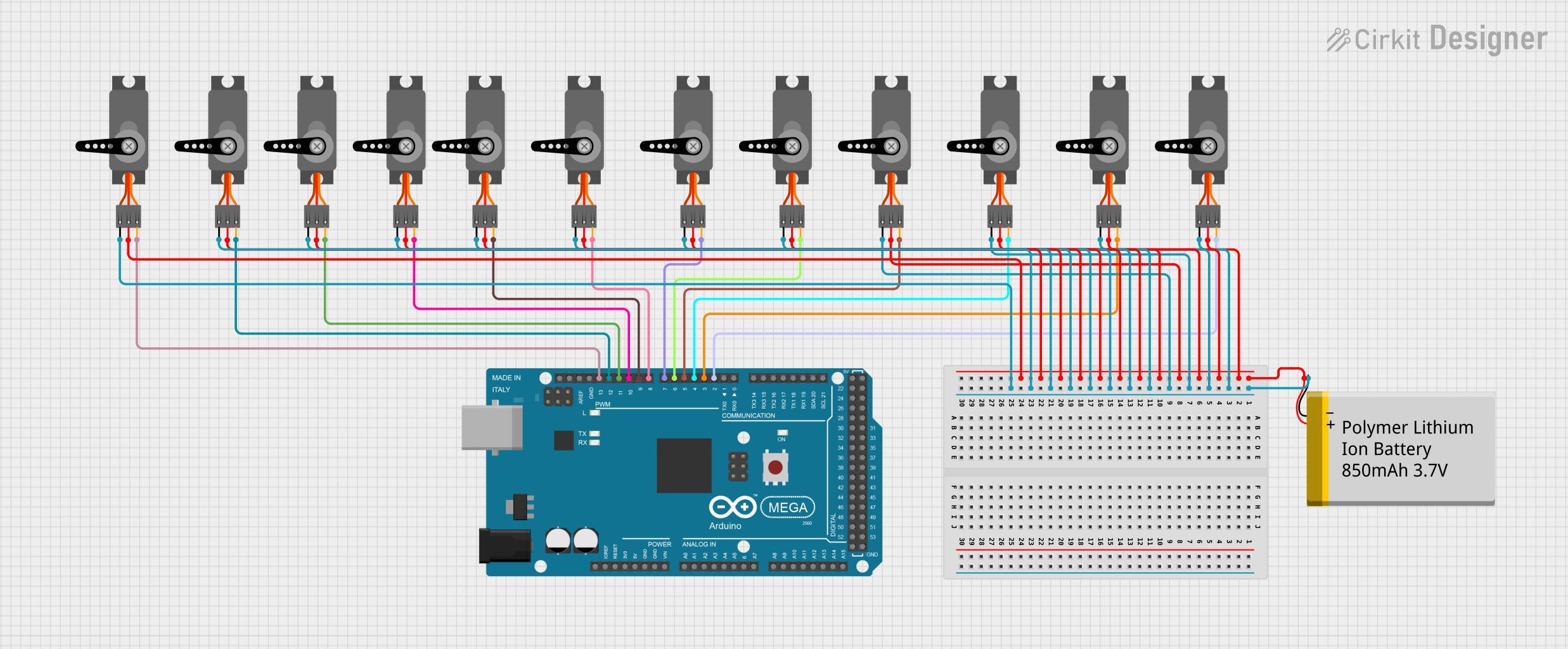

Explore Projects Built with Servo

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Servo

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

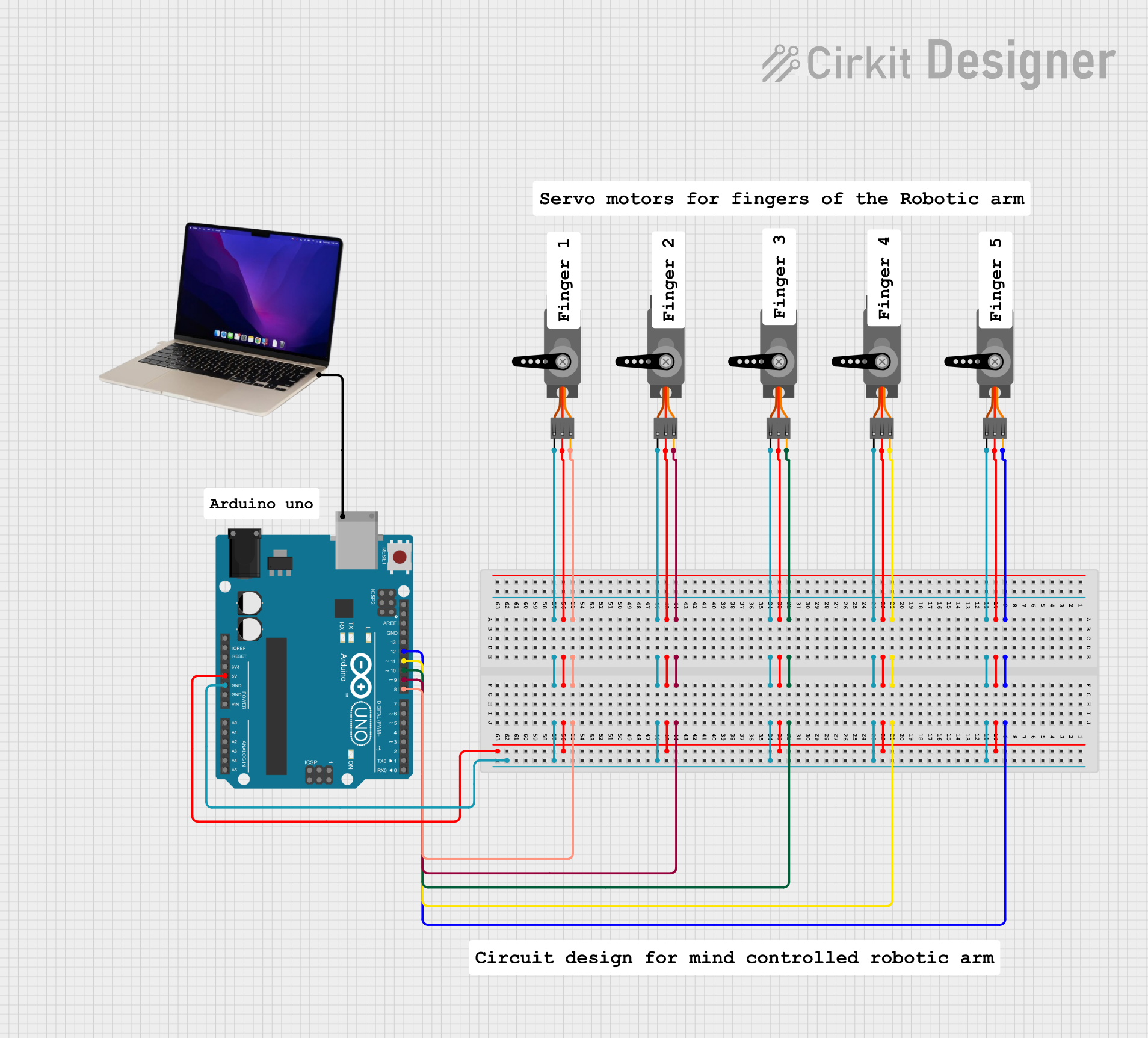

- Robotics: For controlling robotic arms, grippers, and joints.

- Remote-controlled vehicles: Steering mechanisms and throttle control.

- Automation: Conveyor systems and precise positioning tasks.

- Hobby projects: Model airplanes, boats, and cars.

- Camera gimbals: Stabilization and precise movement.

Technical Specifications

Below are the general technical specifications for a standard hobby servo. Note that specifications may vary depending on the specific model and manufacturer.

Key Technical Details

- Operating Voltage: 4.8V to 6V (typical range)

- Current Draw: 10mA to 100mA (idle), up to 1A (under load)

- Torque: 1.5 kg-cm to 20 kg-cm (varies by model)

- Rotation Range: 0° to 180° (standard), 360° for continuous rotation servos

- Control Signal: Pulse Width Modulation (PWM)

- Pulse width: 1ms (0°), 1.5ms (90°), 2ms (180°)

- Frequency: 50Hz (20ms period)

Pin Configuration and Descriptions

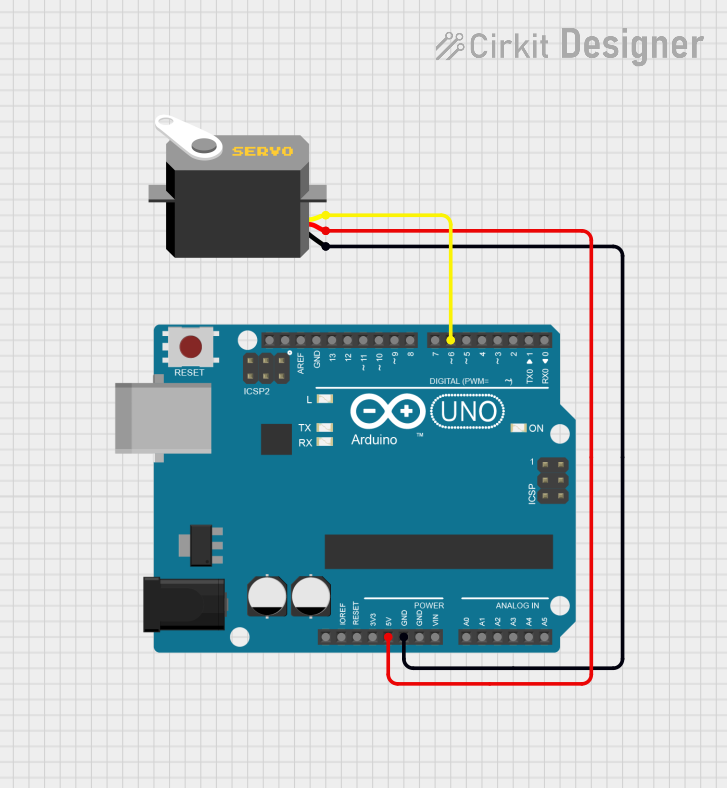

The servo typically has three wires for connection:

| Pin Name | Wire Color (Common) | Description |

|---|---|---|

| VCC | Red | Power supply (4.8V to 6V) |

| GND | Black/Brown | Ground |

| Signal | Yellow/Orange/White | PWM control signal |

Usage Instructions

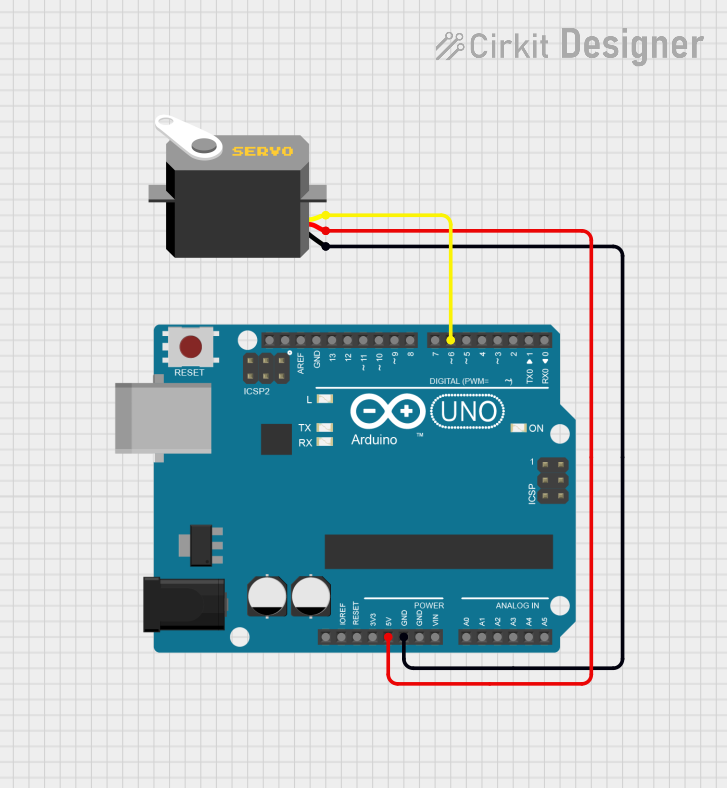

How to Use the Servo in a Circuit

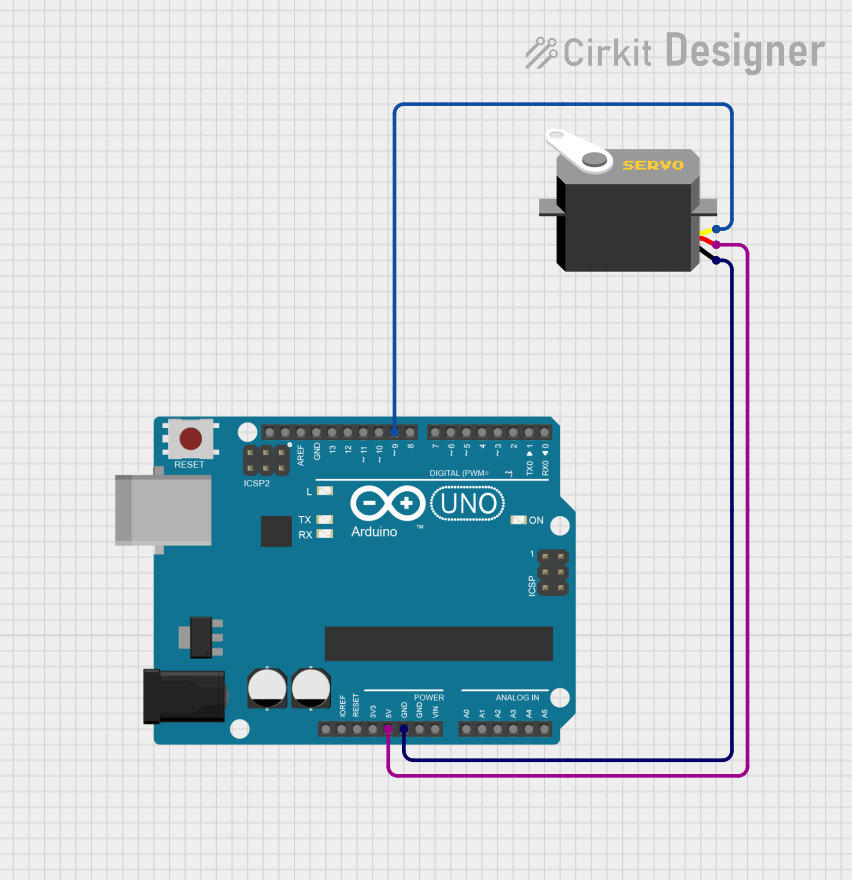

- Power the Servo: Connect the VCC pin to a 5V or 6V power source and the GND pin to the ground of the circuit.

- Control Signal: Connect the Signal pin to a PWM-capable pin of a microcontroller (e.g., Arduino).

- PWM Signal: Generate a PWM signal with a frequency of 50Hz and adjust the pulse width to control the servo's position:

- 1ms pulse: 0° position

- 1.5ms pulse: 90° position

- 2ms pulse: 180° position

Important Considerations and Best Practices

- Power Supply: Use a separate power supply for the servo if it draws significant current, as this can prevent voltage drops in the microcontroller.

- Avoid Overloading: Do not exceed the torque rating of the servo to avoid damage.

- Signal Stability: Ensure the PWM signal is stable and within the specified frequency range.

- Continuous Rotation Servos: For continuous rotation servos, the pulse width controls speed and direction rather than position.

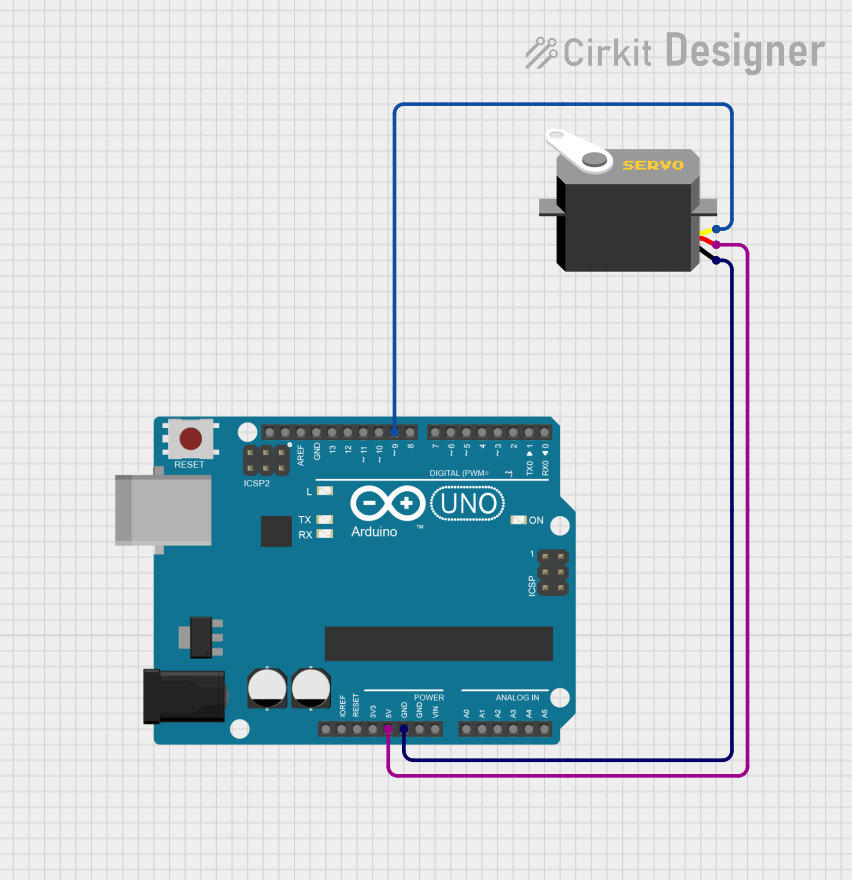

Example: Connecting a Servo to an Arduino UNO

Below is an example of how to control a servo using an Arduino UNO:

#include <Servo.h> // Include the Servo library

Servo myServo; // Create a Servo object

void setup() {

myServo.attach(9); // Attach the servo to pin 9 on the Arduino

}

void loop() {

myServo.write(0); // Move the servo to 0 degrees

delay(1000); // Wait for 1 second

myServo.write(90); // Move the servo to 90 degrees

delay(1000); // Wait for 1 second

myServo.write(180); // Move the servo to 180 degrees

delay(1000); // Wait for 1 second

}

Notes on the Code

- The

Servolibrary simplifies the process of generating PWM signals. - The

myServo.attach(9)function links the servo to pin 9. - The

myServo.write(angle)function sets the servo to a specific angle (0° to 180°).

Troubleshooting and FAQs

Common Issues and Solutions

Servo Not Moving

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check the connections and ensure the power supply meets the servo's requirements.

Jittery or Erratic Movement

- Cause: Unstable PWM signal or electrical noise.

- Solution: Use a decoupling capacitor near the servo's power pins and ensure the PWM signal is stable.

Overheating

- Cause: Overloading the servo or running it continuously at high torque.

- Solution: Reduce the load or use a servo with a higher torque rating.

Limited Range of Motion

- Cause: Mechanical obstruction or incorrect PWM signal.

- Solution: Check for physical obstructions and verify the pulse width range.

FAQs

Q: Can I power the servo directly from the Arduino?

A: While possible for small servos, it is recommended to use an external power supply to avoid overloading the Arduino.Q: How do I control a continuous rotation servo?

A: For continuous rotation servos, use themyServo.write()function with values around 90 for stop, less than 90 for one direction, and greater than 90 for the opposite direction.Q: Can I connect multiple servos to a single Arduino?

A: Yes, but ensure the power supply can handle the combined current draw of all servos.

This documentation provides a comprehensive guide to understanding and using a servo in various applications.