How to Use A4988: Examples, Pinouts, and Specs

Design with A4988 in Cirkit Designer

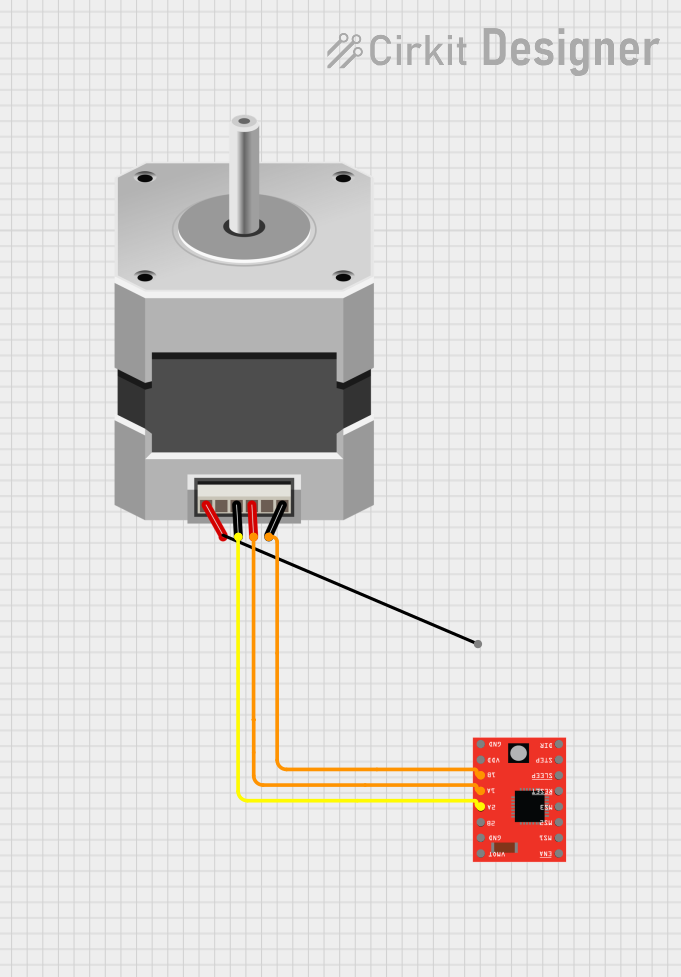

Design with A4988 in Cirkit DesignerIntroduction

The A4988 is a microstepping driver designed for controlling bipolar stepper motors. Manufactured by Adafruit under the part ID "Stepper Driver," this component enables precise control of motor position and speed. It supports up to 2A per phase with adjustable current control, making it ideal for applications requiring fine motor control. The A4988 also includes built-in protection features such as over-temperature and short-circuit protection, ensuring reliable operation.

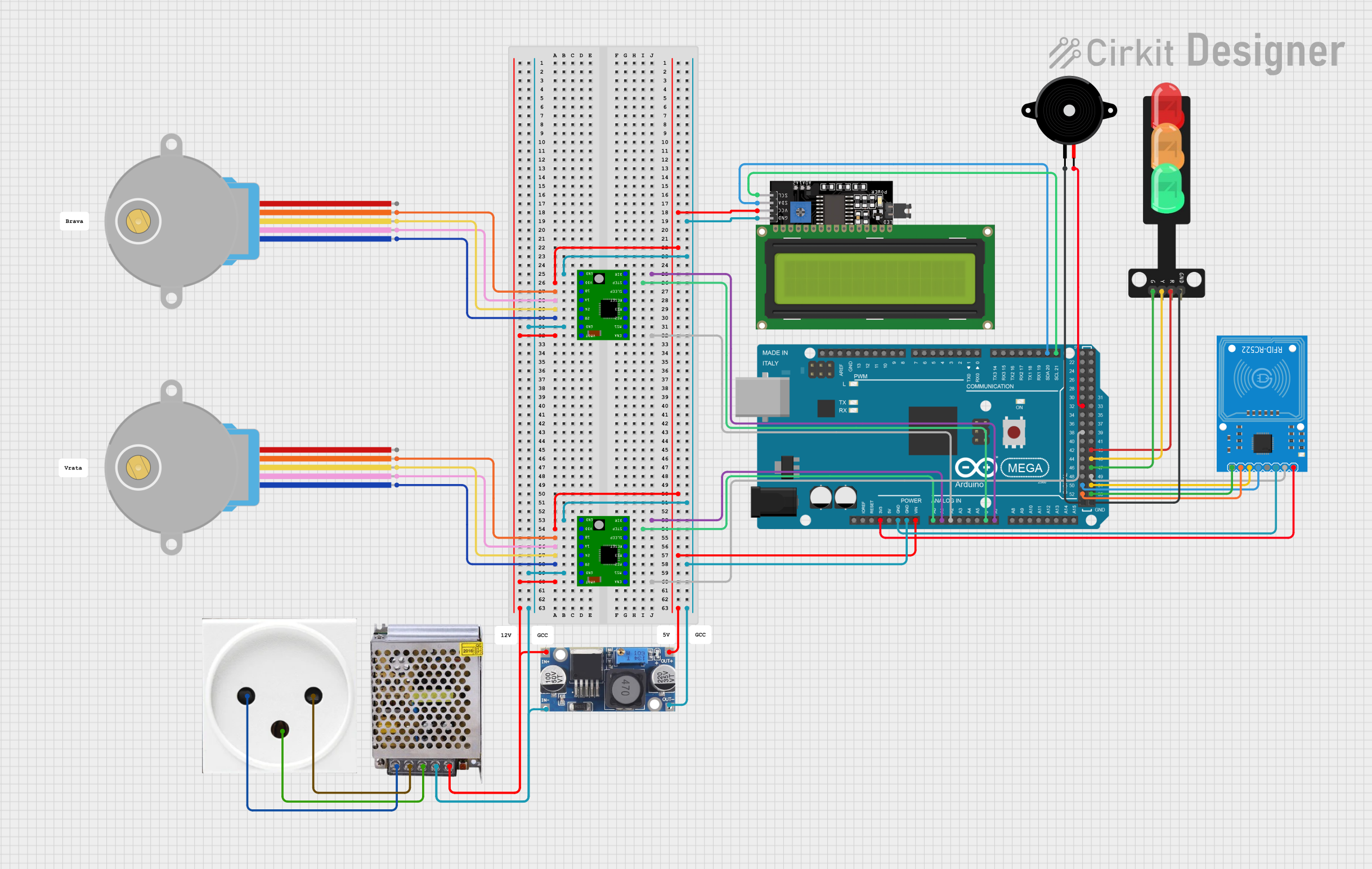

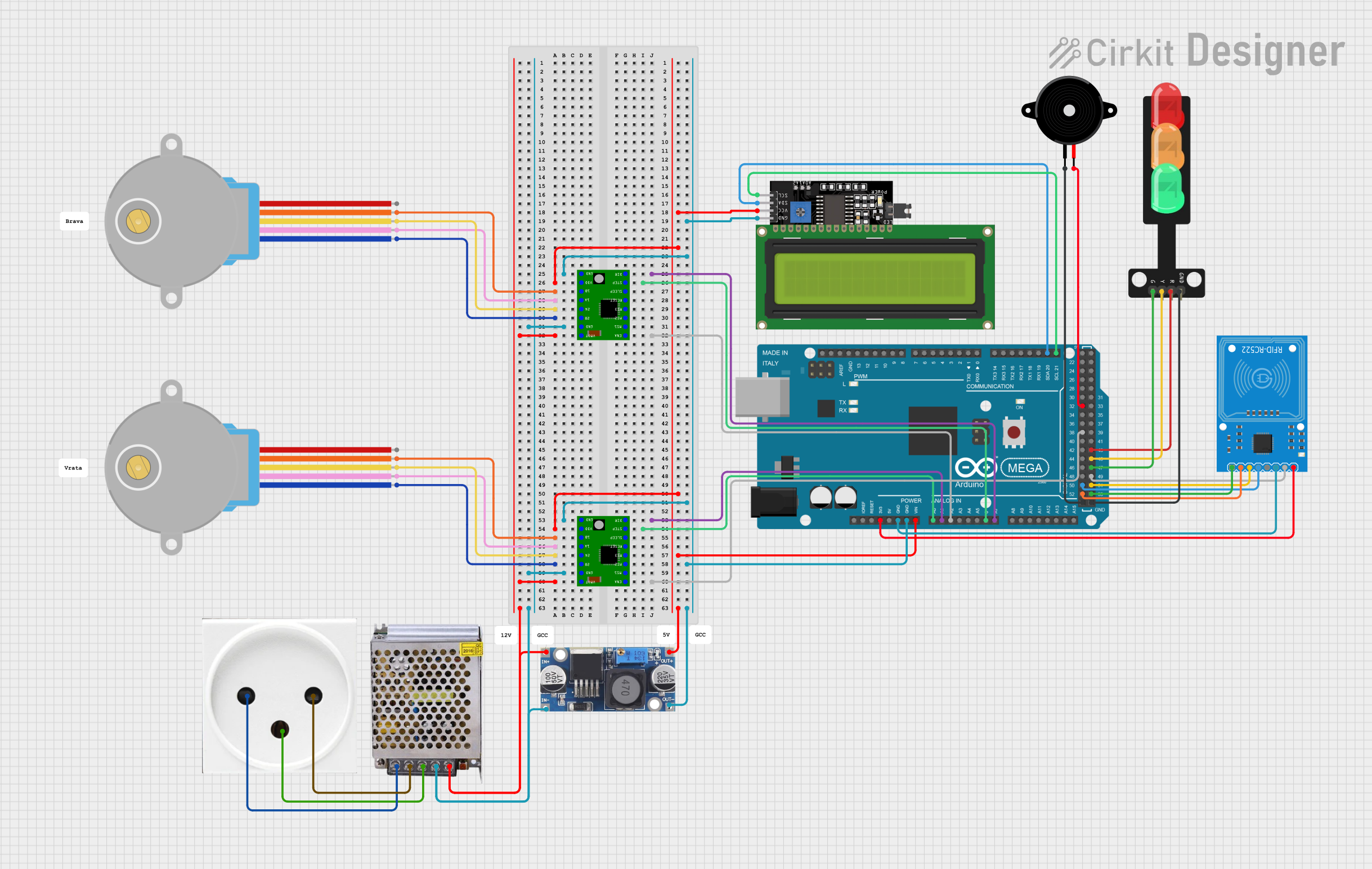

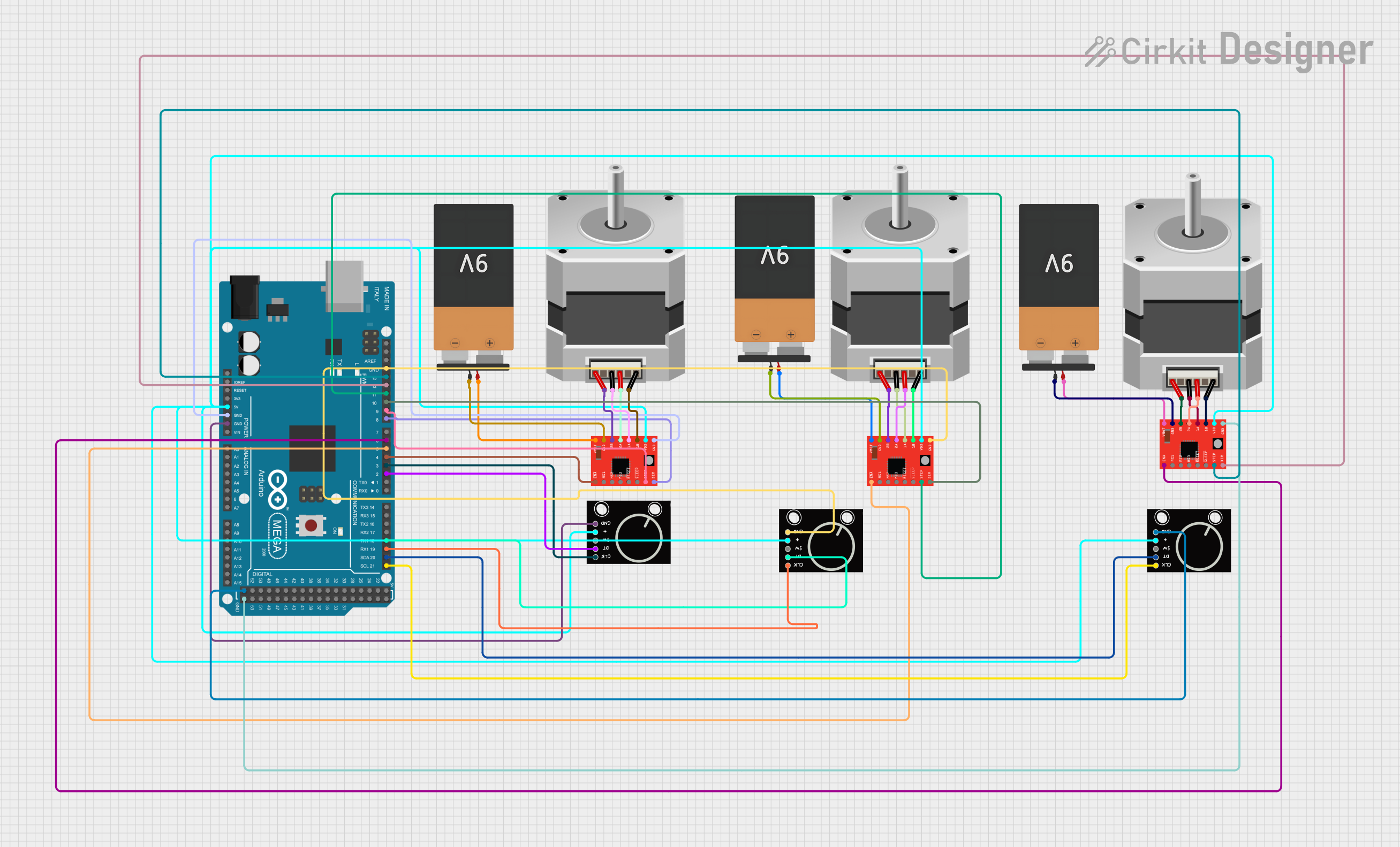

Explore Projects Built with A4988

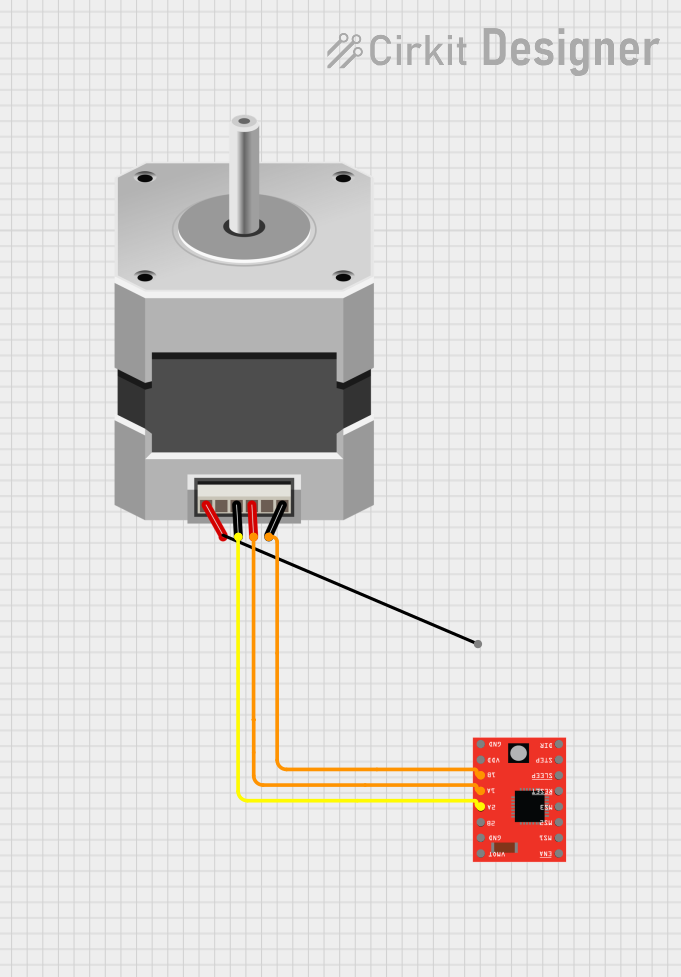

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

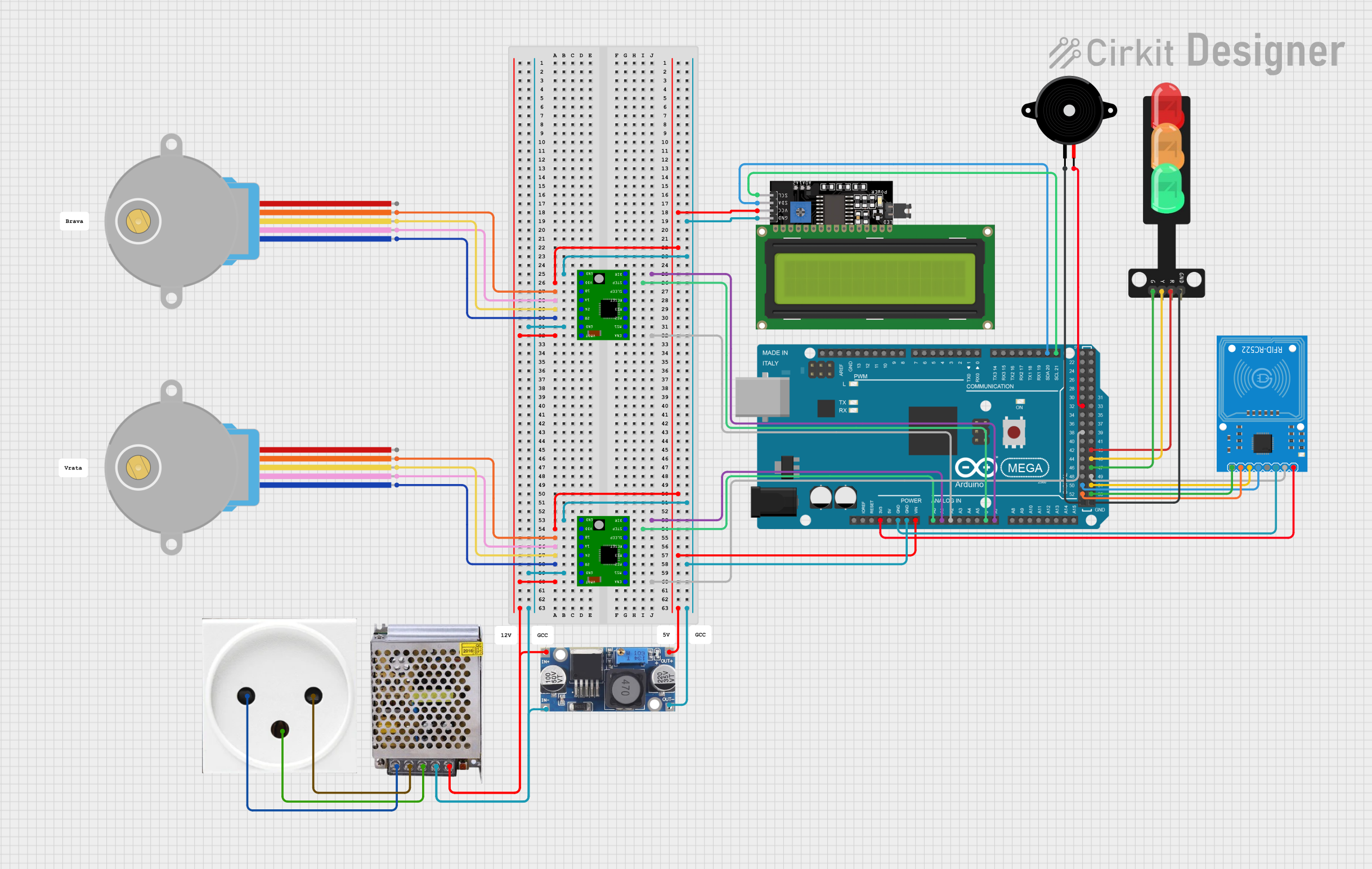

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with A4988

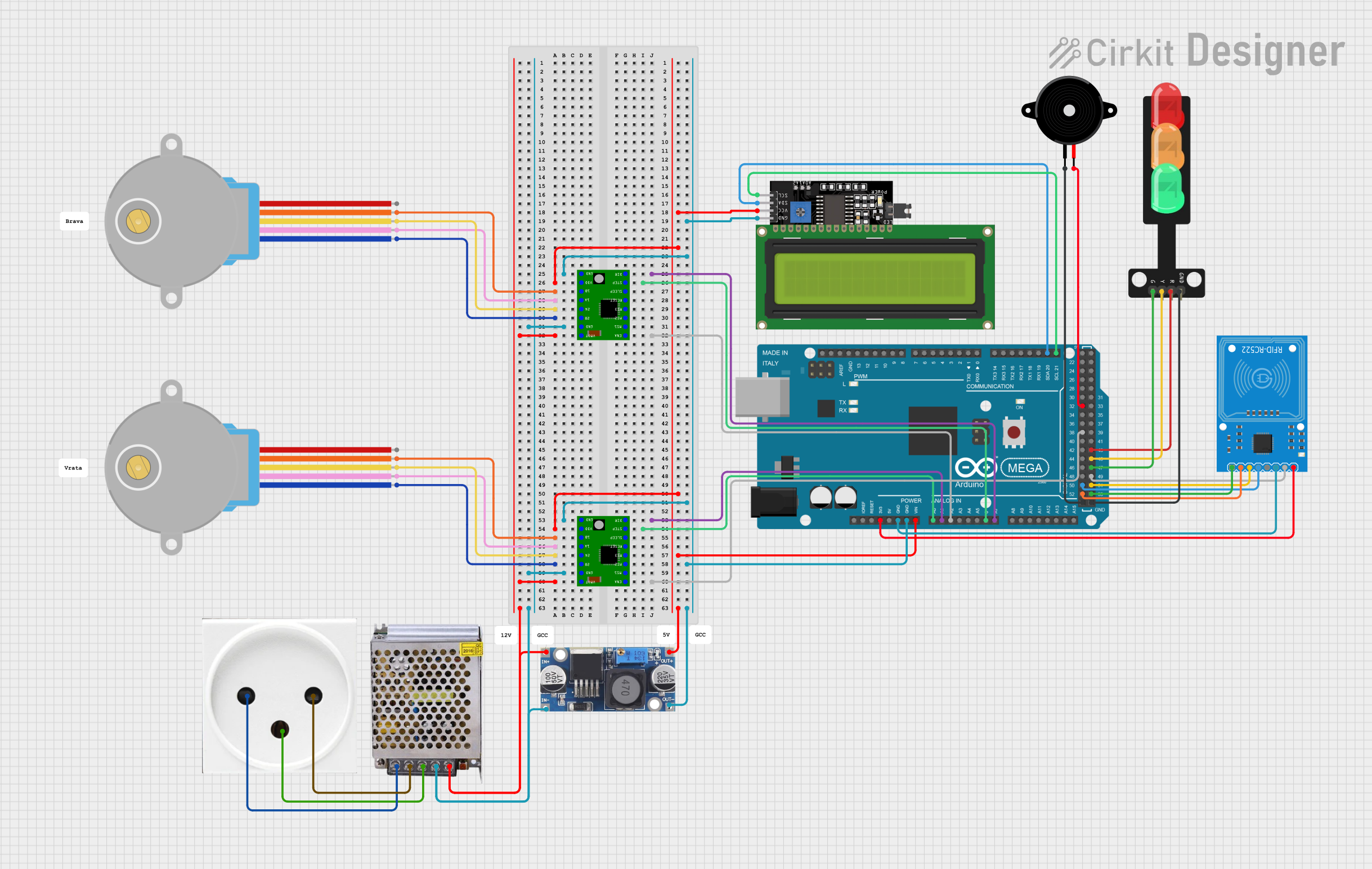

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

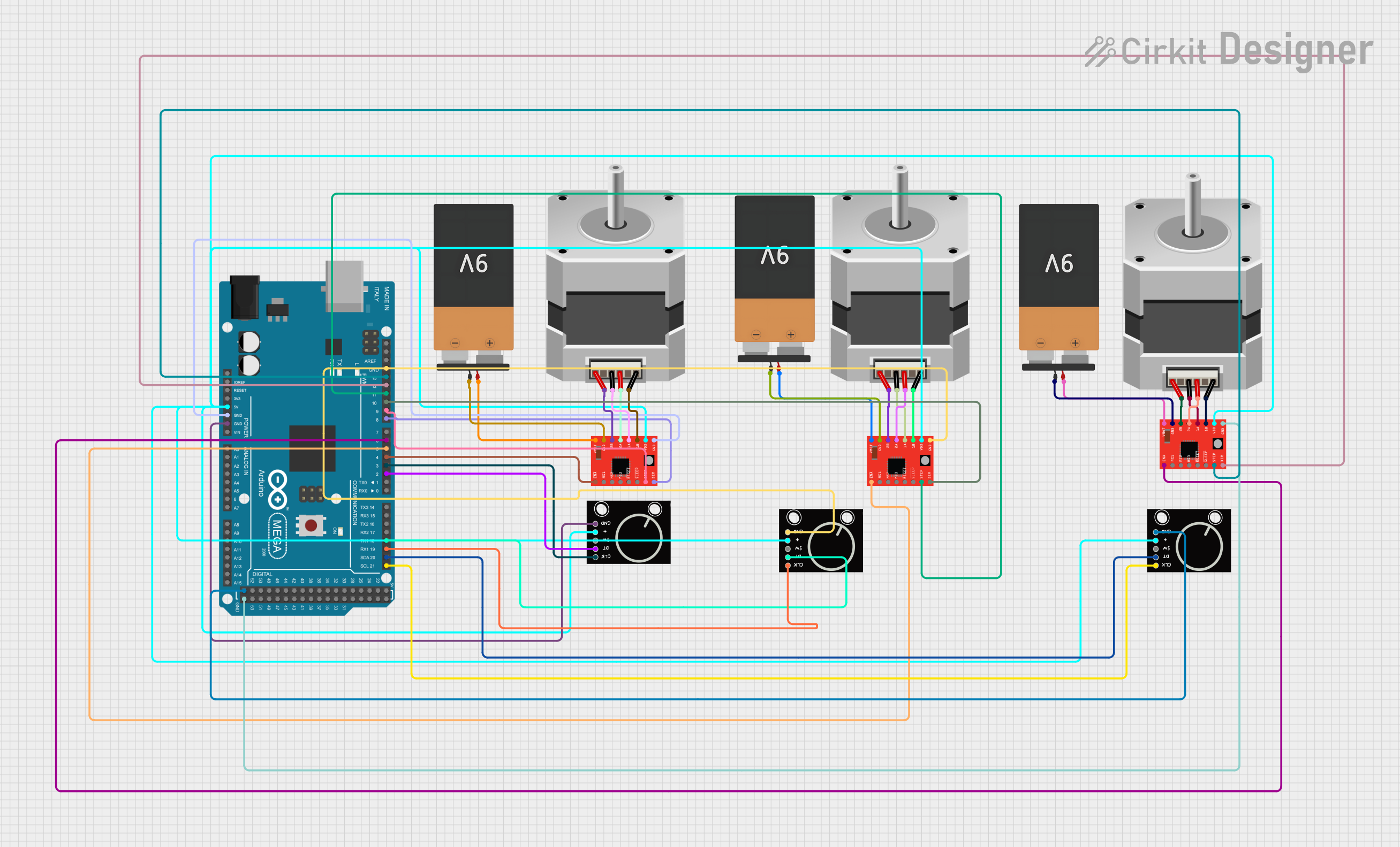

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- 3D printers

- CNC machines

- Robotics

- Automated camera sliders

- Precision positioning systems

Technical Specifications

Key Technical Details

- Operating Voltage (Vmotor): 8V to 35V

- Logic Voltage (Vlogic): 3.3V or 5V

- Maximum Current per Phase: 2A (with sufficient cooling)

- Microstepping Modes: Full, 1/2, 1/4, 1/8, 1/16 steps

- Current Control: Adjustable via potentiometer

- Protection Features: Over-temperature, over-current, and short-circuit protection

- Dimensions: 20mm x 15mm x 11mm (approx.)

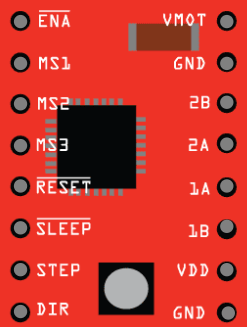

Pin Configuration and Descriptions

The A4988 has 16 pins, which are described in the table below:

| Pin Name | Type | Description |

|---|---|---|

| VMOT | Power Input | Motor power supply (8V to 35V). Connect a decoupling capacitor close to this pin. |

| GND | Power Ground | Ground connection for motor power supply. |

| VDD | Power Input | Logic power supply (3.3V or 5V). |

| GND | Power Ground | Ground connection for logic power supply. |

| 1A, 1B | Motor Output | Connect to one coil of the stepper motor. |

| 2A, 2B | Motor Output | Connect to the other coil of the stepper motor. |

| STEP | Logic Input | Controls the step signal. A rising edge triggers a step. |

| DIR | Logic Input | Controls the direction of motor rotation. |

| ENABLE | Logic Input | Enables or disables the driver (active low). |

| MS1, MS2, MS3 | Logic Input | Selects the microstepping resolution. |

| RESET | Logic Input | Resets the driver (active low). |

| SLEEP | Logic Input | Puts the driver into low-power sleep mode (active low). |

| REF | Analog Input | Sets the current limit via an external potentiometer. |

| FAULT | Logic Output | Indicates a fault condition (active low). |

Usage Instructions

How to Use the A4988 in a Circuit

Power Connections:

- Connect VMOT to a motor power supply (8V to 35V) and GND to the power ground.

- Connect VDD to a logic power supply (3.3V or 5V) and GND to the logic ground.

Motor Connections:

- Connect the stepper motor coils to the 1A, 1B, 2A, and 2B pins. Ensure the correct pairing of motor wires.

Control Signals:

- Use the STEP pin to send pulses for stepping the motor.

- Use the DIR pin to control the direction of rotation.

- Configure the microstepping resolution by setting MS1, MS2, and MS3 pins (refer to the datasheet for resolution settings).

Current Adjustment:

- Adjust the current limit using the REF pin and the onboard potentiometer. This prevents overheating and ensures optimal performance.

Decoupling Capacitors:

- Place a 100µF capacitor close to the VMOT pin to reduce voltage spikes.

- Add a 0.1µF capacitor near the VDD pin for logic power stability.

Arduino UNO Example Code

Below is an example of how to control a stepper motor using the A4988 and an Arduino UNO:

// Define control pins for the A4988 driver

#define STEP_PIN 3 // Connect to STEP pin on A4988

#define DIR_PIN 4 // Connect to DIR pin on A4988

void setup() {

pinMode(STEP_PIN, OUTPUT); // Set STEP pin as output

pinMode(DIR_PIN, OUTPUT); // Set DIR pin as output

digitalWrite(DIR_PIN, HIGH); // Set initial direction (HIGH = clockwise)

}

void loop() {

// Rotate the motor one step at a time

digitalWrite(STEP_PIN, HIGH); // Generate a step pulse

delayMicroseconds(1000); // Wait for 1ms

digitalWrite(STEP_PIN, LOW); // End the step pulse

delayMicroseconds(1000); // Wait for 1ms

// Repeat the loop to continue stepping

}

Important Considerations

- Heat Management: The A4988 can get hot during operation. Use a heat sink or active cooling if driving high currents.

- Microstepping Settings: Ensure the MS1, MS2, and MS3 pins are configured correctly for the desired resolution.

- Current Limit: Set the current limit appropriately to avoid damaging the motor or driver.

- Fault Handling: Monitor the FAULT pin to detect and respond to fault conditions.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check motor connections and ensure the power supply meets voltage and current requirements.

Driver Overheating:

- Cause: Current limit set too high or inadequate cooling.

- Solution: Adjust the current limit using the potentiometer and add a heat sink or fan.

Erratic Motor Movement:

- Cause: Noise on control signals or incorrect microstepping settings.

- Solution: Use pull-up or pull-down resistors on control pins and verify MS1, MS2, and MS3 configurations.

FAULT Pin Active (Low):

- Cause: Over-temperature, over-current, or short-circuit condition.

- Solution: Check for wiring errors, reduce the current limit, and ensure proper cooling.

FAQs

Q: Can I use the A4988 with a unipolar stepper motor?

A: No, the A4988 is designed for bipolar stepper motors only.

Q: How do I calculate the current limit using the REF pin?

A: The current limit is approximately VREF / (8 * R_sense), where R_sense is the value of the sense resistor (typically 0.1Ω).

Q: What happens if I exceed the maximum current rating?

A: The driver may overheat or enter a fault condition. Always set the current limit below the motor's rated current.

Q: Can I control multiple A4988 drivers with one Arduino?

A: Yes, you can control multiple drivers by assigning separate STEP and DIR pins for each driver.

By following this documentation, you can effectively use the A4988 stepper driver in your projects.