How to Use Servo Motor 9G: Examples, Pinouts, and Specs

Design with Servo Motor 9G in Cirkit Designer

Design with Servo Motor 9G in Cirkit DesignerIntroduction

The Servo Motor 9G is a compact and lightweight actuator capable of precise rotational positioning. It is widely used in robotics, remote-controlled vehicles, and various DIY electronics projects. The servo is designed to operate on a 5V power supply and can be easily interfaced with microcontrollers such as the Arduino UNO for accurate angle control.

Explore Projects Built with Servo Motor 9G

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Servo Motor 9G

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

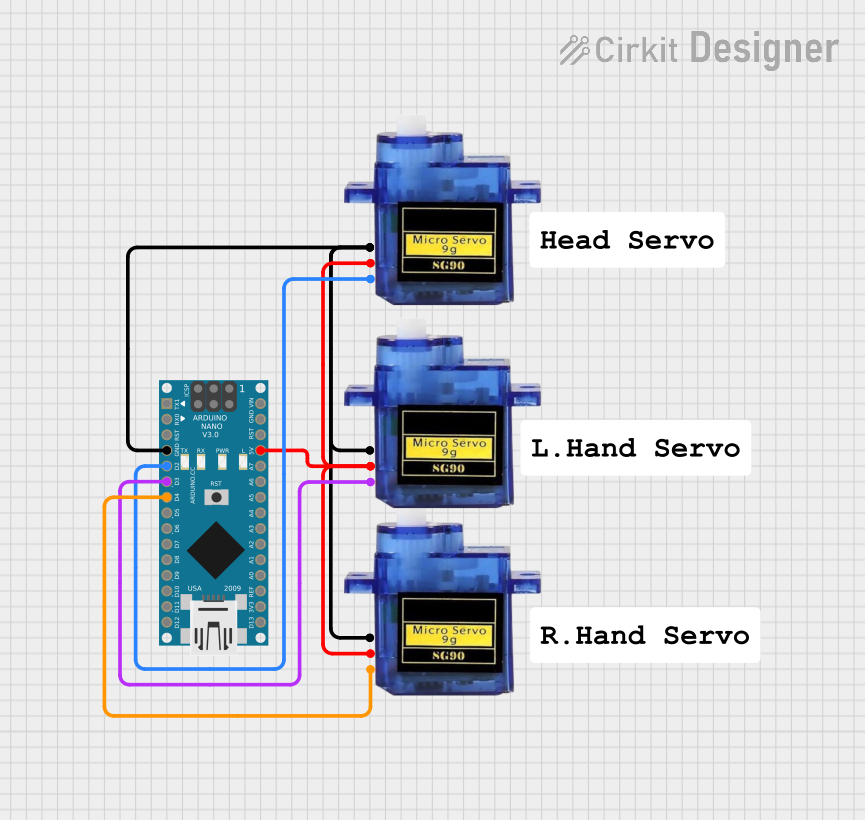

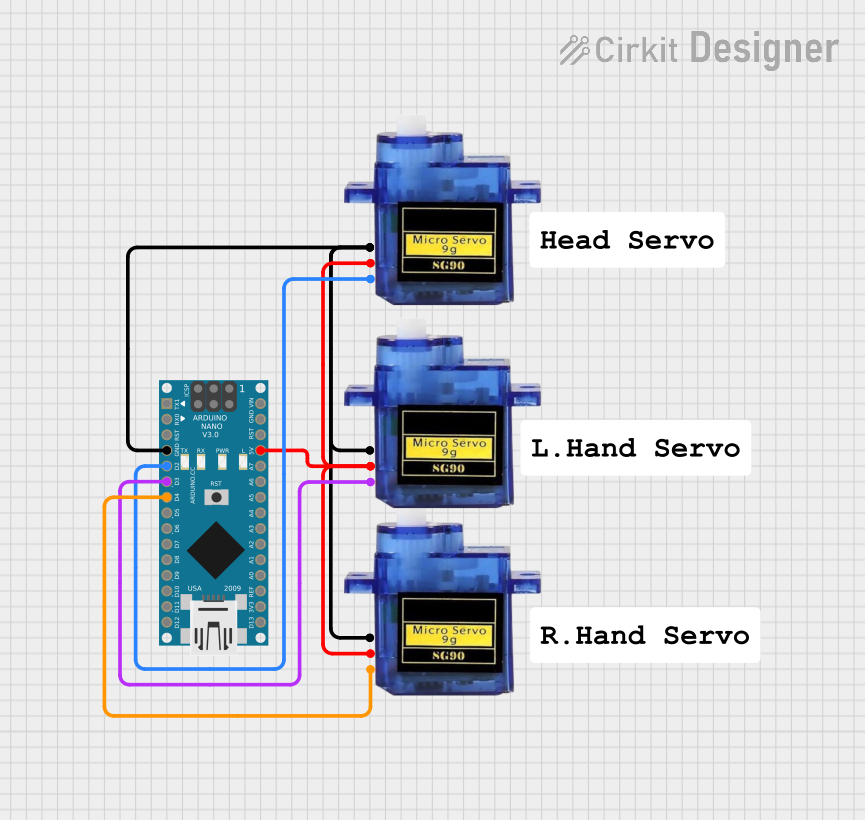

- Robotics arms and linkages

- Steering mechanisms for RC cars and boats

- Camera pan/tilt systems

- Animatronics

Technical Specifications

Key Technical Details

- Operating Voltage: 4.8V to 6V

- Stall Torque: 1.8 kg-cm at 4.8V, 2.2 kg-cm at 6V

- Operating Speed: 0.12 sec/60° at 4.8V, 0.10 sec/60° at 6V

- Temperature Range: -30°C to +60°C

- Weight: Approximately 9g

- Dimensions: 22.2 x 11.8 x 31 mm (LxWxH)

Pin Configuration and Descriptions

| Pin Number | Color | Description |

|---|---|---|

| 1 | Brown | Ground (GND) |

| 2 | Red | Power Supply (VCC) |

| 3 | Orange | Control Signal (PWM) |

Usage Instructions

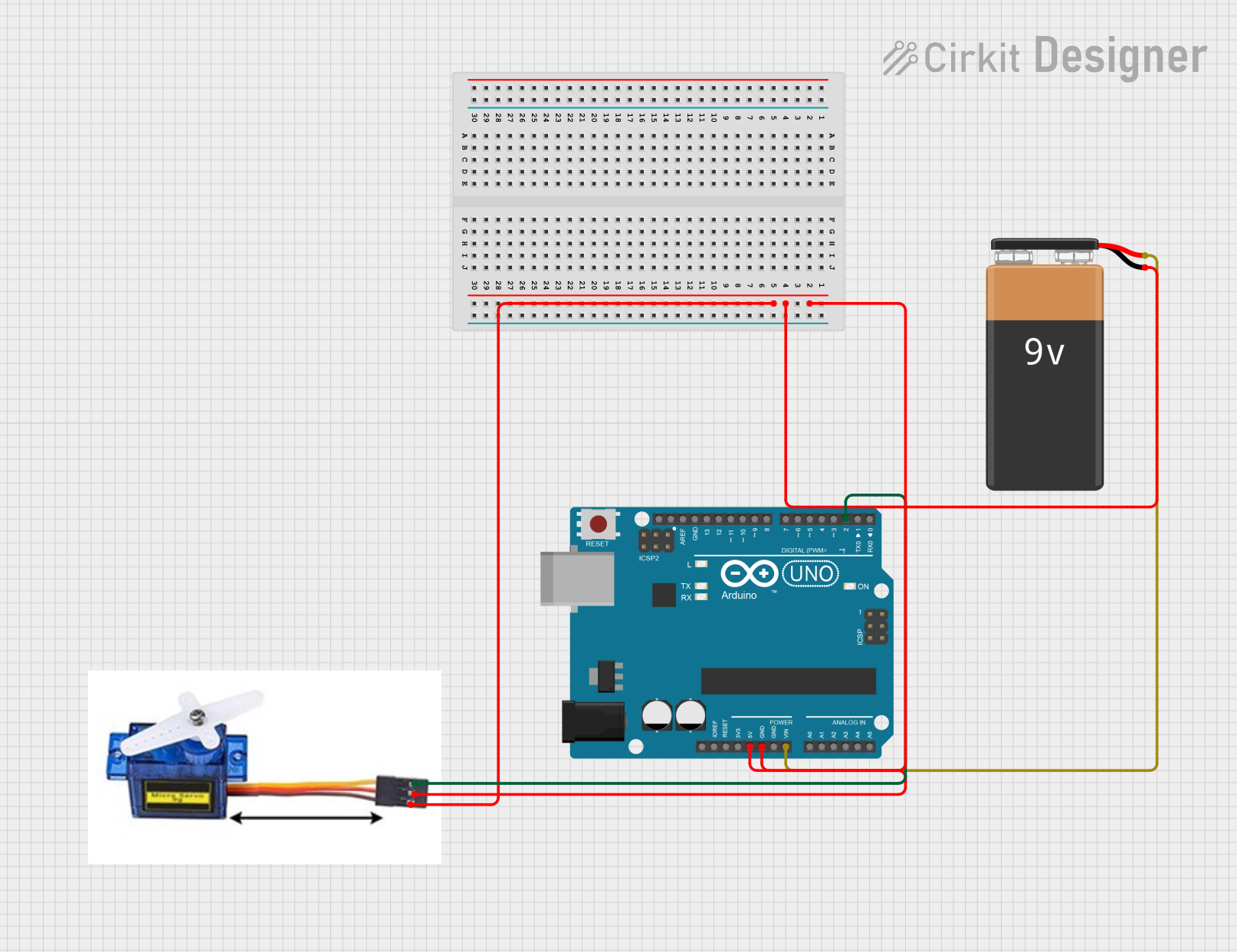

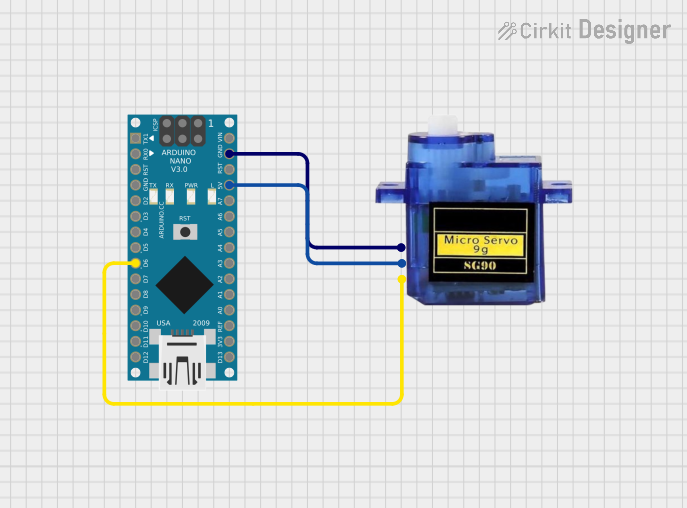

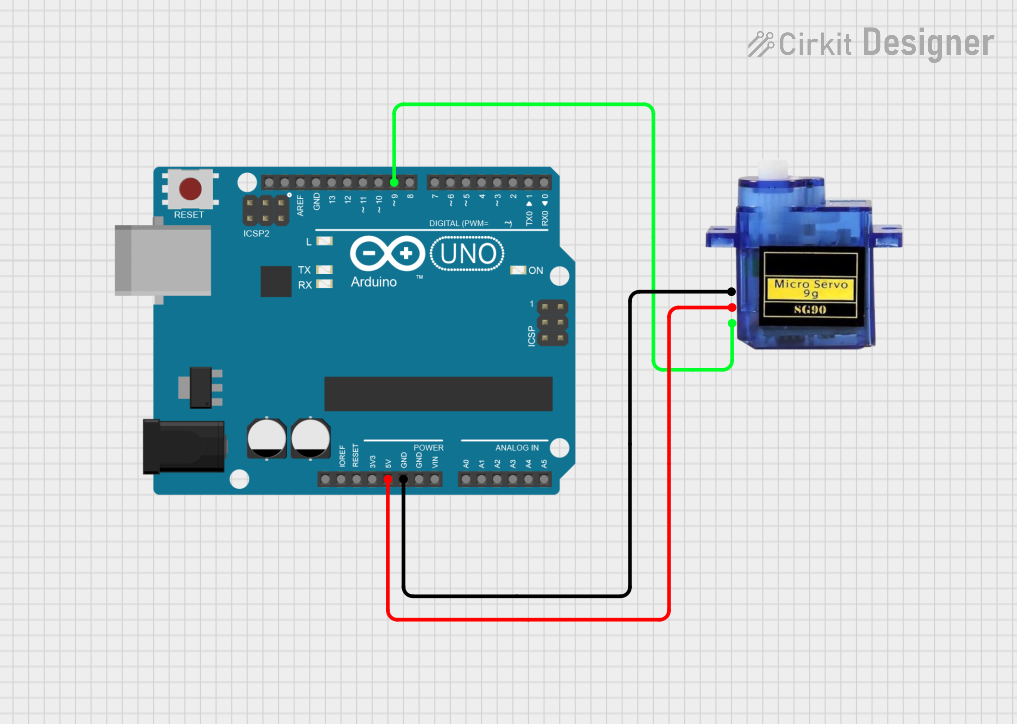

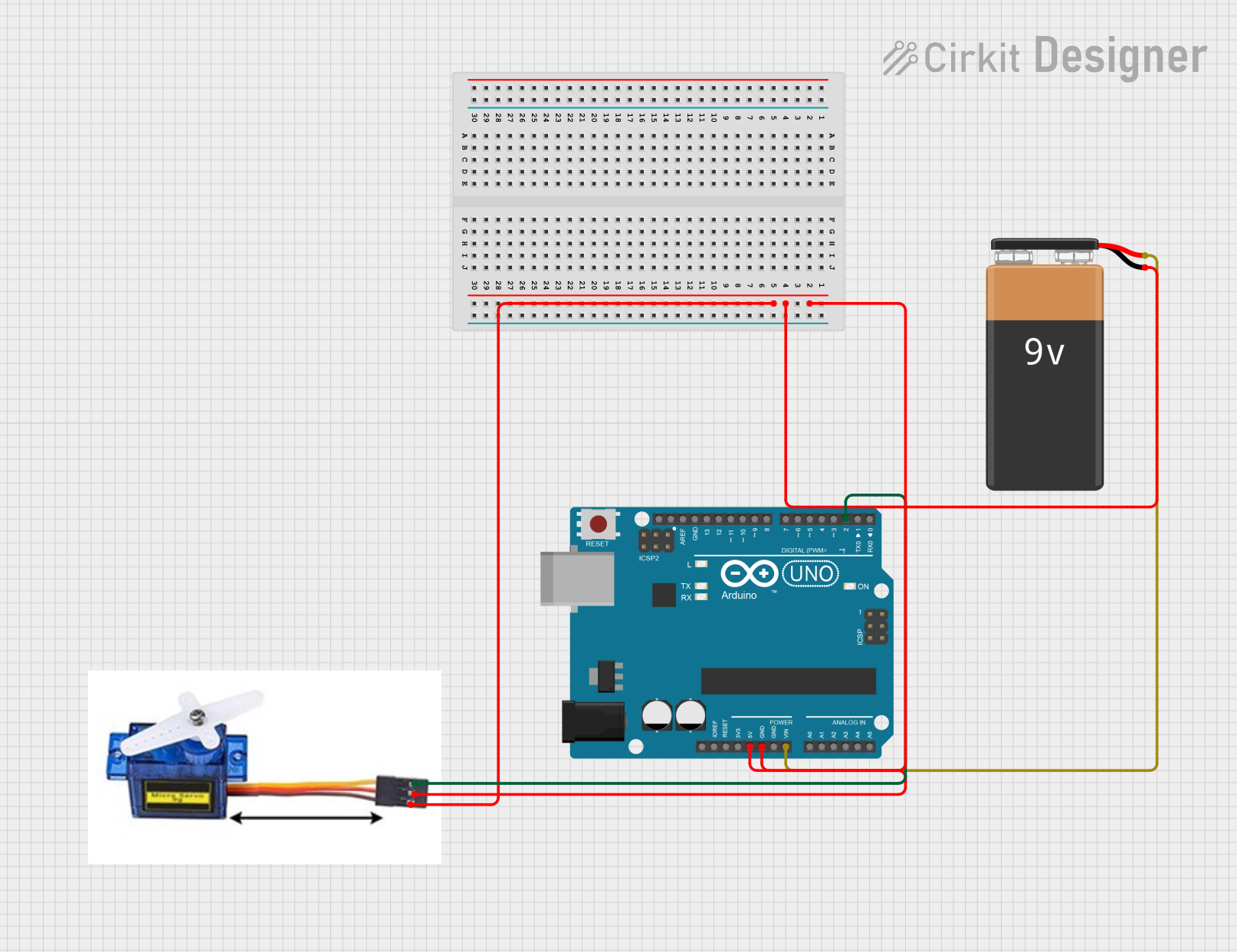

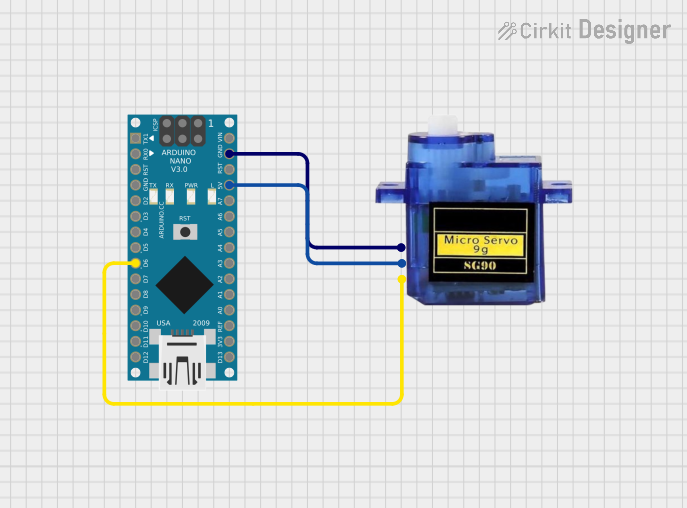

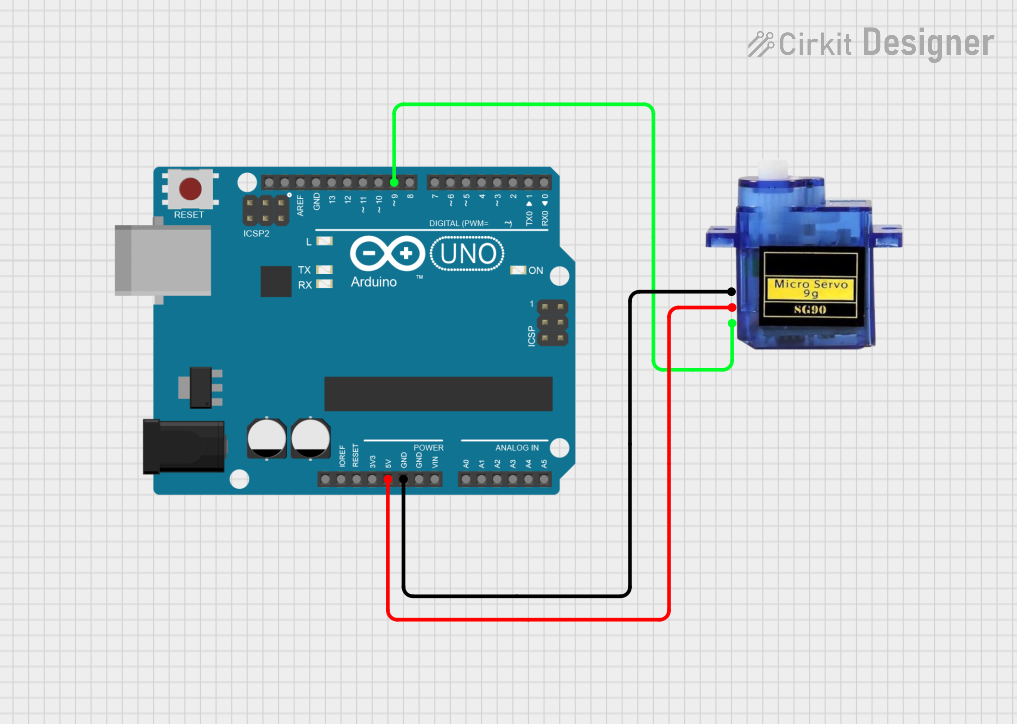

Interfacing with Arduino UNO

Power Connections:

- Connect the brown wire of the servo to one of the GND pins on the Arduino.

- Connect the red wire to the 5V output pin on the Arduino.

Signal Connection:

- Connect the orange wire to a digital pin on the Arduino capable of PWM (e.g., pin 9).

Programming the Servo:

- Use the

Servolibrary included with the Arduino IDE to control the servo motor.

- Use the

Example Code

#include <Servo.h>

Servo myservo; // Create servo object to control the Servo Motor 9G

void setup() {

myservo.attach(9); // Attaches the servo on pin 9 to the servo object

}

void loop() {

myservo.write(90); // Sets the servo position to 90°

delay(1000); // Wait for 1 second

myservo.write(0); // Sets the servo position to 0°

delay(1000); // Wait for 1 second

}

Important Considerations and Best Practices

- Do not exceed the recommended voltage as it may damage the servo.

- Ensure that the power supply can deliver sufficient current for the servo's operation.

- Avoid mechanical blockage or excessive load on the servo's shaft to prevent damage.

- Use a decoupling capacitor (e.g., 100 µF) across the power lines close to the servo to reduce electrical noise.

Troubleshooting and FAQs

Common Issues

- Servo not responding: Check connections, ensure proper power supply, and verify that the control signal is correctly programmed.

- Erratic movements: This may be due to electrical noise. Use a decoupling capacitor and keep power and signal wires away from high-current cables.

- Insufficient torque: Ensure the servo is not overloaded and that the power supply is adequate.

FAQs

Q: Can I control the Servo Motor 9G with a battery? A: Yes, as long as the battery voltage is within the operating range of 4.8V to 6V.

Q: How can I reverse the direction of the servo?

A: You can reverse the direction by modifying the control signal in software, using myservo.write(180 - angle); where angle is the desired position.

Q: What is the maximum angle the Servo Motor 9G can rotate? A: The servo typically has a range of motion of approximately 180 degrees.

Q: Can I use the Servo Motor 9G for continuous rotation? A: No, the Servo Motor 9G is designed for precise positioning, not continuous rotation. You would need a modified or a different type of servo for continuous rotation.

For further assistance, consult the community forums or contact the manufacturer's support.