How to Use Force Sensing Resistor: Examples, Pinouts, and Specs

Design with Force Sensing Resistor in Cirkit Designer

Design with Force Sensing Resistor in Cirkit DesignerIntroduction

A Force Sensing Resistor (FSR) is a passive component that exhibits a decrease in resistance when pressure or force is applied to its surface. It is constructed from a conductive polymer that changes resistance in a predictable manner following the application of force. FSRs are widely used in applications requiring force feedback, such as touch-sensitive interfaces, robotics, musical instruments, and a variety of pressure-sensing mechanisms.

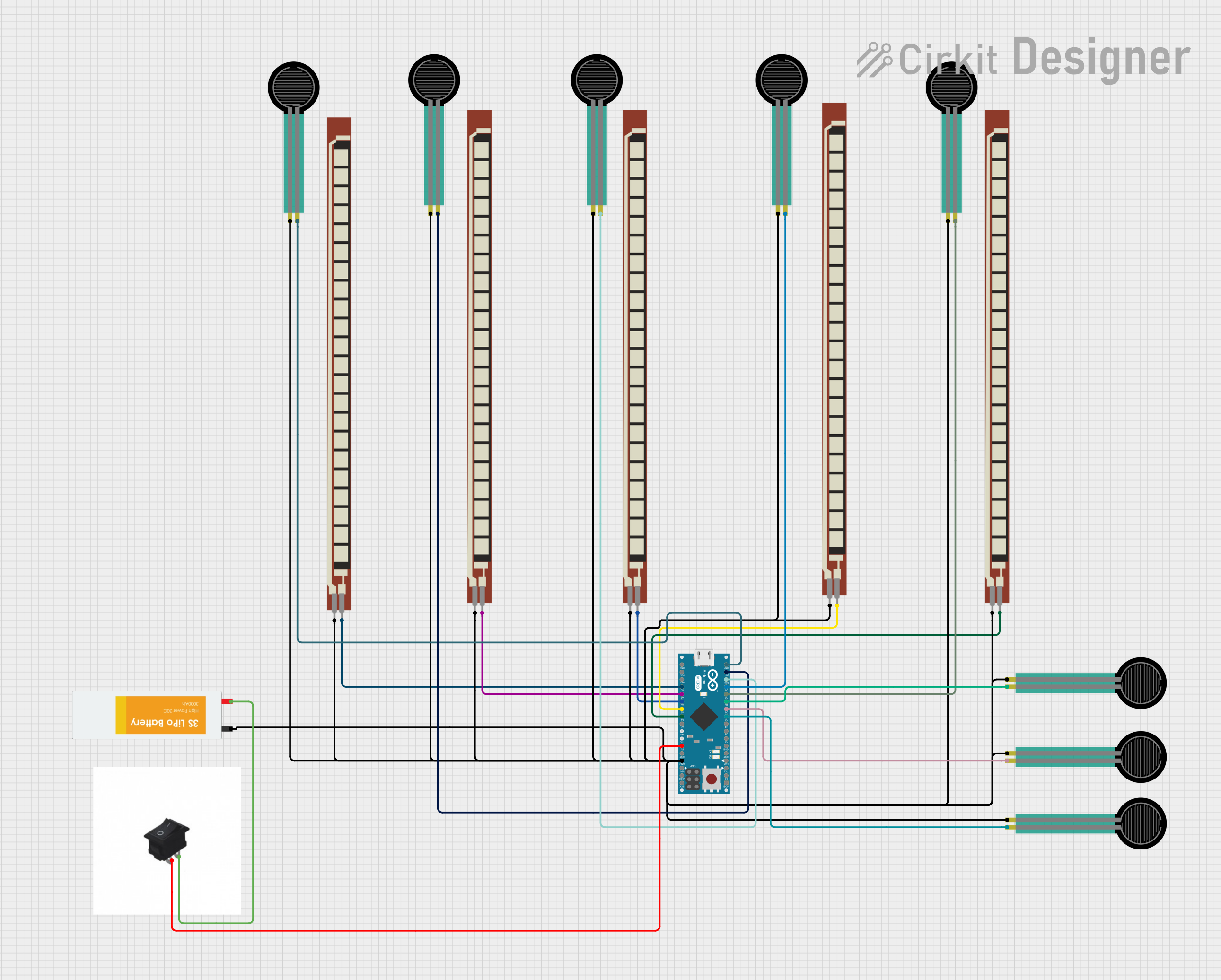

Explore Projects Built with Force Sensing Resistor

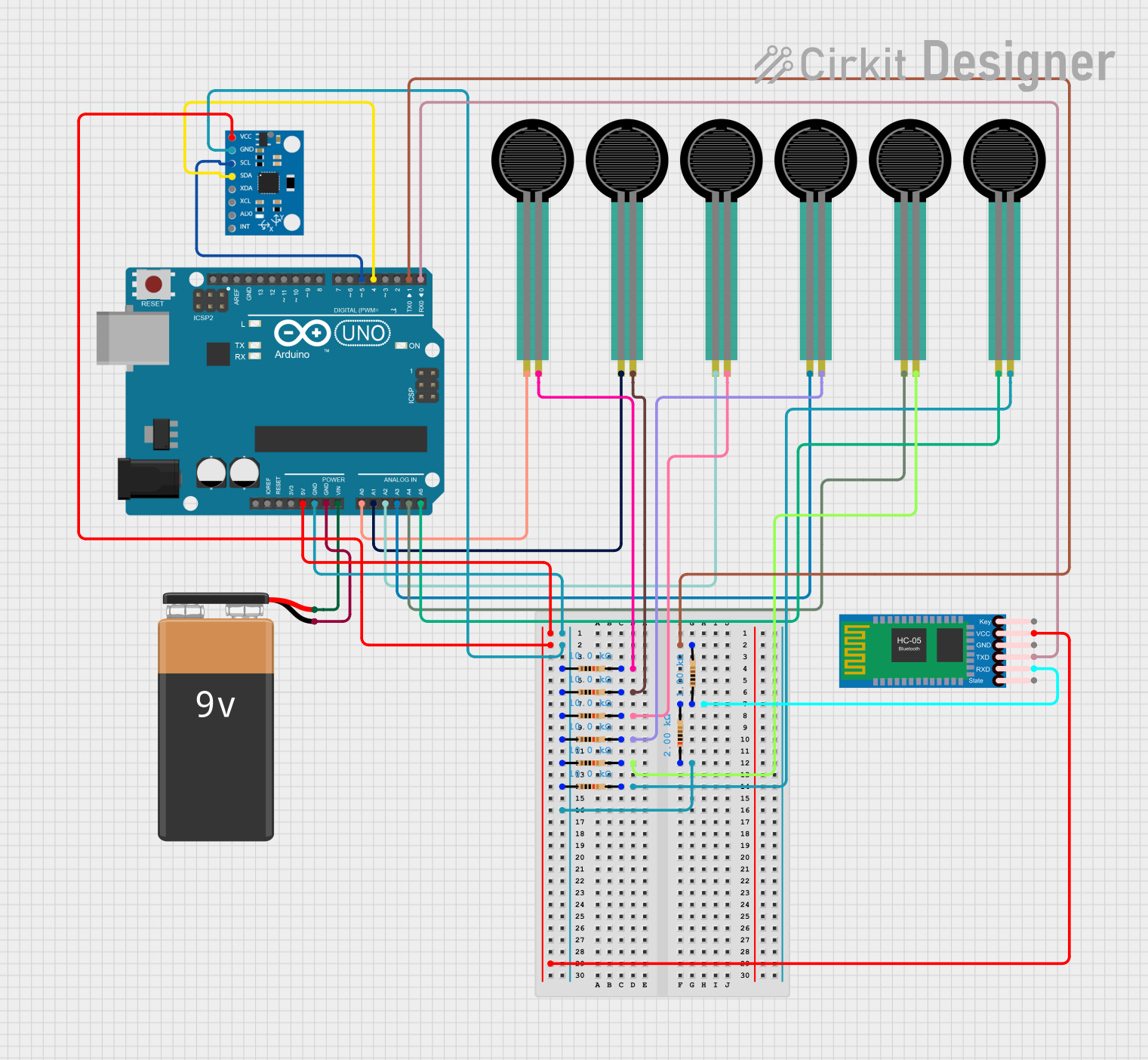

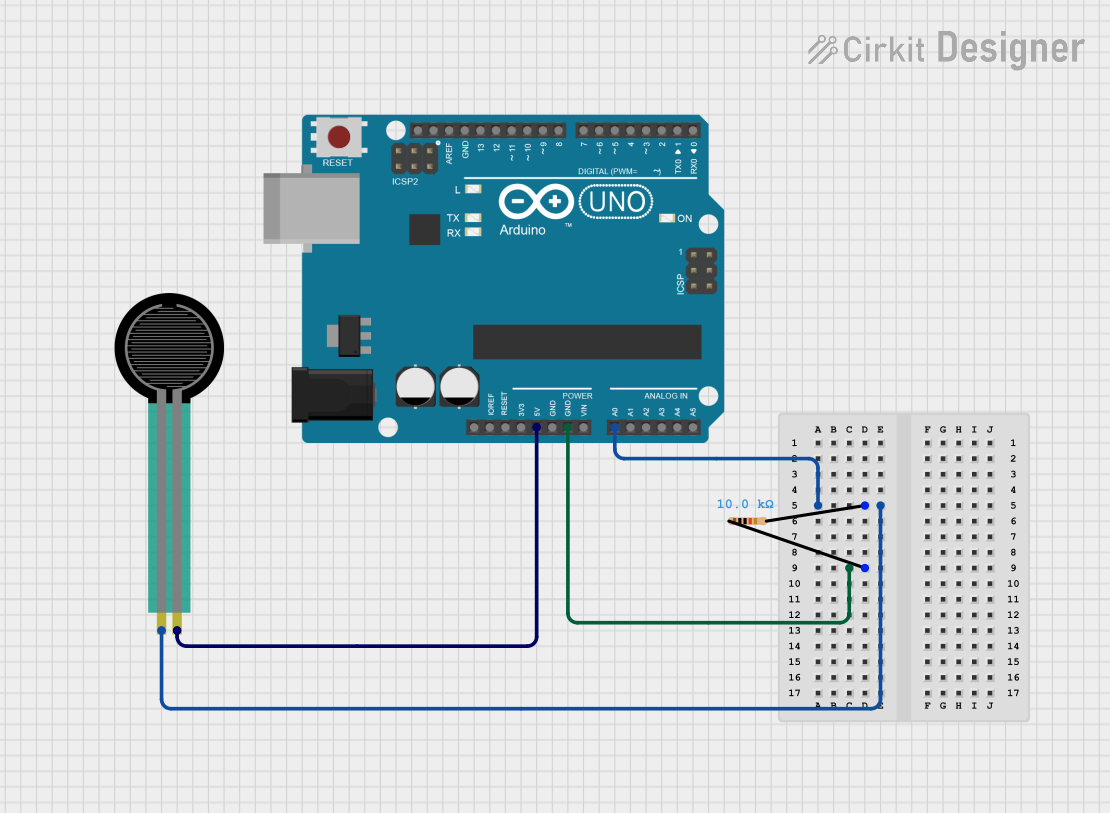

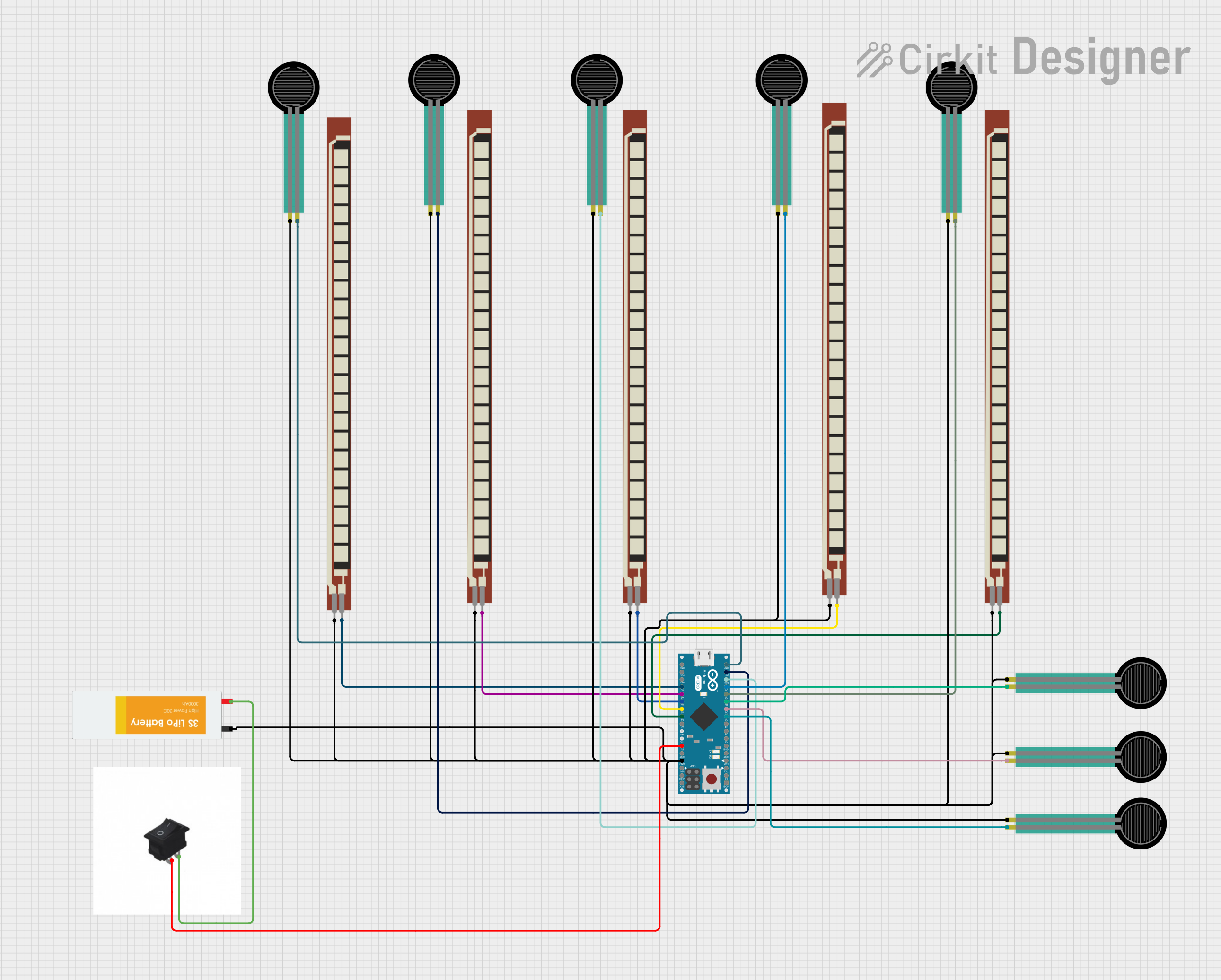

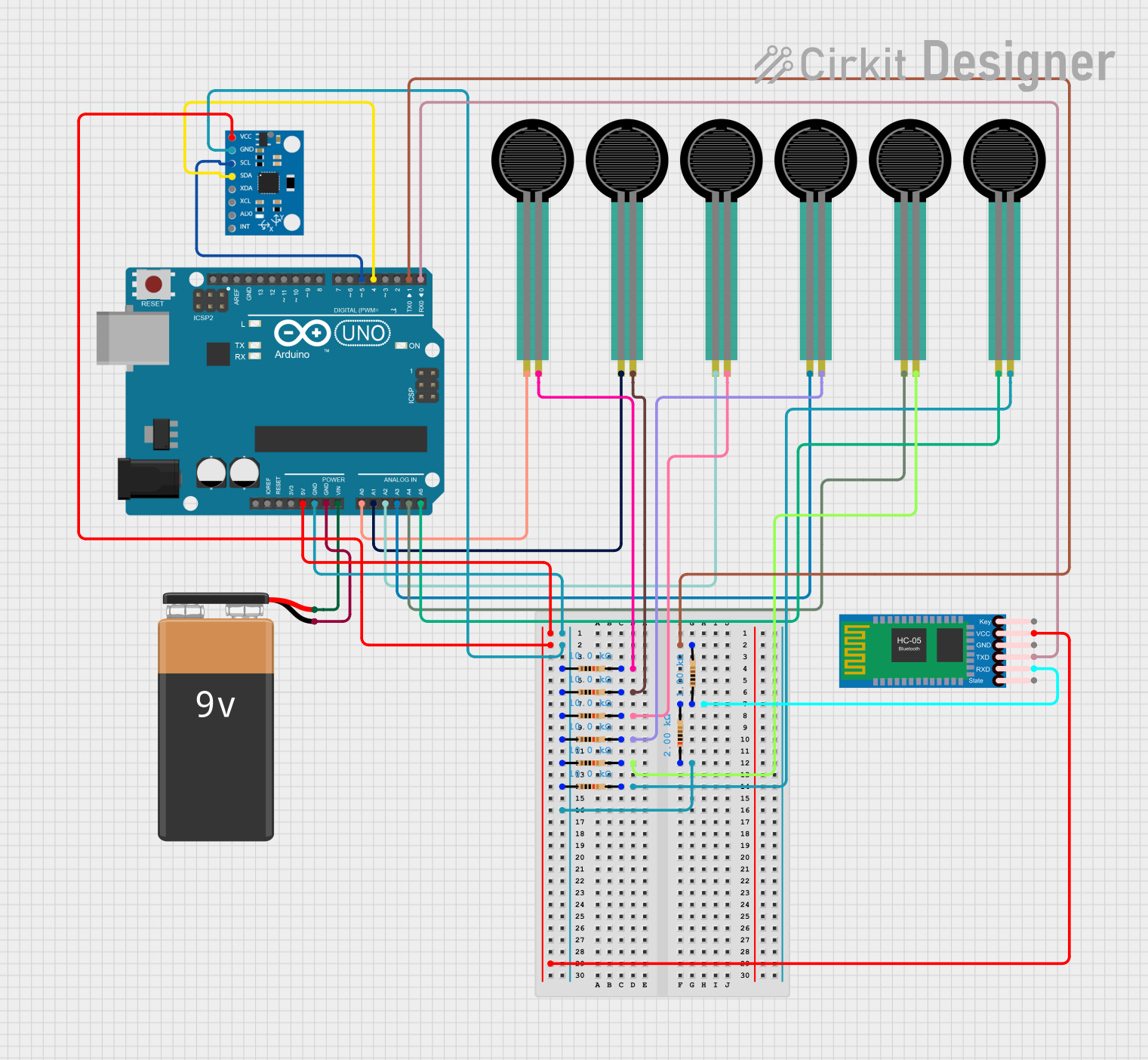

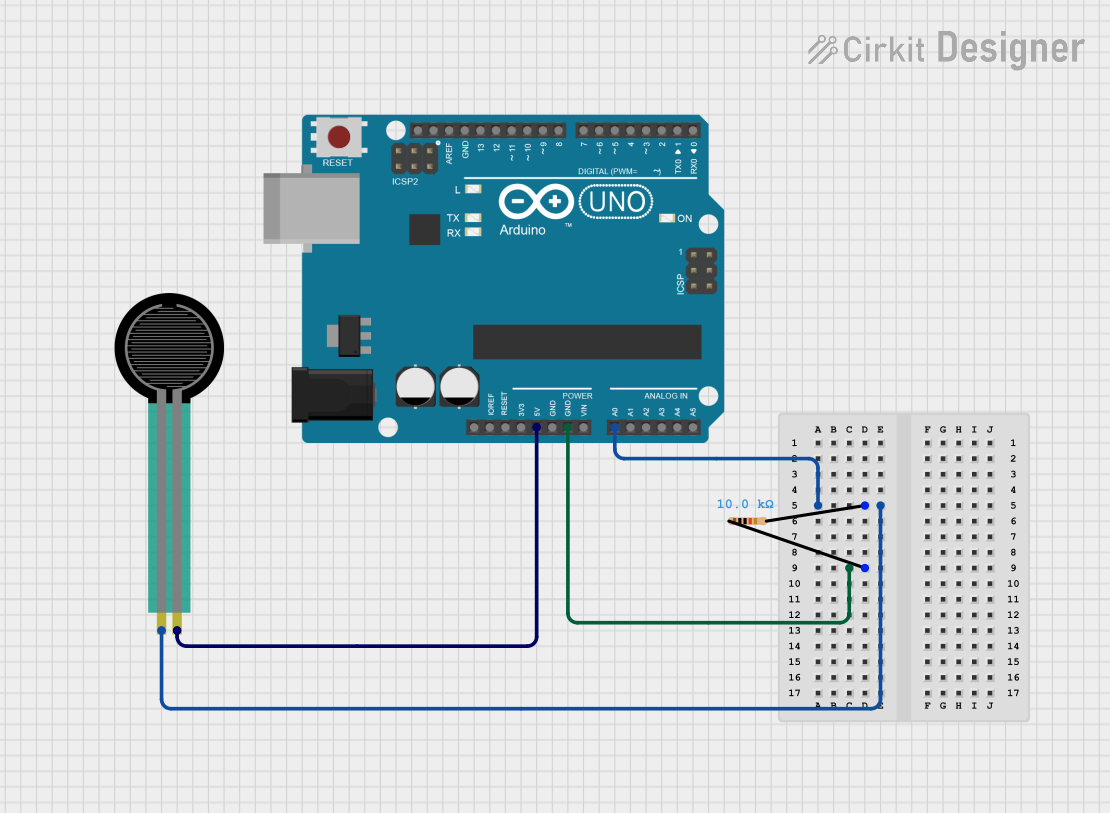

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Force Sensing Resistor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Human touch input for interactive electronics

- Pressure-sensitive controls and buttons

- Weight sensing

- Medical devices such as blood pressure monitors

- Musical instruments like electronic drums

- Robotics for grip and touch sensing

Technical Specifications

Key Technical Details

- Resistance Range: Typically from a few kilo-ohms to mega-ohms with no pressure, down to a few hundred ohms with maximum pressure.

- Force Sensitivity Range: Usually from a few grams to several kilograms.

- Operating Temperature: Varies with the model, often from -30°C to +70°C.

- Response Time: Typically less than 5 milliseconds.

- Durability: Rated for up to 1 million actuations, depending on the model and usage conditions.

Pin Configuration and Descriptions

FSRs typically have two terminals. Below is a table describing the pin configuration:

| Pin Number | Description |

|---|---|

| 1 | Active Sensing Area |

| 2 | Active Sensing Area |

Note: The two terminals are interchangeable as the FSR is non-polarized.

Usage Instructions

How to Use the Component in a Circuit

- Connect the FSR: Attach one terminal of the FSR to an analog input pin on a microcontroller, such as an Arduino UNO. Connect the other terminal to ground.

- Voltage Divider: To read the varying resistance, set up a voltage divider by connecting a fixed resistor (10kΩ is commonly used) from the analog input pin to the supply voltage (5V for Arduino UNO).

- Analog Read: Use the microcontroller's ADC (Analog-to-Digital Converter) to read the voltage across the fixed resistor, which is inversely proportional to the force applied to the FSR.

Important Considerations and Best Practices

- Calibration: Since FSRs can vary in their response, it is important to calibrate each sensor for the specific application.

- Overforce Protection: Avoid applying force that exceeds the sensor's maximum rating to prevent damage.

- Mounting: Ensure the FSR is mounted flat and is not subject to bending or twisting forces.

- Temperature Effects: Be aware that the sensor's resistance can change with temperature, which may require compensation in the software.

Example Arduino Code

// Define the FSR pin and the fixed resistor value

const int fsrPin = A0; // FSR is connected to analog pin A0

const int fixedResistorValue = 10000; // 10kΩ fixed resistor

void setup() {

Serial.begin(9600); // Start serial communication at 9600 baud

}

void loop() {

int fsrReading = analogRead(fsrPin); // Read the voltage divider value

// Calculate the voltage at the FSR

float voltage = fsrReading * (5.0 / 1023.0);

// Calculate the resistance of the FSR

float fsrResistance = (5.0 - voltage) * fixedResistorValue / voltage;

// Print the resistance value to the Serial Monitor

Serial.println("FSR Resistance: " + String(fsrResistance) + " ohms");

delay(500); // Wait half a second before reading again

}

Note: The above code assumes a 5V system voltage. Adjust the voltage in the code if using a different system voltage.

Troubleshooting and FAQs

Common Issues

- Inaccurate Readings: Ensure that the FSR is properly connected and that there are no loose connections. Calibrate the sensor for your specific application.

- No Change in Resistance: Check for any damage to the FSR or for a disconnected terminal.

- Drifting Values: Temperature changes can affect the resistance. Implement software compensation if necessary.

Solutions and Tips for Troubleshooting

- Calibration: Use known weights to create a calibration curve for the FSR.

- Connection Check: Verify all connections are secure and that the voltage divider is set up correctly.

- Code Verification: Ensure that the code is correctly reading the analog input and that the calculations for resistance are accurate.

FAQs

Q: Can I use an FSR to measure exact weights? A: FSRs are not typically used for precise weight measurements due to their non-linear response and variability. They are better suited for relative pressure sensing.

Q: How do I increase the sensitivity of the FSR? A: Sensitivity can be adjusted by changing the value of the fixed resistor in the voltage divider circuit. A higher value will increase sensitivity.

Q: What is the lifespan of an FSR? A: The lifespan can vary based on the force applied and the frequency of use, but they are generally rated for up to 1 million actuations.

Q: Can FSRs be used in harsh environments? A: FSRs vary in their environmental tolerance. Check the manufacturer's specifications for temperature, humidity, and mechanical stress limits.