How to Use PLC OMRON: Examples, Pinouts, and Specs

Design with PLC OMRON in Cirkit Designer

Design with PLC OMRON in Cirkit DesignerIntroduction

The OMRON CP1L is a compact and versatile Programmable Logic Controller (PLC) designed for automating industrial processes. It offers robust programming capabilities, real-time control, and extensive input/output (I/O) options, making it suitable for a wide range of applications. The CP1L is ideal for small to medium-sized automation tasks, providing high performance in a compact form factor.

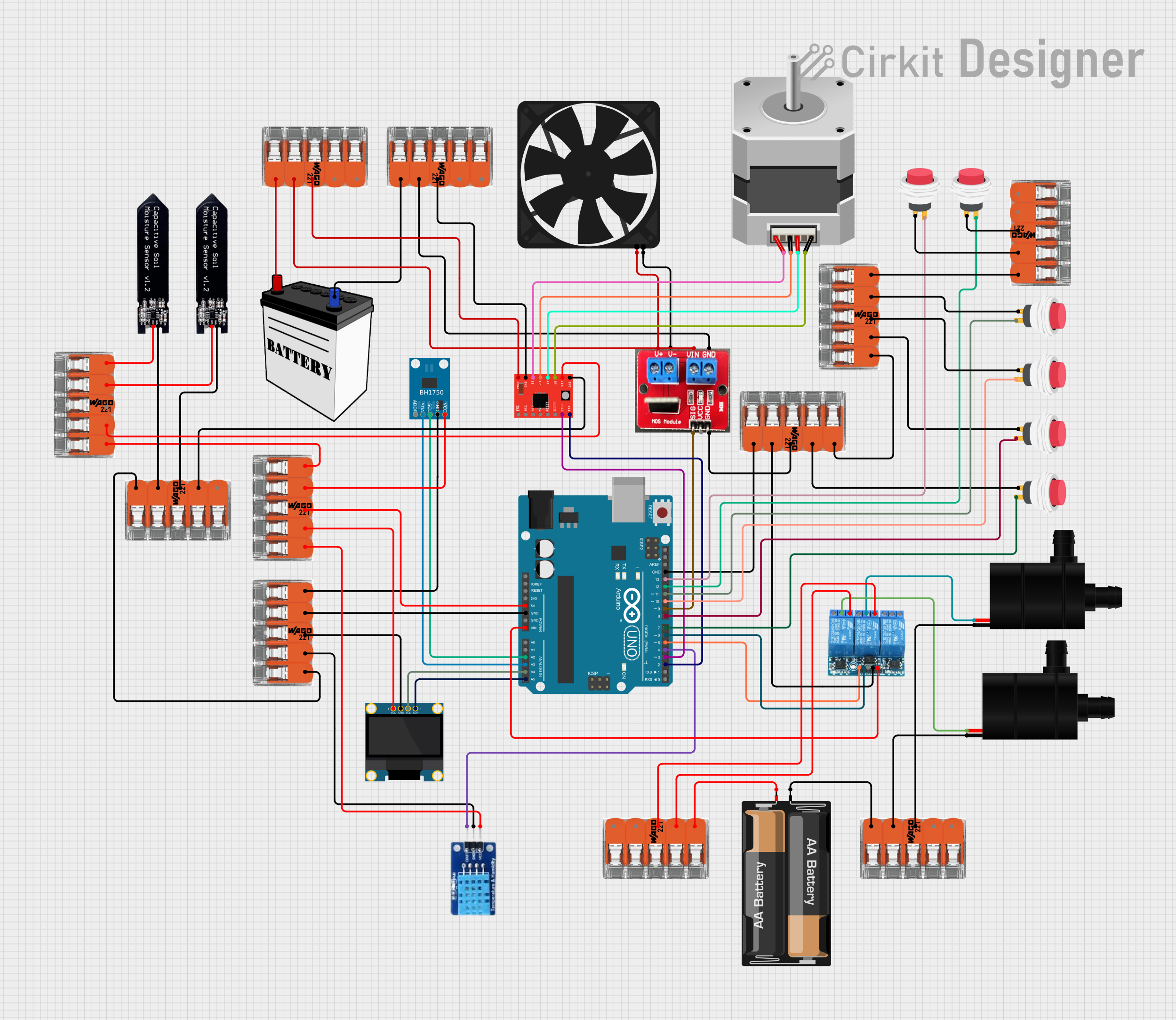

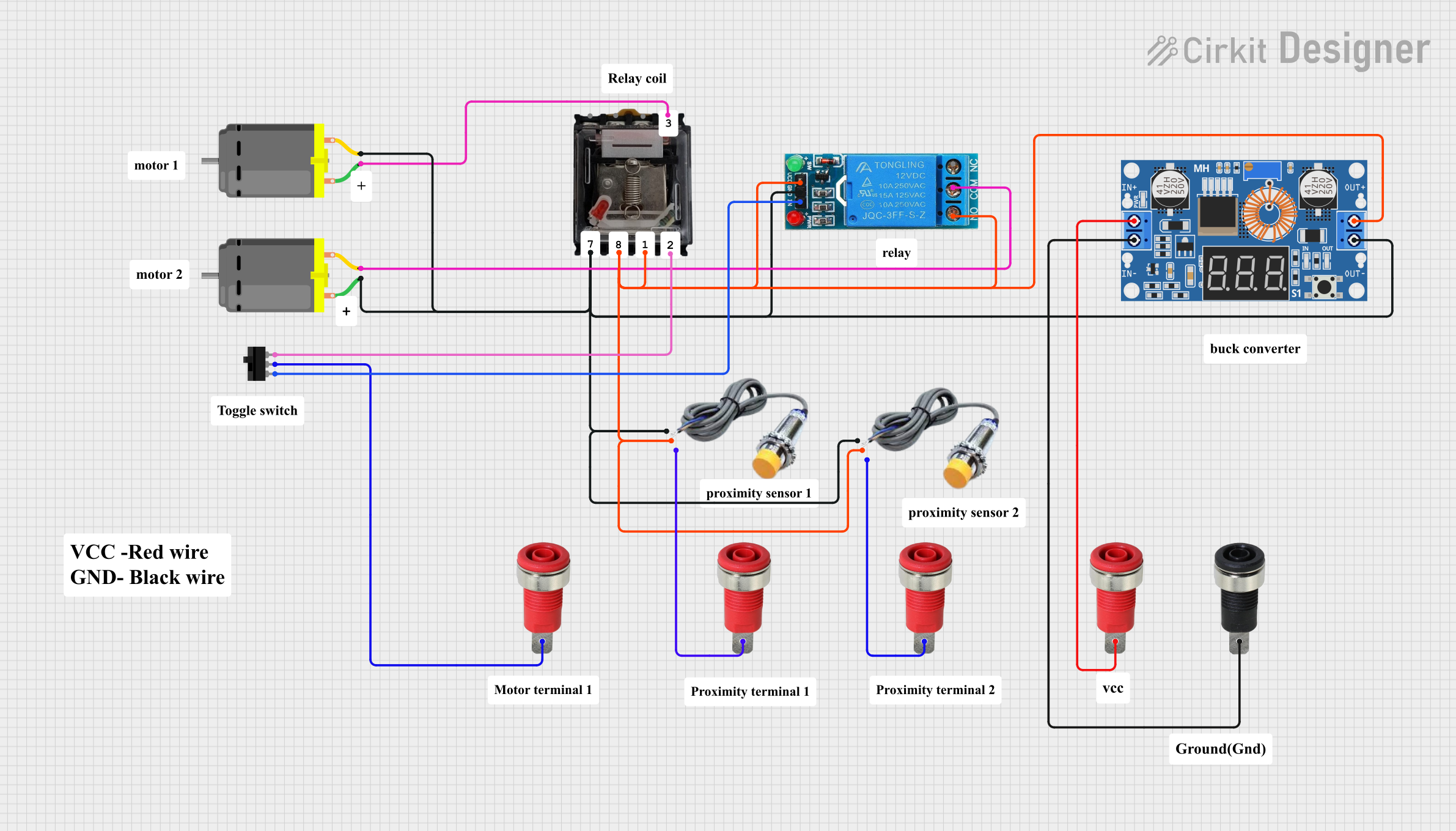

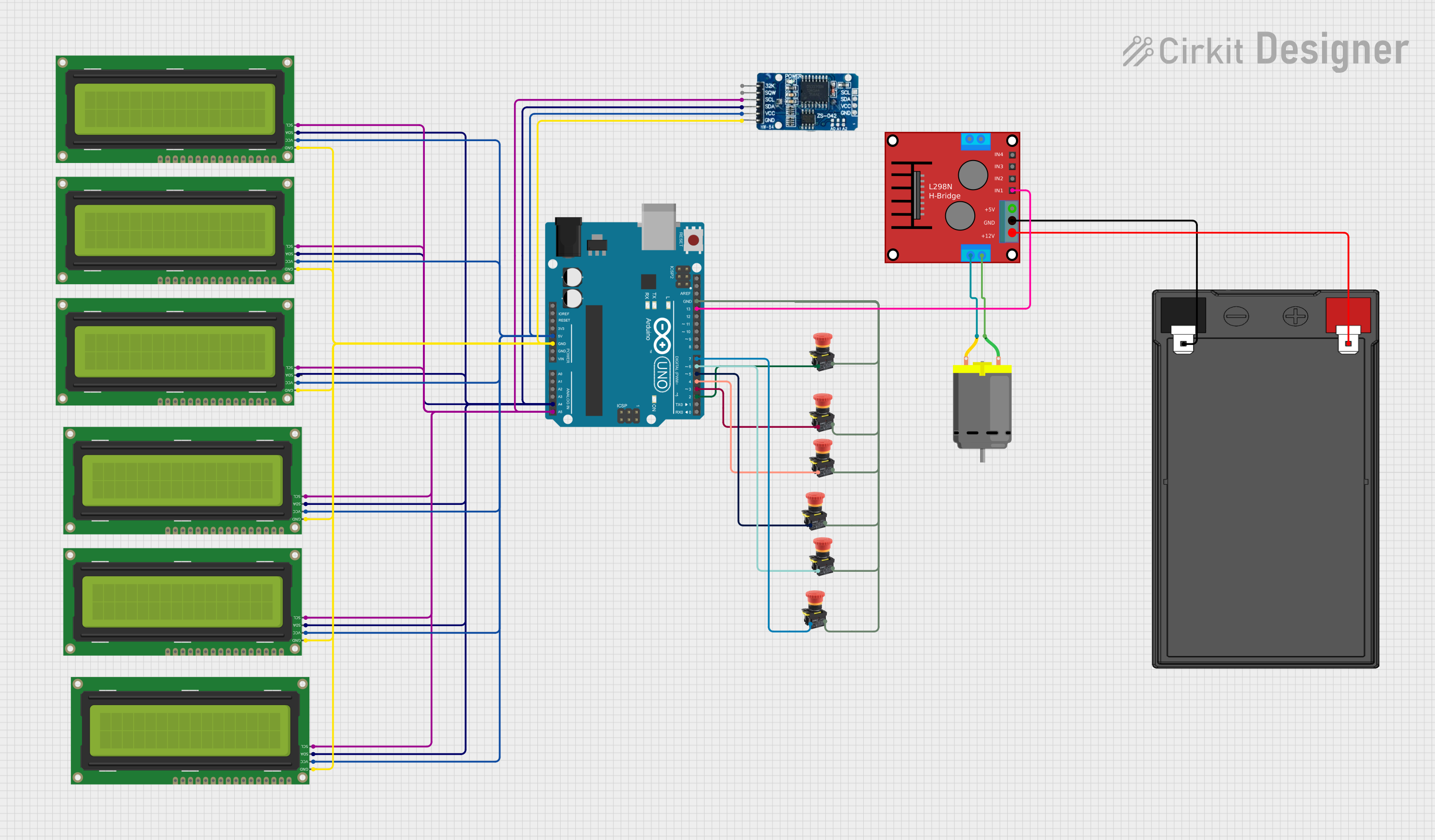

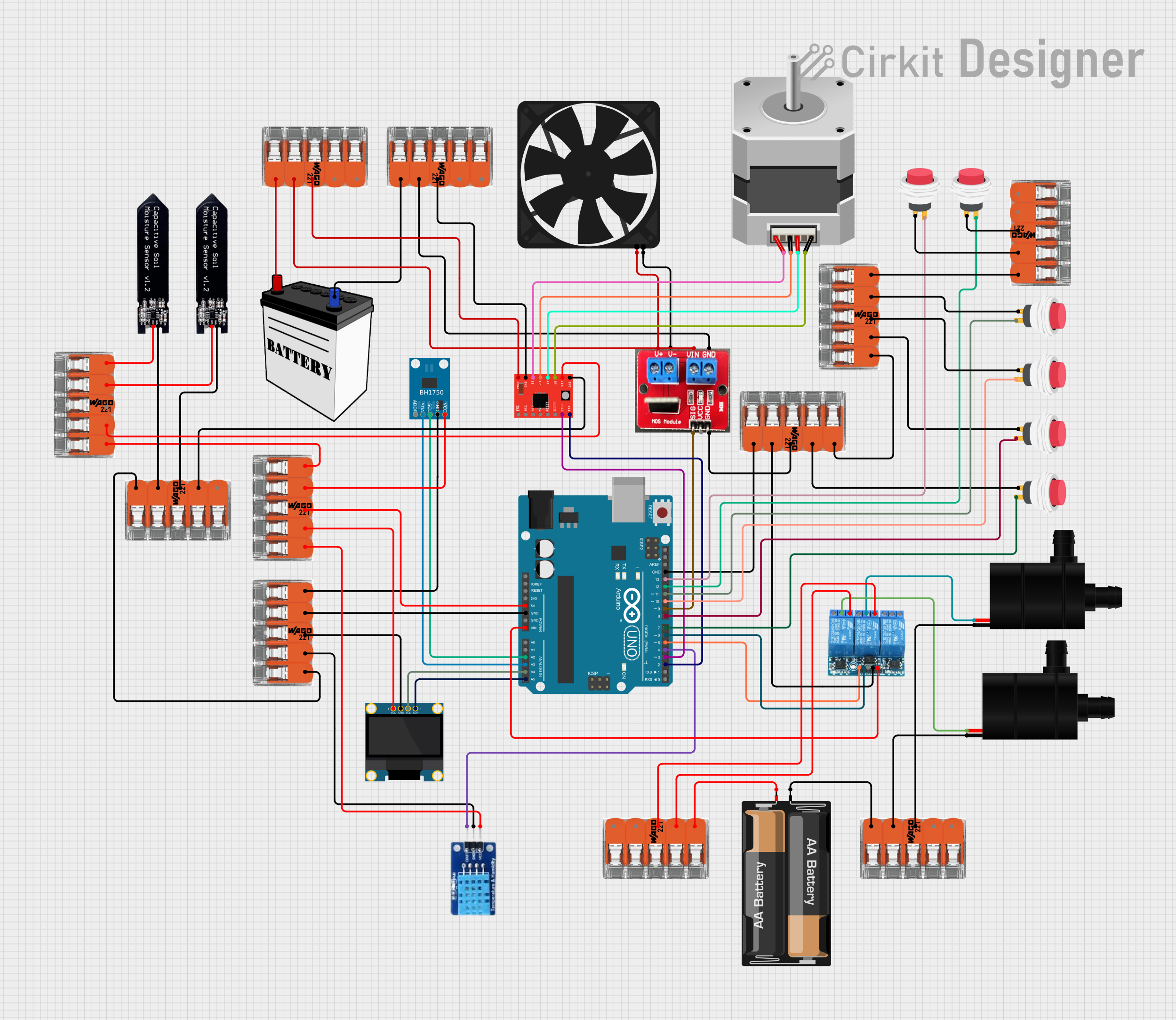

Explore Projects Built with PLC OMRON

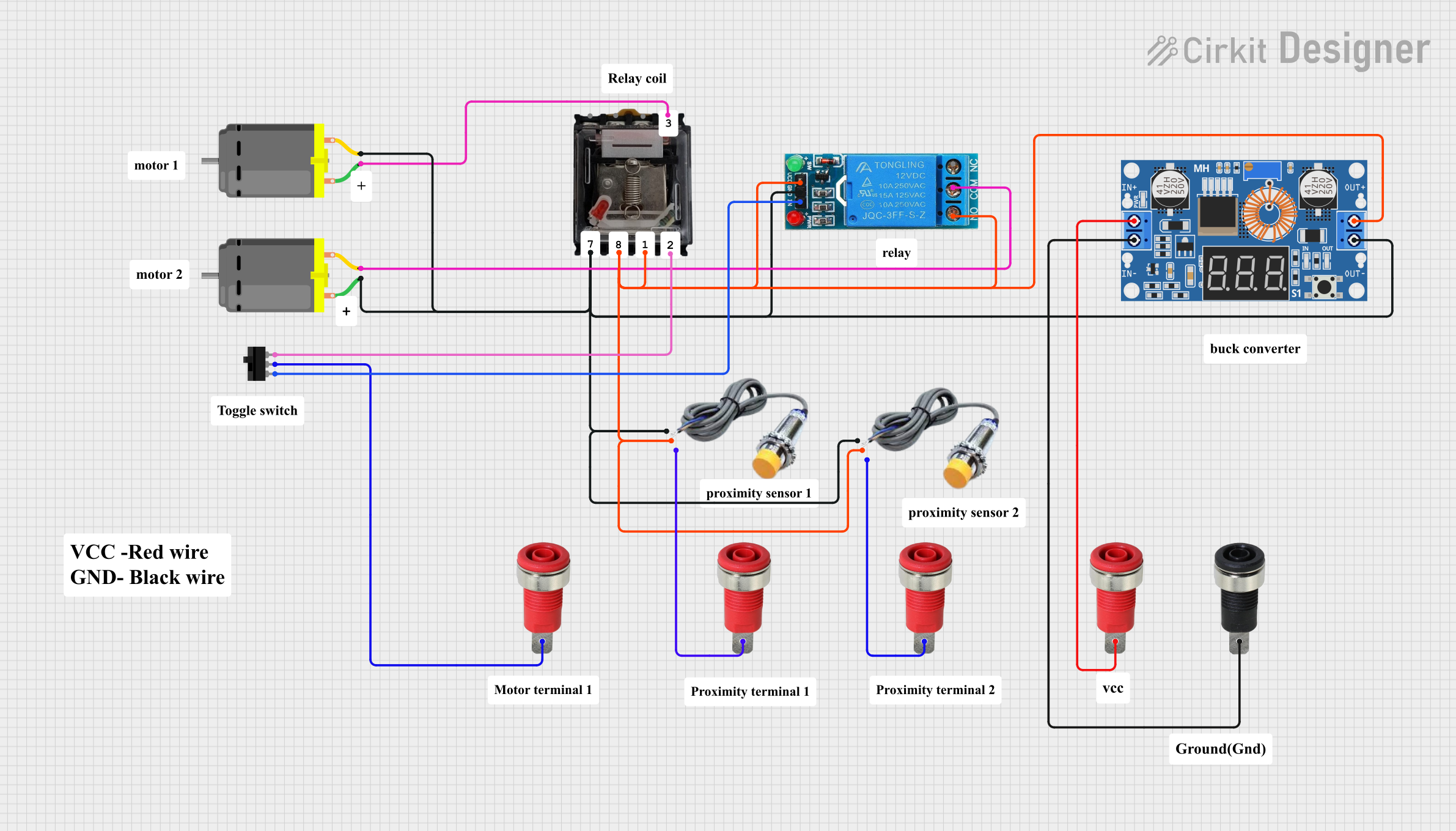

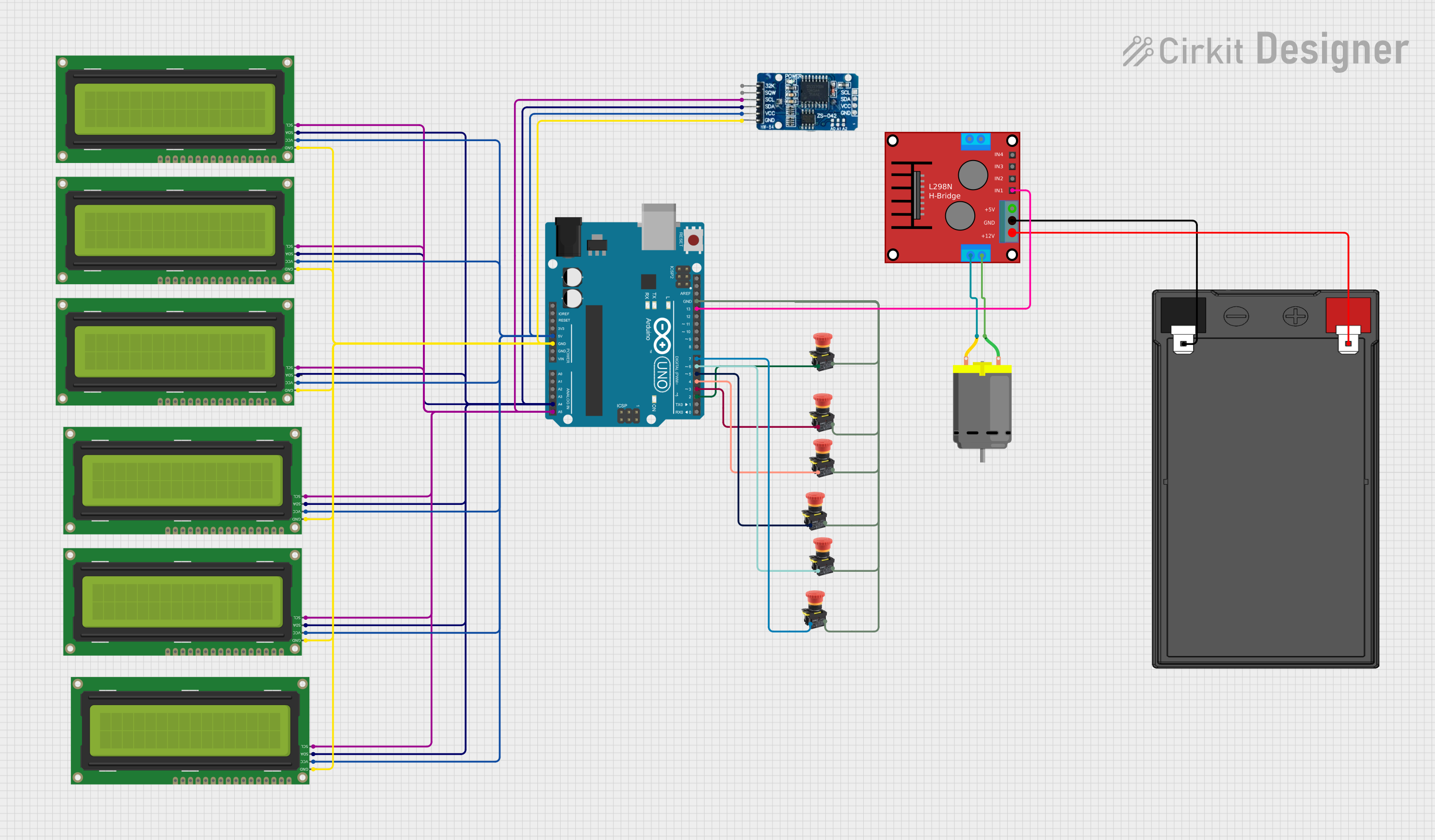

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with PLC OMRON

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial automation and process control

- Conveyor belt systems

- Packaging machinery

- HVAC systems

- Automated assembly lines

- Monitoring and controlling sensors and actuators

Technical Specifications

The OMRON CP1L PLC is available in various models with different I/O configurations. Below are the key technical specifications:

General Specifications

| Parameter | Value |

|---|---|

| Manufacturer | OMRON |

| Part Number | CP1L |

| Power Supply Voltage | 24 VDC or 100-240 VAC (model-dependent) |

| Program Capacity | 5 ksteps |

| Data Memory | 10 kwords |

| Communication Ports | USB, RS-232C, RS-485, Ethernet (optional) |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -20°C to 75°C |

| Dimensions | Varies by model (e.g., 90x85x70 mm) |

I/O Specifications

| Model Variant | Digital Inputs | Digital Outputs | Analog Inputs | Analog Outputs |

|---|---|---|---|---|

| CP1L-L10 | 6 | 4 | 0 | 0 |

| CP1L-L14 | 8 | 6 | 0 | 0 |

| CP1L-L20 | 12 | 8 | 0 | 0 |

| CP1L-L30 | 18 | 12 | 0 | 0 |

| CP1L-M40 | 24 | 16 | 2 | 1 |

Pin Configuration and Descriptions

The CP1L PLC has multiple terminal blocks for connecting inputs, outputs, and power. Below is an example pin configuration for the CP1L-L10 model:

Digital Input Terminals

| Pin Number | Description | Signal Type |

|---|---|---|

| 1 | Input 0 | Digital Input |

| 2 | Input 1 | Digital Input |

| 3 | Input 2 | Digital Input |

| 4 | Input 3 | Digital Input |

| 5 | Input 4 | Digital Input |

| 6 | Input 5 | Digital Input |

Digital Output Terminals

| Pin Number | Description | Signal Type |

|---|---|---|

| 7 | Output 0 | Digital Output |

| 8 | Output 1 | Digital Output |

| 9 | Output 2 | Digital Output |

| 10 | Output 3 | Digital Output |

Power Terminals

| Pin Number | Description | Signal Type |

|---|---|---|

| 11 | 24V Power Supply | Power Input |

| 12 | Ground (GND) | Power Input |

Usage Instructions

How to Use the CP1L in a Circuit

- Power Supply Connection: Connect a 24 VDC or 100-240 VAC power supply (depending on the model) to the power terminals.

- Input Connections: Wire sensors, switches, or other input devices to the digital input terminals. Ensure the input voltage matches the PLC's specifications.

- Output Connections: Connect actuators, relays, or other output devices to the digital output terminals. Verify the output voltage and current ratings.

- Programming: Use OMRON's CX-Programmer software to write and upload ladder logic programs to the PLC via the USB or RS-232C port.

- Testing: After programming, test the system to ensure proper operation of inputs, outputs, and logic.

Important Considerations and Best Practices

- Power Supply: Use a regulated power supply to avoid voltage fluctuations that could damage the PLC.

- Grounding: Properly ground the PLC to prevent electrical noise and ensure safety.

- I/O Protection: Use external protection devices (e.g., diodes, fuses) to safeguard the PLC's I/O terminals.

- Communication: Configure communication settings (e.g., baud rate, parity) correctly when using RS-232C or RS-485.

- Environment: Install the PLC in a clean, dry, and vibration-free environment to ensure reliable operation.

Example Code for Arduino UNO Communication

The CP1L can communicate with an Arduino UNO via RS-232C or RS-485. Below is an example of Arduino code for sending data to the PLC:

#include <SoftwareSerial.h>

// Define RX and TX pins for SoftwareSerial

SoftwareSerial plcSerial(10, 11); // RX = pin 10, TX = pin 11

void setup() {

// Initialize serial communication with the PLC

plcSerial.begin(9600); // Set baud rate to 9600 (match PLC settings)

Serial.begin(9600); // For debugging via Serial Monitor

Serial.println("Arduino to OMRON CP1L Communication Initialized");

}

void loop() {

// Example: Send a command to the PLC

String command = "WRITE 100.00 ON"; // Replace with actual PLC command

plcSerial.println(command); // Send command to PLC

// Check for response from the PLC

if (plcSerial.available()) {

String response = plcSerial.readString();

Serial.println("PLC Response: " + response); // Print response to Serial Monitor

}

delay(1000); // Wait 1 second before sending the next command

}

Troubleshooting and FAQs

Common Issues and Solutions

PLC Not Powering On

- Cause: Incorrect power supply voltage or loose connections.

- Solution: Verify the power supply voltage and ensure all connections are secure.

Inputs Not Responding

- Cause: Faulty wiring or incompatible input devices.

- Solution: Check the wiring and ensure the input devices meet the PLC's specifications.

Outputs Not Activating

- Cause: Overloaded output terminals or incorrect programming.

- Solution: Verify the output load and review the ladder logic program.

Communication Failure

- Cause: Incorrect communication settings or damaged cables.

- Solution: Check the baud rate, parity, and cable connections. Replace damaged cables if necessary.

FAQs

Q: Can the CP1L be expanded with additional I/O modules?

A: Yes, the CP1L supports expansion modules for additional I/O, analog inputs/outputs, and communication options.

Q: What software is used to program the CP1L?

A: The CP1L is programmed using OMRON's CX-Programmer software, which is part of the CX-One suite.

Q: Is the CP1L compatible with Ethernet communication?

A: Yes, Ethernet communication is available with an optional Ethernet module.

Q: Can the CP1L be used in harsh environments?

A: The CP1L is designed for industrial use but should be installed in a clean, dry, and vibration-free environment for optimal performance.