How to Use Volage Regulator - 3.3V 3.6A Step Down : Examples, Pinouts, and Specs

Design with Volage Regulator - 3.3V 3.6A Step Down in Cirkit Designer

Design with Volage Regulator - 3.3V 3.6A Step Down in Cirkit DesignerIntroduction

The Pololu D36V28F3 is a high-performance step-down voltage regulator designed to convert a higher input voltage into a stable 3.3V output. It is capable of delivering up to 3.6A of current, making it ideal for powering sensitive electronic components that require a consistent and reliable 3.3V supply. This regulator is compact, efficient, and versatile, making it suitable for a wide range of applications.

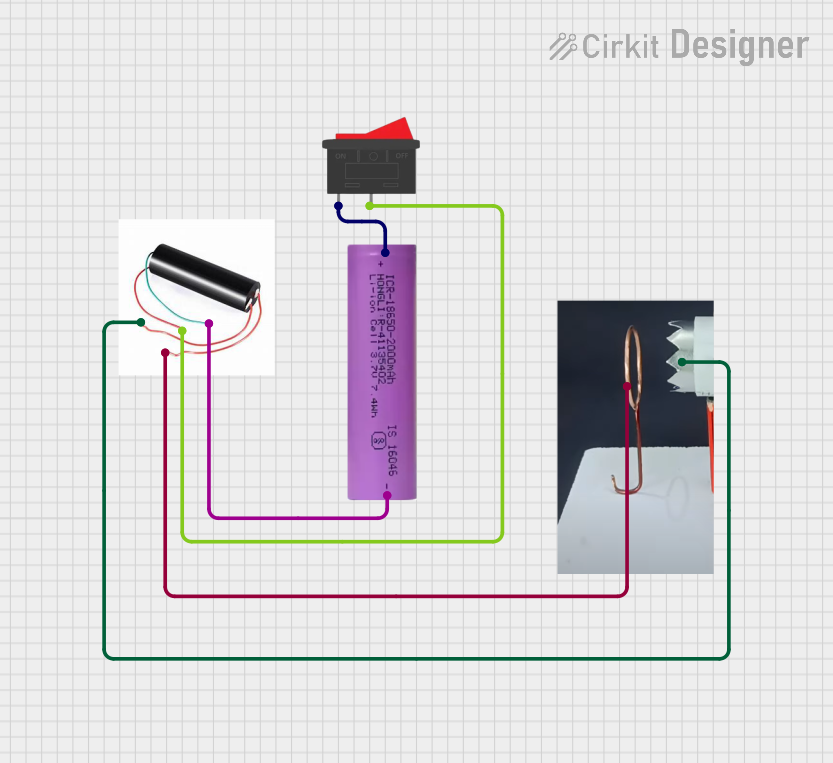

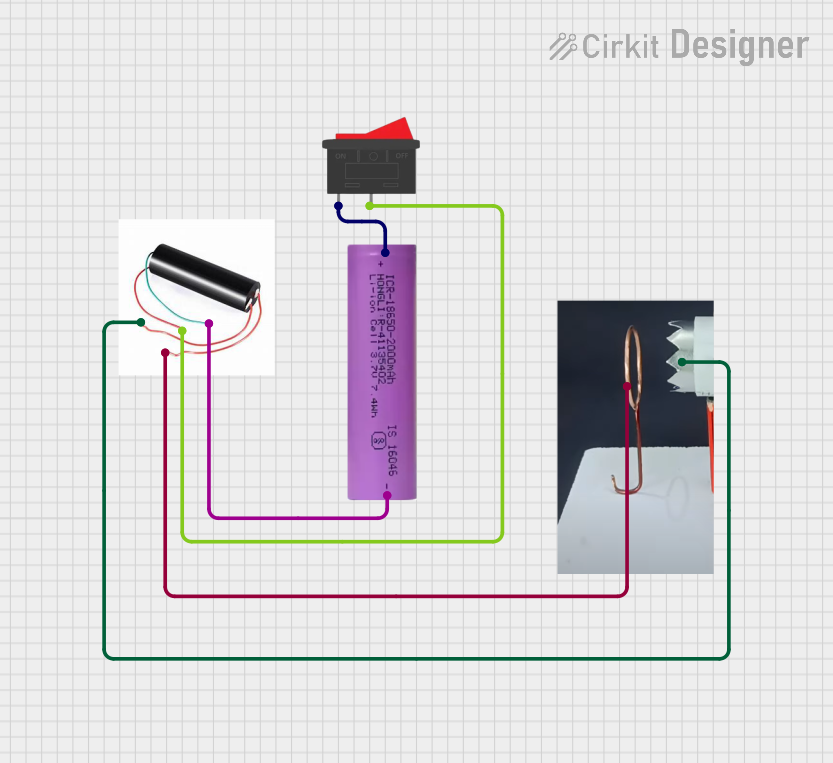

Explore Projects Built with Volage Regulator - 3.3V 3.6A Step Down

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Volage Regulator - 3.3V 3.6A Step Down

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Powering microcontrollers, sensors, and other 3.3V devices.

- Battery-powered systems requiring efficient voltage regulation.

- Robotics and automation projects.

- Embedded systems and IoT devices.

- Replacing linear regulators for improved efficiency and reduced heat dissipation.

Technical Specifications

Below are the key technical details of the Pololu D36V28F3 voltage regulator:

| Parameter | Value |

|---|---|

| Input Voltage Range | 4.5V to 50V |

| Output Voltage | 3.3V (fixed) |

| Maximum Output Current | 3.6A |

| Efficiency | Up to 90% (depending on input voltage and load) |

| Quiescent Current | < 1 mA |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 0.9" × 0.6" × 0.1" (22.9 mm × 15.2 mm × 3 mm) |

| Weight | 1.2 g |

Pin Configuration and Descriptions

The Pololu D36V28F3 has six pins, as described in the table below:

| Pin Name | Description |

|---|---|

| VIN | Input voltage pin. Connect to the positive terminal of the input power source. |

| GND | Ground pin. Connect to the negative terminal of the input power source. |

| VOUT | Regulated 3.3V output pin. Connect to the load requiring 3.3V. |

| SHDN | Shutdown pin. Drive low to disable the regulator; leave floating or high to enable. |

| PG | Power good indicator. Outputs high when the output voltage is in regulation. |

| FB | Feedback pin. Used internally for regulation; do not connect externally. |

Usage Instructions

How to Use the Component in a Circuit

Connect the Input Voltage:

- Connect the VIN pin to a power source with a voltage between 4.5V and 50V.

- Connect the GND pin to the ground of the power source.

Connect the Output Voltage:

- Connect the VOUT pin to the load that requires a 3.3V supply.

- Ensure the load does not exceed the maximum current rating of 3.6A.

Optional Connections:

- Use the SHDN pin to enable or disable the regulator. Leave it floating or pull it high (logic high) to enable the regulator. Pull it low (logic low) to disable it.

- The PG pin can be used to monitor the output voltage. It will output a high signal when the output voltage is stable.

Bypass Capacitors:

- Place a capacitor (e.g., 10 µF) close to the VIN and GND pins to reduce input voltage noise.

- Place a capacitor (e.g., 10 µF) close to the VOUT and GND pins to stabilize the output voltage.

Important Considerations and Best Practices

- Heat Dissipation: Although the regulator is efficient, it may still generate heat under high loads. Ensure adequate ventilation or use a heatsink if necessary.

- Input Voltage Range: Do not exceed the maximum input voltage of 50V, as this may damage the regulator.

- Current Limitation: Ensure the connected load does not draw more than 3.6A to prevent overloading the regulator.

- PCB Layout: Minimize the length of the traces between the regulator and the load to reduce voltage drops and noise.

Example: Using with an Arduino UNO

The Pololu D36V28F3 can be used to power an Arduino UNO by providing a stable 3.3V supply to its 3.3V pin. Below is an example of how to connect the regulator to an Arduino UNO:

- Connect the VIN pin of the regulator to a 12V power source.

- Connect the GND pin of the regulator to the ground of the power source and the Arduino.

- Connect the VOUT pin of the regulator to the 3.3V pin of the Arduino.

Here is an example Arduino sketch to read a sensor powered by the regulator:

// Example: Reading a sensor powered by the Pololu D36V28F3 regulator

// Ensure the sensor is connected to the 3.3V output of the regulator.

const int sensorPin = A0; // Analog pin connected to the sensor output

int sensorValue = 0; // Variable to store the sensor reading

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

pinMode(sensorPin, INPUT); // Set the sensor pin as an input

}

void loop() {

sensorValue = analogRead(sensorPin); // Read the sensor value

Serial.print("Sensor Value: ");

Serial.println(sensorValue); // Print the sensor value to the Serial Monitor

delay(1000); // Wait for 1 second before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Ensure the input voltage is within the specified range (4.5V to 50V).

- Check that the SHDN pin is not pulled low. Leave it floating or pull it high to enable the regulator.

- Verify all connections, especially VIN, GND, and VOUT.

Overheating:

- Check if the load is drawing more than 3.6A. Reduce the load if necessary.

- Ensure proper ventilation or add a heatsink to dissipate heat.

Output Voltage Fluctuations:

- Add bypass capacitors (e.g., 10 µF) close to the VIN and VOUT pins.

- Check for noise or instability in the input power source.

PG Pin Not High:

- Ensure the output voltage is within regulation. If the load is too high, the regulator may not maintain 3.3V.

FAQs

Q: Can I use this regulator to power a 5V device?

A: No, this regulator provides a fixed 3.3V output. For 5V devices, use a 5V step-down regulator.

Q: Is reverse polarity protection included?

A: No, the regulator does not have built-in reverse polarity protection. Ensure correct polarity when connecting the input voltage.

Q: Can I use this regulator with a LiPo battery?

A: Yes, as long as the battery voltage is within the input range (4.5V to 50V).

Q: What happens if the input voltage drops below 4.5V?

A: The regulator may fail to maintain a stable 3.3V output, and the PG pin will indicate that the output is not in regulation.