How to Use MPU-9250/6500/9255: Examples, Pinouts, and Specs

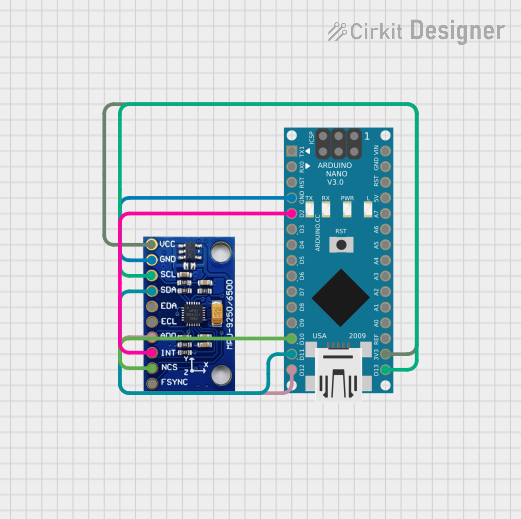

Design with MPU-9250/6500/9255 in Cirkit Designer

Design with MPU-9250/6500/9255 in Cirkit DesignerIntroduction

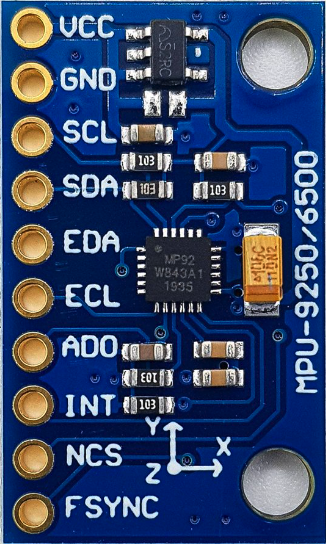

The MPU-9250/6500/9255 is a multi-faceted motion tracking device that integrates a 3-axis gyroscope, 3-axis accelerometer, and a 3-axis magnetometer. This 9-axis sensor is capable of providing comprehensive motion sensing and orientation data, making it an ideal component for a wide range of applications including but not limited to robotics, wearable technology, drones, and augmented reality.

Explore Projects Built with MPU-9250/6500/9255

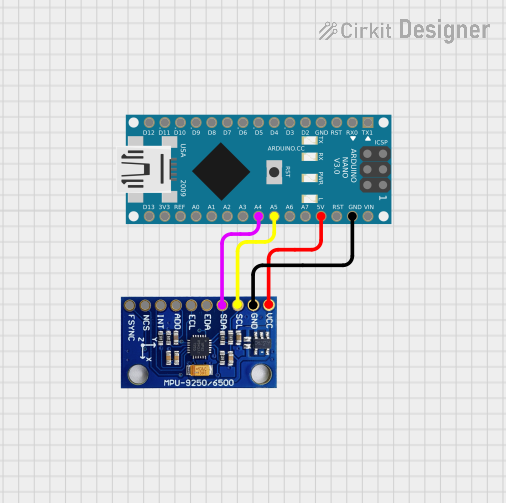

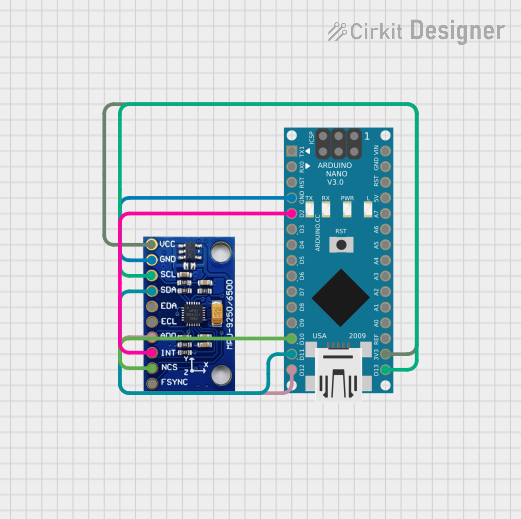

Open Project in Cirkit Designer

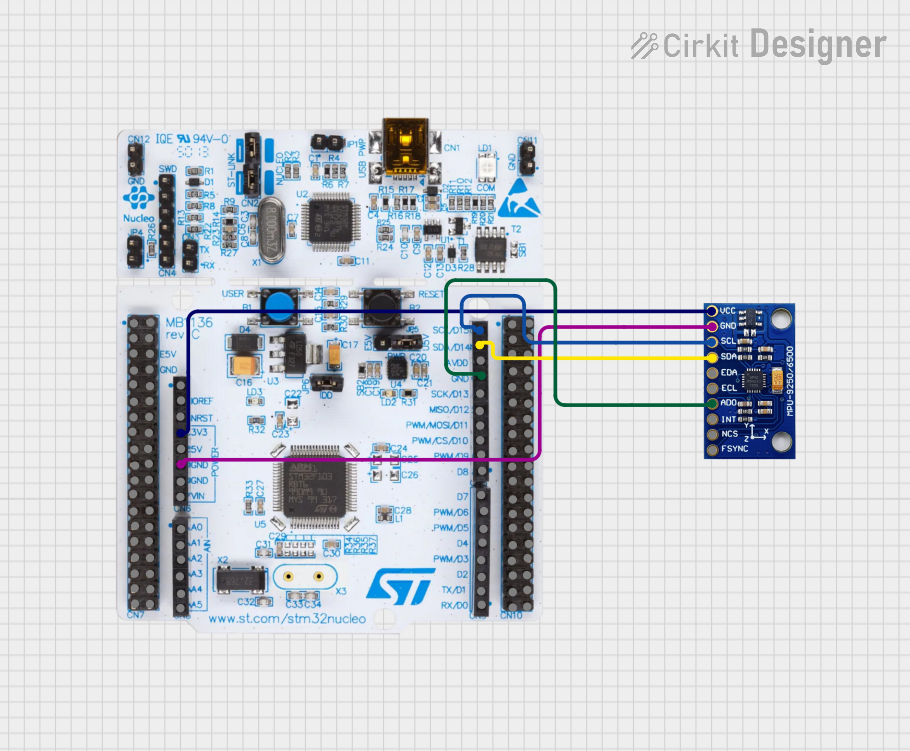

Open Project in Cirkit Designer

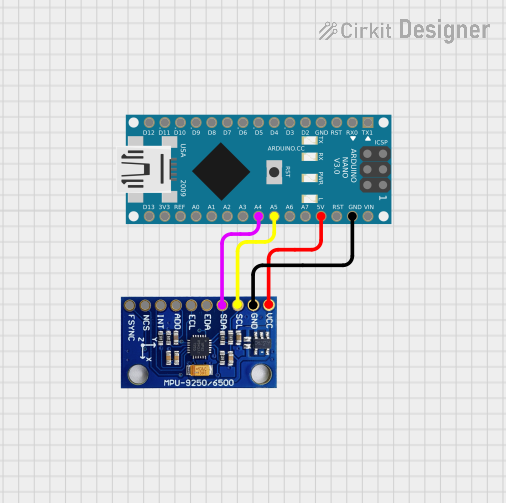

Open Project in Cirkit Designer

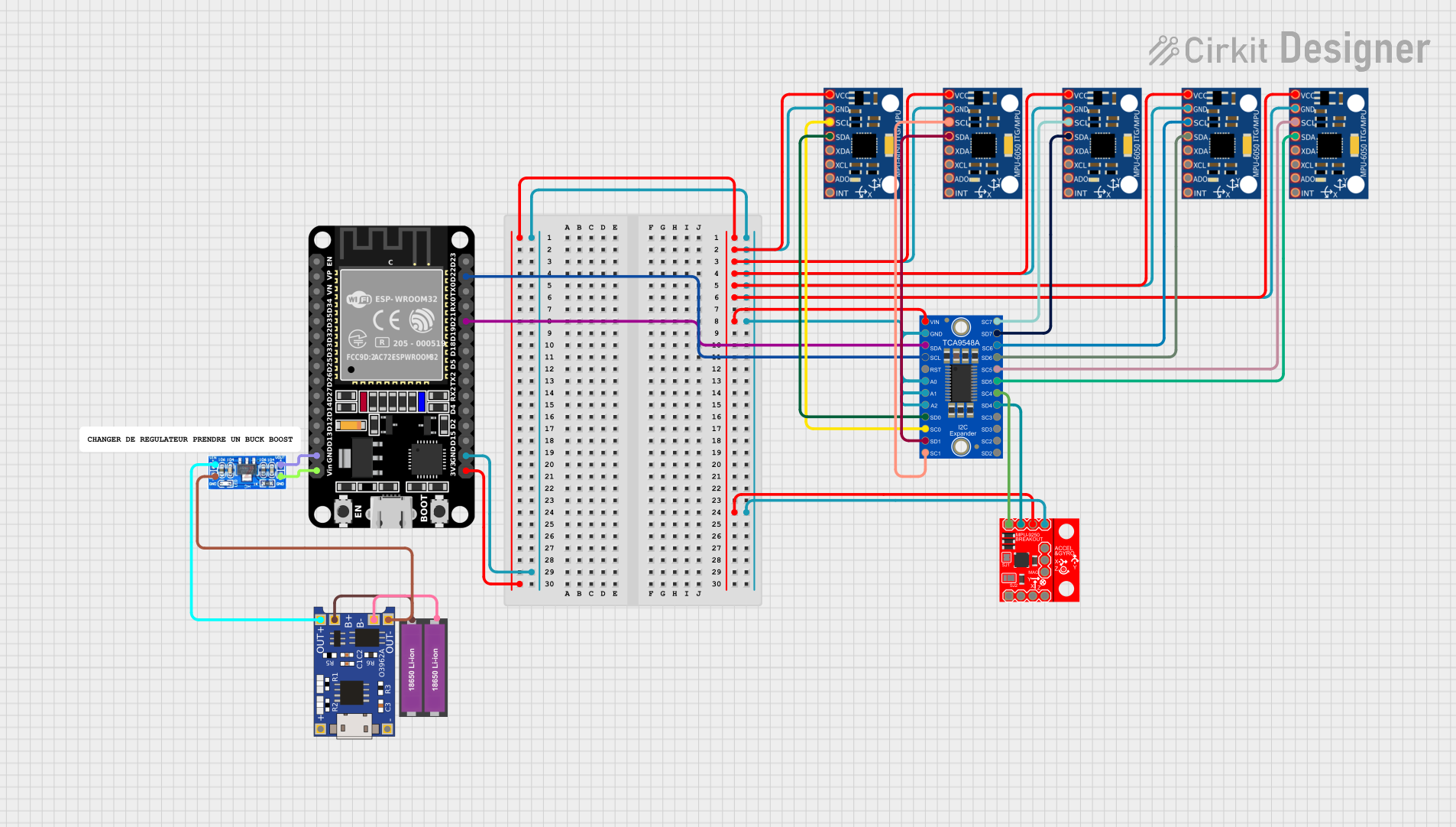

Open Project in Cirkit Designer

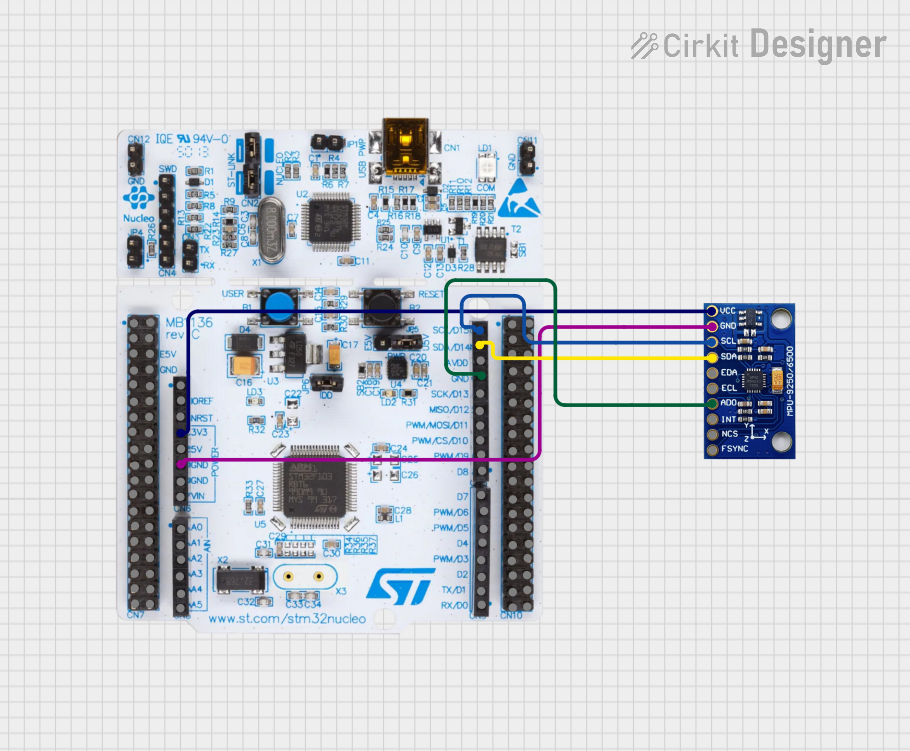

Open Project in Cirkit Designer

Open Project in Cirkit Designer

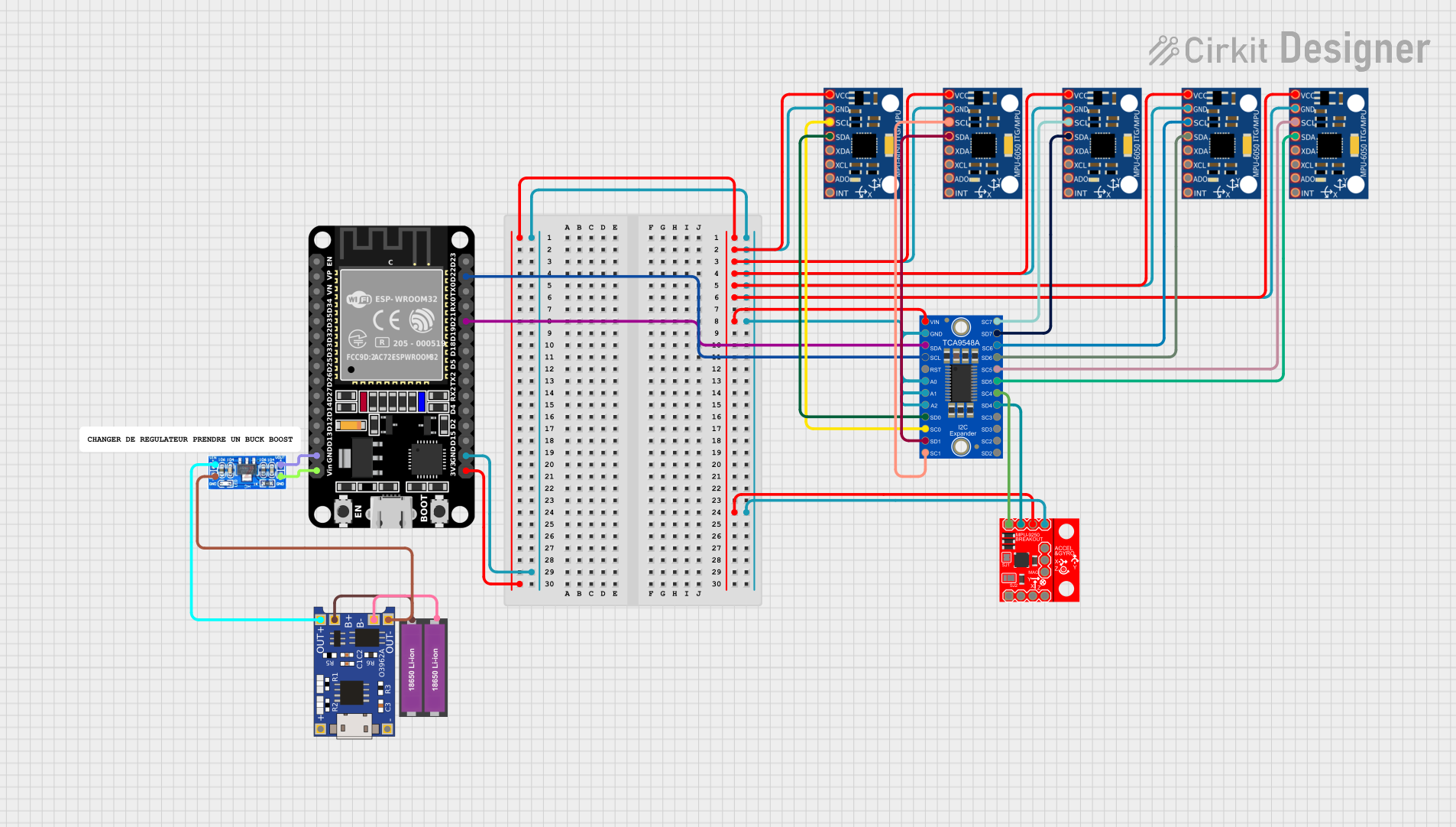

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MPU-9250/6500/9255

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Supply Voltage (VDD): 2.4V - 3.6V

- Operating Current: 3.2mA

- Gyroscope Range: ±250, ±500, ±1000, ±2000 degrees/sec

- Accelerometer Range: ±2g, ±4g, ±8g, ±16g

- Magnetometer Range (MPU-9250/9255 only): ±4800 µT

- Communication: I2C and SPI

- Operating Temperature: -40°C to +85°C

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | VDD | Power supply (2.4V - 3.6V) |

| 2 | GND | Ground |

| 3 | SCL/SPC | I2C clock / SPI clock |

| 4 | SDA/SDI | I2C data / SPI data input |

| 5 | AD0/SDO | I2C address select / SPI data output |

| 6 | NCS | SPI chip select (active low) |

| 7 | INT | Interrupt output (active high) |

| 8 | FSYNC | Frame synchronization (optional) |

Usage Instructions

Integration into a Circuit

To use the MPU-9250/6500/9255 in a circuit:

- Connect VDD to a 2.4V - 3.6V power supply.

- Connect GND to the ground of your system.

- For I2C communication, connect SCL to the I2C clock and SDA to the I2C data line.

- For SPI communication, connect SPC to the SPI clock, SDI to the SPI data input, SDO to the SPI data output, and NCS to the SPI chip select.

- Optionally, connect INT to an interrupt pin on your microcontroller to use the interrupt feature.

- Optionally, connect FSYNC to synchronize frames if required by your application.

Best Practices

- Use pull-up resistors on the I2C data and clock lines.

- Ensure that the power supply is stable and within the specified voltage range.

- When using SPI, ensure that the NCS line is held high when the device is not in use.

- For accurate readings, calibrate the sensors following the manufacturer's guidelines.

Example Code for Arduino UNO

#include <Wire.h>

// MPU-9250 I2C address (depends on AD0 pin, here we assume it's connected to GND)

const int MPU9250_ADDRESS = 0x68;

void setup() {

Wire.begin(); // Initialize I2C

Serial.begin(115200); // Start serial communication at 115200 baud

setupMPU9250(); // Setup MPU-9250 registers

}

void loop() {

// Read sensor data and print it

readSensorData();

delay(100); // Delay for readability

}

void setupMPU9250() {

// Wake up MPU-9250

writeMPU9250(MPU9250_ADDRESS, 0x6B, 0x00);

// Configure gyroscope and accelerometer

// This is a basic configuration and should be adjusted for your application

writeMPU9250(MPU9250_ADDRESS, 0x1B, 0x00); // Set gyroscope to ±250 degrees/sec

writeMPU9250(MPU9250_ADDRESS, 0x1C, 0x00); // Set accelerometer to ±2g

}

void readSensorData() {

// Read accelerometer and gyroscope data

// Implement data reading logic here

}

void writeMPU9250(byte address, byte reg, byte data) {

Wire.beginTransmission(address);

Wire.write(reg);

Wire.write(data);

Wire.endTransmission();

}

Troubleshooting and FAQs

Common Issues

- No data is being read from the sensor: Ensure that the I2C or SPI connections are correct and secure. Check that the correct communication protocol is being used in your code.

- Inaccurate sensor readings: Calibrate the sensors as per the manufacturer's instructions. Ensure that the sensor is not being affected by magnetic fields or vibrations.

- Intermittent connection: Check for loose connections and ensure that the pull-up resistors are correctly installed on the I2C lines.

FAQs

Q: Can the MPU-9250/6500/9255 be used with both I2C and SPI simultaneously? A: No, you must choose either I2C or SPI for communication with the MPU-9250/6500/9255.

Q: What is the purpose of the AD0/SDO pin? A: The AD0/SDO pin is used to set the I2C address of the device when using I2C communication. For SPI, it serves as the data output pin.

Q: How do I calibrate the MPU-9250/6500/9255? A: Calibration involves capturing sensor data at known orientations and then using these values to correct for offsets and scaling errors. Refer to the manufacturer's documentation for detailed calibration procedures.

Q: What should I do if the MPU-9250/6500/9255 is not responding? A: Verify the power supply, check all connections, and ensure that the correct I2C address or SPI settings are being used. Reset the device and try initializing it again with the correct configuration settings.