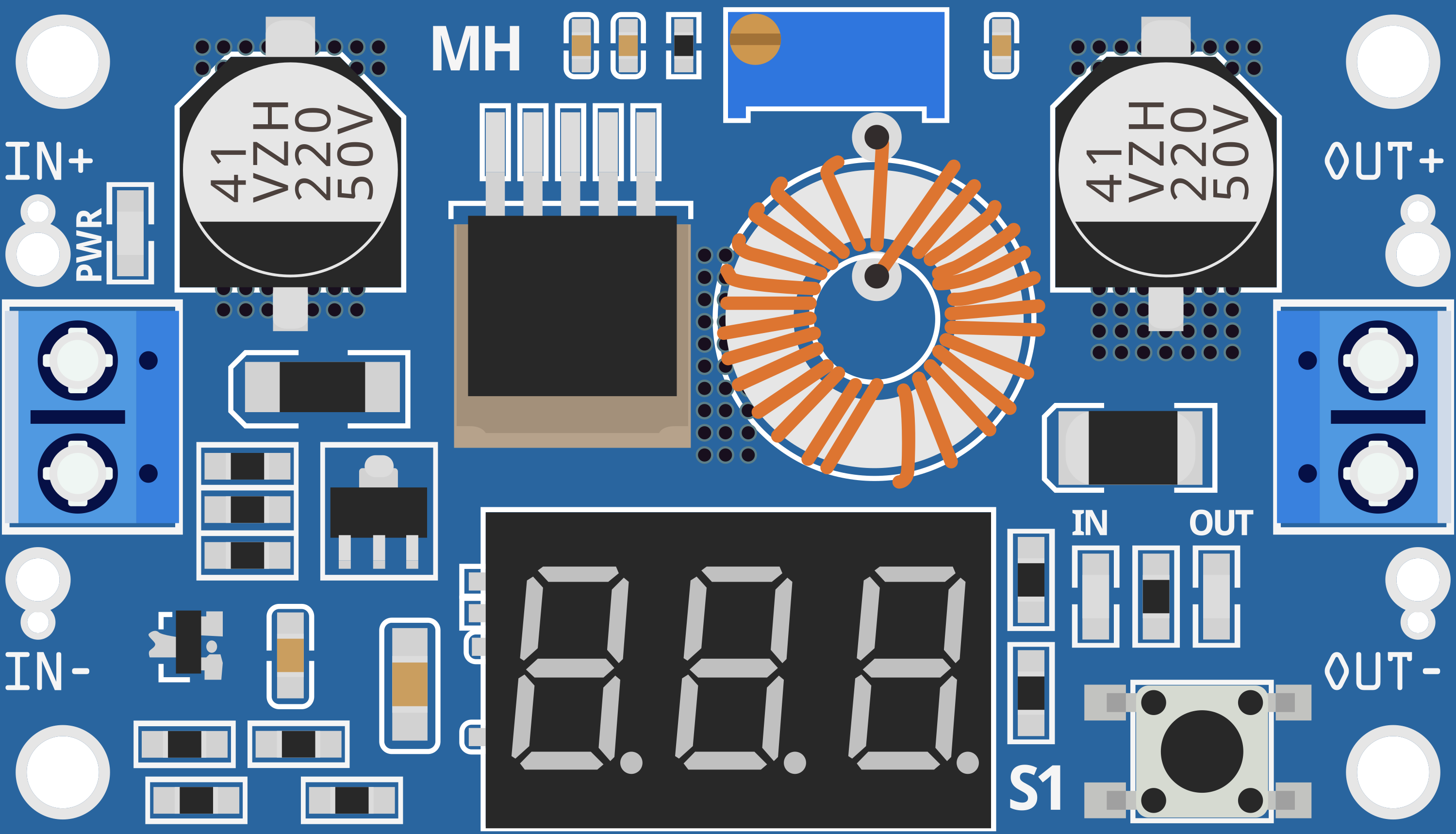

How to Use XL4015 5A DC Buck Step-down: Examples, Pinouts, and Specs

Design with XL4015 5A DC Buck Step-down in Cirkit Designer

Design with XL4015 5A DC Buck Step-down in Cirkit DesignerIntroduction

The XL4015 is a high-performance DC-DC buck converter designed to step down voltage efficiently while delivering a maximum output current of 5A. It features an adjustable output voltage, making it versatile for a wide range of applications. The XL4015 is widely used in power supply circuits, battery charging systems, LED drivers, and other electronic projects requiring stable and efficient voltage regulation.

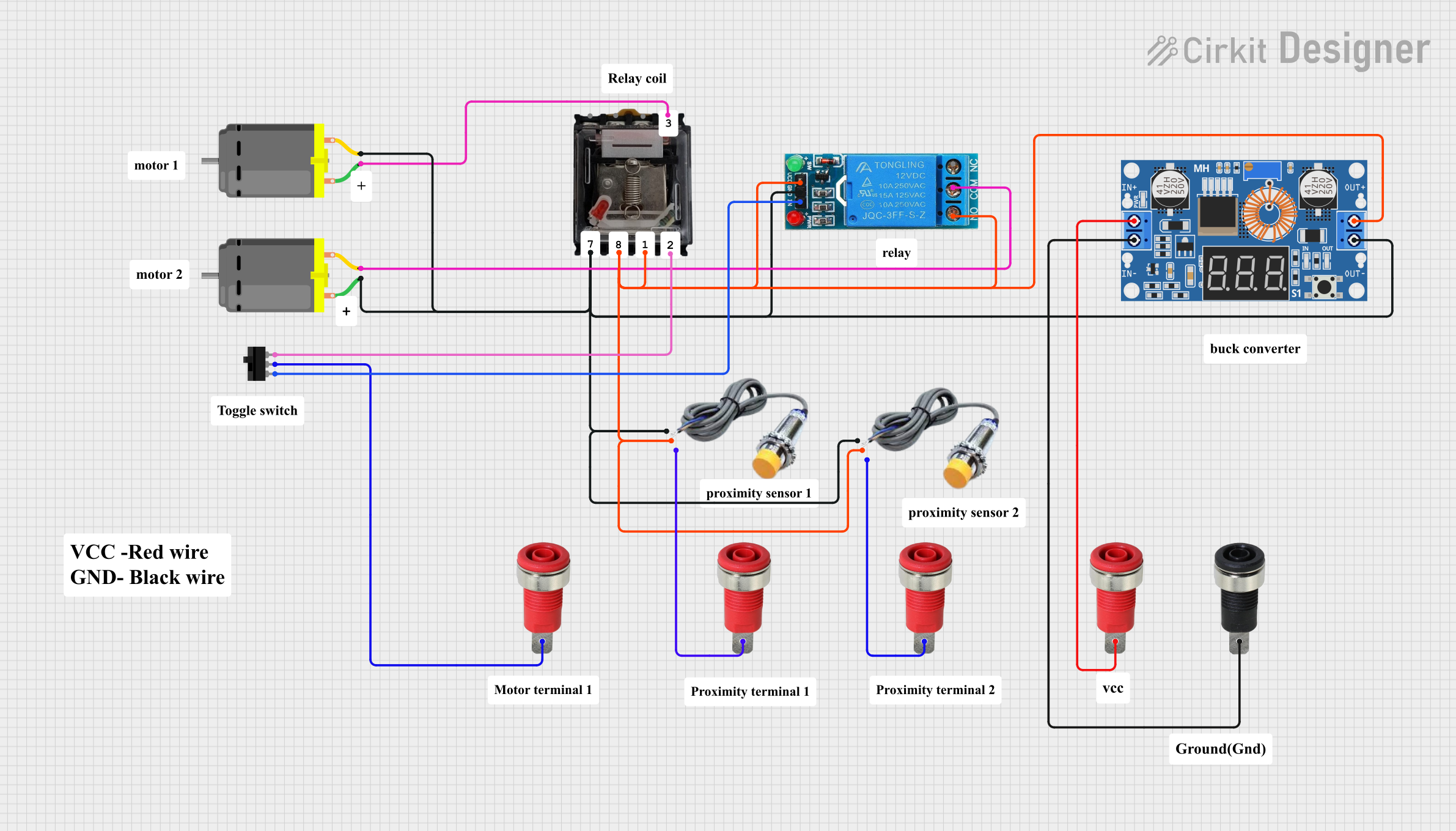

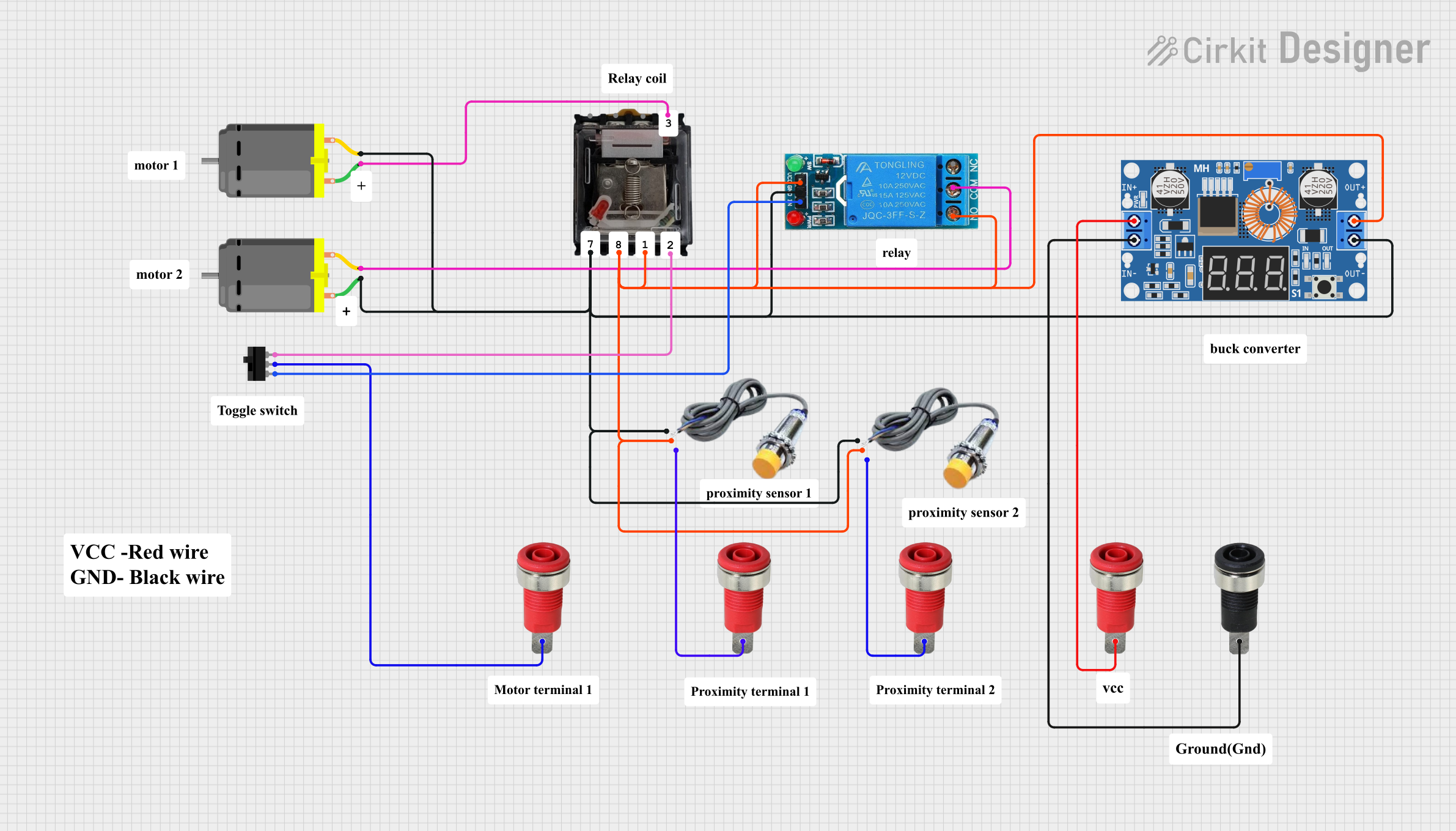

Explore Projects Built with XL4015 5A DC Buck Step-down

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with XL4015 5A DC Buck Step-down

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Power supply modules for electronic devices

- Battery charging circuits

- LED lighting systems

- Voltage regulation in embedded systems

- DIY electronics and prototyping

Technical Specifications

The XL4015 is a robust and efficient buck converter with the following key specifications:

| Parameter | Value |

|---|---|

| Input Voltage Range | 4V to 38V |

| Output Voltage Range | 1.25V to 36V (adjustable) |

| Maximum Output Current | 5A (with proper heat dissipation) |

| Output Power | Up to 75W |

| Efficiency | Up to 96% |

| Switching Frequency | 180 kHz |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 43mm x 21mm x 14mm |

Pin Configuration and Descriptions

The XL4015 module typically has the following pin layout:

| Pin Name | Description |

|---|---|

| VIN | Input voltage (connect to the positive terminal of the power source) |

| GND | Ground (common ground for input and output) |

| VOUT | Output voltage (connect to the load) |

| ADJ | Voltage adjustment (via onboard potentiometer) |

Usage Instructions

How to Use the XL4015 in a Circuit

Connect the Input Voltage:

- Connect the positive terminal of the power source to the

VINpin. - Connect the negative terminal of the power source to the

GNDpin.

- Connect the positive terminal of the power source to the

Connect the Load:

- Connect the positive terminal of the load to the

VOUTpin. - Connect the negative terminal of the load to the

GNDpin.

- Connect the positive terminal of the load to the

Adjust the Output Voltage:

- Use the onboard potentiometer to adjust the output voltage.

- Turn the potentiometer clockwise to increase the output voltage and counterclockwise to decrease it.

- Use a multimeter to measure the output voltage for precise adjustment.

Ensure Proper Heat Dissipation:

- If the output current exceeds 3A, attach a heatsink to the XL4015 module to prevent overheating.

Important Considerations

- Input Voltage: Ensure the input voltage is at least 1.5V higher than the desired output voltage.

- Current Limitation: Do not exceed the maximum output current of 5A. Use proper cooling if operating near the limit.

- Polarity: Double-check the polarity of the input and output connections to avoid damage.

- Load Testing: Test the module with a dummy load before connecting sensitive devices.

Example: Using XL4015 with Arduino UNO

The XL4015 can be used to power an Arduino UNO by stepping down a higher voltage (e.g., 12V) to 5V. Below is an example circuit and code:

Circuit Setup

- Connect a 12V power source to the

VINandGNDpins of the XL4015. - Adjust the output voltage to 5V using the potentiometer.

- Connect the

VOUTpin of the XL4015 to the5Vpin of the Arduino UNO. - Connect the

GNDpin of the XL4015 to theGNDpin of the Arduino UNO.

Example Code

// Example code to blink an LED using Arduino UNO powered by XL4015

// Ensure the XL4015 output is set to 5V before connecting to the Arduino

const int ledPin = 13; // Built-in LED pin on Arduino UNO

void setup() {

pinMode(ledPin, OUTPUT); // Set LED pin as output

}

void loop() {

digitalWrite(ledPin, HIGH); // Turn the LED on

delay(1000); // Wait for 1 second

digitalWrite(ledPin, LOW); // Turn the LED off

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Check the input voltage and ensure it is within the specified range (4V to 38V).

- Verify the polarity of the input and output connections.

- Ensure the onboard potentiometer is not set to the minimum output voltage.

Overheating:

- Attach a heatsink to the XL4015 module if the output current exceeds 3A.

- Ensure proper ventilation around the module.

Fluctuating Output Voltage:

- Check for loose connections or poor solder joints.

- Ensure the input voltage is stable and not dropping under load.

Output Voltage Not Adjustable:

- Verify that the onboard potentiometer is functioning correctly.

- Replace the potentiometer if it is damaged.

FAQs

Q: Can the XL4015 be used to charge batteries?

A: Yes, the XL4015 can be used for battery charging applications. However, you must add a current-limiting circuit or ensure the battery's charging current is within safe limits.

Q: What is the maximum input voltage for the XL4015?

A: The maximum input voltage is 38V. Exceeding this limit may damage the module.

Q: Can the XL4015 power a Raspberry Pi?

A: Yes, the XL4015 can step down voltage to 5V to power a Raspberry Pi. Ensure the output current is sufficient for the Raspberry Pi model being used.

Q: Is the XL4015 suitable for audio applications?

A: The XL4015 can be used in audio applications, but additional filtering may be required to reduce noise.

By following this documentation, you can effectively use the XL4015 DC-DC buck converter in your projects.