How to Use motor driver : Examples, Pinouts, and Specs

Design with motor driver in Cirkit Designer

Design with motor driver in Cirkit DesignerIntroduction

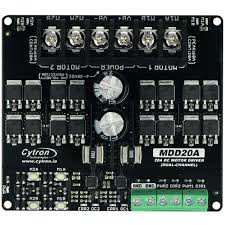

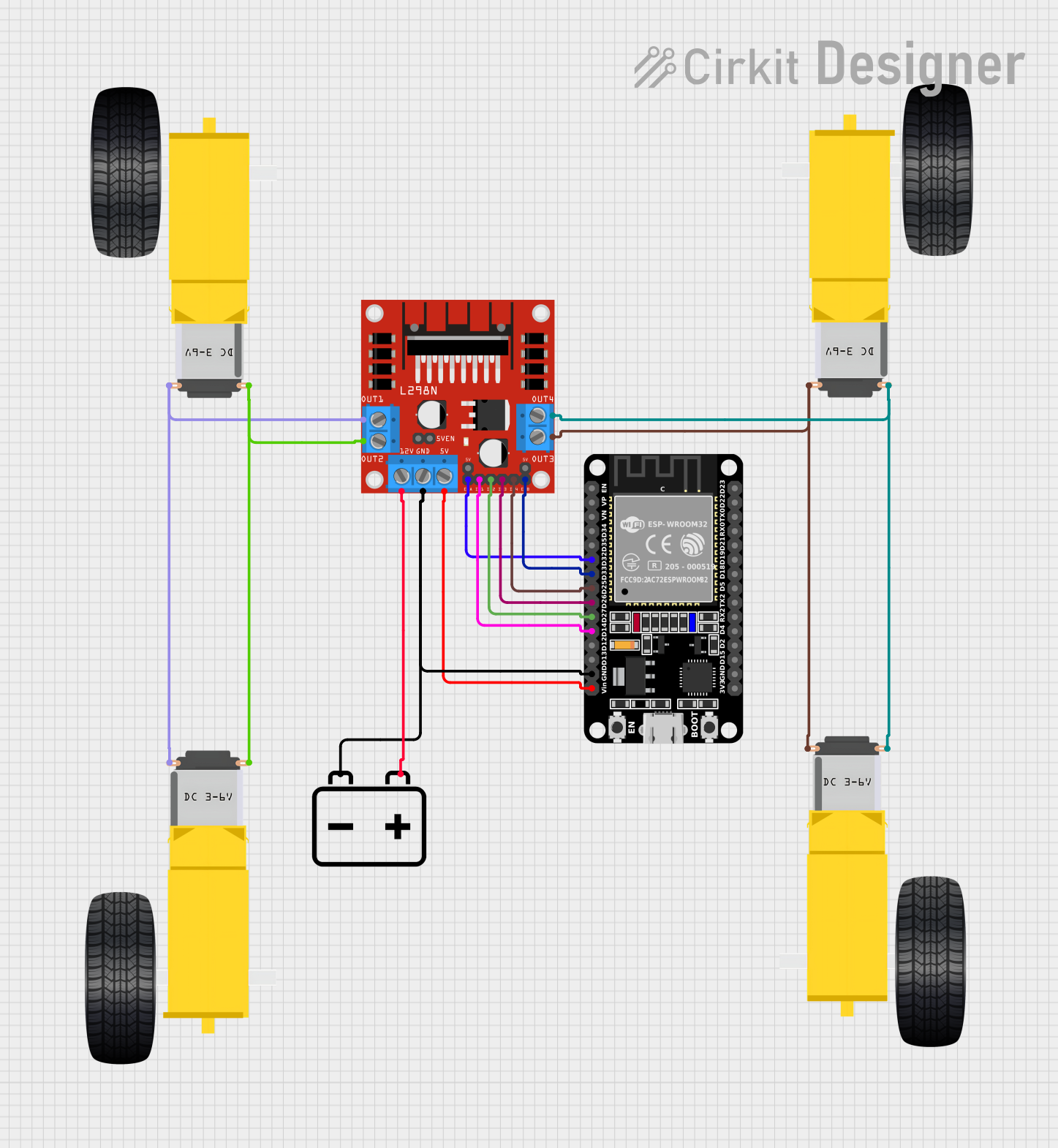

A motor driver is an essential component in robotics and automation, allowing precise control over the speed and direction of motors. The Cytron 2020 motor driver is a versatile and robust module designed to interface with a wide range of motors, including DC, stepper, and servo motors. Common applications include robotic vehicles, conveyor systems, and positioning mechanisms.

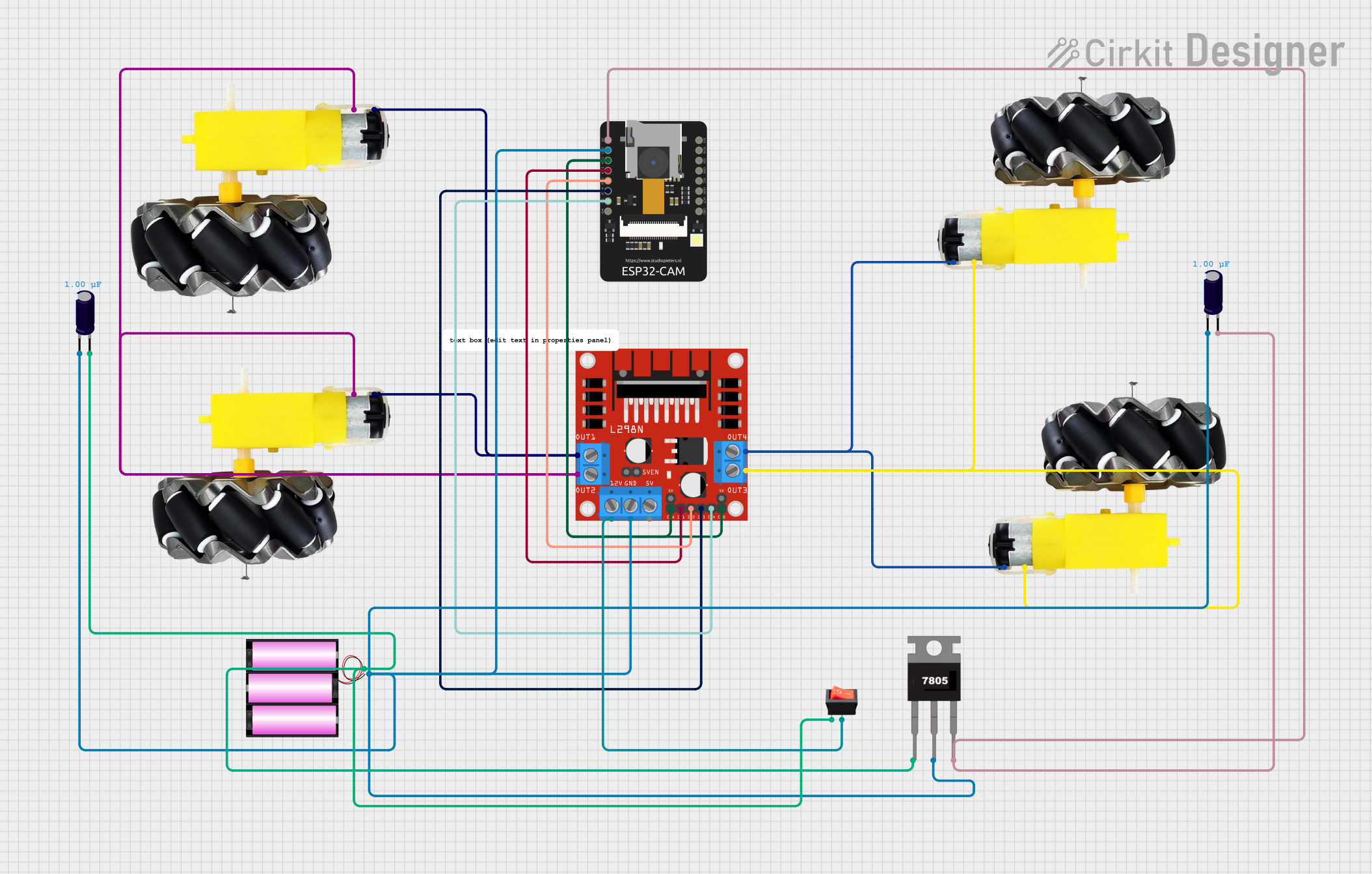

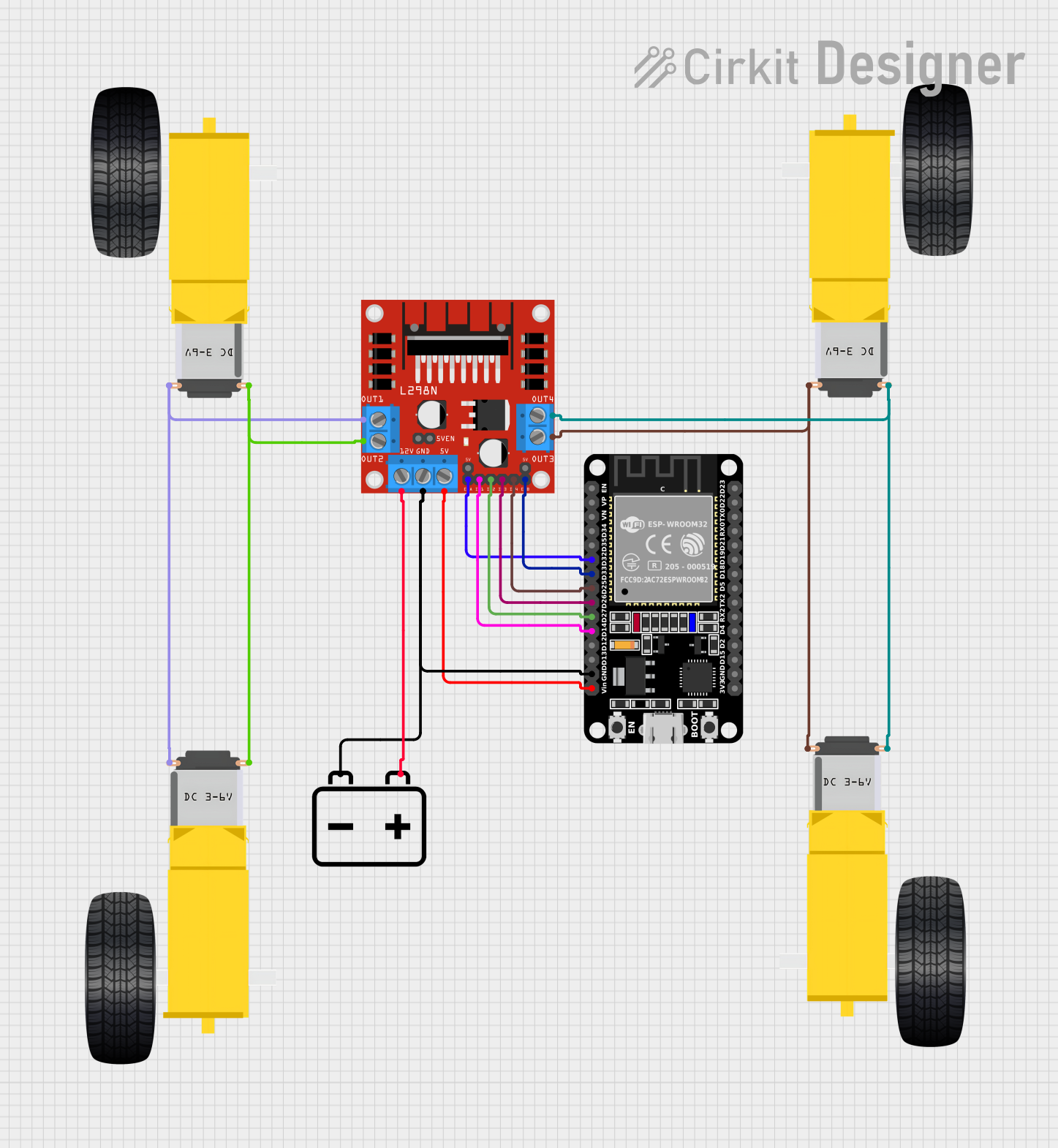

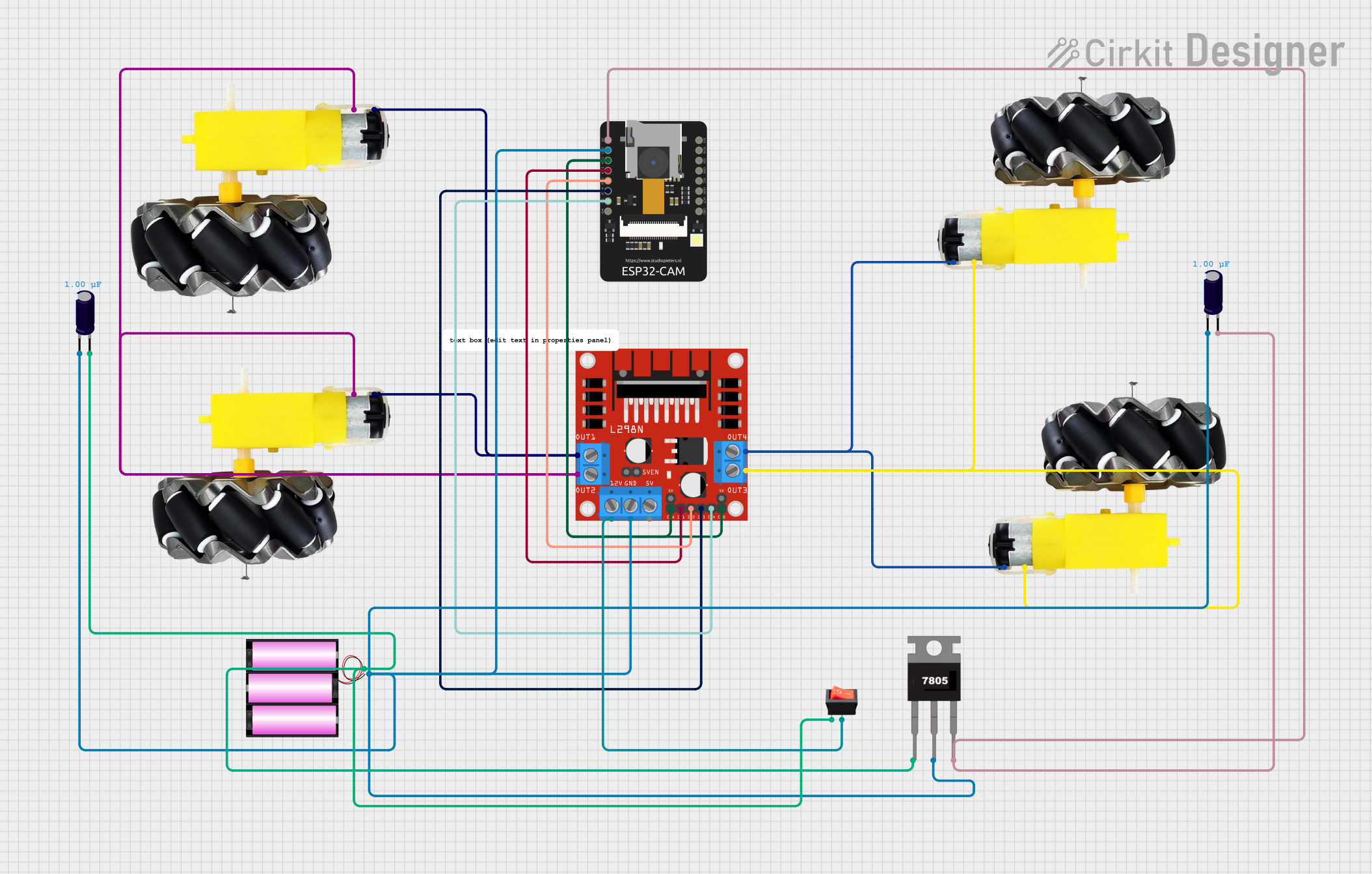

Explore Projects Built with motor driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with motor driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Operating Voltage: 6V to 30V

- Continuous Current: Up to 10A

- Peak Current: Up to 30A (for a few seconds)

- Control Signal Input Voltage: 3.3V to 5V (TTL compatible)

- Dimensions: 75mm x 43mm x 42mm

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply for the motor (6V-30V) |

| 2 | GND | Ground connection |

| 3 | A+ | Motor output A positive |

| 4 | A- | Motor output A negative |

| 5 | B+ | Motor output B positive (if applicable) |

| 6 | B- | Motor output B negative (if applicable) |

| 7 | PWM | Pulse Width Modulation input for speed control |

| 8 | DIR | Direction control input |

| 9 | EN | Enable input for the motor driver |

Usage Instructions

How to Use the Component in a Circuit

- Power Connections: Connect the motor power supply to the VCC and GND pins, ensuring the voltage is within the specified range.

- Motor Connections: Attach the motor leads to the A+ and A- pins (and B+ and B- if using a bipolar stepper motor).

- Control Connections: Connect the PWM pin to a PWM-capable pin on your microcontroller for speed control. The DIR pin determines the motor's direction, and the EN pin can be used to enable or disable the motor driver.

Important Considerations and Best Practices

- Ensure the power supply can handle the motor's current requirements.

- Use appropriate flyback diodes to protect against voltage spikes when driving inductive loads.

- Avoid running the motor driver at its peak current for extended periods to prevent overheating.

- Implement proper heat dissipation techniques if operating near the maximum current rating.

Example Code for Arduino UNO

// Define motor driver control pins

const int pwmPin = 3; // PWM input for speed control

const int dirPin = 4; // Direction control input

const int enPin = 5; // Enable input for the motor driver

void setup() {

// Set motor driver pins as outputs

pinMode(pwmPin, OUTPUT);

pinMode(dirPin, OUTPUT);

pinMode(enPin, OUTPUT);

// Enable the motor driver

digitalWrite(enPin, HIGH);

}

void loop() {

// Set motor direction to clockwise

digitalWrite(dirPin, HIGH);

// Set motor speed to 50% duty cycle

analogWrite(pwmPin, 127);

delay(2000);

// Set motor direction to counter-clockwise

digitalWrite(dirPin, LOW);

// Set motor speed to 75% duty cycle

analogWrite(pwmPin, 191);

delay(2000);

}

Troubleshooting and FAQs

Common Issues

- Motor not running: Check power supply connections and ensure the EN pin is set high.

- Motor running hot: Ensure the current draw is within the driver's limits and improve cooling.

- Inconsistent motor speed: Verify the PWM signal is stable and within the correct voltage range.

Solutions and Tips

- Use a multimeter to check connections and signal levels.

- Implement a soft start mechanism to reduce inrush current.

- If using long wires, consider using twisted pairs to reduce electromagnetic interference.

FAQs

Q: Can I drive two motors with this motor driver? A: Yes, the Cytron 2020 motor driver can control two motors if they are within the current and voltage specifications.

Q: What is the maximum frequency for the PWM input? A: The maximum recommended frequency for the PWM input is 25kHz.

Q: How do I reverse the motor direction? A: Change the logic level of the DIR pin to reverse the motor's direction.

Q: Can I use this motor driver with a microcontroller that operates at 3.3V logic? A: Yes, the control signal input is TTL compatible and can accept 3.3V logic levels.