How to Use FIT0774 Vibration motor: Examples, Pinouts, and Specs

Design with FIT0774 Vibration motor in Cirkit Designer

Design with FIT0774 Vibration motor in Cirkit DesignerIntroduction

The FIT0774 is a compact and lightweight vibration motor manufactured by DFRobot. This electromechanical device converts electrical energy into mechanical vibrations. When powered, it produces a rapid motion in a back-and-forth motion or sometimes in a circular motion, depending on the design. It is commonly used in applications such as mobile phones, game controllers, and wearable devices to provide haptic feedback to the user.

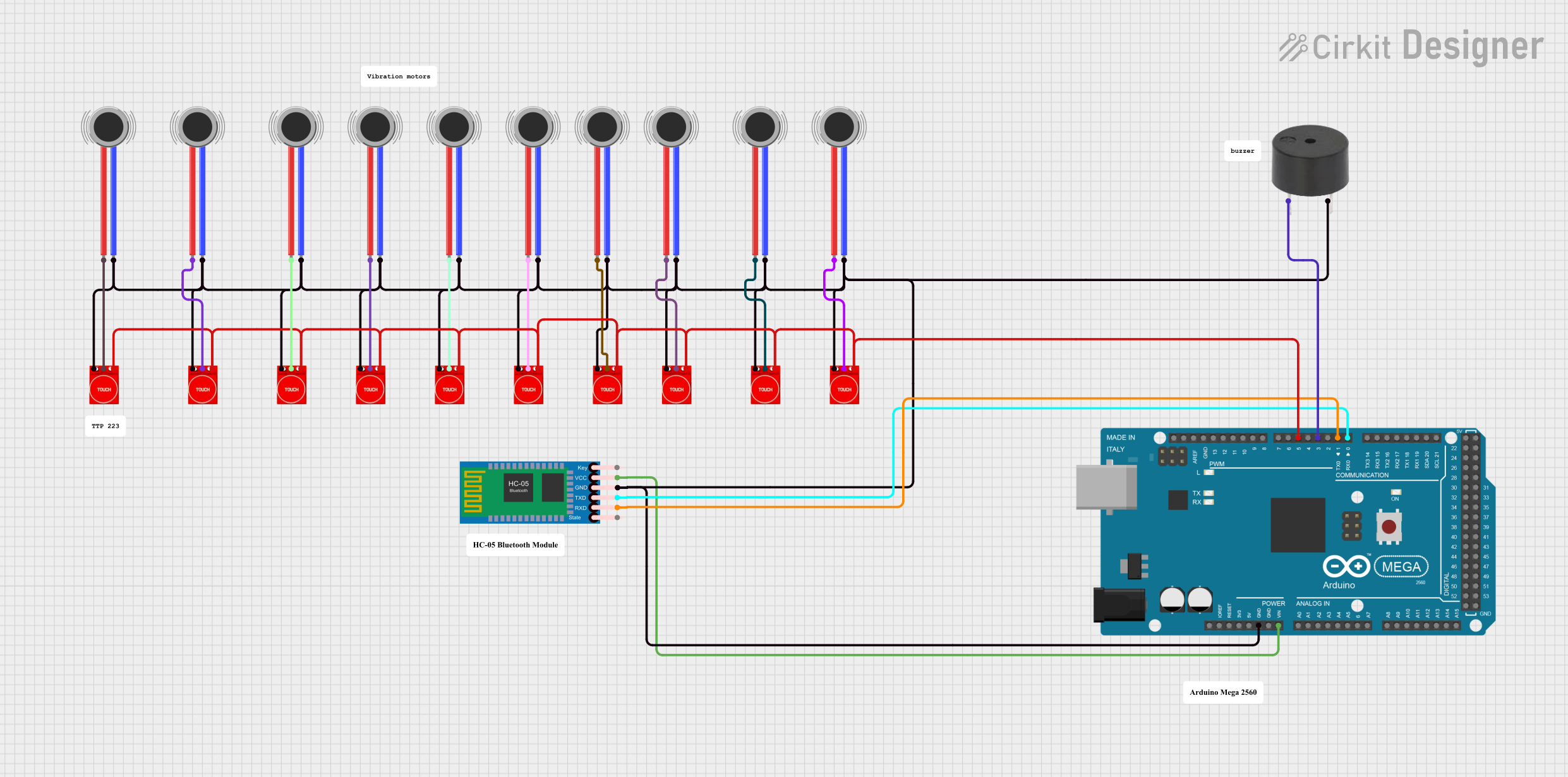

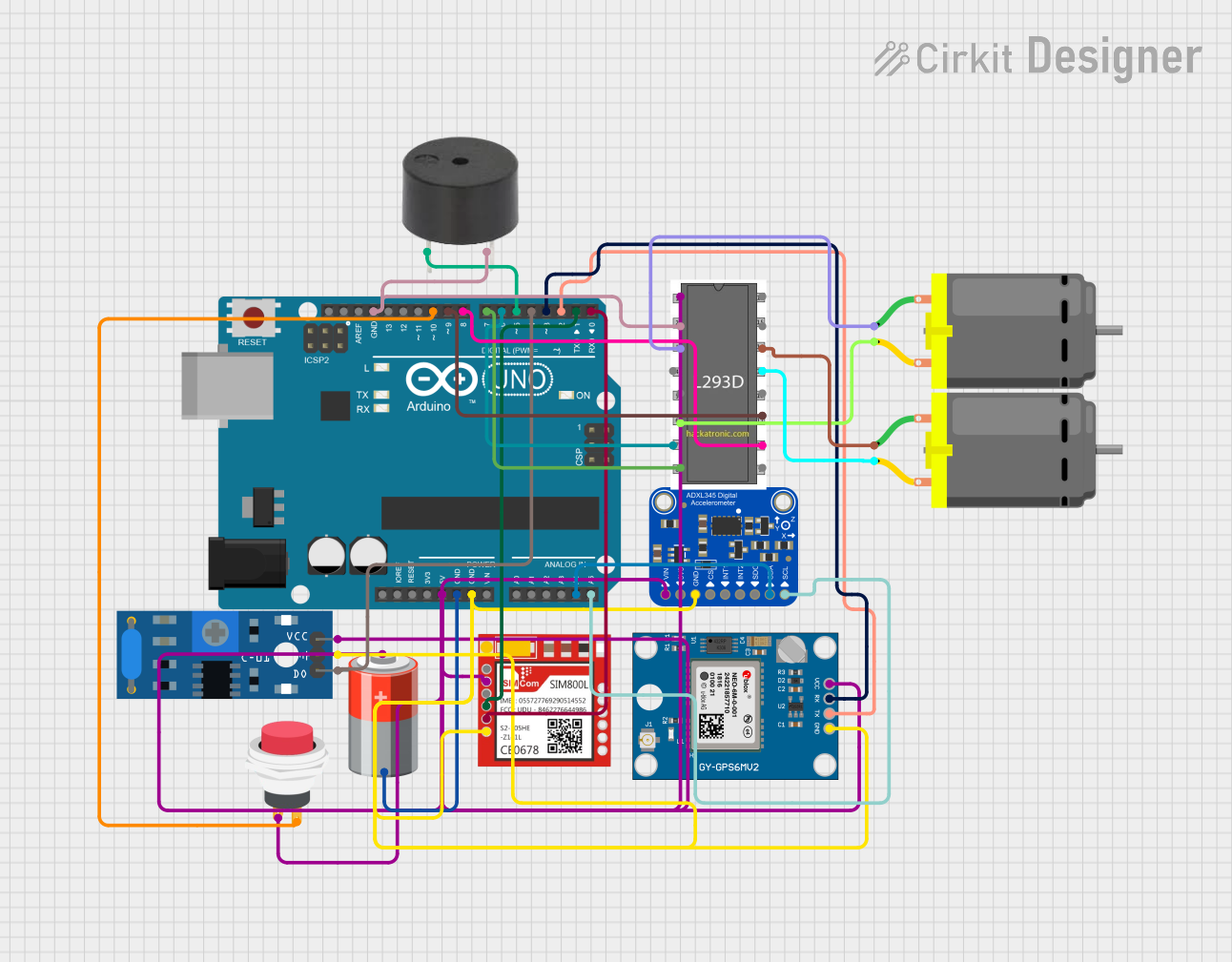

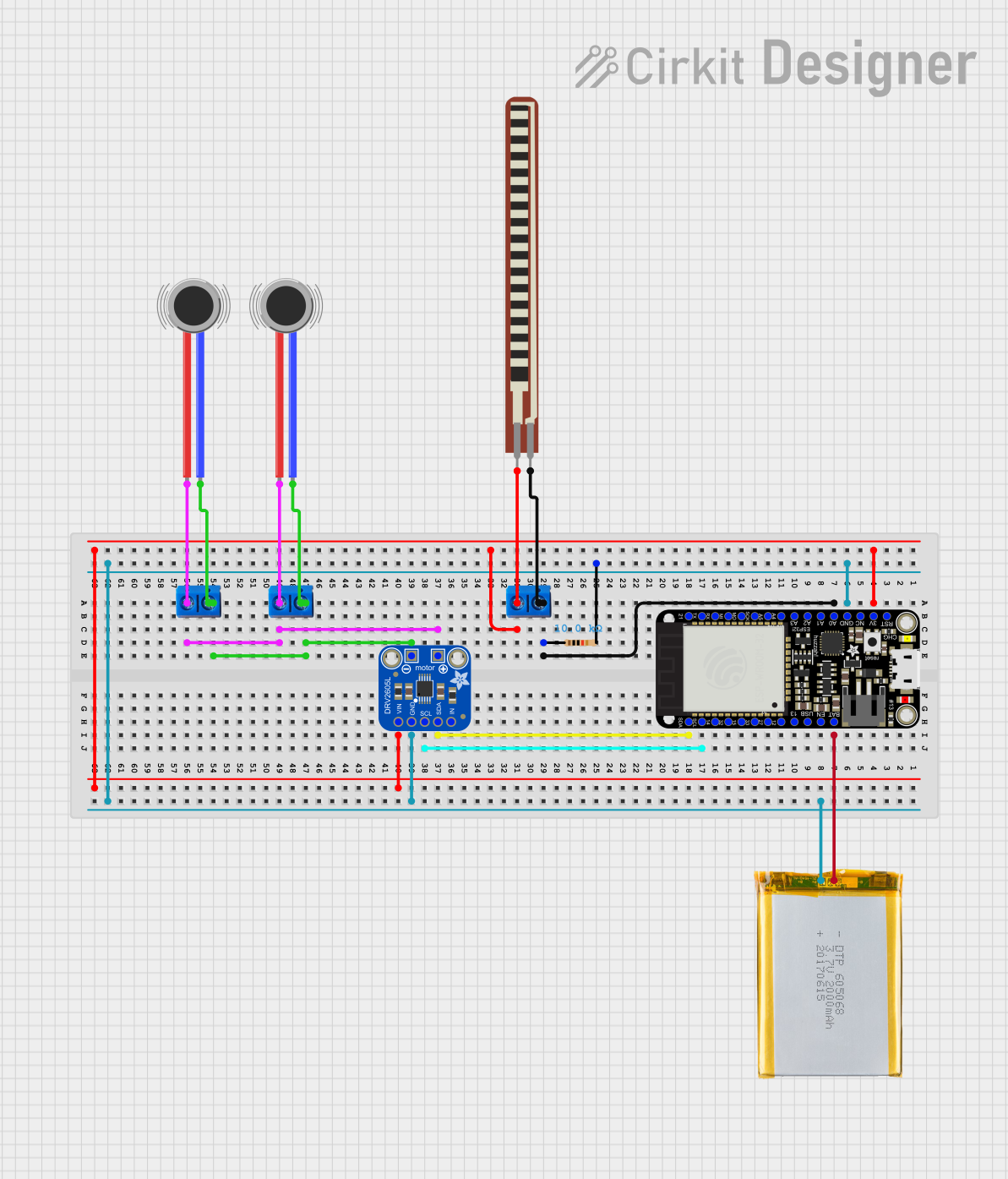

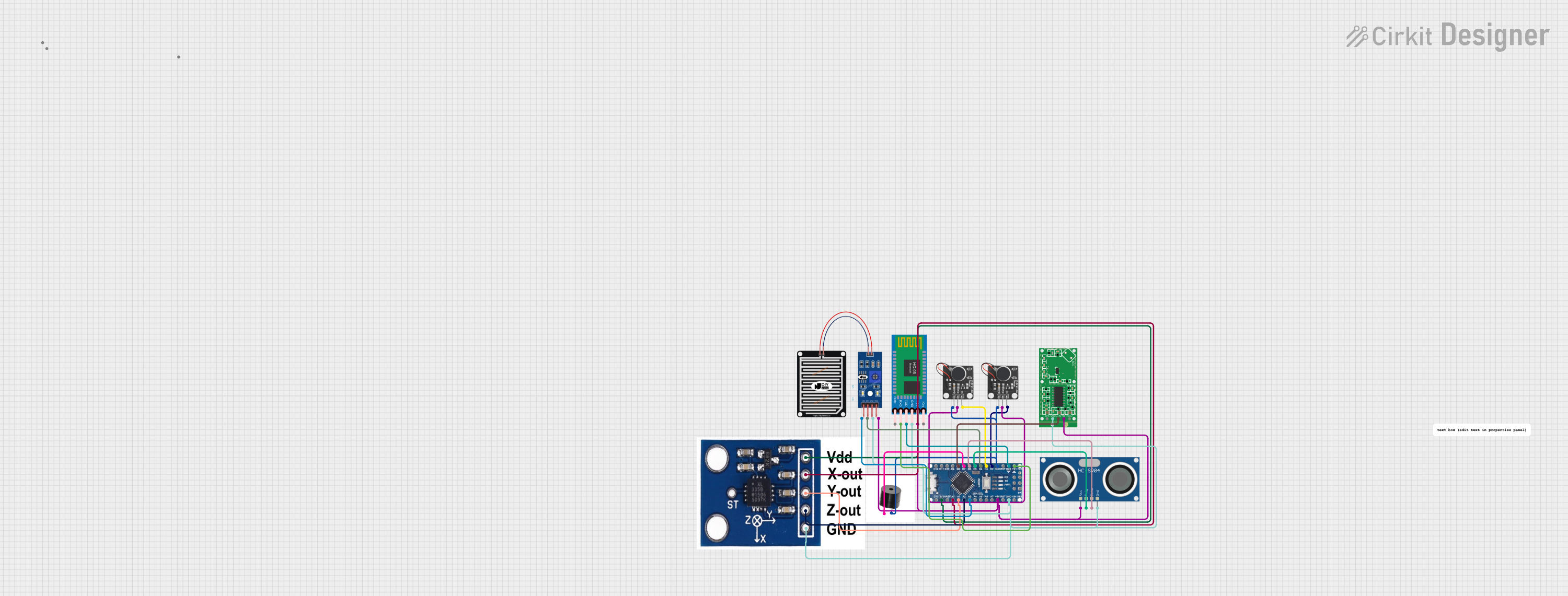

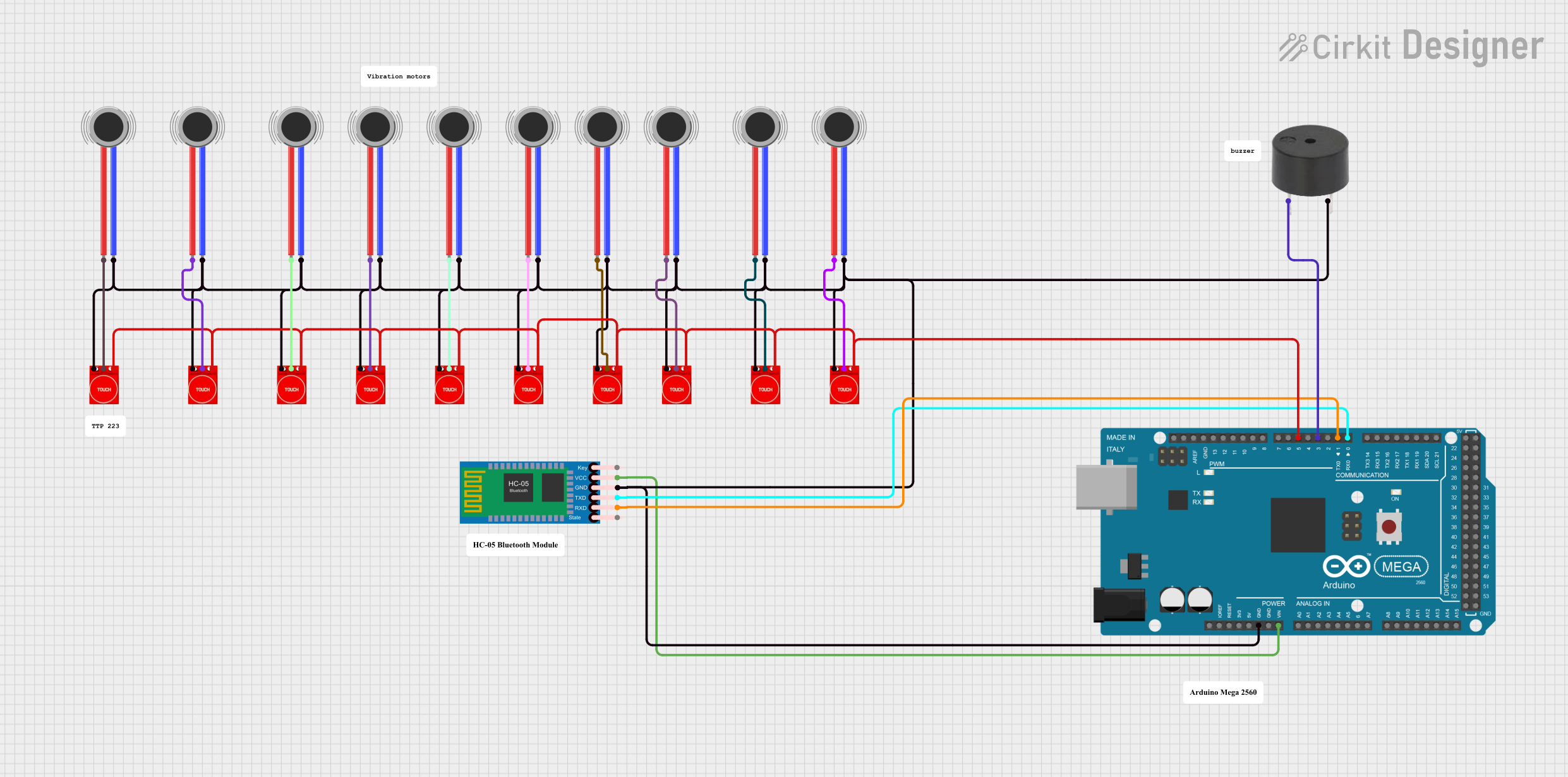

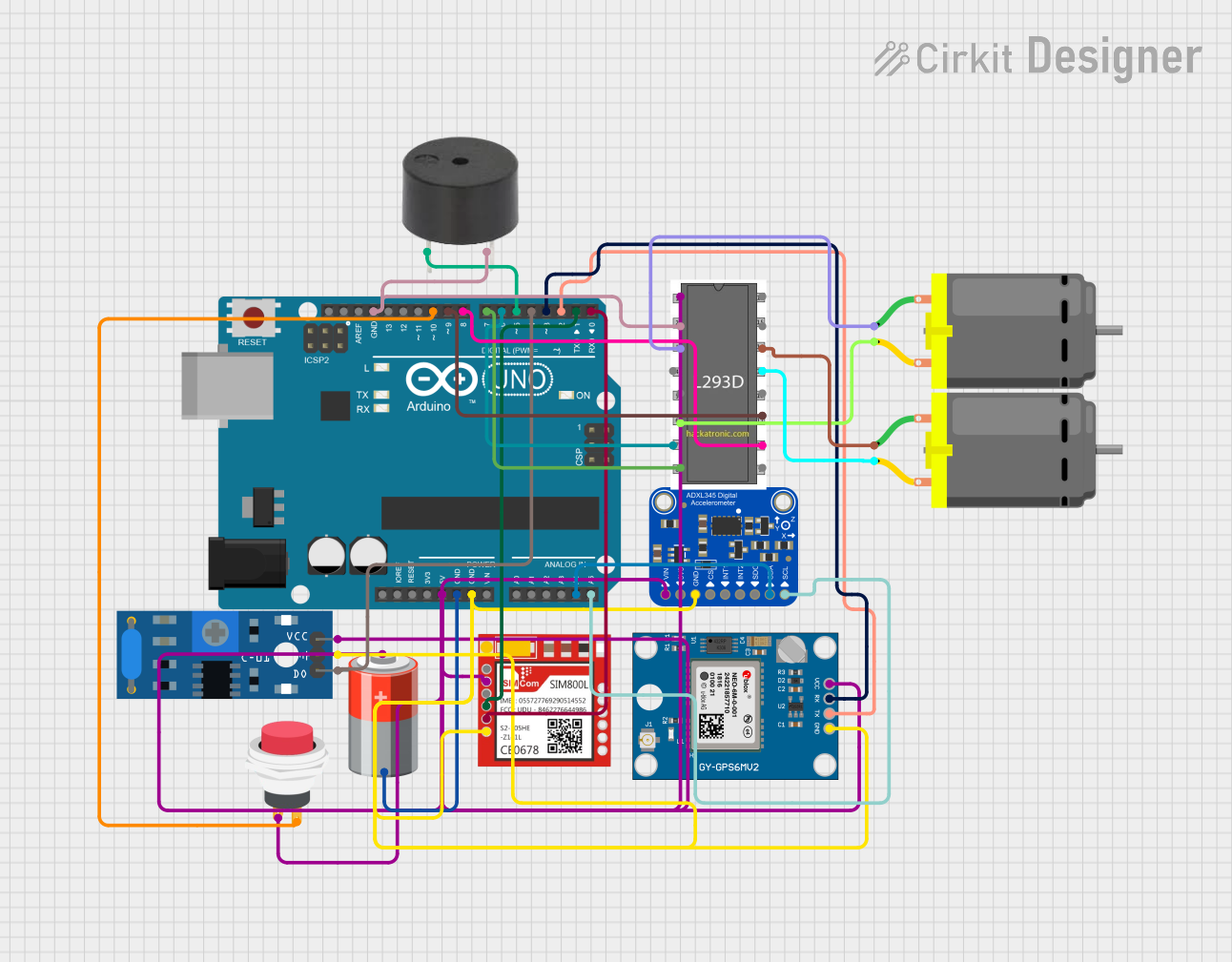

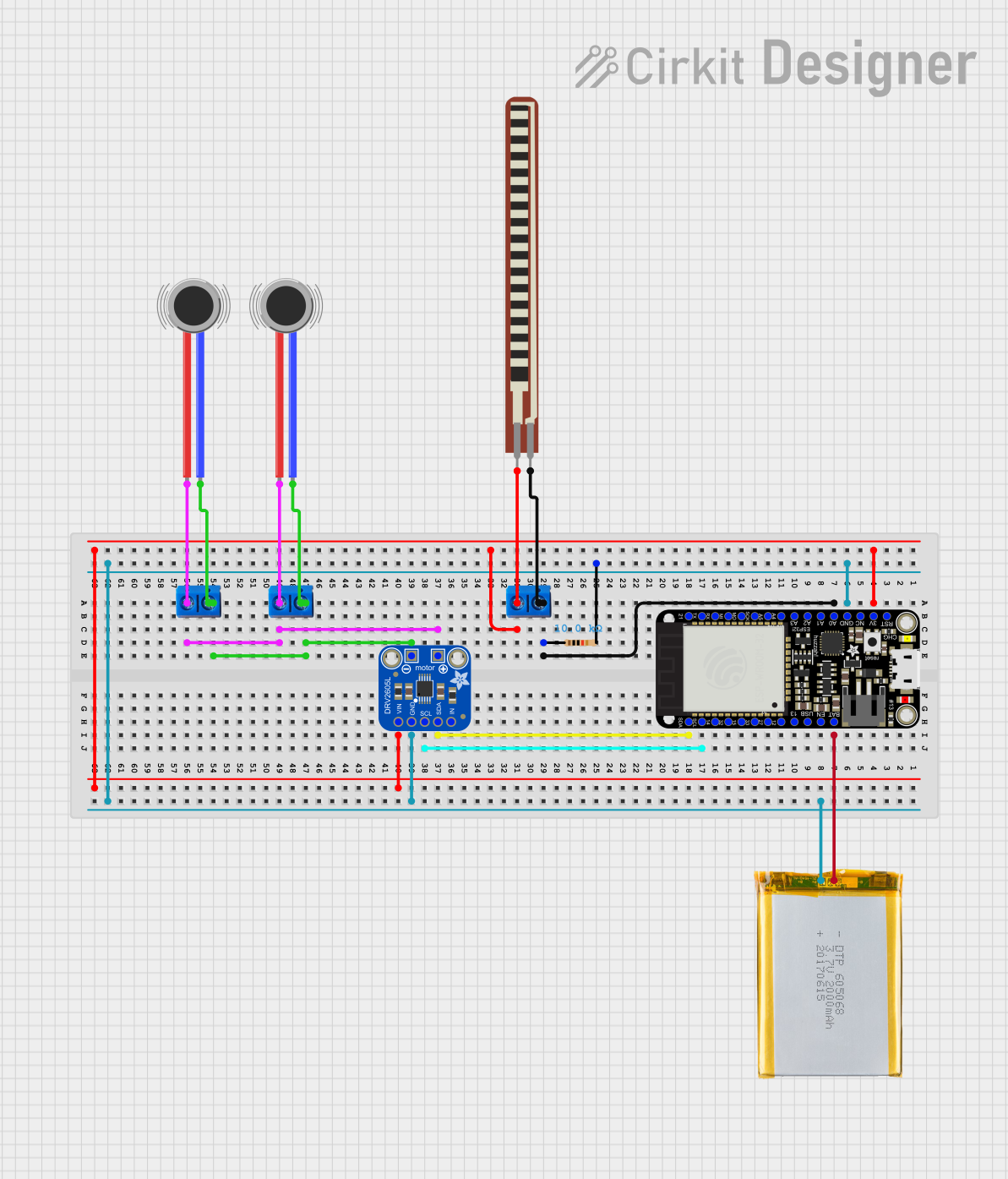

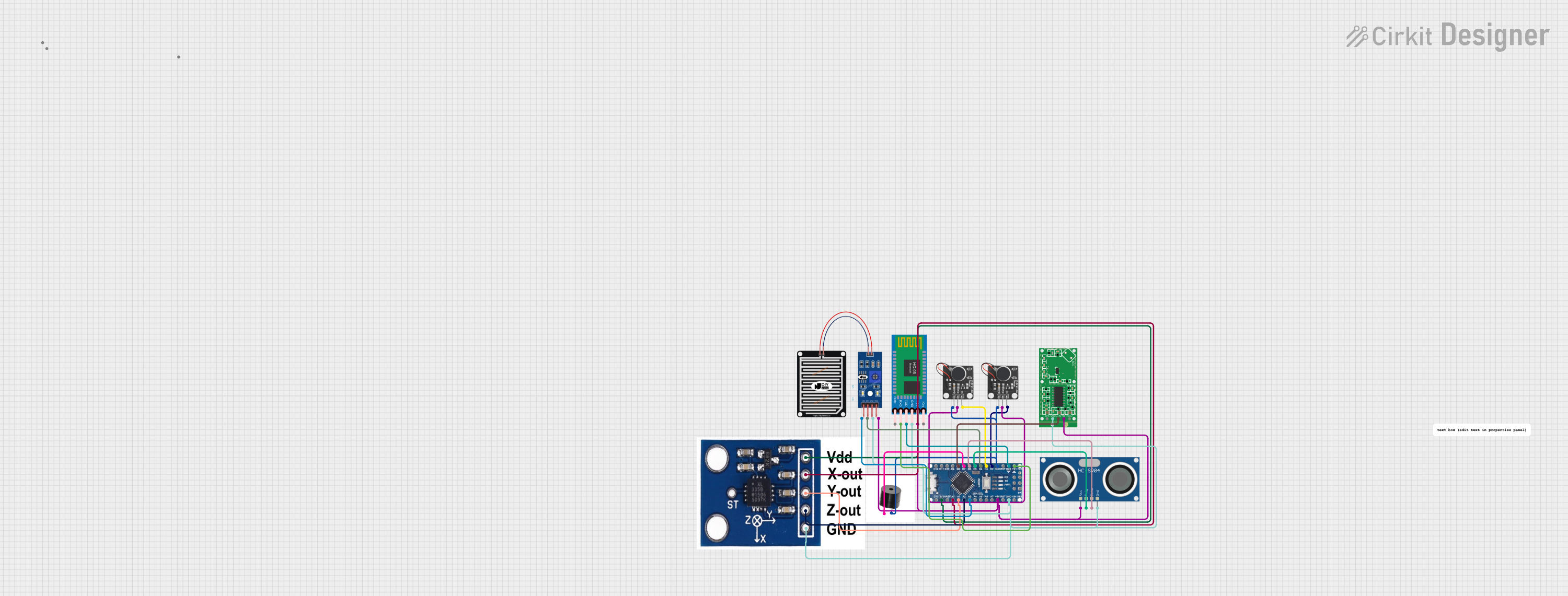

Explore Projects Built with FIT0774 Vibration motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with FIT0774 Vibration motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Mobile phones and tablets for silent notifications and haptic feedback

- Wearable devices for alerts and notifications

- Game controllers to enhance user experience

- Medical devices for tactile feedback

- Robotics for sensory feedback and alerts

Technical Specifications

Key Technical Details

- Operating Voltage: 3.0V - 4.2V

- Rated Current: 75mA (max)

- Starting Voltage: 2.3V (min)

- Operating Temperature: -10°C to +60°C

- Rated Speed: 9000 rpm ± 2500 rpm at 3.0V

- Body Dimensions: 10mm x 2.7mm

- Wire Length: 90mm

- Weight: 1.8g

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Vibration Motor + |

| 2 | Vibration Motor - |

Usage Instructions

How to Use the Component in a Circuit

Power Connection: Connect the positive pin of the FIT0774 to a digital output pin on your microcontroller (e.g., Arduino UNO) and the negative pin to the ground (GND).

Driving the Motor: To activate the motor, set the digital output pin to HIGH. To stop the vibrations, set the pin to LOW.

PWM Control (Optional): For varying the intensity of the vibrations, use a PWM signal. The duty cycle of the PWM will determine the strength of the vibrations.

Important Considerations and Best Practices

- Do not exceed the maximum rated voltage and current, as this may damage the motor.

- Ensure that the motor is securely mounted to prevent any unwanted movement.

- Consider using a transistor or a motor driver if the current exceeds the microcontroller's output capacity.

- Use a flyback diode if you are driving the motor with a transistor to protect against voltage spikes.

Example Code for Arduino UNO

// Define the pin connected to the vibration motor

const int motorPin = 3; // PWM pin for intensity control

void setup() {

pinMode(motorPin, OUTPUT);

}

void loop() {

// Turn on the vibration motor at full intensity

analogWrite(motorPin, 255); // Set PWM to maximum

delay(1000); // Vibrate for 1 second

// Turn off the vibration motor

analogWrite(motorPin, 0); // Set PWM to zero (off)

delay(1000); // Pause for 1 second

// Vibrate the motor at half intensity

analogWrite(motorPin, 127); // Set PWM to half (50% duty cycle)

delay(1000); // Vibrate for 1 second

// Turn off the motor

analogWrite(motorPin, 0); // Set PWM to zero (off)

delay(1000); // Pause for 1 second

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor not vibrating: Check the connections and ensure the power supply is within the operating voltage range.

- Weak vibrations: Ensure the power supply is adequate and the PWM signal is set correctly if used.

- Motor overheating: Avoid running the motor continuously at high voltages or currents beyond the rated specifications.

Solutions and Tips for Troubleshooting

- Double-check wiring and connections for any loose ends or incorrect polarity.

- Use a multimeter to verify the voltage at the motor's terminals.

- If using PWM, ensure the code is correctly implemented and the correct pin is being used.

- Consider adding a heat sink or cooling mechanism if overheating occurs during prolonged use.

FAQs

Q: Can I run the FIT0774 directly from an Arduino pin? A: Yes, but ensure that the current draw is within the limits of the Arduino pin (typically 40mA).

Q: How can I adjust the vibration strength? A: Use PWM to control the intensity of the vibrations by varying the duty cycle.

Q: Is it necessary to use a flyback diode with this motor? A: It is good practice to use a flyback diode when driving inductive loads like motors to protect against inductive voltage spikes, especially when using a transistor or relay.

Q: Can the FIT0774 be powered by a battery? A: Yes, as long as the battery can provide the appropriate voltage and current within the operating specifications of the motor.