How to Use DC Motor: Examples, Pinouts, and Specs

Design with DC Motor in Cirkit Designer

Design with DC Motor in Cirkit DesignerIntroduction

A DC motor is an electrical machine that converts direct current electrical power into mechanical power. It is one of the most common actuators used in electronic control systems and robotics. DC motors are widely used in various applications such as electric vehicles, household appliances, industrial machinery, and hobbyist projects.

Explore Projects Built with DC Motor

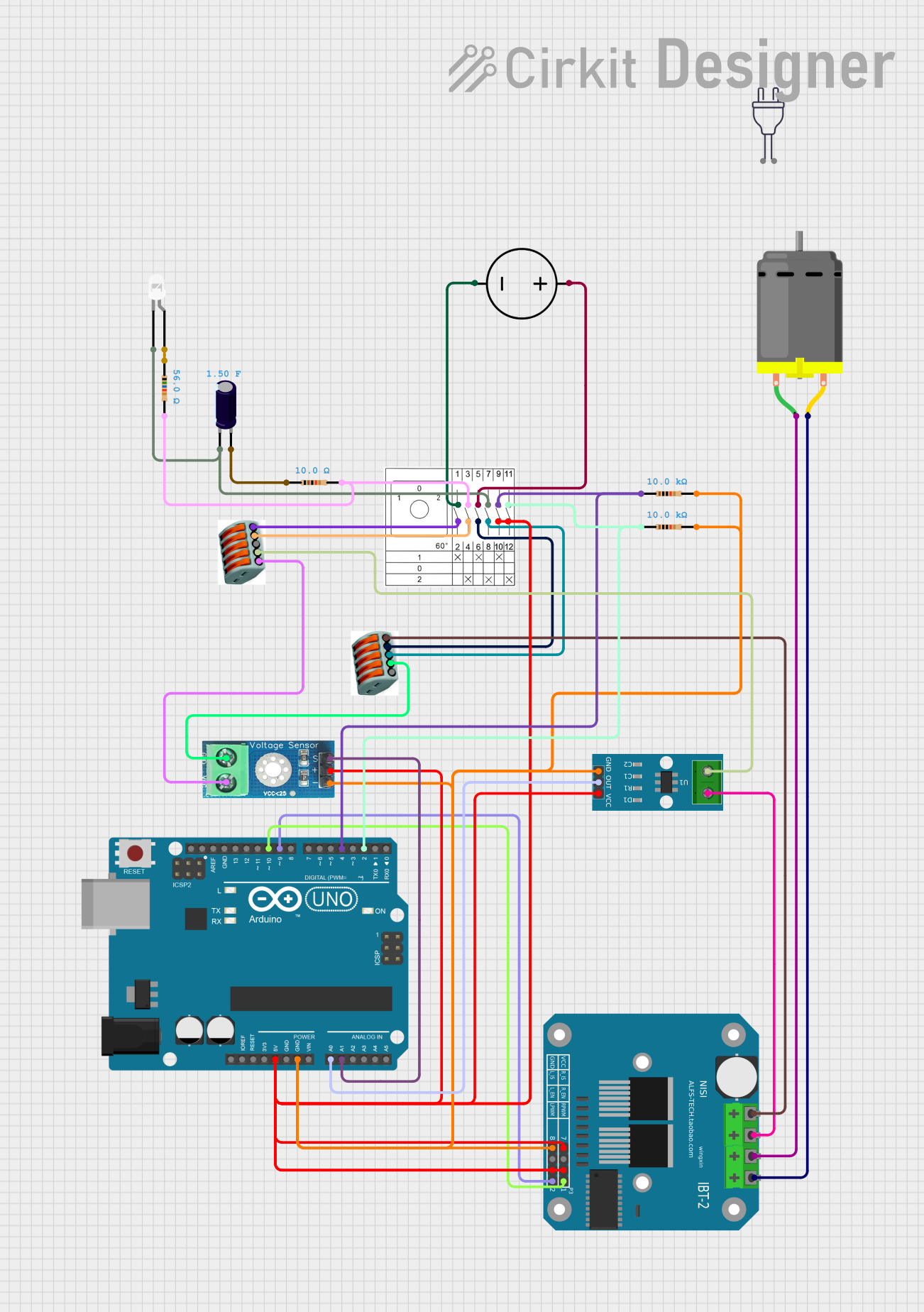

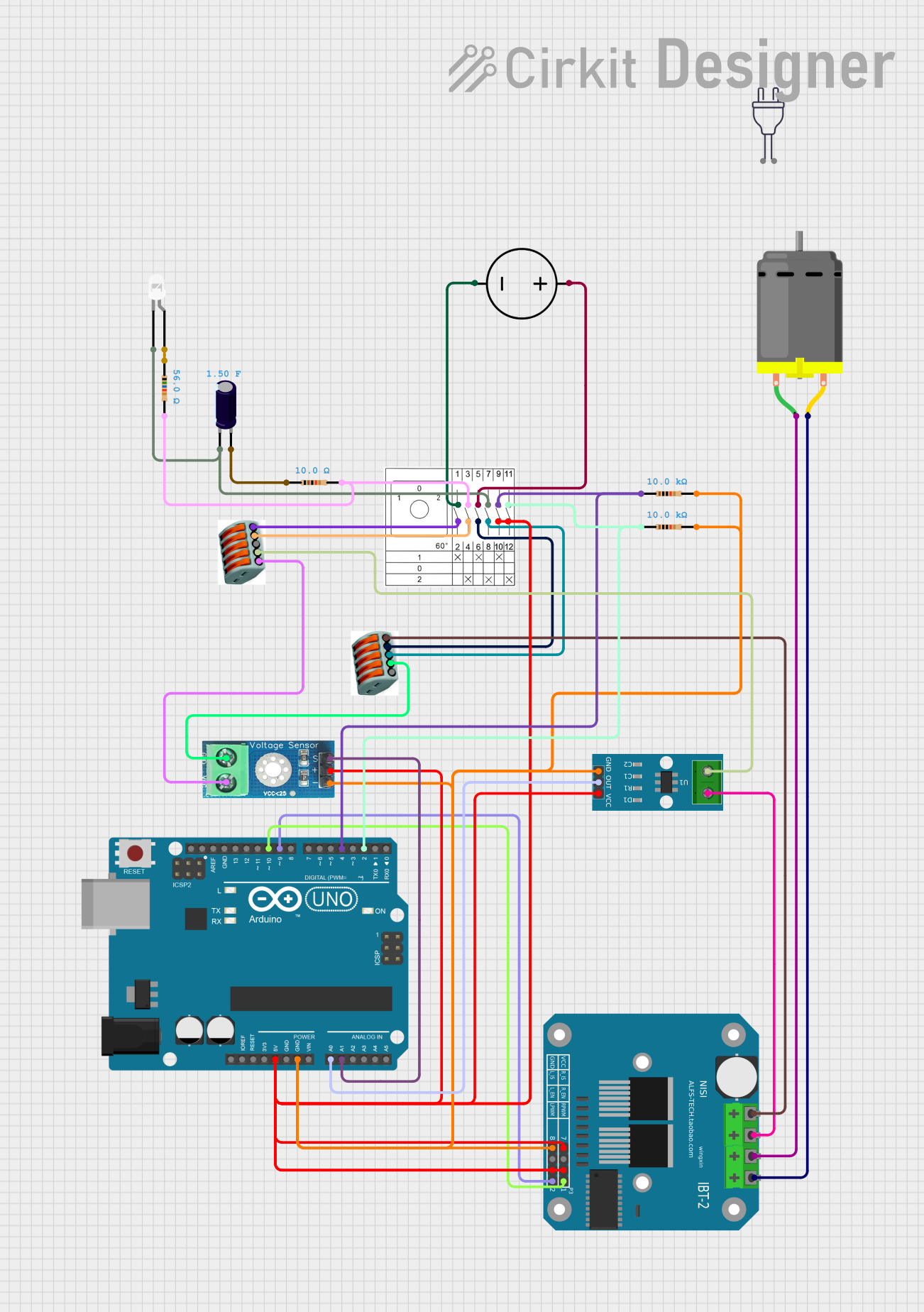

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DC Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Actuating wheels, arms, and other moving parts.

- Automotive: Powering electric vehicles, window lifters, and wipers.

- Industrial: Driving conveyor belts, pumps, and fans.

- Consumer Electronics: Operating disk drives, toys, and handheld tools.

Technical Specifications

Key Technical Details

- Voltage Range: Typically 1.5V to 24V (varies by model)

- Current Consumption: Depends on load and motor size

- Power Ratings: Varies widely, from milliwatts to kilowatts

- Speed: Typically hundreds to thousands of RPM (revolutions per minute)

- Torque: Depends on motor design and power

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Motor Terminal (+) |

| 2 | Motor Terminal (-) |

Note: Some DC motors may come with more than two terminals if they include additional features like built-in encoders.

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect a suitable power supply to the motor terminals. Ensure the voltage matches the motor's specifications.

- Direction Control: To reverse the motor direction, swap the polarity of the power supply connections.

- Speed Control: Use a PWM (Pulse Width Modulation) signal to control the motor speed. This can be achieved using a microcontroller like an Arduino UNO.

- Motor Driver: For motors that draw more current than a microcontroller can handle, use a motor driver or an H-bridge circuit.

Important Considerations and Best Practices

- Current Rating: Ensure the power supply and control circuitry can handle the motor's maximum current draw.

- Heat Dissipation: Motors can generate heat; provide adequate cooling if necessary.

- Electrical Noise: DC motors can introduce electrical noise into a circuit; use filtering if needed.

- Mechanical Load: Avoid overloading the motor, as excessive load can lead to reduced performance or damage.

Example Code for Arduino UNO

// Example code to control a DC motor speed and direction using an Arduino UNO

#include <Arduino.h>

const int motorPin = 3; // Connect the motor control signal to pin 3 (PWM capable)

void setup() {

pinMode(motorPin, OUTPUT); // Set the motor control pin as an output

}

void loop() {

// Set motor speed (0 to 255)

analogWrite(motorPin, 127); // Set to approximately 50% speed

delay(2000); // Run for 2 seconds

// Change motor direction by stopping the motor briefly

analogWrite(motorPin, 0); // Stop the motor

delay(1000); // Wait for 1 second

// Reverse motor direction by changing the polarity

// This would require an H-bridge and is not directly supported by a single pin

// Additional circuitry is required to safely reverse the motor direction

}

Note: The above code assumes the use of a simple motor driver or transistor to control the motor. For reversing the motor direction, an H-bridge circuit or a motor driver with direction control would be necessary.

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor not running: Check power supply connections and voltage levels.

- Motor running slowly or weakly: Ensure the power supply can deliver sufficient current.

- Overheating: Reduce load or improve cooling.

- Erratic behavior: Check for electrical noise and use filtering if necessary.

Solutions and Tips for Troubleshooting

- Check Connections: Loose connections can cause intermittent issues.

- Power Supply: Verify that the power supply is adequate for the motor's requirements.

- Motor Driver: Ensure the motor driver is functioning correctly and is not damaged.

- PWM Frequency: Adjust the PWM frequency to optimize motor performance.

FAQs

Q: Can I control the speed of a DC motor without a microcontroller? A: Yes, a variable resistor or potentiometer can be used for basic speed control, but this is less efficient and provides less control than PWM.

Q: How do I know if my motor requires a motor driver? A: If the motor's current or power ratings exceed the output capabilities of your control device (like an Arduino), a motor driver is needed.

Q: Can I run a DC motor directly from an Arduino pin? A: Only if the motor's current draw is within the pin's current limit (typically 20-40mA for Arduino). Otherwise, use a motor driver.

Q: How can I reverse the direction of a DC motor? A: To reverse the direction, you need to reverse the polarity of the power applied to the motor. This is commonly done using an H-bridge circuit or a motor driver with direction control.