How to Use Air Pump And Vacuum Dc Motor - 4.5v And 1.8 Lpm - Zr320-02pm: Examples, Pinouts, and Specs

Design with Air Pump And Vacuum Dc Motor - 4.5v And 1.8 Lpm - Zr320-02pm in Cirkit Designer

Design with Air Pump And Vacuum Dc Motor - 4.5v And 1.8 Lpm - Zr320-02pm in Cirkit DesignerIntroduction

The Air Pump and Vacuum DC Motor - ZR320-02PM by Adafruit is a compact and efficient motor-driven air pump designed for low-power applications. Operating at 4.5 volts, this pump delivers a flow rate of 1.8 liters per minute (LPM), making it ideal for projects requiring air movement or vacuum generation. Its small size and lightweight design make it suitable for portable devices, hobby projects, and small-scale automation systems.

Explore Projects Built with Air Pump And Vacuum Dc Motor - 4.5v And 1.8 Lpm - Zr320-02pm

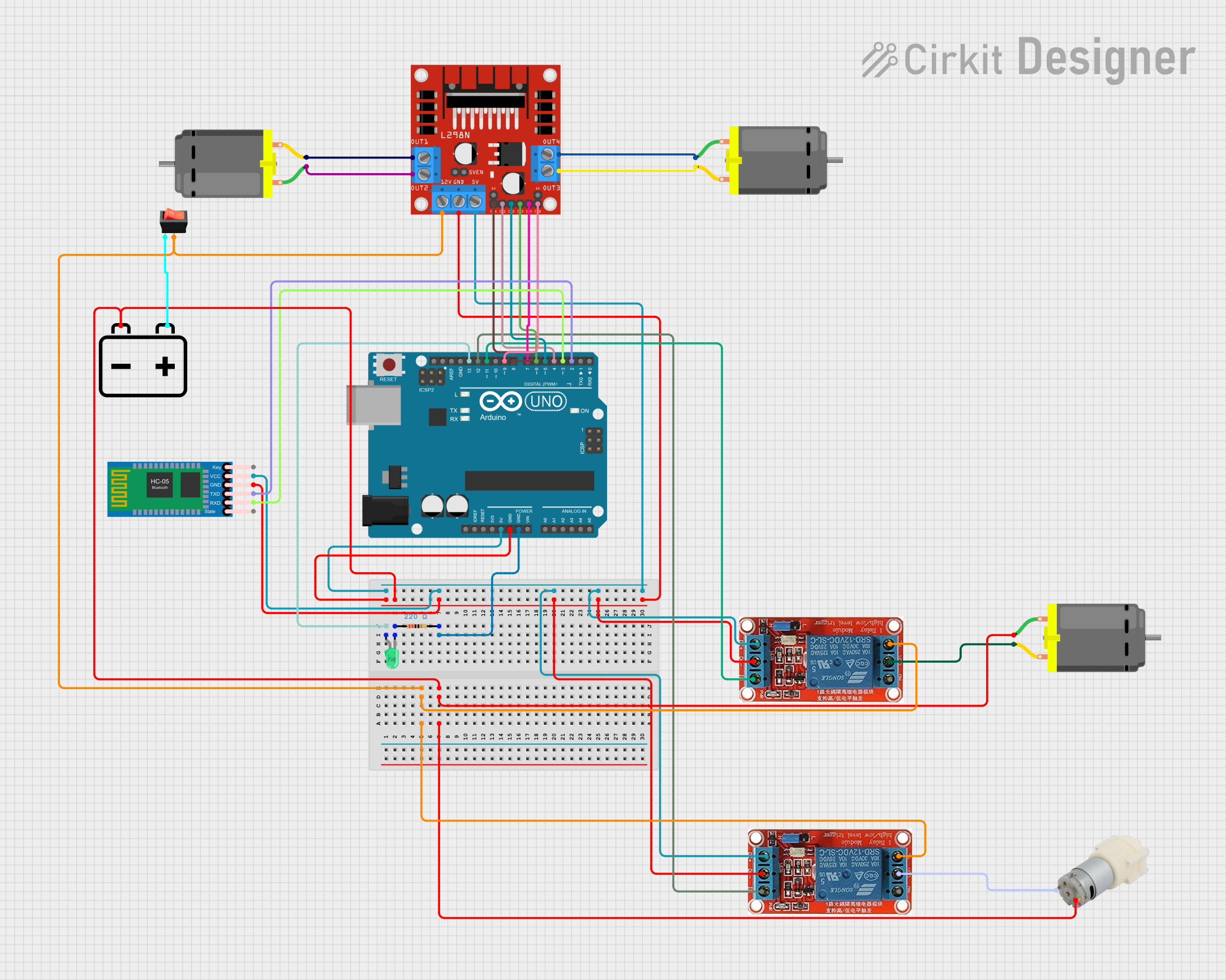

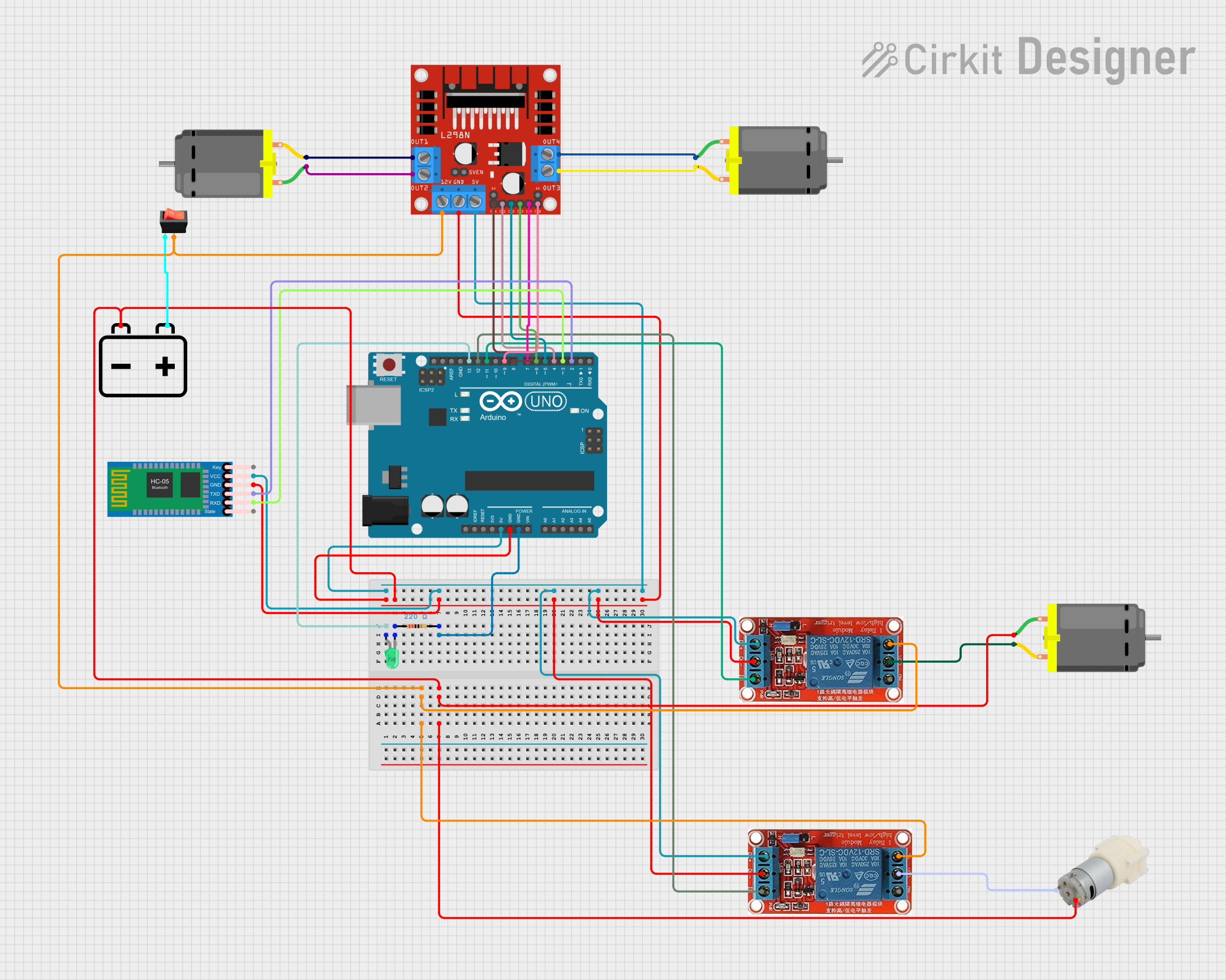

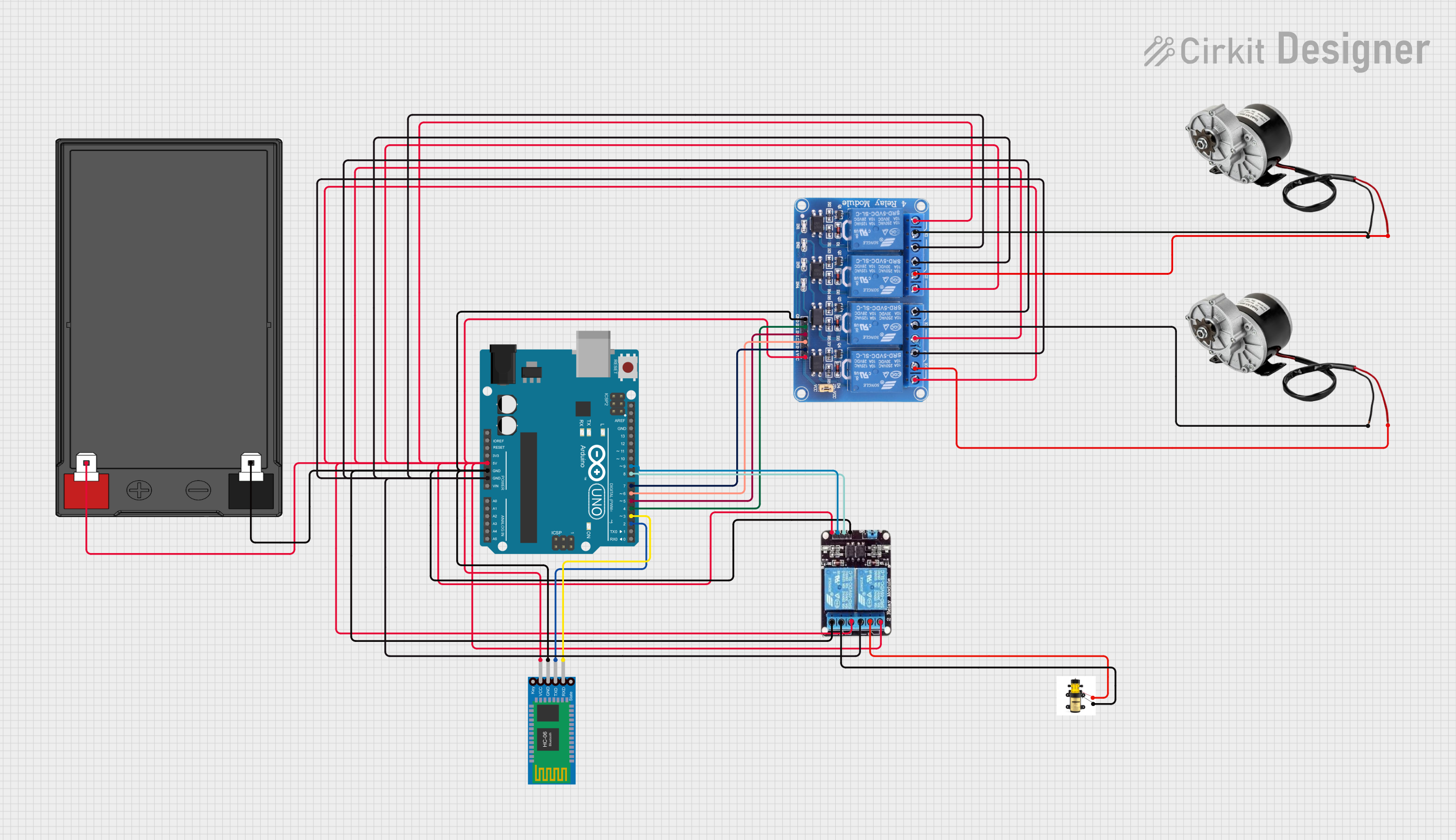

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Air Pump And Vacuum Dc Motor - 4.5v And 1.8 Lpm - Zr320-02pm

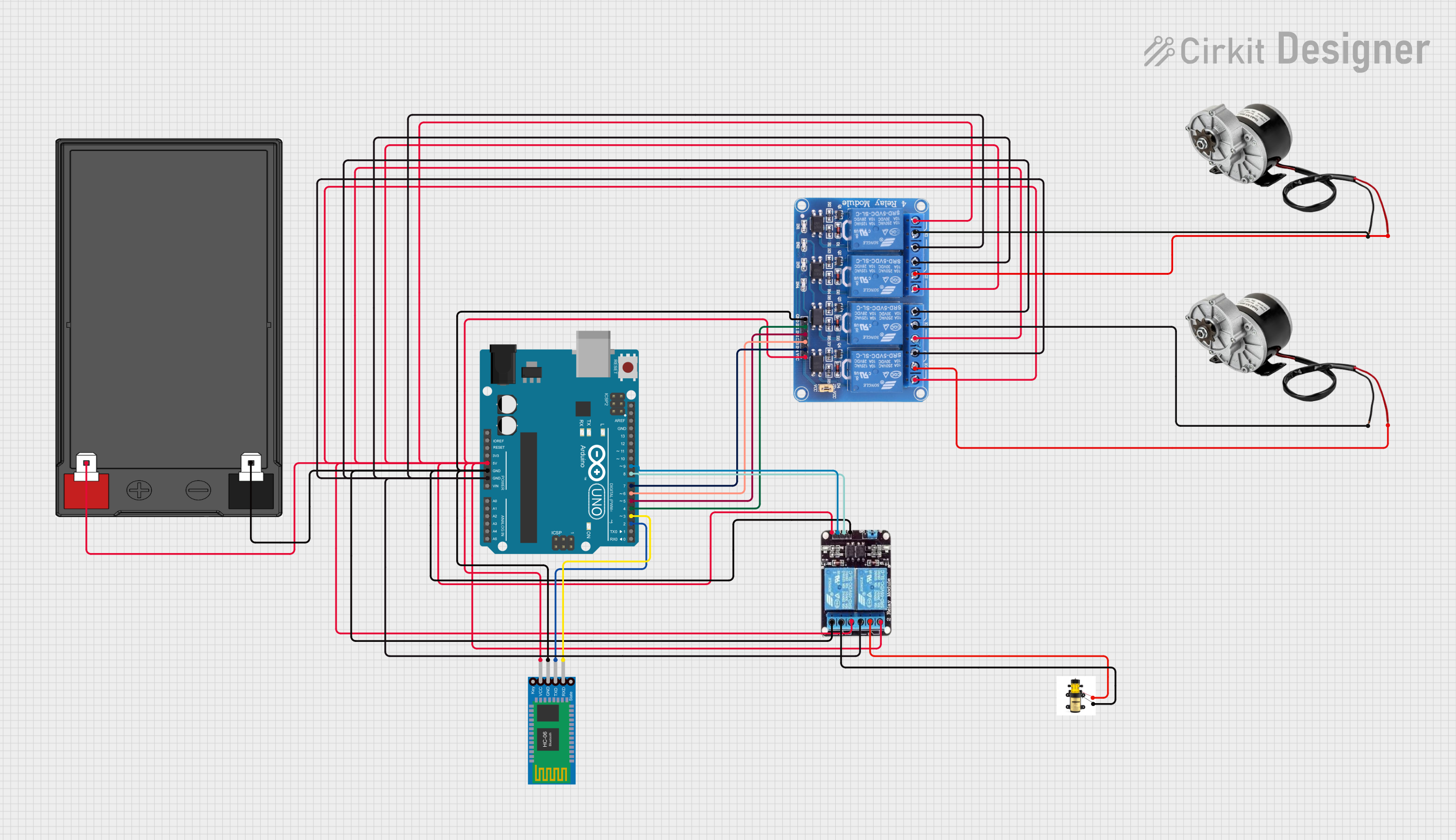

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Air circulation in small enclosures or devices

- Vacuum generation for suction-based mechanisms

- Medical devices such as nebulizers or air samplers

- DIY projects like airbrush systems or pneumatic controls

- Robotics and automation requiring air or vacuum flow

Technical Specifications

Below are the key technical details of the ZR320-02PM air pump:

| Parameter | Value |

|---|---|

| Operating Voltage | 4.5V DC |

| Operating Current | 200-300 mA (typical) |

| Maximum Flow Rate | 1.8 LPM |

| Maximum Vacuum | -50 kPa |

| Noise Level | ≤ 60 dB |

| Dimensions | 27 mm x 12 mm x 40 mm |

| Weight | 30 g |

| Operating Temperature | -10°C to 50°C |

| Lifespan | ~500 hours (continuous use) |

Pin Configuration and Descriptions

The ZR320-02PM has two electrical terminals for power input:

| Pin | Description |

|---|---|

| + | Positive terminal (4.5V) |

| - | Negative terminal (GND) |

Ensure correct polarity when connecting the pump to avoid damage.

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the positive terminal (

+) to a 4.5V DC power source and the negative terminal (-) to ground (GND). A regulated power supply or battery pack is recommended. - Switch Control: To control the pump, you can use a mechanical switch or an electronic switch (e.g., a transistor or relay) in series with the power supply.

- PWM Control: For variable speed control, you can use a Pulse Width Modulation (PWM) signal from a microcontroller like an Arduino. This allows you to adjust the airflow or vacuum strength.

Important Considerations and Best Practices

- Polarity: Always ensure correct polarity when connecting the pump to avoid permanent damage.

- Voltage Range: Do not exceed the rated voltage of 4.5V, as this may overheat the motor or reduce its lifespan.

- Mounting: Secure the pump using screws or adhesive to minimize vibration and noise during operation.

- Noise Reduction: Use rubber mounts or dampeners to reduce noise and vibration in sensitive applications.

- Continuous Use: Avoid running the pump continuously for extended periods to prevent overheating. Allow it to cool down periodically.

Example: Connecting to an Arduino UNO

Below is an example of how to control the ZR320-02PM pump using an Arduino UNO and a transistor for switching:

Circuit Diagram

- Connect the pump's positive terminal to the collector of an NPN transistor (e.g., 2N2222).

- Connect the pump's negative terminal to GND.

- Connect the emitter of the transistor to GND.

- Use a 1kΩ resistor between the Arduino digital pin and the transistor's base.

Arduino Code

// Define the pin connected to the transistor base

const int pumpPin = 9;

void setup() {

pinMode(pumpPin, OUTPUT); // Set the pump control pin as an output

}

void loop() {

digitalWrite(pumpPin, HIGH); // Turn the pump ON

delay(5000); // Run the pump for 5 seconds

digitalWrite(pumpPin, LOW); // Turn the pump OFF

delay(5000); // Wait for 5 seconds before restarting

}

Notes:

- Use a flyback diode (e.g., 1N4007) across the pump terminals to protect the circuit from voltage spikes caused by the motor's inductive load.

- If using PWM for speed control, ensure the frequency is within the motor's operating range (typically 1-2 kHz).

Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Pump does not start | Incorrect wiring or polarity | Verify connections and polarity |

| Pump runs but airflow is weak | Insufficient voltage or current | Ensure power supply meets requirements |

| Excessive noise or vibration | Loose mounting or worn components | Secure the pump and check for damage |

| Pump overheats during operation | Continuous use without cooling | Allow the pump to cool periodically |

| No response to PWM control | Incorrect PWM frequency or wiring | Check PWM signal and connections |

FAQs

Can I use a higher voltage to increase airflow?

No, exceeding 4.5V can damage the motor and reduce its lifespan.Is the pump waterproof?

No, the ZR320-02PM is not waterproof. Avoid exposing it to liquids.Can I use this pump for inflating balloons?

Yes, but it is better suited for small-scale applications due to its limited flow rate.What is the recommended duty cycle for continuous use?

Operate the pump for a maximum of 30 minutes continuously, followed by a 10-minute cooldown period.

By following this documentation, you can effectively integrate the ZR320-02PM air pump into your projects and troubleshoot common issues with ease.