How to Use power distribution board: Examples, Pinouts, and Specs

Design with power distribution board in Cirkit Designer

Design with power distribution board in Cirkit DesignerIntroduction

A Power Distribution Board (PDB) is an essential electronic component designed to distribute electrical power to multiple circuits or devices within a system. It ensures that each connected component receives the appropriate voltage and current, simplifying power management in complex systems. PDBs are commonly used in applications such as drones, robotics, RC vehicles, and other multi-component electronic systems.

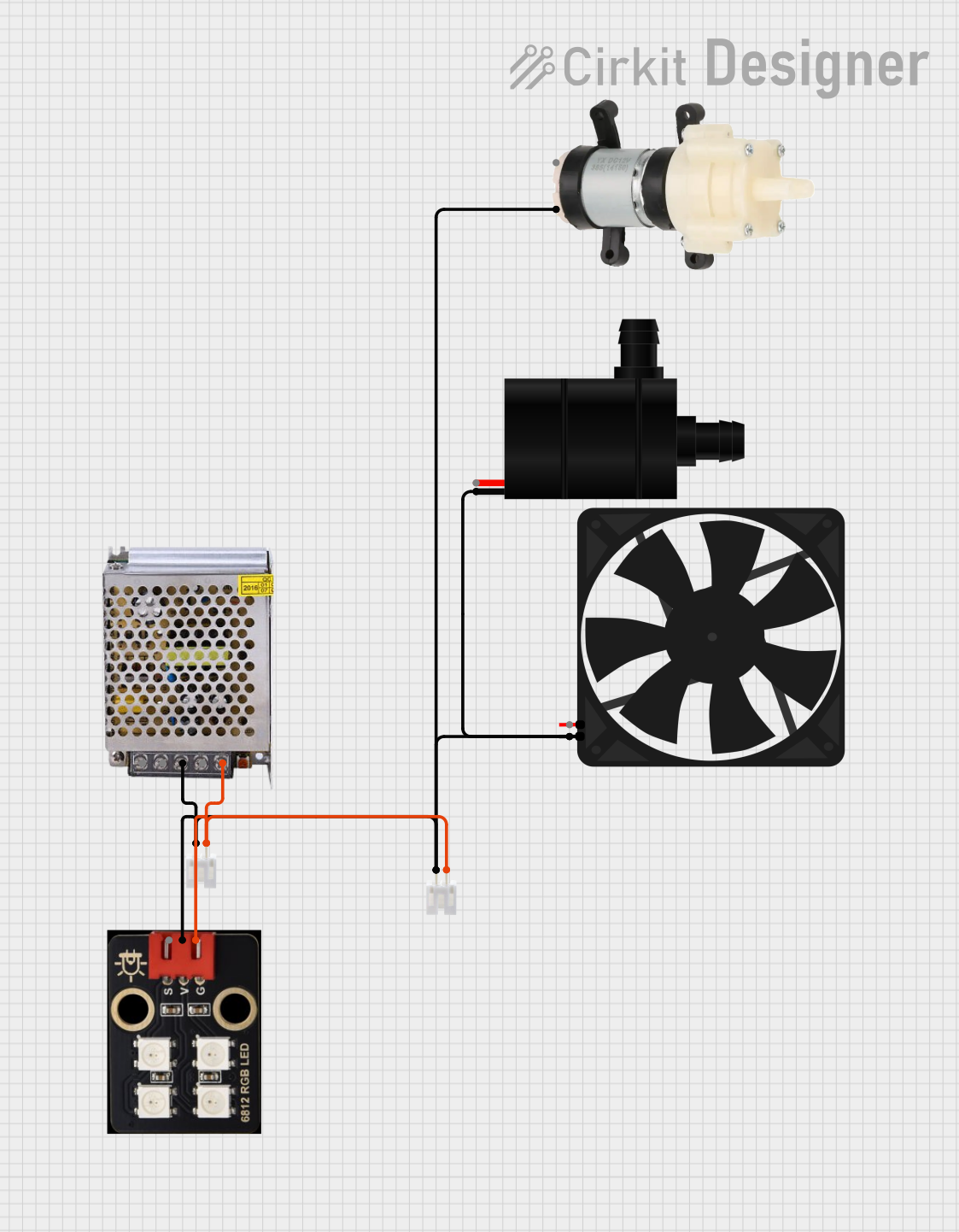

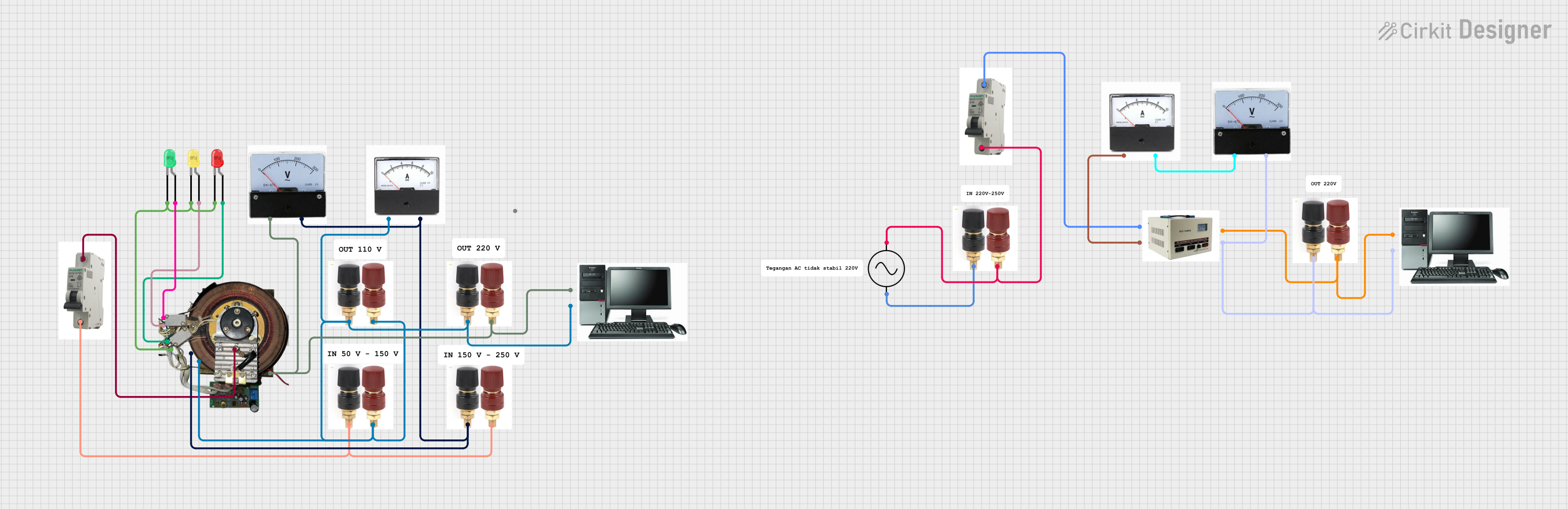

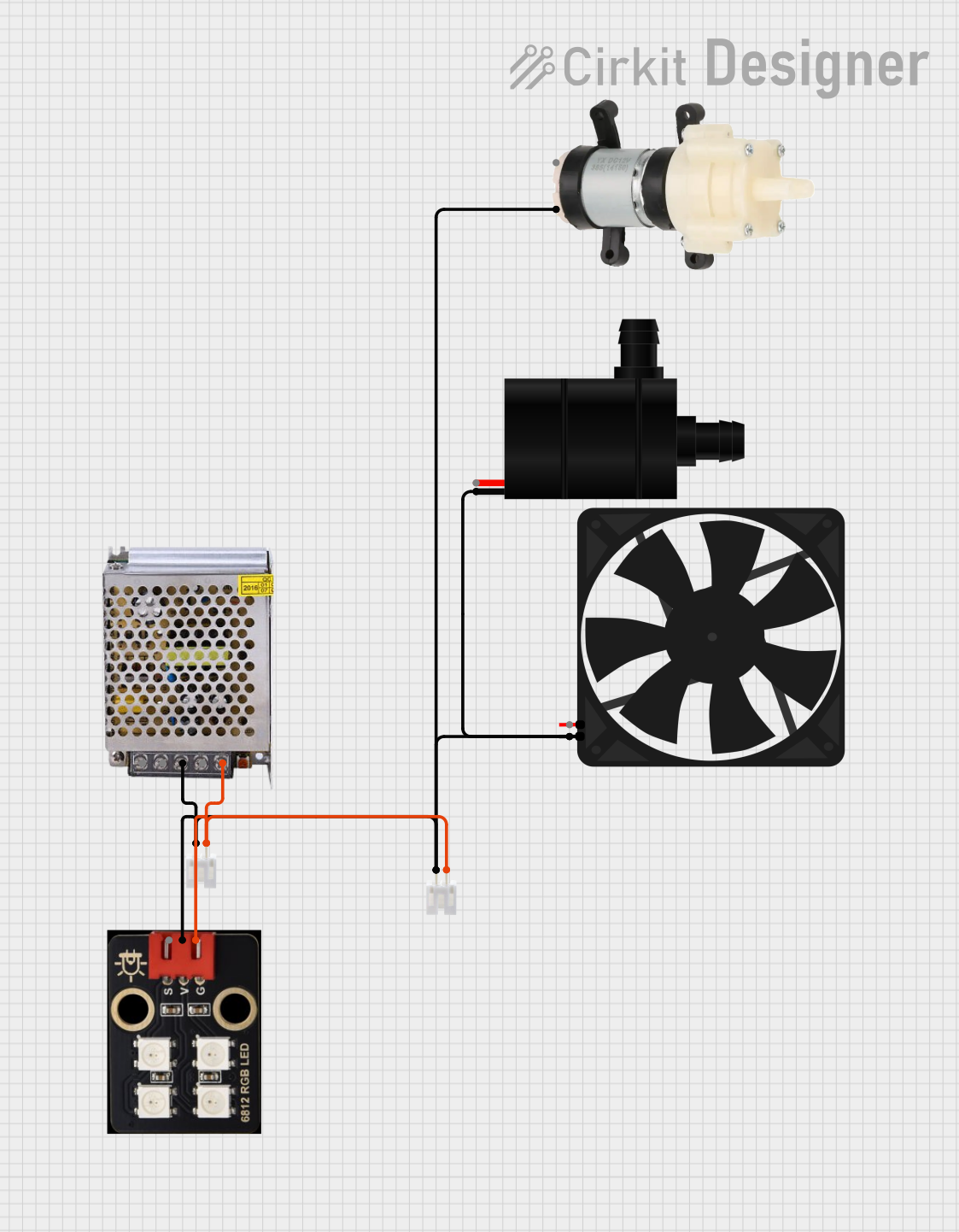

Explore Projects Built with power distribution board

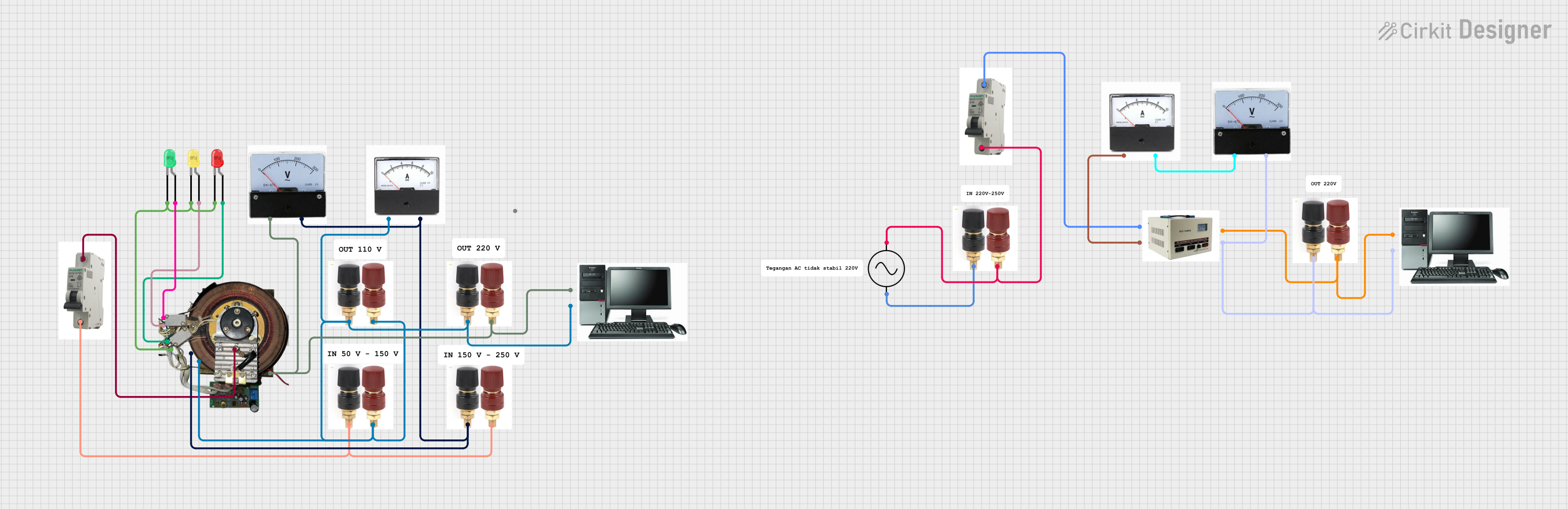

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with power distribution board

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Drones and UAVs: Distributing power to motors, flight controllers, and other peripherals.

- Robotics: Powering multiple actuators, sensors, and control boards.

- RC Vehicles: Supplying power to motors, servos, and receivers.

- DIY Electronics Projects: Managing power for multiple modules in a compact setup.

Technical Specifications

Below are the general technical specifications for a typical Power Distribution Board. Note that specific models may vary, so always refer to the datasheet of your PDB for exact details.

Key Technical Details

- Input Voltage Range: 7V to 26V (2S to 6S LiPo batteries)

- Maximum Current Rating: 100A (total across all outputs)

- Number of Outputs: 4 to 8 (varies by model)

- Output Voltage: Matches input voltage or includes regulated outputs (e.g., 5V, 12V)

- Dimensions: Typically 36mm x 36mm (varies by model)

- Weight: ~10g to 20g

- Connectors: XT60/XT90 for input, solder pads or pin headers for outputs

- Built-in Protection: Overcurrent, overvoltage, and short-circuit protection (on some models)

Pin Configuration and Descriptions

The following table describes the typical pin or pad layout of a Power Distribution Board:

| Pin/Pad | Description |

|---|---|

| VIN+ | Positive input voltage terminal (connect to battery positive terminal). |

| VIN- | Negative input voltage terminal (connect to battery negative terminal). |

| VOUT+ (x4) | Positive output voltage terminals for connected devices. |

| VOUT- (x4) | Negative output voltage terminals for connected devices. |

| 5V Output | Regulated 5V output for powering low-voltage devices (if available). |

| 12V Output | Regulated 12V output for powering specific devices (if available). |

| Ground (GND) | Common ground connection for all devices. |

Usage Instructions

How to Use the Component in a Circuit

Connect the Input Power Source:

- Attach the positive terminal of your power source (e.g., LiPo battery) to the VIN+ pad.

- Attach the negative terminal of your power source to the VIN- pad.

Connect Devices to the Outputs:

- Solder or connect the positive wire of each device to a VOUT+ pad.

- Solder or connect the negative wire of each device to a VOUT- pad.

- If your PDB includes regulated outputs (e.g., 5V or 12V), connect devices requiring those voltages to the corresponding pads.

Secure Connections:

- Ensure all connections are secure and insulated to prevent short circuits.

- Use heat shrink tubing or electrical tape to cover exposed wires.

Power On the System:

- Double-check all connections before powering on the system.

- Monitor the PDB for any signs of overheating or unusual behavior during initial use.

Important Considerations and Best Practices

- Check Voltage and Current Ratings: Ensure the PDB can handle the total current draw of all connected devices.

- Use Proper Connectors: Use high-quality connectors (e.g., XT60) for the input power source to minimize resistance and heat.

- Avoid Overloading: Do not exceed the maximum current rating of the PDB to prevent damage.

- Heat Dissipation: If the PDB gets warm during operation, consider adding a heatsink or improving airflow.

- Polarity: Always double-check the polarity of your connections to avoid damaging the PDB or connected devices.

Example: Using a PDB with an Arduino UNO

If you are using a PDB to power an Arduino UNO and other peripherals, follow these steps:

- Connect the PDB's 5V regulated output to the Arduino's 5V pin.

- Connect the PDB's ground (GND) to the Arduino's GND pin.

- Use the remaining PDB outputs to power other devices, such as sensors or motors.

Here is an example Arduino code to control a motor powered by the PDB:

// Example code to control a motor using an Arduino UNO

// Ensure the motor is powered via the PDB and connected to a motor driver

const int motorPin = 9; // PWM pin connected to motor driver

void setup() {

pinMode(motorPin, OUTPUT); // Set motor pin as output

}

void loop() {

analogWrite(motorPin, 128); // Set motor speed to 50% (PWM value: 128)

delay(2000); // Run motor for 2 seconds

analogWrite(motorPin, 0); // Stop motor

delay(2000); // Wait for 2 seconds

}

Troubleshooting and FAQs

Common Issues and Solutions

PDB Overheating:

- Cause: Exceeding the maximum current rating or poor ventilation.

- Solution: Reduce the load on the PDB or improve airflow around the board.

No Power to Connected Devices:

- Cause: Loose or incorrect connections.

- Solution: Verify all connections and ensure proper polarity.

Short Circuit Detected:

- Cause: Exposed wires or solder bridges.

- Solution: Inspect the board for shorts and insulate exposed wires.

Voltage Drop on Outputs:

- Cause: High current draw or insufficient input voltage.

- Solution: Use a higher-capacity power source or reduce the load.

FAQs

Can I use a PDB with a 3S LiPo battery? Yes, most PDBs support 3S (11.1V) batteries. Check the input voltage range of your specific PDB.

What happens if I exceed the PDB's current rating? Exceeding the current rating can cause overheating, damage to the PDB, or failure of connected devices.

Can I power both 5V and 12V devices simultaneously? Yes, if your PDB includes both 5V and 12V regulated outputs, you can power devices requiring these voltages simultaneously.

Do I need a fuse for my PDB? Some PDBs include built-in fuses. If not, consider adding an external fuse to protect your system.

By following this documentation, you can effectively integrate a Power Distribution Board into your electronic projects and ensure reliable power management.