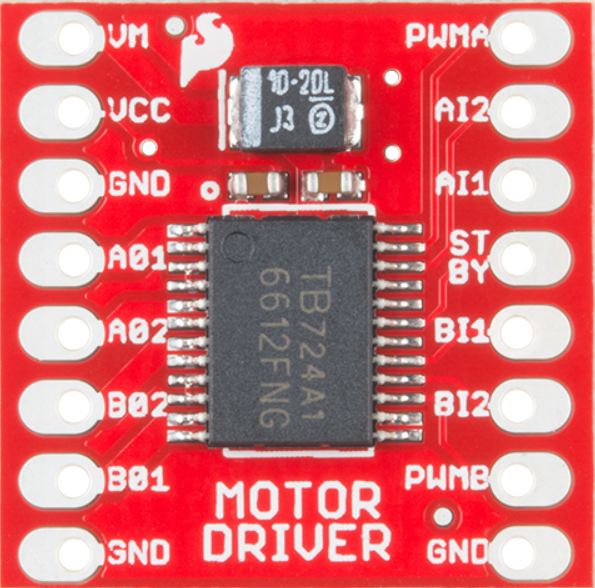

How to Use TB6612FNG Motor Driver: Examples, Pinouts, and Specs

Design with TB6612FNG Motor Driver in Cirkit Designer

Design with TB6612FNG Motor Driver in Cirkit DesignerIntroduction

The TB6612FNG is a dual H-bridge motor driver IC designed to control two DC motors or one stepper motor. It supports PWM (Pulse Width Modulation) for precise speed control and direction management. With built-in thermal shutdown protection, overcurrent protection, and low standby current, the TB6612FNG is a reliable choice for robotics, automation, and other motor control applications.

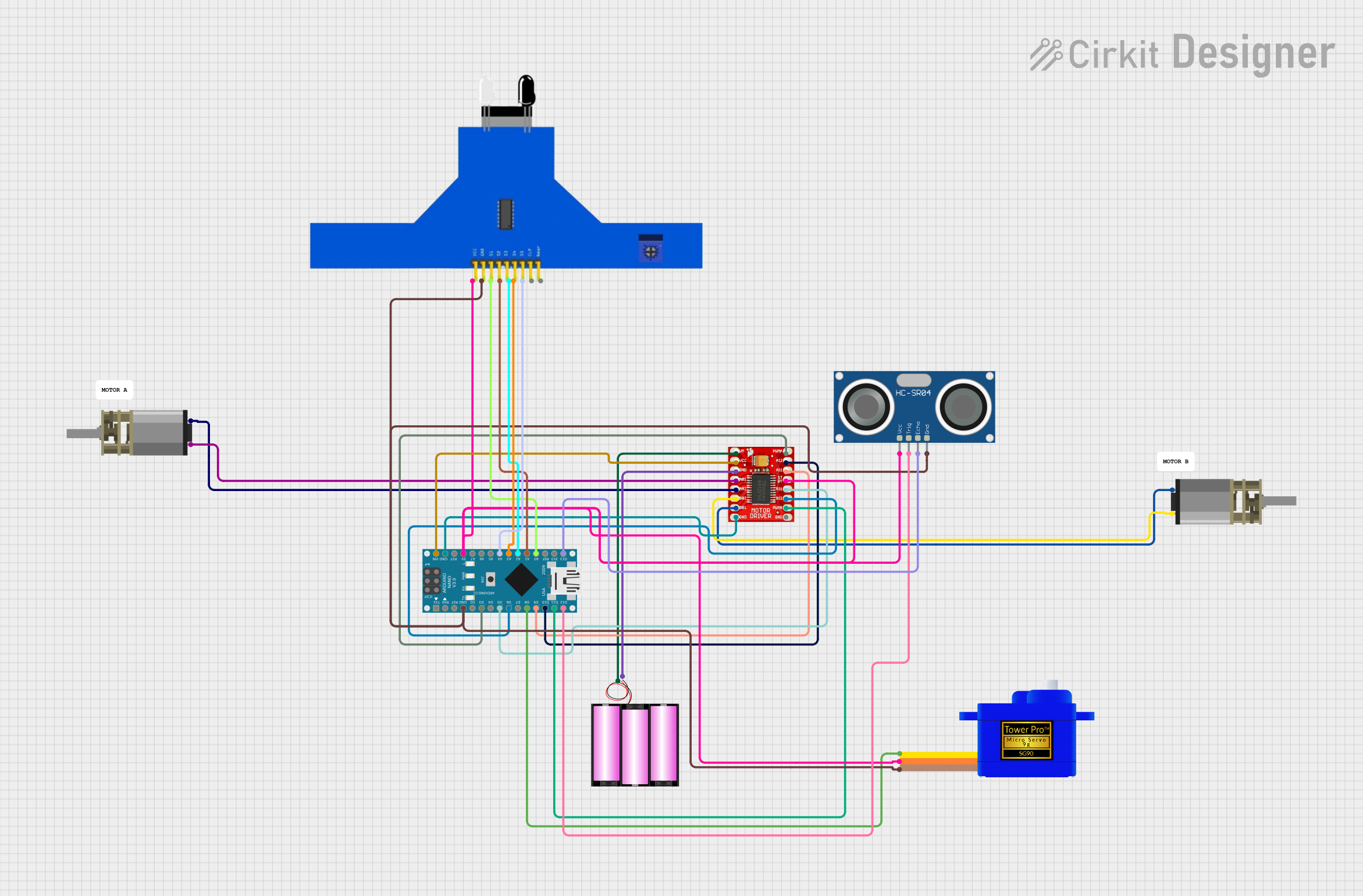

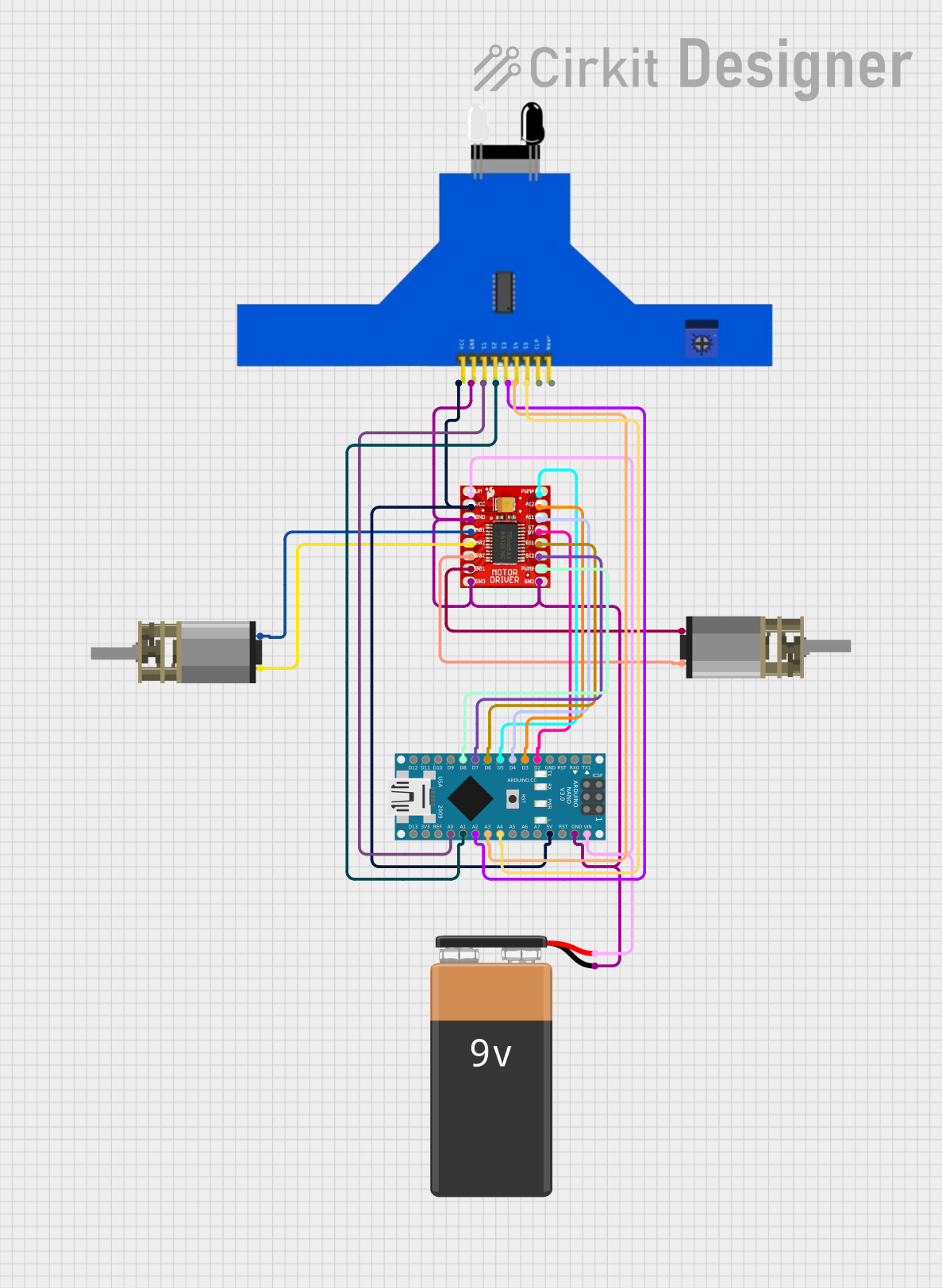

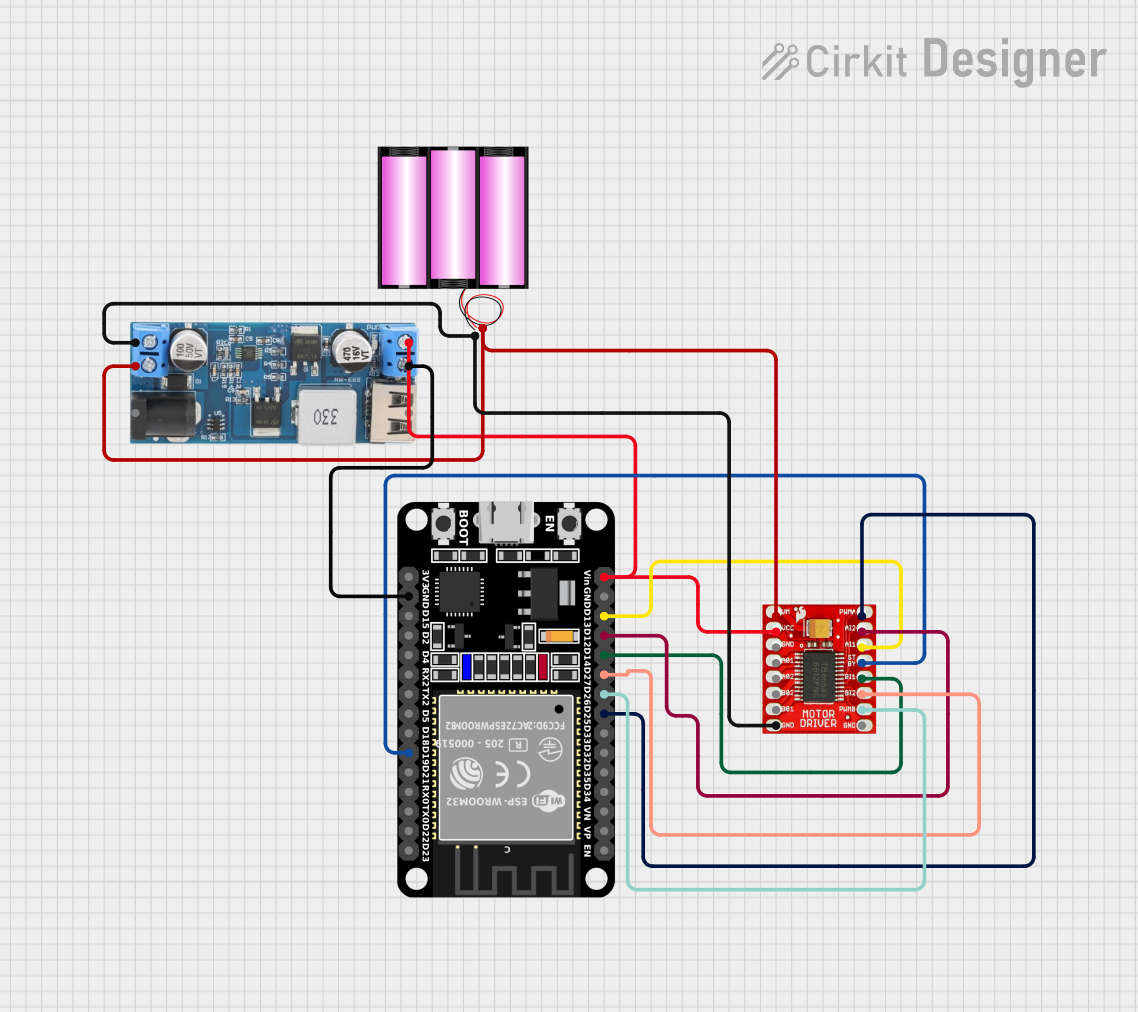

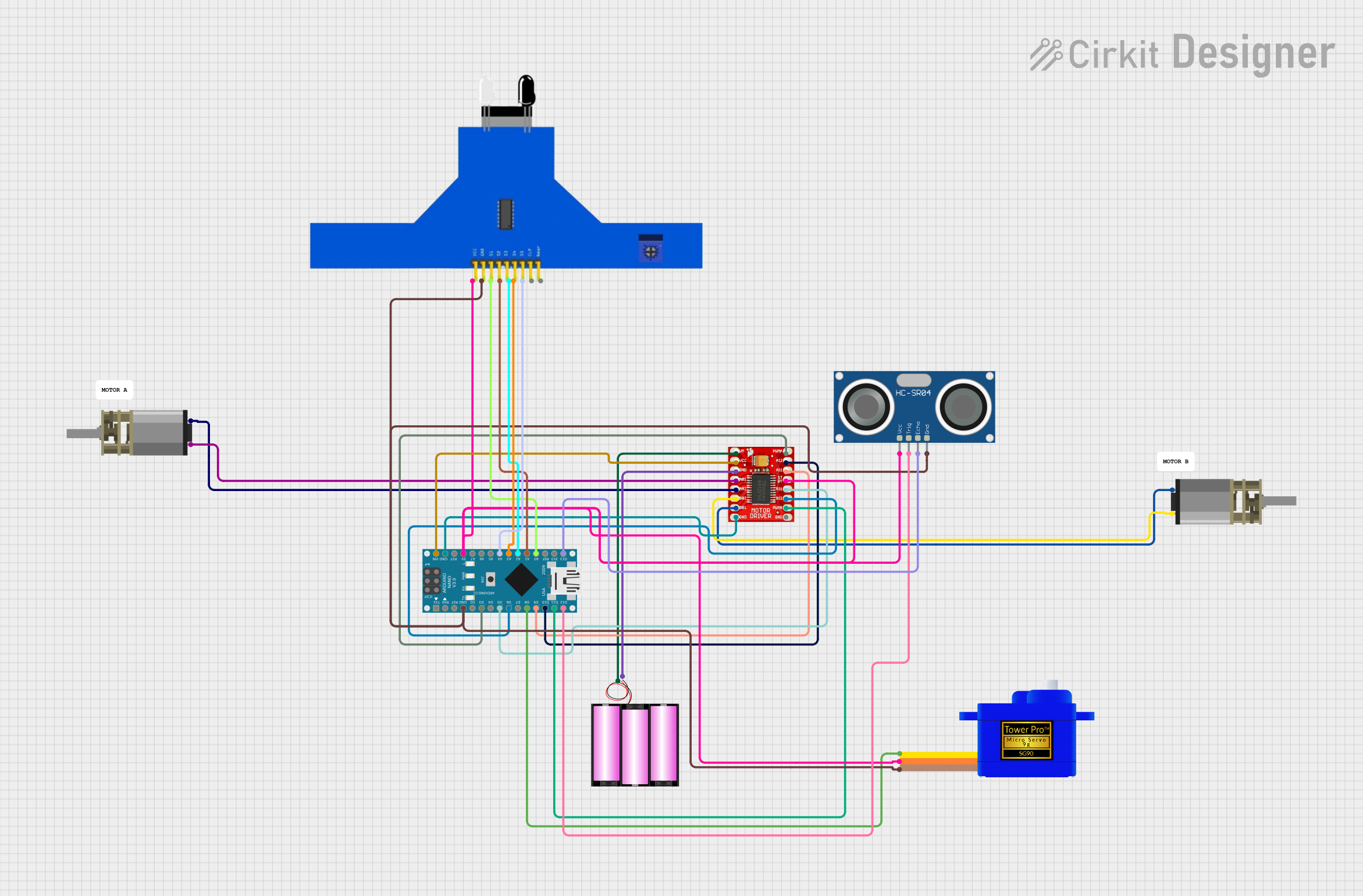

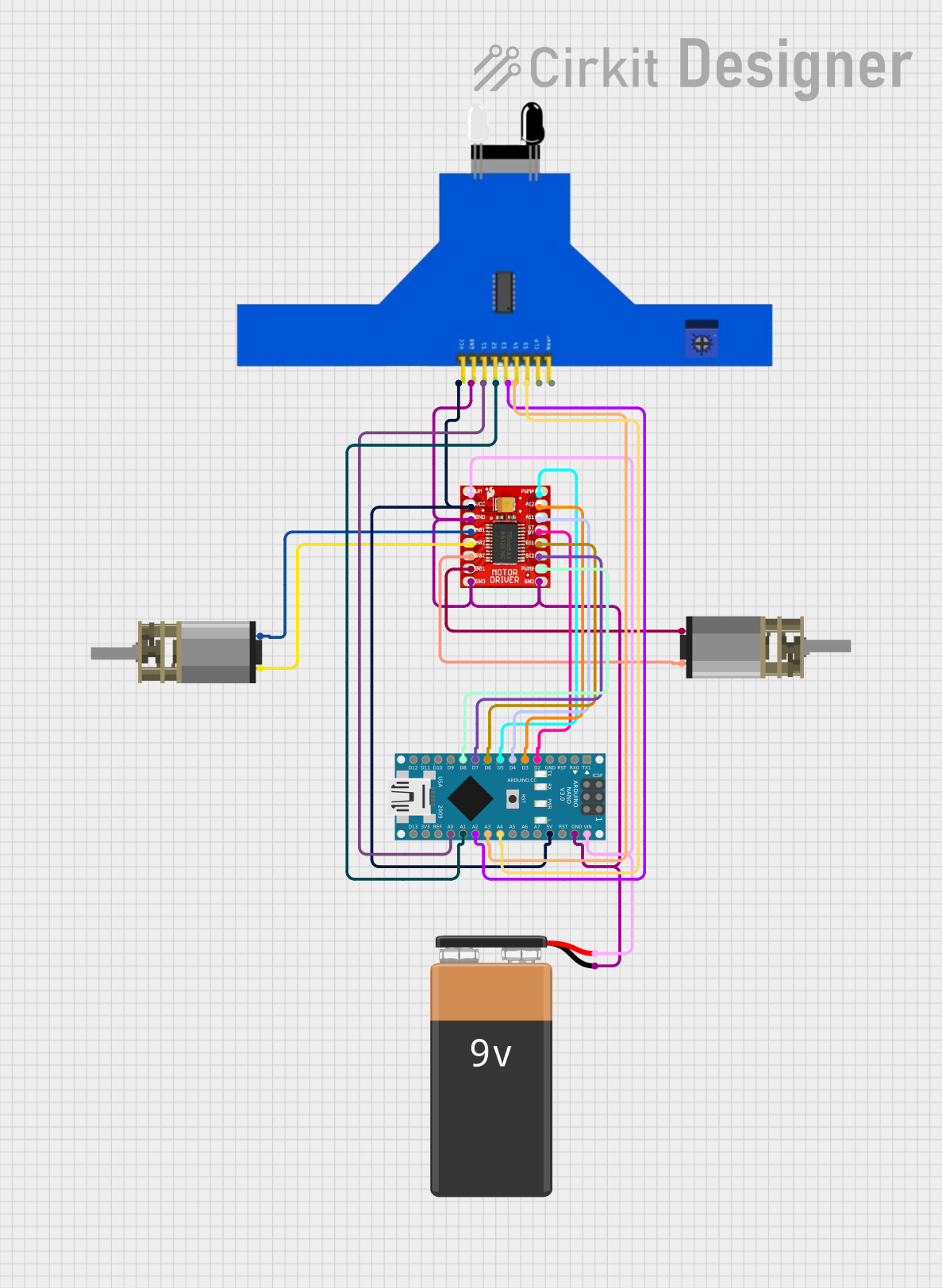

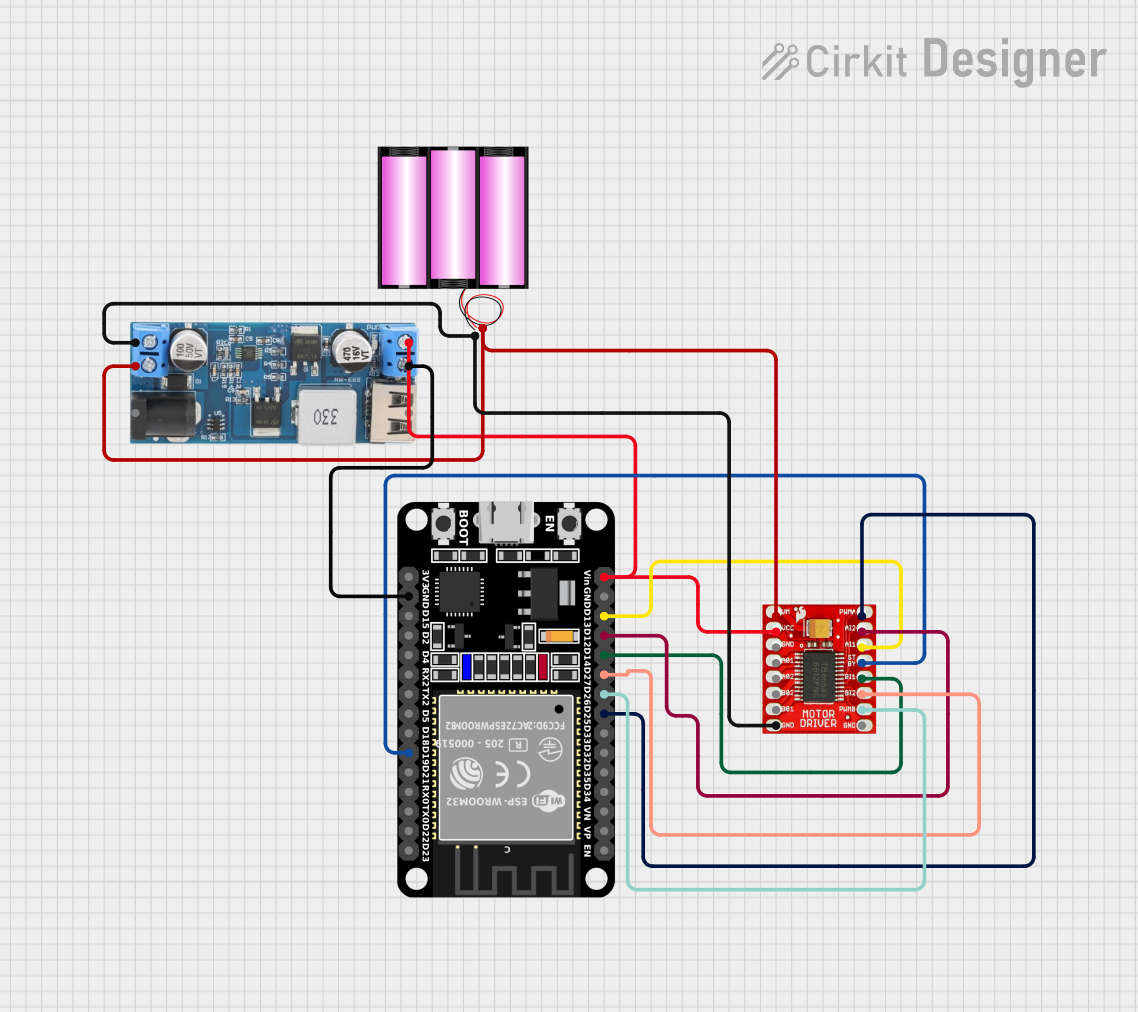

Explore Projects Built with TB6612FNG Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with TB6612FNG Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics (e.g., controlling wheels or arms)

- Automated conveyor systems

- Remote-controlled vehicles

- DIY electronics projects

- Stepper motor control for CNC machines or 3D printers

Technical Specifications

Key Technical Details

- Operating Voltage (Vcc): 2.7V to 5.5V

- Motor Voltage (VM): 4.5V to 13.5V

- Output Current (per channel): 1.2A (continuous), 3.2A (peak)

- Control Inputs: PWM, IN1, IN2 for each channel

- Standby Current: 1 µA (typical)

- Built-in Protections: Thermal shutdown, overcurrent, and undervoltage lockout

- Operating Temperature Range: -20°C to +85°C

- Package Type: HTSSOP-20

Pin Configuration and Descriptions

The TB6612FNG has 20 pins. Below is the pinout and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Logic power supply (2.7V to 5.5V) |

| 2 | GND | Ground connection |

| 3 | AIN1 | Input 1 for Motor A (controls direction) |

| 4 | AIN2 | Input 2 for Motor A (controls direction) |

| 5 | PWMA | PWM input for Motor A (controls speed) |

| 6 | A01 | Output 1 for Motor A |

| 7 | A02 | Output 2 for Motor A |

| 8 | VM | Motor power supply (4.5V to 13.5V) |

| 9 | STBY | Standby control (active HIGH to enable the IC) |

| 10 | BIN1 | Input 1 for Motor B (controls direction) |

| 11 | BIN2 | Input 2 for Motor B (controls direction) |

| 12 | PWMB | PWM input for Motor B (controls speed) |

| 13 | B01 | Output 1 for Motor B |

| 14 | B02 | Output 2 for Motor B |

| 15 | NC | No connection |

| 16 | NC | No connection |

| 17 | NC | No connection |

| 18 | NC | No connection |

| 19 | NC | No connection |

| 20 | NC | No connection |

Usage Instructions

How to Use the TB6612FNG in a Circuit

Power Connections:

- Connect the VCC pin to a 3.3V or 5V logic power supply.

- Connect the VM pin to the motor power supply (4.5V to 13.5V).

- Connect the GND pin to the ground of the power supply.

Motor Connections:

- Connect the motor terminals to A01 and A02 for Motor A, and B01 and B02 for Motor B.

Control Pins:

- Use AIN1 and AIN2 to control the direction of Motor A, and BIN1 and BIN2 for Motor B.

- Use PWMA and PWMB to control the speed of Motor A and Motor B, respectively, via PWM signals.

- Pull the STBY pin HIGH to enable the IC. Pull it LOW to put the IC in standby mode.

PWM Control:

- Apply a PWM signal (0-100% duty cycle) to the PWMA or PWMB pins to control motor speed.

Example Arduino Code

Below is an example of how to control two DC motors using the TB6612FNG and an Arduino UNO:

// Pin definitions for Motor A

const int AIN1 = 7; // Direction control pin 1 for Motor A

const int AIN2 = 8; // Direction control pin 2 for Motor A

const int PWMA = 9; // PWM speed control pin for Motor A

// Pin definitions for Motor B

const int BIN1 = 4; // Direction control pin 1 for Motor B

const int BIN2 = 5; // Direction control pin 2 for Motor B

const int PWMB = 6; // PWM speed control pin for Motor B

// Standby pin

const int STBY = 10; // Standby control pin

void setup() {

// Set all pins as outputs

pinMode(AIN1, OUTPUT);

pinMode(AIN2, OUTPUT);

pinMode(PWMA, OUTPUT);

pinMode(BIN1, OUTPUT);

pinMode(BIN2, OUTPUT);

pinMode(PWMB, OUTPUT);

pinMode(STBY, OUTPUT);

// Enable the motor driver by pulling STBY HIGH

digitalWrite(STBY, HIGH);

}

void loop() {

// Example: Run Motor A forward at 50% speed

digitalWrite(AIN1, HIGH); // Set direction

digitalWrite(AIN2, LOW);

analogWrite(PWMA, 128); // Set speed (128/255 = 50%)

// Example: Run Motor B backward at 75% speed

digitalWrite(BIN1, LOW); // Set direction

digitalWrite(BIN2, HIGH);

analogWrite(PWMB, 192); // Set speed (192/255 = 75%)

delay(2000); // Run for 2 seconds

// Stop both motors

analogWrite(PWMA, 0); // Stop Motor A

analogWrite(PWMB, 0); // Stop Motor B

delay(2000); // Wait for 2 seconds

}

Important Considerations

- Ensure the motor power supply voltage (VM) matches the motor's rated voltage.

- Use appropriate decoupling capacitors near the power supply pins to reduce noise.

- Avoid exceeding the maximum current rating to prevent damage to the IC.

- Always pull the STBY pin HIGH to enable the motor driver.

Troubleshooting and FAQs

Common Issues and Solutions

Motors not spinning:

- Ensure the STBY pin is pulled HIGH.

- Verify that the motor power supply (VM) is connected and within the specified range.

- Check the PWM signal and ensure it is being generated correctly.

Motors spinning in the wrong direction:

- Swap the connections to AIN1 and AIN2 (or BIN1 and BIN2) to reverse the direction.

Overheating:

- Ensure the current drawn by the motors does not exceed the IC's maximum rating.

- Add a heatsink or improve ventilation if necessary.

No response from the motor driver:

- Check all connections, especially power and ground.

- Verify that the logic voltage (VCC) is within the specified range.

FAQs

Can I control a stepper motor with the TB6612FNG? Yes, the TB6612FNG can control a stepper motor by driving its two coils. Use appropriate stepper motor control logic.

What happens if the IC overheats? The TB6612FNG has built-in thermal shutdown protection. It will disable the outputs until the temperature returns to a safe level.

Can I use the TB6612FNG with a 3.3V microcontroller? Yes, the TB6612FNG supports logic levels as low as 2.7V, making it compatible with 3.3V microcontrollers.